By jstarne1

— Last update

Other robots from Synthiam community

Wolfie's Scraps

Custom electronics project assembled from many parts, progress photos show intricate wiring and assembly; more parts and...

DJ's Omnibot TV Watching

Synthiam ARC and EZ-SDK enhanced motion tracking with improved edge detection for omnibot vision, demonstrating cartoon...

Peterfrisch's It's Yellow, It's Boxy, It's .... No Wall-E...

Convert a Caterpillar toy with EZ-Bot: install continuous servos for treads, hot-glue servo horns and route cables for...

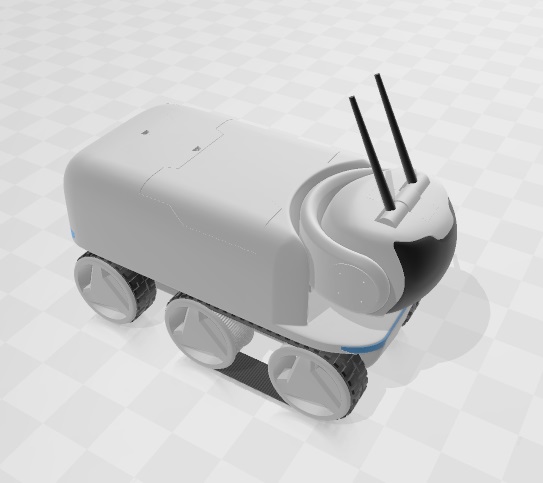

