jstarne1

USA

Asked

— Edited

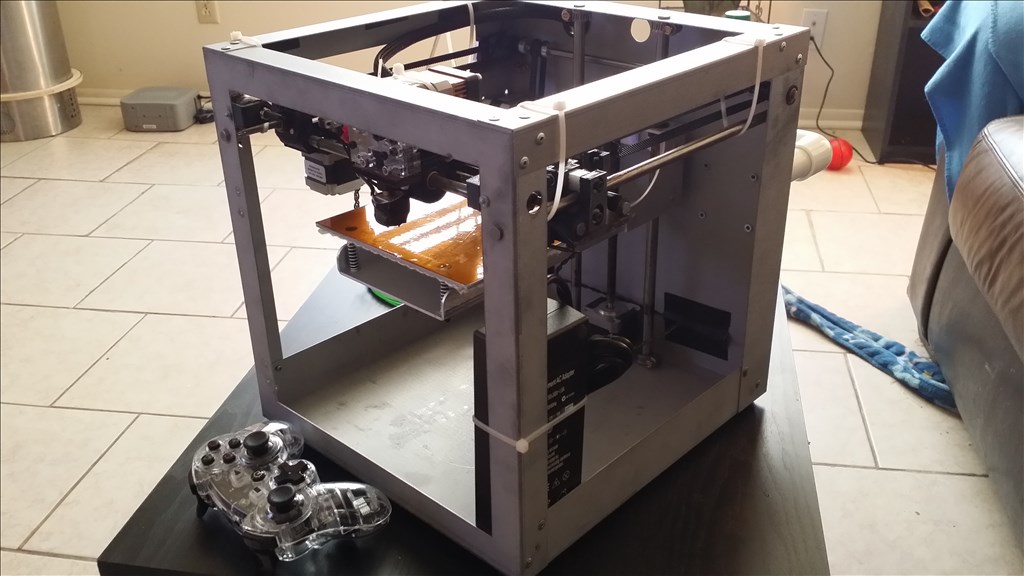

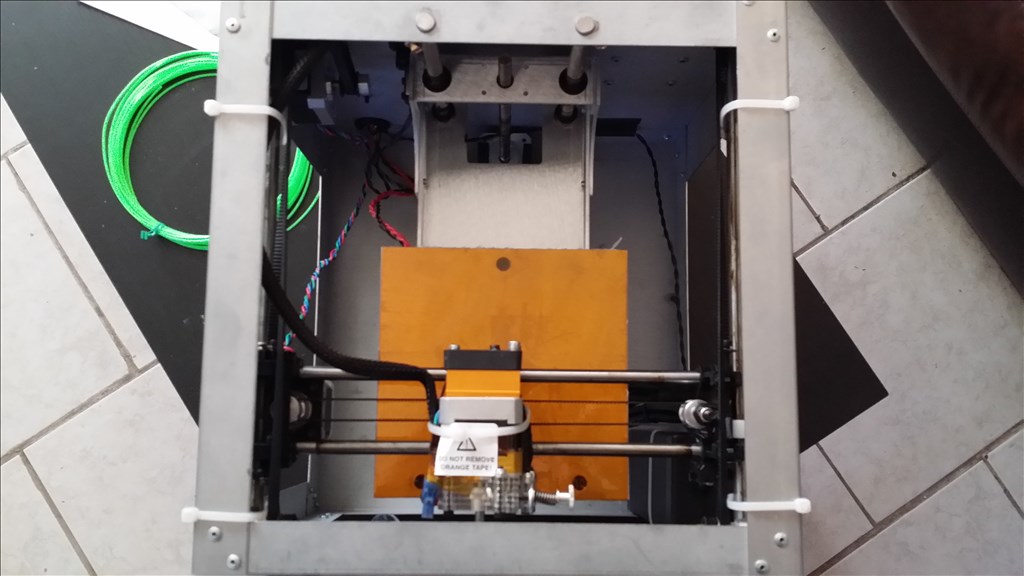

I ordered a Solidoodle 2 Pro which arrived today. I also ordered with that 2 rolls of filament. It should be 4 total pounds of material to start with.

I would say 1000 percent improvement and there are still a few more tweeks to go! gotta love that!

Ok next print , 2 fingers the middle and ring finger. They were a 5 hour print and came out great except the top edge of one and bottom edge of another. The overhang was too much and needed support. It is a easy fix and very minor so these prints are keepers!

