Asked

— Edited

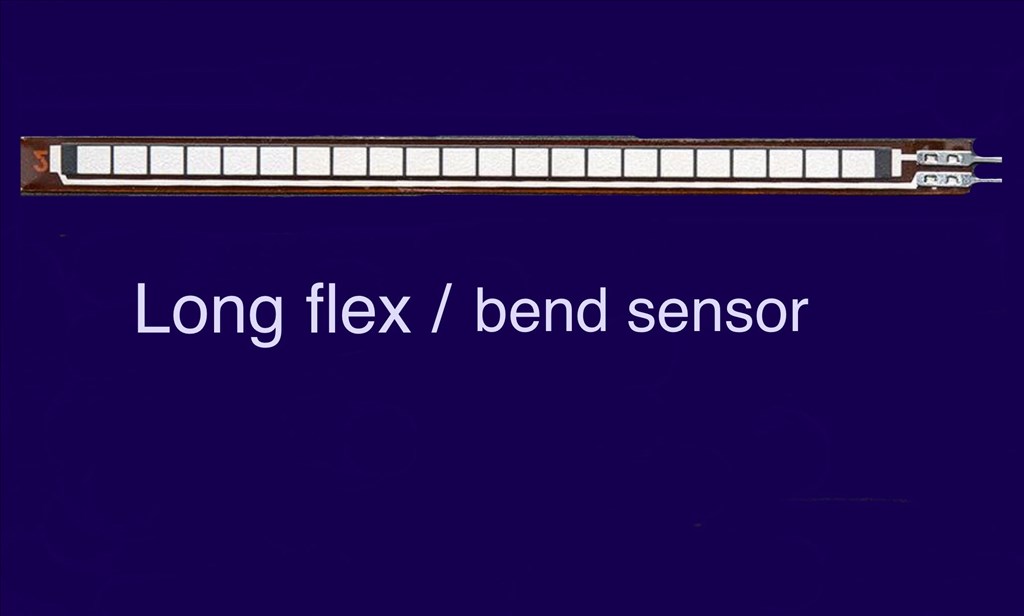

Has anybody used, or know if these can be used with the EZ-B v4? And if do, how do they connect? These flex/bend sensors would be great if they worked with the EZ-B and ARC. Not much information on power, but they can be used on analog or digital (although I think analog would be better).

Outstanding! Team work! So just make sure we feed it 5v useing the risistor your useing and make sure the leads are attached properly to the strip?

If you have time please do a how to and a video.

Great @Steve G, glad you got it working!

I don't mean to be a buzz kill but a flex sensor is essentially just a variable resistor, changing the leads around won't change anything in terms of resistance, remember there are only two leads and resistors aren't polarity sensitive. I can almost guarantee that the flex sensor can work on any voltage regardless if it's 3.3V, 5V, or otherwise.

My theory is that since the flex sensor has crimp connections onto the resistive substrate the plastic may have melted a little during soldering process and provided intermittent contact. After a few more tries it may have made contact again.

If the sensor starts reading really low again, it's likely the this is the case.

@Dave.

No problem. I'll try to knock something up. Great teamwork. High 5's all round.

@Jeremie.

Truth be told, I didn't think the polarity would make a difference either. I was careful when soldering and can't see any visible damage/melted plastic as I had already tinned the wires so the soldering was very quick (there was a warning on the website saying to take care when soldering on to these sensors). I've got another one to do for the other bumper so I'll have another play around with that one and post back. BTW, you're not being a buzz kill dude. Any info you supply is always good and always appreciated.

@Jeremie.

Maybe you were right (I didn't doubt it for a second). I wired up the second sensor, this time without a regulator, and it worked. I did the same with a third strip I had and it worked too . The readings now are 138/140 straight, then 120 and 10 degree bend, and so on. And the first one I hooked up now works without a regulator too. So it is possible I did do a little heat damage I can't see.

. The readings now are 138/140 straight, then 120 and 10 degree bend, and so on. And the first one I hooked up now works without a regulator too. So it is possible I did do a little heat damage I can't see.

@Dave.

I took a couple of pics and posted a video demo of the second sensor I just wired up for you. It's pretty straight forward so you'll get this straight away. But if anyone else coming across this who wants to do the same, I wrote a quick tutorial as well. So here's how I did it...

1.) Using a servo extension cable, snip off the male connector and strip the white and red wires. Then tin the ends with solder.

2.) In the middle of the White and black wires, strip back the outer casing to bare the wire, and tin with some solder.

3.) Solder a 10 Kohm pull up resistor to the tinned White and black wires mentioned in step #2.

4.) Carefully and quickly (as has been mentioned in above posts ), solder the White and red wires to the sensor connections.

), solder the White and red wires to the sensor connections.

5.) Add some heat shrink to insulate the solder joins.

6.) Connect the servo wire plug to an ADC port, wires matching the pins.

7.) load up an ADC meter in ARC, set the port the sensor is connected to, and bend away. As mentioned above, you should see a static reading of about 140, then the further the sensor is bent, the lower this value will drop (as seen in video below).

NOTE: For a little added stability, apply a small drop of clear silicone adhesive over the crimp connectors on the flex sensor, as thay are a bit fragile and this will give added strength.

Awesome @Steve G!

Thank you for sharing your findings and creating a great tutorial!

No problem at all. Just happy I can share and give back to the community.

Sweet. Thanks.

No problem Dave.

Hope it helps.