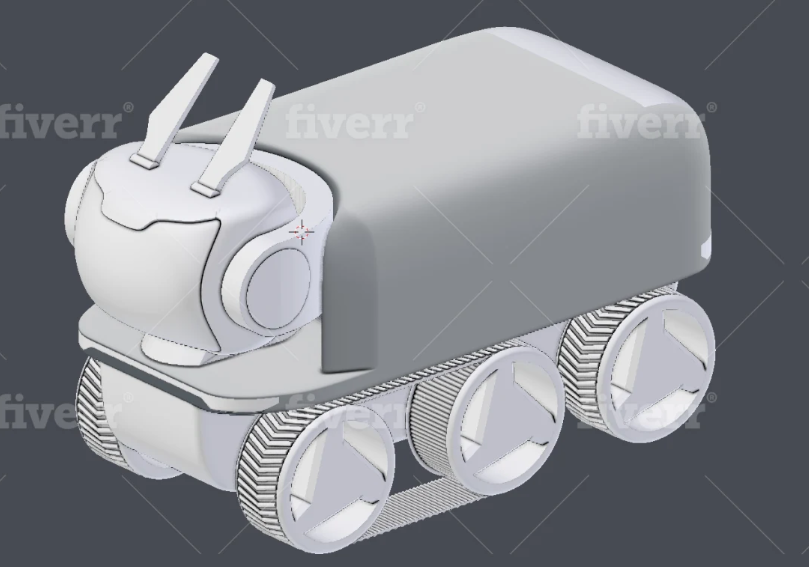

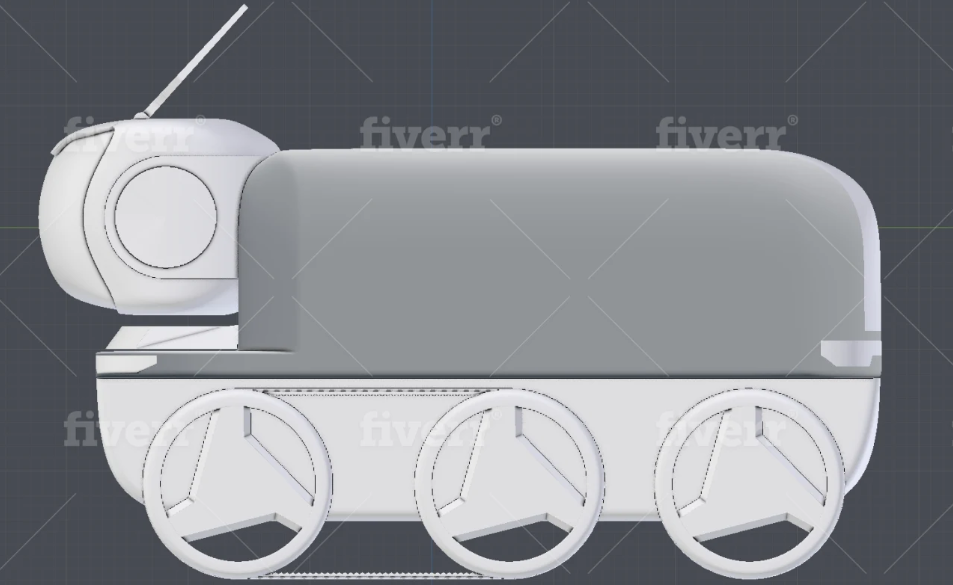

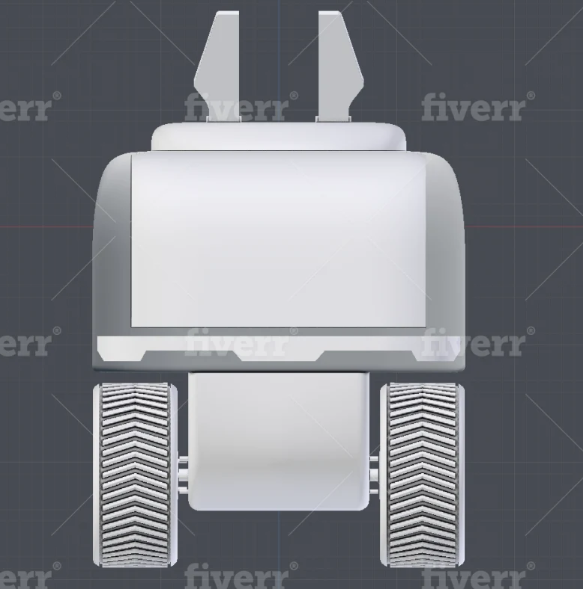

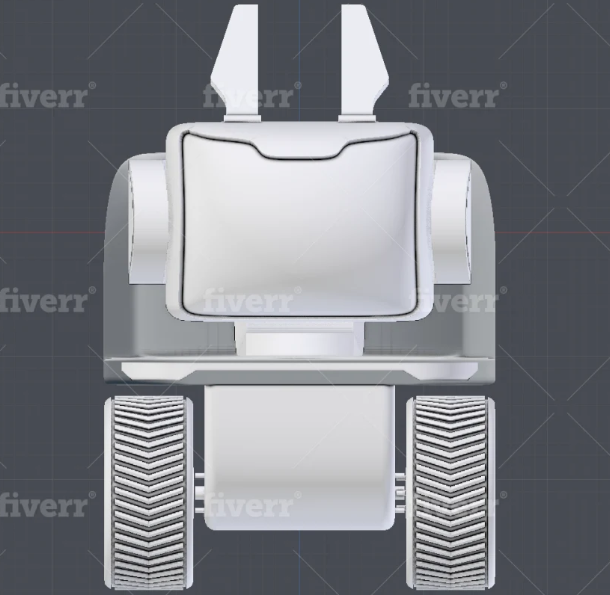

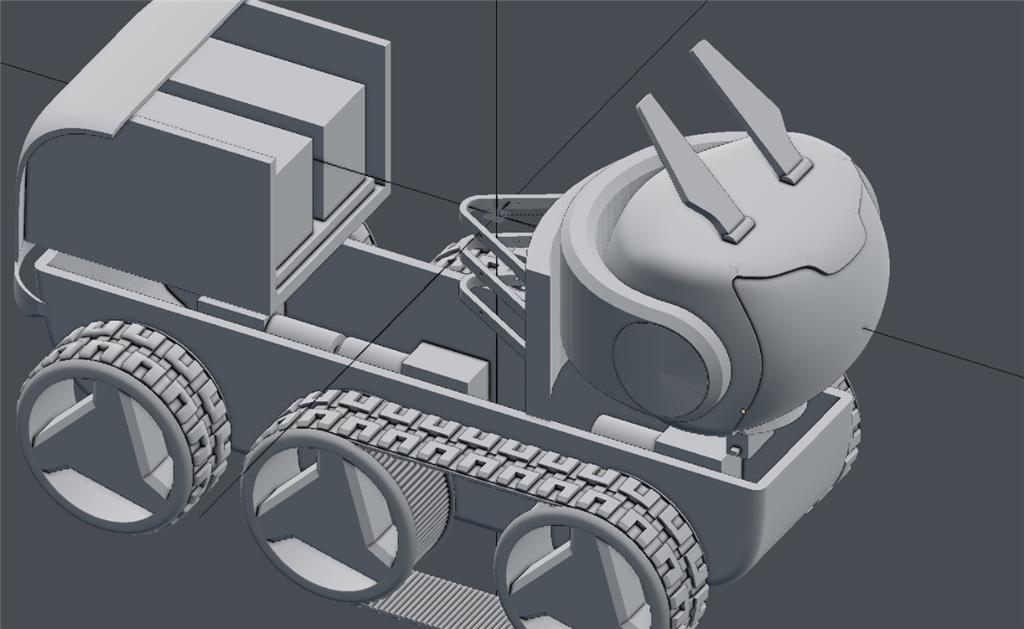

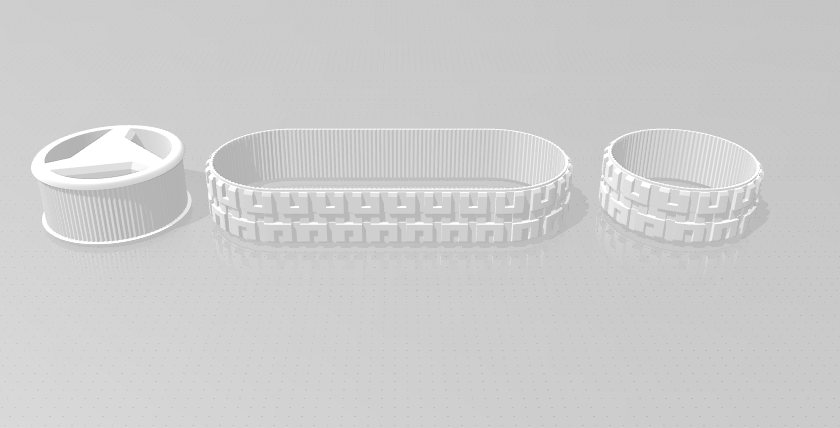

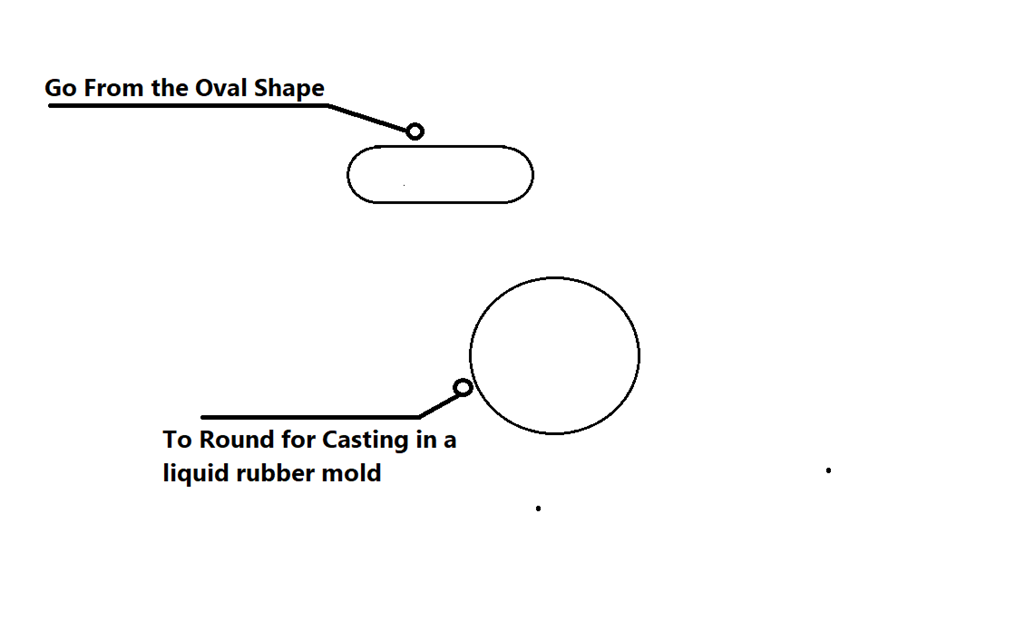

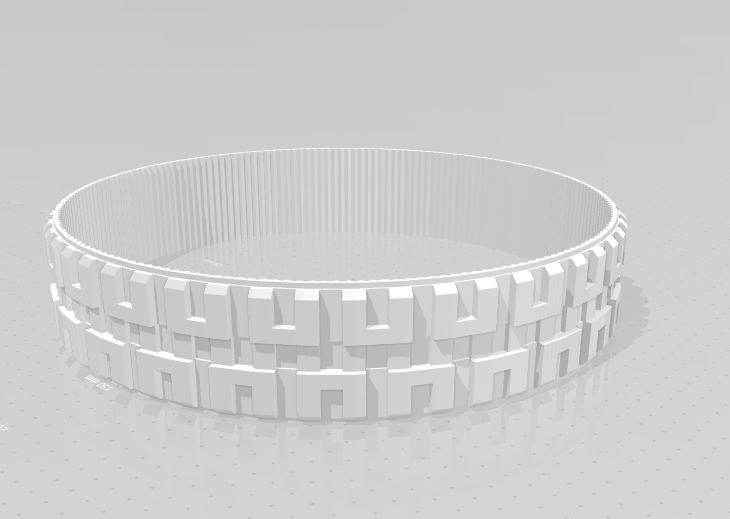

