Asked

— Edited

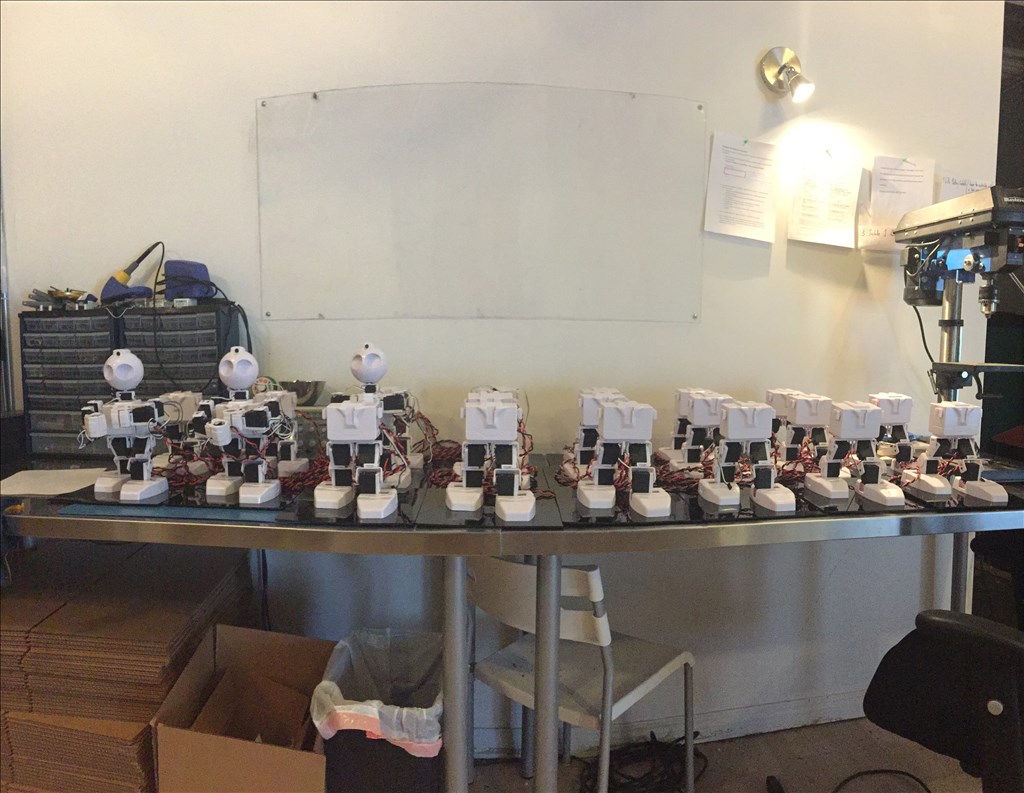

In another thread, wbs asked about all the jd's in the office - if they were Brookstone demos. The answer is yup. They are attached to black pexi glass base. The custom code in the ezb allows them to operate without a computer. It's a pre programmed sequence using the code generator from the auto positioner (it's mentioned in the universalBot video).

There is no wifi module or camera in these jd's. The ezb is specially made just for these 200 custom versions. The camera is fake and 3d printed. Also the ankle servo in their feet are 3d printed as well - this saves us some cash on the demo units.

@nomad.... Who do you think designed all their Revolution robots and ez bits? Cory did CAD design for ez robot when he worked there. I know that DJ also has some experience in 3D design himself too....

goodmorning richard R

i just though they make the standard parts only.

I designed plastics for six and jd. Cory was hired to fine tune my designs and create a few new ones - such as cubes, etc...

When we got to the point of tooling the mold for injection, the manufacturer came back and said we had many issues with the design and advised that we have a professional company help us tweak them for tooling. They didn't tell us what we were missing and because the parts worked well and were 3d printed we assumed it would be okay.

We contracted a local company to assist us with tooling. We were missing much at all - however, there was one important feature which is highly recommended for your mold to last a long time. It's drafting the parts so the eject better. Not all startups are aware of this and it's why our plastics have a very professional fit and polish. The draft angles the sides of all molds so they can be pushed out of the tool with ease.

The contracting company helped us do that.

Finally, the next challenge was getting the clipping figments exact. We started by making our molds too big. The parts would be too small / but that was on purpose. You can cut material from the mold much much easier than adding material.

So we did many revisions. Each revision cut a little more material from the mold until it all worked.

We have a total of 18 molds, I believe? And 50 cavities... That's hundreds of thousands of dollars worth of molds alone, not including the design costs and revisions. It's a very pricy job - specifically when dimensional size resolution is so important.

If we were making little toys or cases for stuff, it would have costed less and taken less time. It's the resolution that we needed.

@DJ With all the money and time you sank into producing these molds.... does EZ Robot own them? I mean if you ever have to switch manufacturers can you take the molds with you?

dj

special items cost money.but am very thankfull you did it. i met a new friend here in belgium and he's gonna by six. he will come to my house to test and play with six i know if you store will be full with all the parts,you will be the only store, who has all items availeble means lots off new customers and new models off robots.

thank you

Yeah - we own all of the molds and IP. However, the biggest challenge with switching manufacturers is the compatibility of the mold machines. If the machines are not the same, the molds are not compatible. We have been looking at a few new manufacturers to help us scale. We have to ensure it makes sense financially before we switch - the biggest expenditure is doubling inventory while parallel manufacturing. What I mean is, when we switch to a new manufacturer, we cannot stop our sales so we would need to have inventory for two companies.

While most companies have a 500-1000% markup on items, we do not. To keep our product accessible, we keep our costs low and in return the community helps fill in the gap.

@DJ... Wow.... EZ Robot has had enviable growth over the last 2 years.... Forget Apple, 20 years from now marketing students going to be studying ez robot to see how successful company's really do it.... I dabble in some stocks....mostly big safe Canadian blue chip.... I do have a couple of US stock, however. I would never touch tech stock with a 10ft pole. However if ez robot ever went public... I know you would never do it, but if you did I would buy as many shares as I could afford.... and retire in the Bahamas.... LOL

When did you get a fisheye lens @DJ? Our office looks so much bigger haha