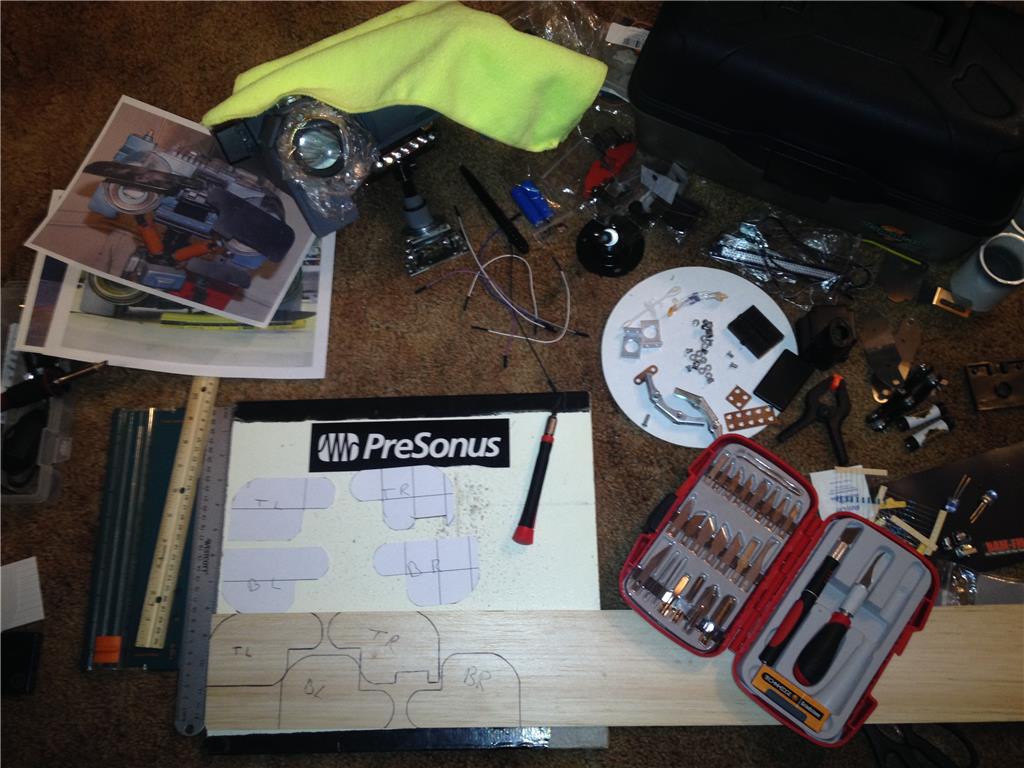

DJ, was able to obtain photos of the real hero Johnny 5 robot torn appart & put back together for measurement along with the Cad Files for the robot; will be working on a life size J5 robot & would like to use the EZ-Robot system to control it, what possible ez robot robot kit would allow this a reality? Hence using lightweight parts rather than the orig heavy duty parts.... Thanks so much for your time!:-) Drew

By Clip2Trigger

— Last update

Other robots from Synthiam community

Jp15sil24's 3Wheelbot

Synthiam ARC-controlled 3-wheel AdventureBot: remote and internet control, camera tilt, ultrasonic wall-avoidance,...

DJ's Adventurebot Chasing Red Ball

Control AdventureBot with Synthiam ARC to track and chase a red ball, creating captivating vision-based robot behavior...

Cjmekeel's 3 Axis Skull Halloween Prop

Build and demo a first robot with EZB and Synthiam ARC, showing basic functionality and planned camera-based...

@WBS00001, thanks for pointing out my B9 project.

@Clip2Trigger, WBS00001 is correct. I struggled with finding proper motors and servos that would handle weight issues throughout my B9 robot. I have very few servos that actually directly move something. I found the more torque you want out of a servo, the more it will cost. for example I'm using a Seiko UAV servo PS-050 rated at 1271 oz-in @ 8.4 VDC. It's even more powerful when run at 12vdc. It will snap your finger in half if your careless and lifts my 8 pound bubble section nicely. It runs about $230 UDS and can be bought here:

troybuiltmodels.com

This is actually a good price for a servo this strong as I've heard other brands this strong wold cost as much as $500 if you can find them.