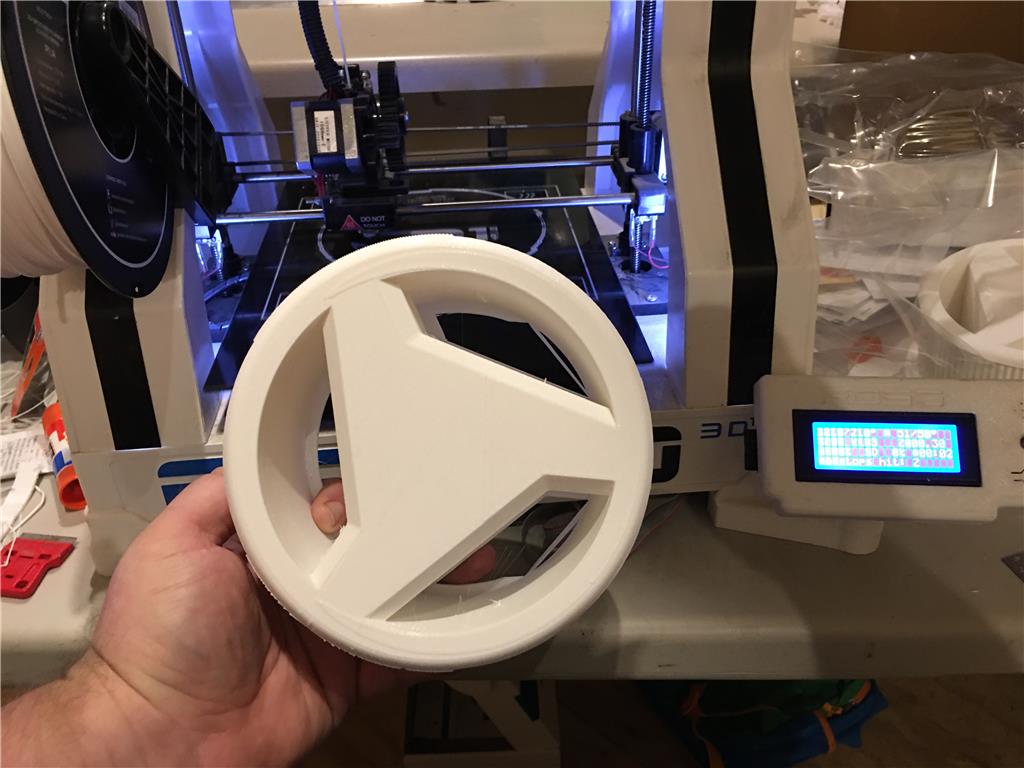

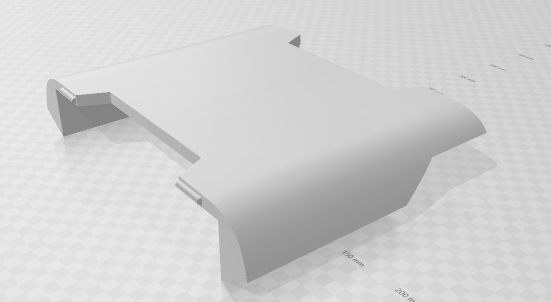

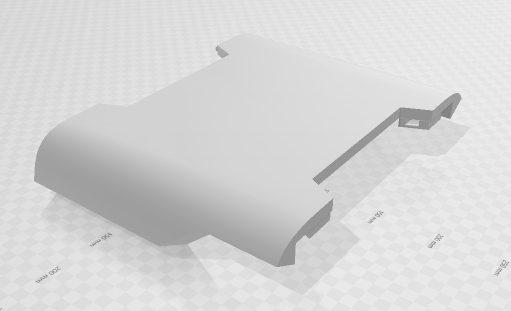

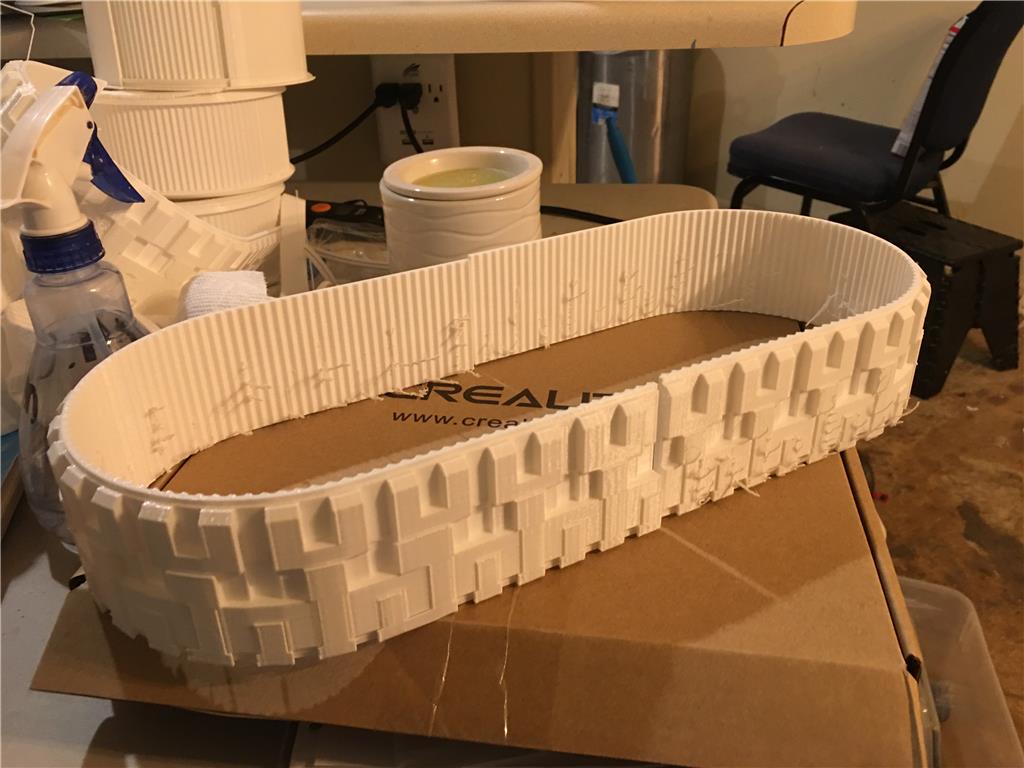

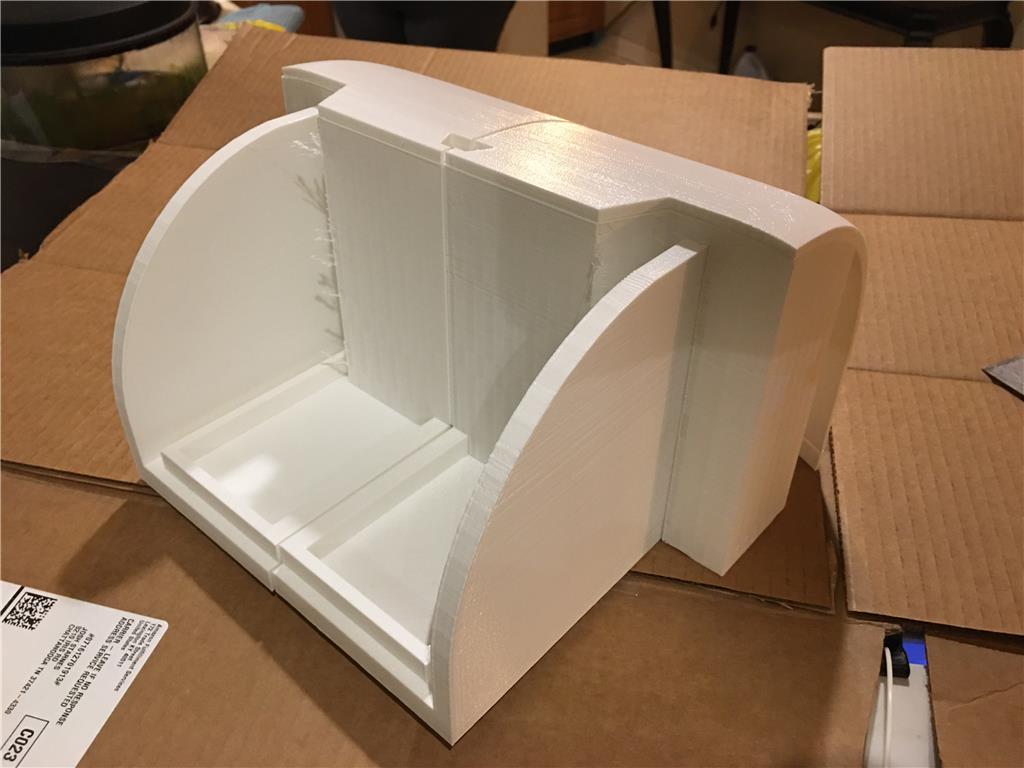

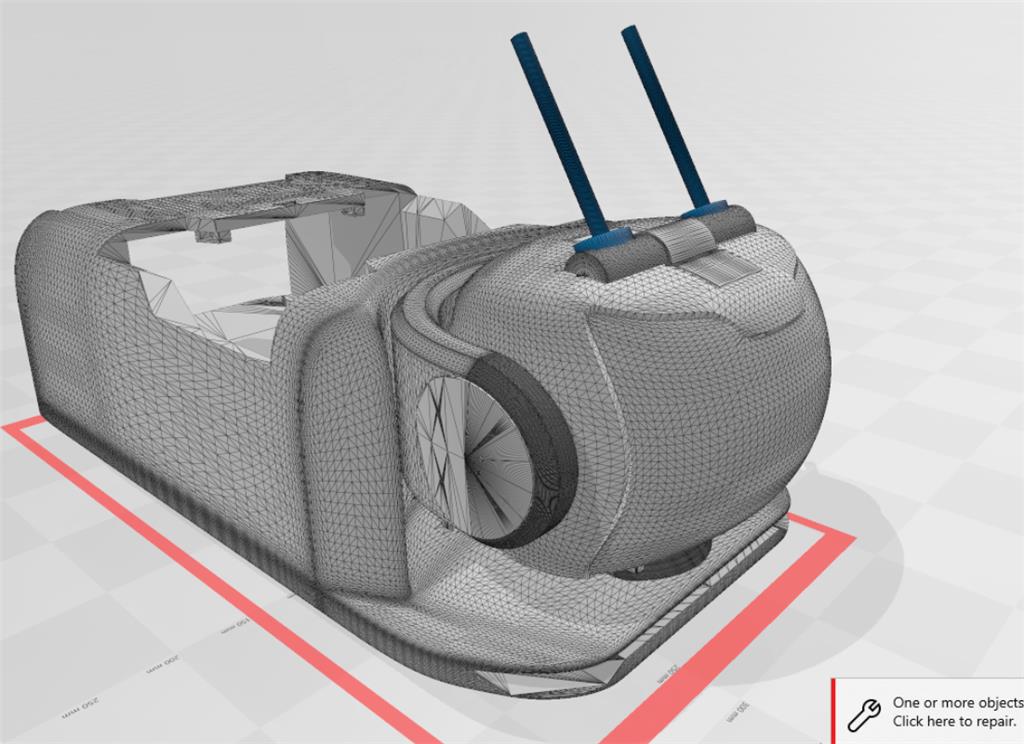

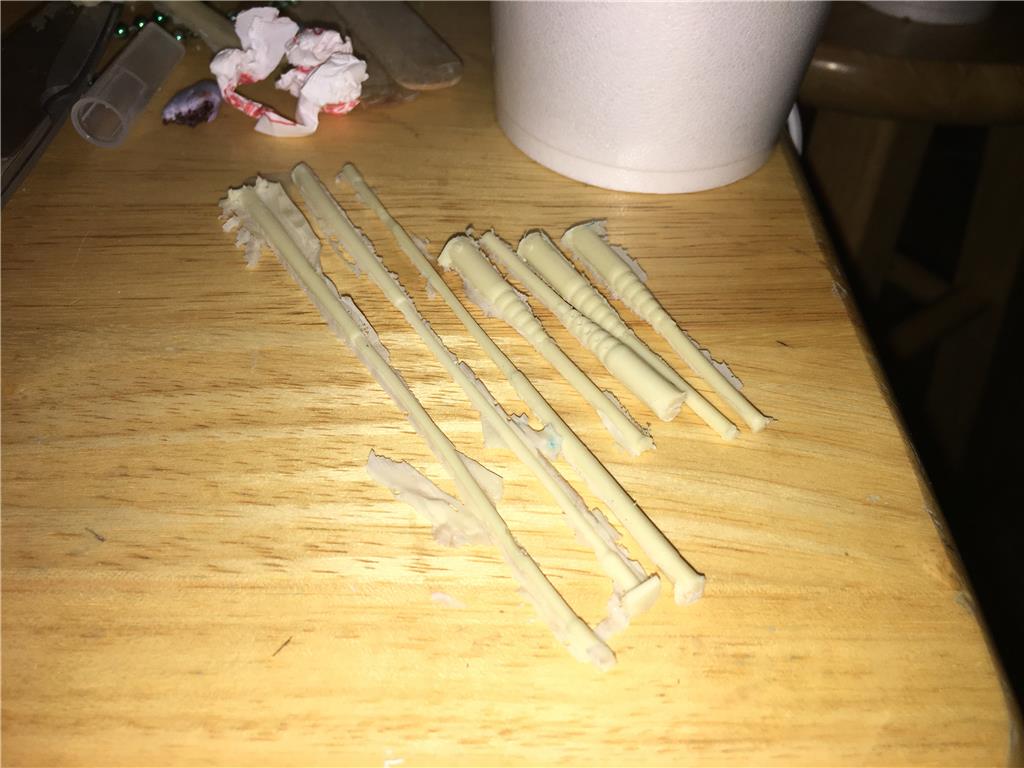

