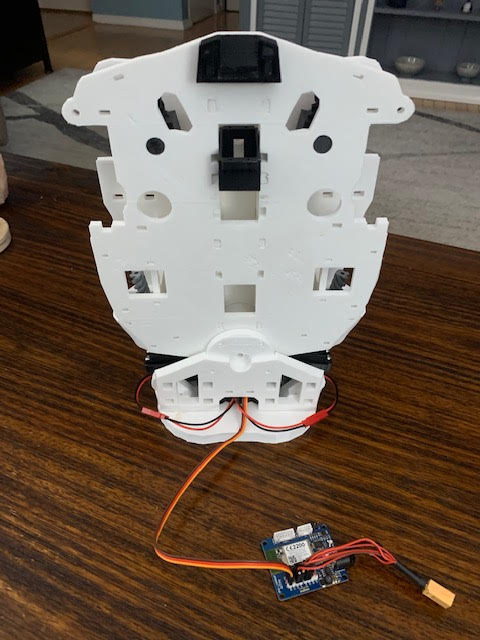

I am really excited about the new Synthiam mapping/nav functions as well as the additions to the Roomba movement panels. I needed a new bot to play with so I am making............"something."

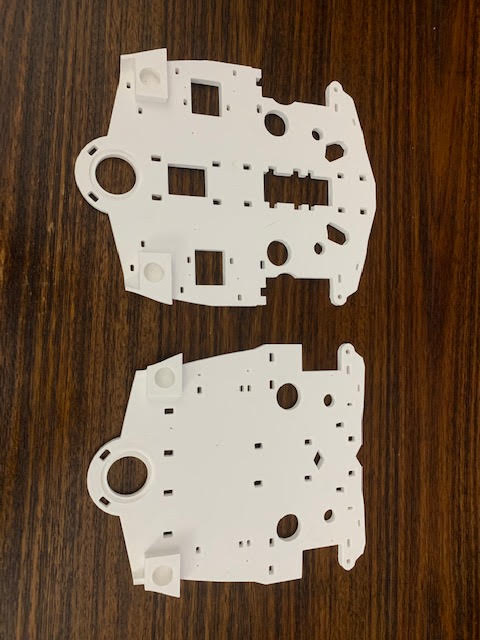

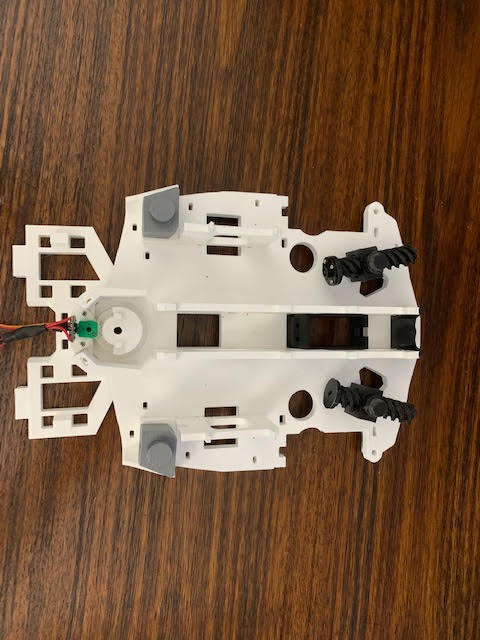

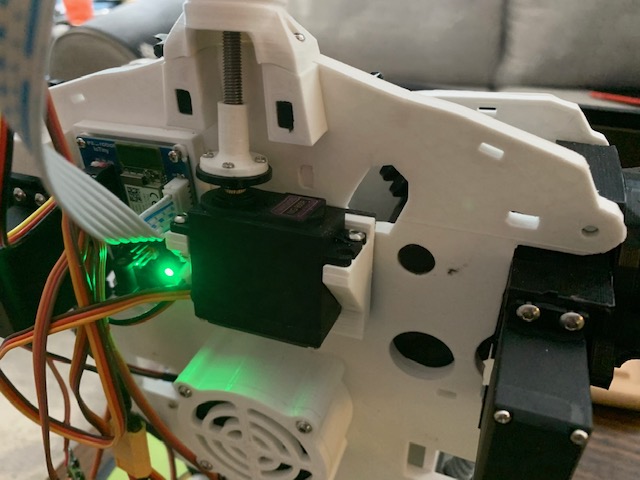

Not quite sure what this will be but I am using an inmoov body printed at .64 scale along with my eyepod design for a head. This is on a new Create 2. I spent a lot of CAD time scaling the inmoov and making sure servos fit and all the functions were preserved. If you scale the inmoov down .64 then the large servos it uses become roughly the size of standard servos, that is why this size was chosen.

Since he is a small inmoov that moves I have named him Mini-Move

By Perry_S

— Last update

Other robots from Synthiam community

Steve's Affirmative. K-9 2.0, Online And Fully Operational....

K-9 2.0 home robot using Synthiam ARC and EZ-B v4 for servos, speech and face recognition, DIY MDF/RC chassis and...

Ezang's My New Whirlybird Project For You To View

Whirlybird showcase: a new Servo City ARC robot project highlighting servo-based hobby robotics

Hablijack's Project: Marvin

DIY MARVIN robot: USB-powered camera, moving head, OWI-arm hand with servo; arms next, feet TBD.

Hi Merne, The legs are static right now. They articulate and have all the degrees of motion that is needed but they currently haver no motors. They could be added easy enough. There is a ratchet function in each joint so you can position the legs how you want and they stay. I guess this could be a good candidate for a walker though as it weighs so little compared to a full size inmoov and it is much stiffer.

Hi Perry, That is very cool. I forgot to ask if you designed the legs. It will be cool when you add the motors. Thanks for sharing your build.

Cheers

Very, very cool look. Nice work!

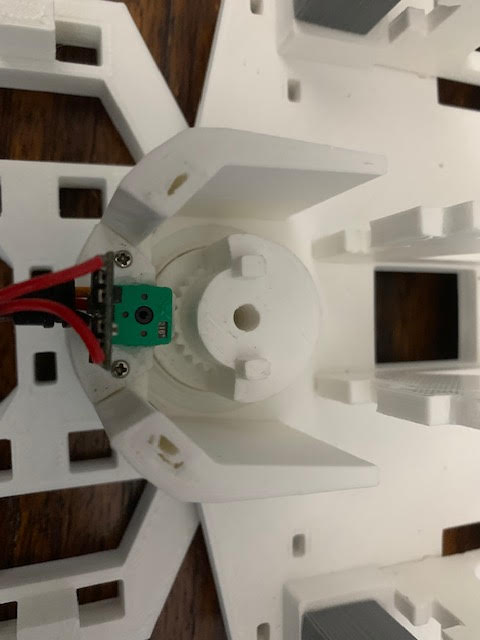

So I am working on the best way to use 3D printed materials. I love the FDM method, that's what most printers that use filament are called. FDM means Fused Deposition Modelling, which means plastic is melted into place. There is also SLA or stereolithography apparatus which uses a polymer that hardens under UV light. So you expose a cross section to UV light and it hardens instantly. Both methods have their pluses and minus'. For instance filament printing is rugged with lesser resolution. SLA parts can support extremely small and complex features but they are not strong. SLA materials are coming along though. So for my minimoov I printed the gearbox housings out of PLA cuz it is strong and has good abrasion resistance. I printed these gears out of ceramic material on a SLA printer and the resolution is incredible. There are no level lines like you see on regular prints.

I added bearings to keep things honest.

Nice! Could you share those stl files Perry?