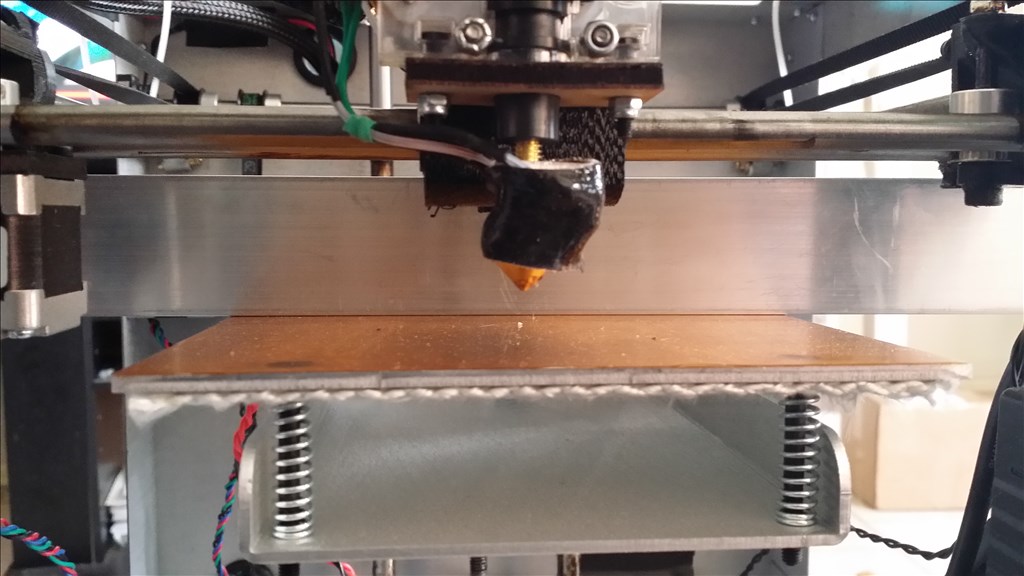

i will fill the tiny tips on the top edges with resin filler and they will be done. These tight overhangs are exactly what the extruder fan is intended to be used for. These edges were thin and we're too hot so they curled. I'm just waiting on the fan I ordered which should be here Friday but the prints are going good enough to continue.

next are the thumb and pinky fingers on the bed right now. Estimated 7 hour print.

These Prints I'm Trying With NO raft and support material for the overhang on the very edges. Hopefully I won't have a chipped edge this time and support will take care of it.

i started recording my prints with amcap which is the software that comes with the V3 ez robot cams. I could use these videos in the future for troubleshooting or technical assistance.

@jstarne1 I'm looking hard into getting a Solidoodle...you are making me really like it Plus the price is nicer than the MakerBot. You might have mentioned it elsewhere, but what software are you using to make your designs?

Plus the price is nicer than the MakerBot. You might have mentioned it elsewhere, but what software are you using to make your designs?

Since you've been using it a while, what would you say are like your top 3-5 tips for 3D printing - things you wished you had know when you started more or less.

Thanks for sharing these posts and your progress!

Hi Justin , i have had the solidoodle for one month now. I'm hardly a expert but I'm still working on it.

Ok so that list

I wish I had started by learning to use autodesk 123d or the pro version autodesk 3ds max before buying a printer. Imagine the printer is just a tool to print what is designed. Sometimes prints don't come out right because the design is not optimized for your printers capabilities. Getting to know how to slice objects and make slight changes is very important and I'm not there yet.

I wish I had either bought a makerbot ( yes way more money but I wish I had its ease of use) or at least the solidoodle 4 to have a bigger build area. 6 inches build volume is good size but bigger is better.

Soon as you get a solidoodle you need to spend your whole first month calibrating it. There are many many options and it takes a while to understand what each does. I'm still learning them and even need to get with solidoodle to show them various price and video of print so they know how to resolve the issues.

Consider using alternative software, different slicers for example because each one has its limitations. Document any changes you make so you can reverse them at a moments notice. Some settings work for one model but not a different one.

Print out all the recommended mods and also replacement parts for your solidoodle. Things like extruder fan shroud, adjustment knobs, z backlash mod, and a over the top filament roll holder. Even if you get a solidoodle with no case a case is absolutely needed as well as the heated bed. You can buy a model with heated bed and even a case included.

Document everything you do , don't make permanant changes to your machine so you still get tech support. Printable mods usually are held on with a screw or magnet but the machine is still intact.

Lastly read through soliforum.com that is your biggest asset considering there is no real instruction manual for these things.

Ok latest print , this is ring finger and pinky finger. One edge is a bit chewed up. Once agian a bridging issue but I believe the fan will resolve this and keep the material cool and stable. Otherwise I had great quality.

i am going to move the printer into a closet downstairs so i can print even when I am asleep and get more use out of it. I can absolutely see myself having another printer in the future. They are useful in so many ways.

@Josh- I see you as the kinda guy that might build his next one.

@antron , knowing me that's not too far fetched lol , you can use a generic board with this same software but there is lots of math to calculate steps for the motors on each axis. Considering solidoodle uses generic parts I was talking to my best friend about making a giant one like 2 or 3 ft wide. It would take forever to print but it would be awesome to print large items.