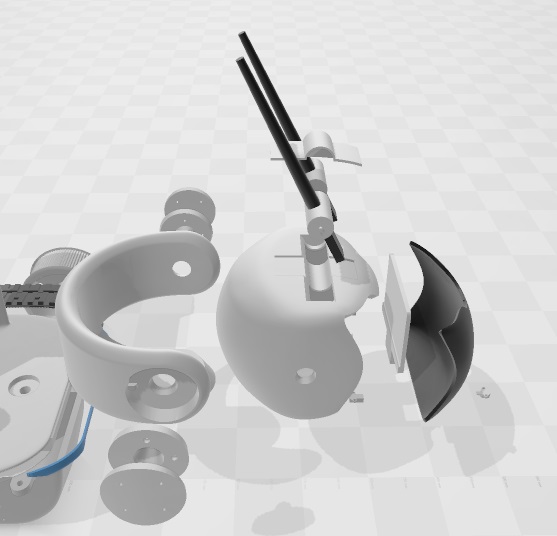

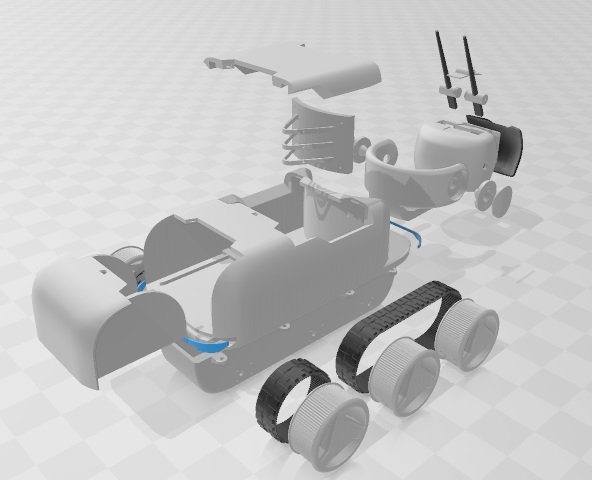

I popped the faux mock up tracks and tire onto some wheels, they are about 5 percent too small, but that should be fine when we are talking about parts that will be rubber and have some level of stretch.

