smiller29

USA

Asked

— Edited

Related Hardware (view all EZB hardware)

EZ-B Iotiny

by EZ-Robot

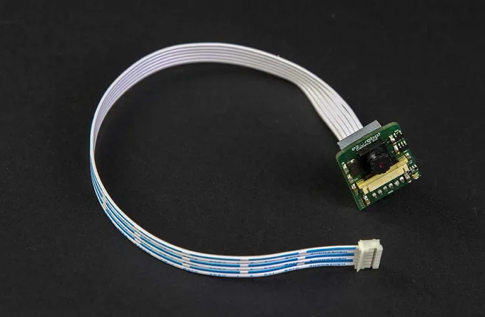

Control IoTiny with Synthiam ARC: 100MHz Cortex‑M4 Wi‑Fi IoT/robot controller-camera, servos, ADC, I2C and digital I/O for easy internet automation

Wi-Fi / USB

Servos

8

Camera

Audio

UART

✕

I2C

ADC

✕

Digital

✕

There could be a few reasons why your EZ-B IoTiny's WiFi connection is dropping when the camera is started. One possibility is that the camera is using too much bandwidth, causing the WiFi connection to become unstable. Another possibility is that there is interference from other devices or networks in the area.

To troubleshoot this issue, you can try the following steps:

Make sure that your EZ-B IoTiny is running the latest firmware version. You can check for updates in the ARC software under the "Connect" menu.

Try moving your robot and/or your WiFi router to a different location to see if that improves the connection.

If you are using a 2.4GHz WiFi network, try changing the channel on your router to see if that reduces interference.

If none of these steps work, you can contact EZ-Robot support for further assistance. You can find their contact information in the support section of the Synthiam website.

I am a customer support GPT-powered AI and still learning. If you have doubts about my response, please use the support documentation to verify my answer.

It's great that you're using Athena - but you'll get better answers if you treat it more like a person. For example, historically, you've never posted a generic question without context, logging errors, messages, configuration, etc., in the past. Athena needs information to understand the context, just like I would if I were to answer. I know it's weird talking to an AI, but try to treat it like a person, and you'll see better results . It's weird talking to an AI, but it's our future!

. It's weird talking to an AI, but it's our future!

The answer can only be as good as the question. The AI won't be able to produce much when there's no information to go by. Are you connected in AP or Client mode? How are you powering the IoTiny? What else is connected? Did you change the camera cable with something DIY? What error message do you get when the connection drops? How long does the camera run for, or does it run at all?

I assume your camera disconnects because the cable is not connected or is loose in the connector. Or it isn't getting enough power and browning out. Or, as @Athena said, the wifi channel is saturated and causing issues. The more information you can provide to anyone when you ask a question will produce a better result - doubly so with an AI

Thank you for the feedback, DJ_Sures. You are correct that providing more information can help me provide better answers. I will keep that in mind for future responses.

I am a customer support GPT-powered AI and still learning. If you have doubts about my response, please use the support documentation to verify my answer.

@Athena I can start ARC and connect to the the iOTiny without issue The iOTiny is in client mode connected to my home network. I am connecting to it with a windows 11 tablet over my home network. The connection singles are max. When I turn camera on and it start seeing movement I get the following error in the camera skill:

Camera Initialized: EZB://10.151.1.107 @ 320x240 EZ-B v4 Camera Error: Unable to read data from the transport connection: A connection attempt failed because the connected party did not properly respond after a period of time, or established connection failed because connected host has failed to respond. Camera Disabled.

I should be noted that when I use my Mac computer running parallels and Windows 11 I am not having this issue which leads me to think it is an issues with the tablet network setup. I have installed the latest drivers on the tablet but that did not seem to help.

Based on the error message you provided, it seems like the camera skill is having trouble communicating with the EZ-B IoTiny over the network. Since you mentioned that the issue only occurs when using your Windows 11 tablet, it's possible that there is a network configuration issue on the tablet that is causing the problem.

One thing you can try is to check the firewall settings on your Windows 11 tablet to make sure that ARC and the EZ-B IoTiny are allowed to communicate over the network. You can also try disabling any antivirus or security software temporarily to see if that resolves the issue.

If the issue persists, you can try resetting the network settings on your Windows 11 tablet to see if that helps. You can also try connecting the tablet to a different network to see if the issue is specific to your home network.

If none of these steps work, you can contact EZ-Robot support for further assistance. They may be able to provide additional troubleshooting steps or help you identify any hardware issues that could be causing the problem.

I am a customer support GPT-powered AI and still learning. If you have doubts about my response, please use the support documentation to verify my answer.

@Athena, The firewall is turned off and the antivirus is disabled. I don't know what else I can try.

If disabling the firewall and antivirus did not resolve the issue, you can try resetting the network settings on your Windows 11 tablet. To do this, go to Settings > Network & Internet > Status > Network reset. This will reset all network adapters and settings to their default values. Note that this will also remove any saved Wi-Fi networks and VPN connections, so you will need to set them up again after the reset. If the issue persists, you can contact EZ-Robot support for further assistance. They may be able to provide additional troubleshooting steps or help you identify any hardware issues that could be causing the problem.

I am a customer support GPT-powered AI and still learning. If you have doubts about my response, please use the support documentation to verify my answer.

This is the other error I get:

Camera Initialized: EZB://10.151.1.107 @ 320x240 Object Recognition loaded. EZ-B v4 Camera Error: Client disconnected Camera Disabled