ptp

USA

Asked

— Edited

I would like to add Pan/Tilt to a Tablet to be the Robot Interface

besides the rotation & lever servo i will need: Clip'n'Play Adapter Plate Extension Cube

similar too:

The tablet is 7" and the weight is 370g (0.82 lbs)

some questions/issues:

- Tilt servo (Lever Servo) can a EZR HD servo handle 400g ?

- I will need a frame similar to (thingiverse):

but with a female EZ-BIT

I'm not familiar with 3d tools, zero "nada" skills!,

anyone did something like that ?

can someone build or adapt an existing frame to support a 7" tablet (119.77 x 196.33 x 15.36 mm) ?

other ideas ?

any help/ideas will be appreciated

can you take the backside off? and take small wooden beam and screw it on. put some foam inside over the screws.see pic.

If your tablet has a car mount available, you could screw or glue an EZ mounting plate to the back.

Padholdr are pricey but have holders for almost every brand https://padholdr.com/collections/holders cheaper options available for popular models of tablet.

Not sure if the servos can manage the weight, but you can augment the stress points with springs or elastic.

Alan

i found a tablet kit car for $12:

front:

back:

maybe can be added to:

but it's not good, the servo needs to hold the position in 90 degrees

versus

the adapter below the frame (initial picture).

but so far i didn't found a holder with side brackets, and below and no upper brackets (tablet cameras)

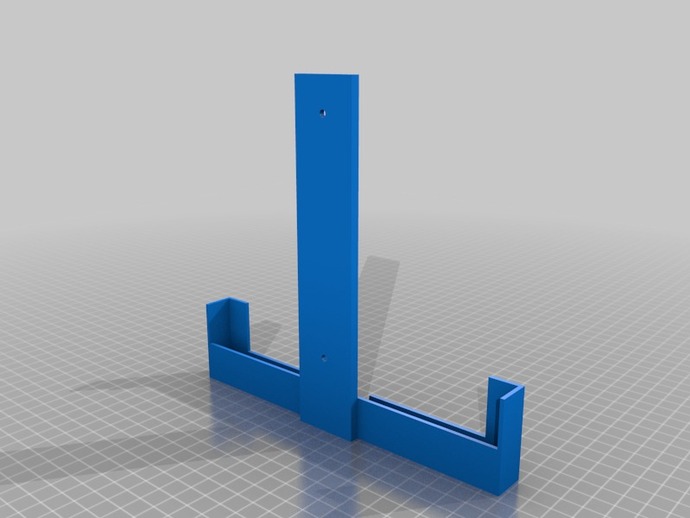

Will this work? If you can print it and verify the size?

PanandTiltTablet.STL

Also, i can make a male clipn'play adapter plate.

@DJ,

yes you are on right track, the tablet dimensions are:

horizontal: 196.5 mm vertical: 85 mm (i reduced the size, to allow the usb connector to charge) thickness: 15.5 mm

those measures are the inside of the frame

regarding the clipn'play needs to be a female right ? to connect to lever servo.

btw i don't see the female clipn'play, only a plane frame.

Okay try this one by those dimensions..

PanandTiltTablet.STL

wow, thanks!

Next step order the print. I let you know the final result.

Should i print in white to match the EZ bits ? or go with black.