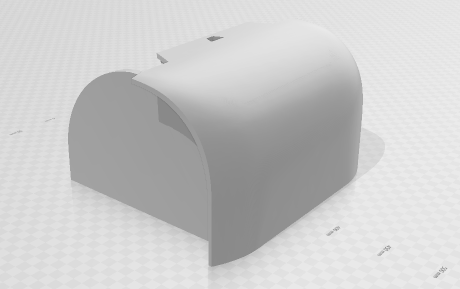

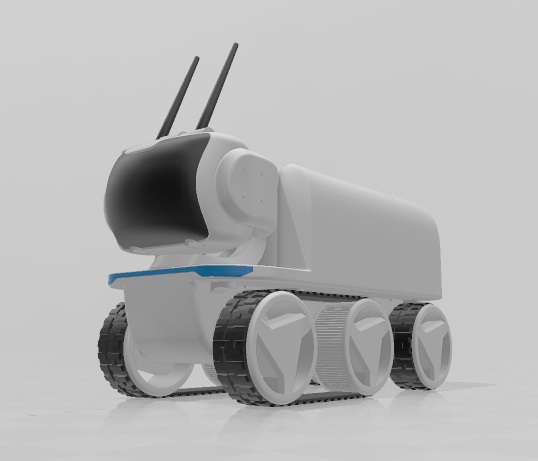

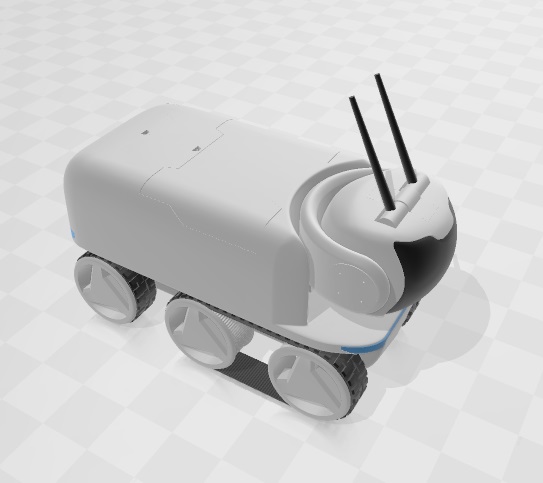

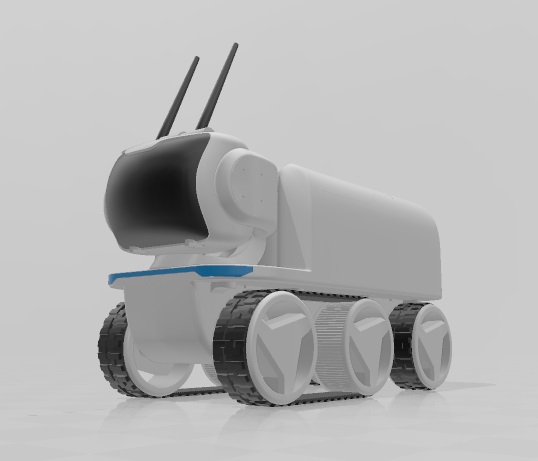

how does it look? Pretty Clean? I like it so far.

