Asked

— Edited

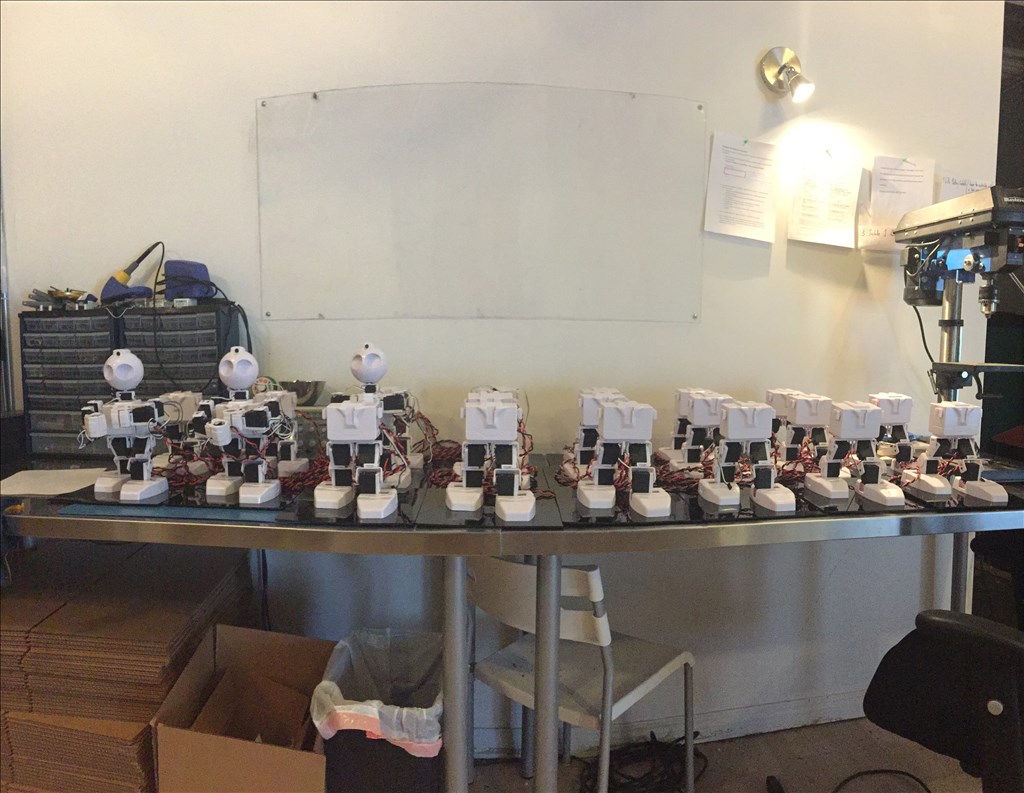

In another thread, wbs asked about all the jd's in the office - if they were Brookstone demos. The answer is yup. They are attached to black pexi glass base. The custom code in the ezb allows them to operate without a computer. It's a pre programmed sequence using the code generator from the auto positioner (it's mentioned in the universalBot video).

There is no wifi module or camera in these jd's. The ezb is specially made just for these 200 custom versions. The camera is fake and 3d printed. Also the ankle servo in their feet are 3d printed as well - this saves us some cash on the demo units.

It's great to see your company grow! Hat tip to DJ and Team.

Also nice to see pictures of your headquarters. Like you printer farm and your plastic enclosures.

Do you know when they are expected to show up in stores?

Cool. I kinda thought all those DJs I had been seeing in the video images showing on the forum main page might be for that purpose. Hope the local Brookstone will carry them. Problem is it's a small store in a mall. Still, I'm a tad chummy with the people there since I got my Parrot Drone. Maybe get them to keep some parts in stock as well as the kits. It would be great to be able to go there and get the odd servo, cable, V4, or connection block as needed. Though I did order a bunch of that stuff with my JD kit so I probably won't need any parts for a while yet, but ya never know. I've been known to inadvertently give components the smoke test from time to time.

Thanks! We will be in all 176 of their stores by August. The demos will be in every store as well

oh btw, @69develper - thanks for the comments on the 3d printing farm. One of them is missing because i have it at my house . The enclosures I made to keep the heat consistent. We found that printing large objects would cause the corners to warp when the material cooled down. With the enclosure, the heat is consistent and the object doesn't warm any longer.

. The enclosures I made to keep the heat consistent. We found that printing large objects would cause the corners to warp when the material cooled down. With the enclosure, the heat is consistent and the object doesn't warm any longer.

It also keeps the noise down - which puts Jeremie to sleep Because it's very soothing with the enclosures.

Because it's very soothing with the enclosures.

Here's the 3d printed parts for the demo robots....

this is the "Fake Camera" that is in JD's head

This is the fake servo that is in JD's ankle

This is the cover that protects the power supply connections. The power supply is hidden behind the shelf. We didn't want any sales associates to get electrocuted so this 3d printed cover protects people and the power supply wires.

wow didn now you had 3D designers there. you cant see that the cam is fake.

Went by the local Brookstone here while I was out and about today. There is a free standing sign at the entrance showing the latest gadgets coming with JDs picture right at the top. Talked to an employee but, of course, he couldn't comit to anything. All he said was they would be stocking an "expansion kit." He's probably referring to the developer's kit. At least I've planted the seed about stocking spare parts beyond just the kits. We'll see. He was also amazed it was already out there (for years) since he had just heard about it. Wondered how others could get it already, it not being stocked in their stores yet. He had no idea. I'm hoping, at the least, the store can get parts I need in faster than I can getting them mail-order, and for free shipping regardless of total dollar value.

As an aside, they are already selling a couple models of nano-drones. One with camera, but no streaming video, just recording to a usb memory stick. Fairly cheap though at about $80-USD. Had it streamed video I would have picked one up on the spot. I've been wanting to get one or two so I've been looking at some with streaming video but they are mostly twice that price. Not sure which one is best yet. Experience with the Parrot Drone 2, however, tells me I want one with excellent hovering stability in a small area as a leading criteria.

You're all elite for having ezrobot way before the rest of the world has heard about it.

They will be stocking parts - and more each month. If you want to encourage beookstone to stock more ezrobot parts, let them know. They listen to their customers. The new CEO is a great guy and is working to make brookstone into an innovation store. They read their product comments, you can leave a comment here: https://www.brookstone.com/ez-robot-jd-humanoid-revolution-robot-kit

Be cautious of those little nano drones. They are hard to fly and every one I've had is broke.