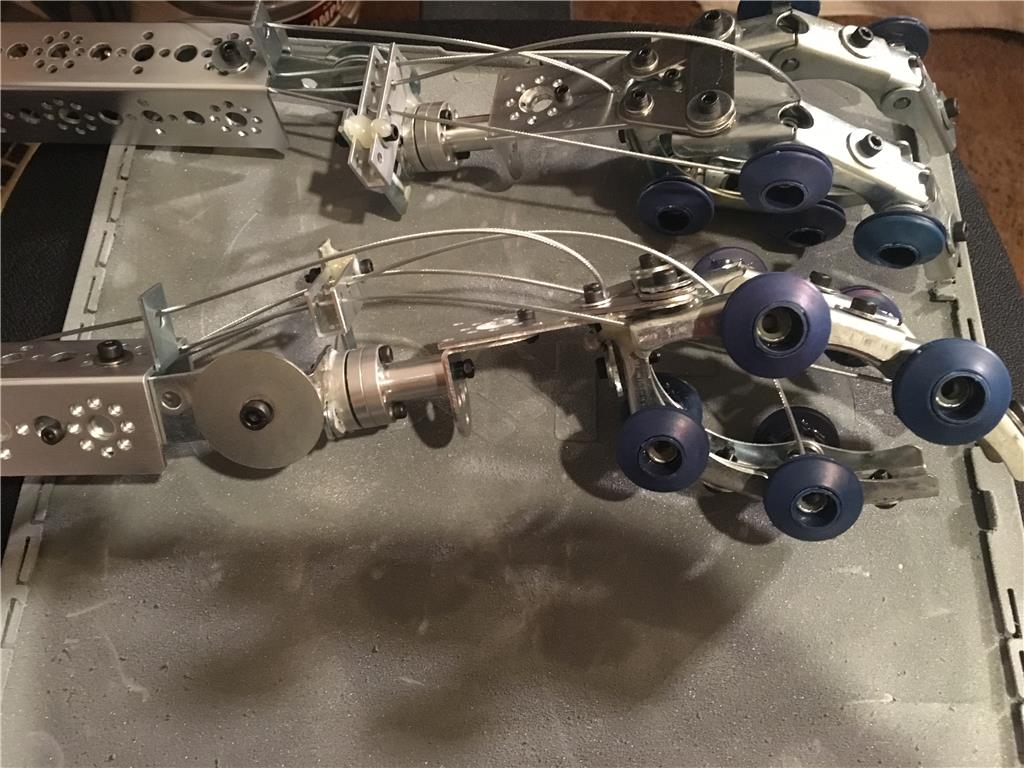

Another option (but not any less expensive) would to use a Robotzone servo Power Gearbox and a good strong servo mounted in an Aluminum Channel. These both can be found at ServoCity. The gearbox comes in server mounting choices and different torque options. With a HS-7950TH servo and 7:1 ratio gears you can get a staggering 3,402 oz-in of torque out of these babies! This setup will run you about $210 USD (ServoCity is currently out of stock on this set). I'm using this combination to lift the heavy and long forearms of my B9 robot arms.

Servocity Gearbox

I found that when lifting real heavy loads a good choice is to use DC motors. In the picture above you can see a black windshield wiper worm-gear motor I'm using at the elbow position. The worm-gear hold position when the motor loses power. It's very powerful and quite. The only motor I could find powerful enough to lift my heavy arm is a AME 226-series 12V 325 in-lb gearmotor bought through The Robot Marketplace. However I now see it's been discontinued. Maybe they can still be bought directly from AME?

AME-226-3003

When using a DC motor you will have to provide your own feedback circuit and motor controller for best and easiest results. This is so you can provide position and speed information to the controller. You can use a Pot or Encoder for the device and attach it to a joint or motor shaft somehow. Just make sure your motor controller or H-Bridge can read either a Pot or Encoder. I use an encoder attached to my motor shafts. This encoder sends position and speed information back to a Kangaroo daugterboard attached to a Sabertooth motor controller. Scripts I write in ARC send simple serial commands to the EZB that relay them through it's Uart port to the Kangaroo that commands the Sabertooth to move the motor to a position at a speed I choose. It sounds confusing but it's actually not that bad at all once you start understanding the process.

;)

Thank you kindly for all the info!:-). I'm sure it will take awhile to complete this project but in time it will be an amazing accomplishment:-) currently cutting & obtaining all the body parts then will add in the EZ system, servos, motors, gears..... Will keep everyone posted and again what an awesome time this is to be in where robotics are coming along for the future!:-)

Was able to finish the hands then head needs to be re-done correctly at that point body frame etc..... What I have learned is it's definitely a lot of robot to chew on (take on) as a lover & admirer of J5 is not possible with my current tools & knowledge to make a j5 using ez-b so have definitely went back to the orig plan to just make a life size j5 using the j5 templates/blueprints... wanted to update the info her for that:-) it's a long hard tedius project for my own private self gratitude:-). On the other hand I'm enjoying The EZ-Robot JD and there's a lot to learn from him, he's still an amazing little humanoid:-). Kinda get bummed on not being able to get a ez system into a life size j5 but we all sometimes have these silly ideas & dreams but sometimes it just don't work the way we think & plan it out:-) other than that EZ-Robot is an amazing system indeed!:-)

EZ Robot works great in full size robots. I am sure It can power your servos.

Any progress on the robot`? Any new pictures?