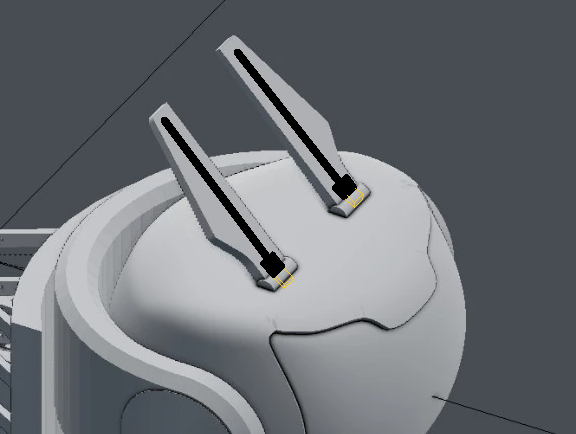

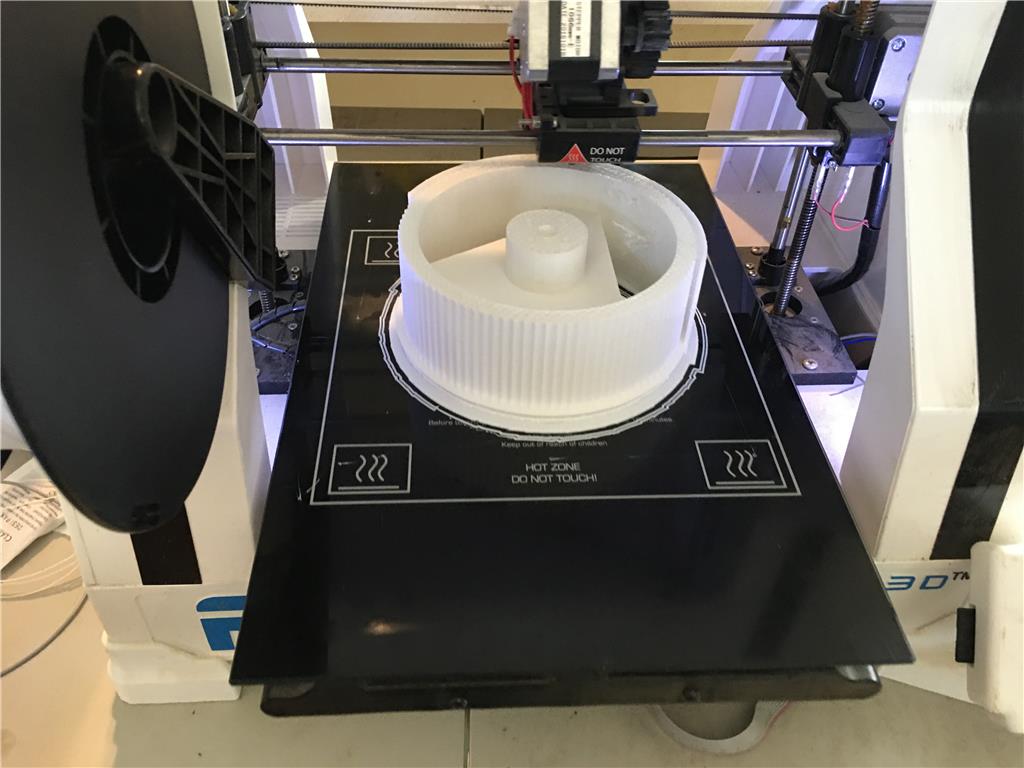

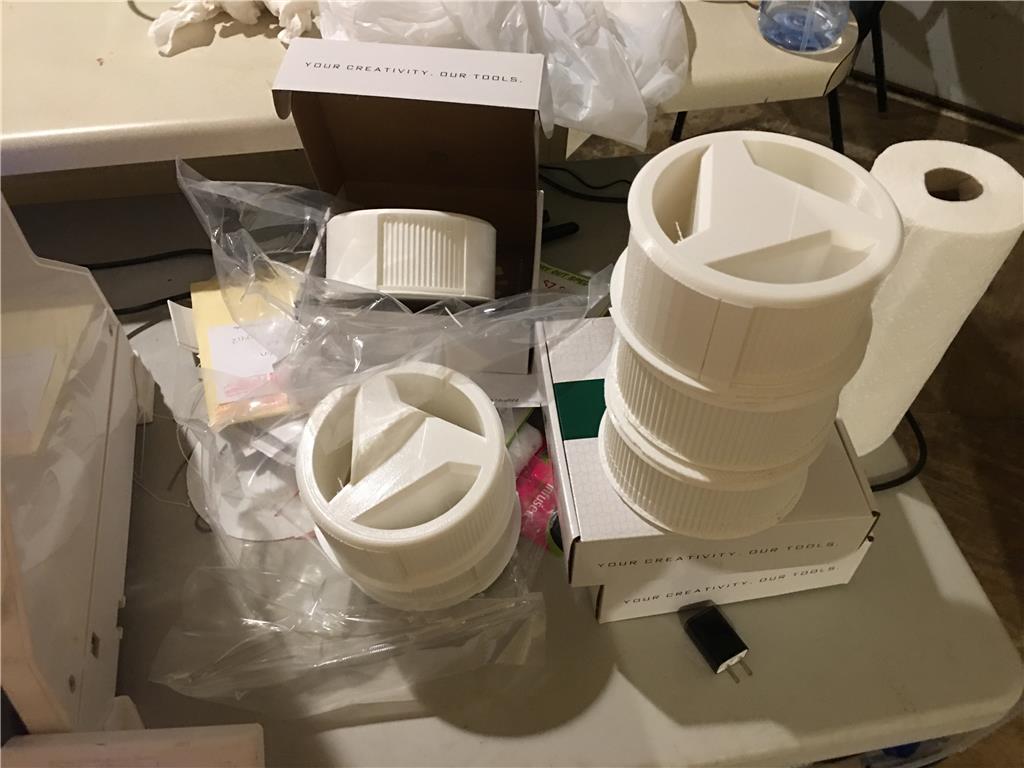

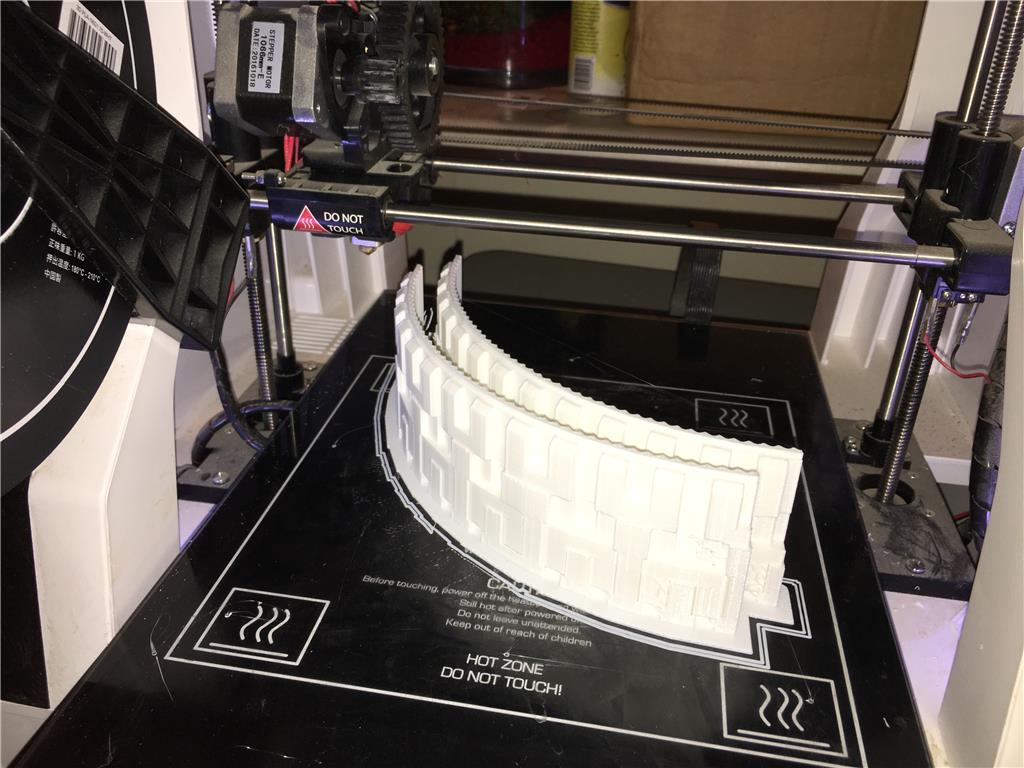

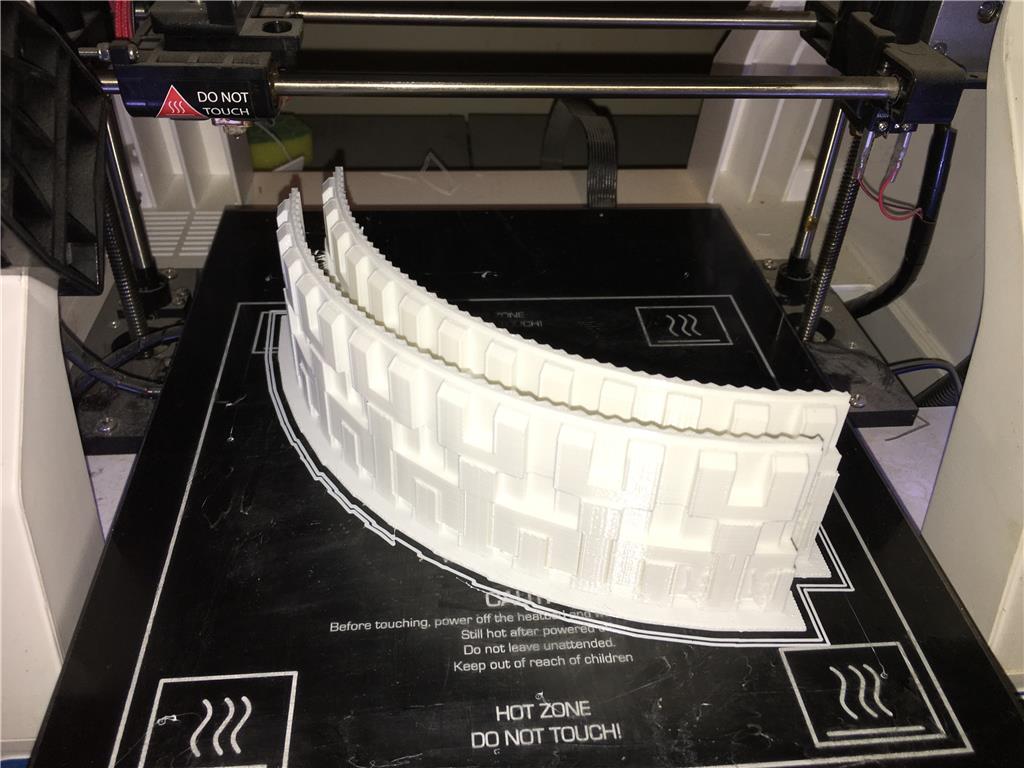

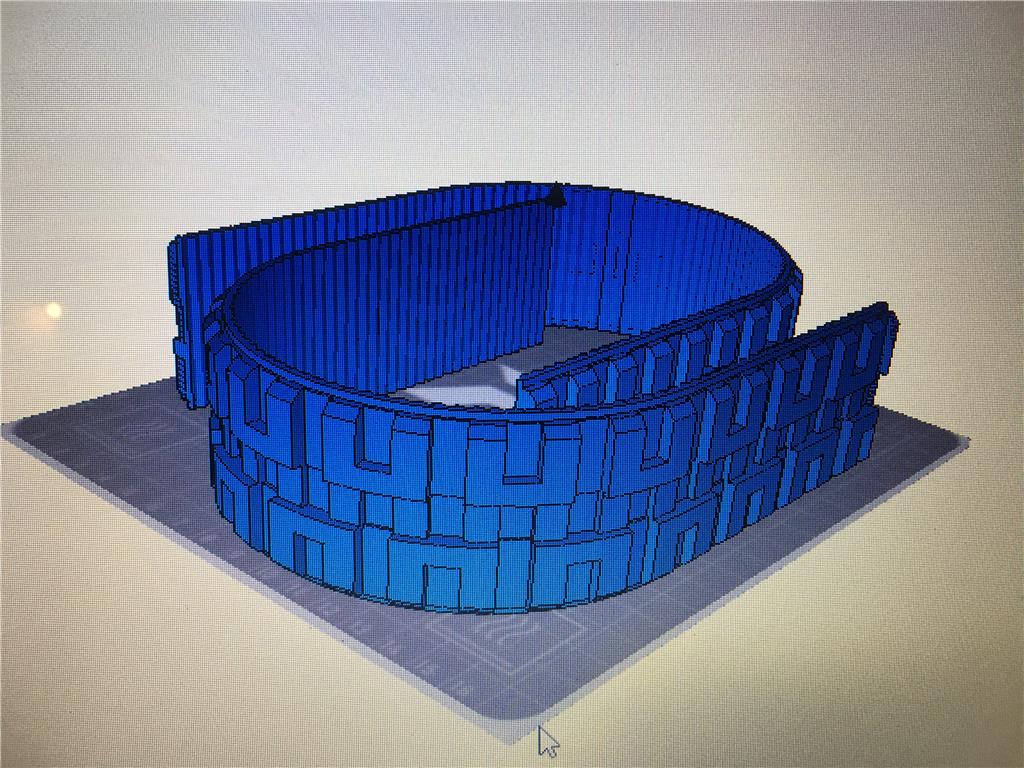

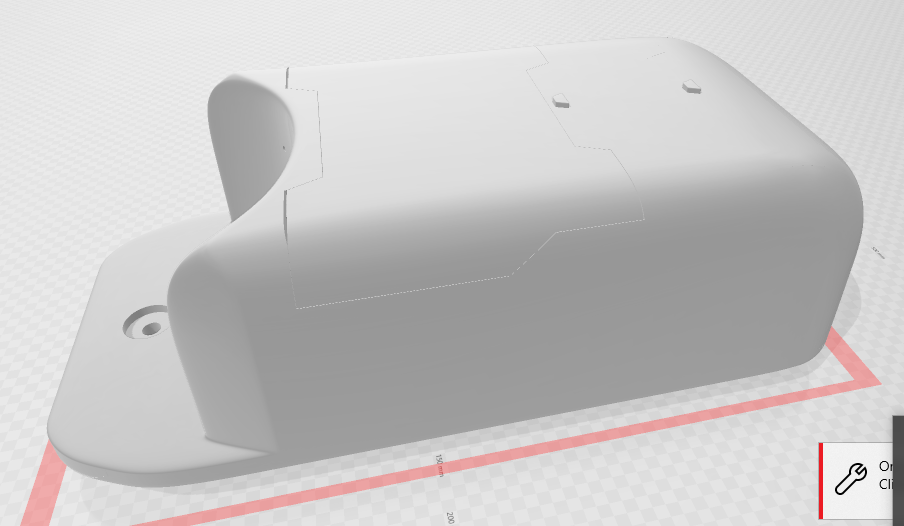

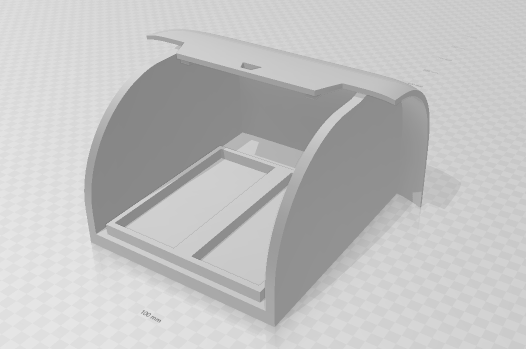

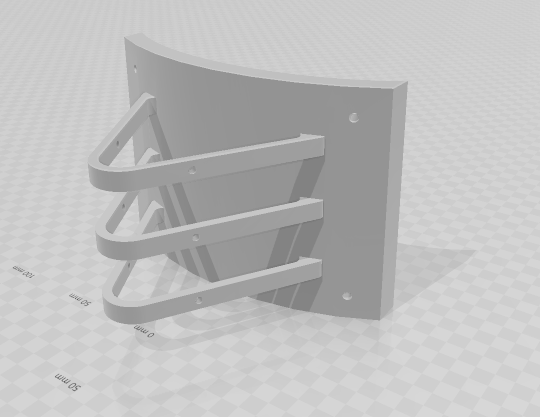

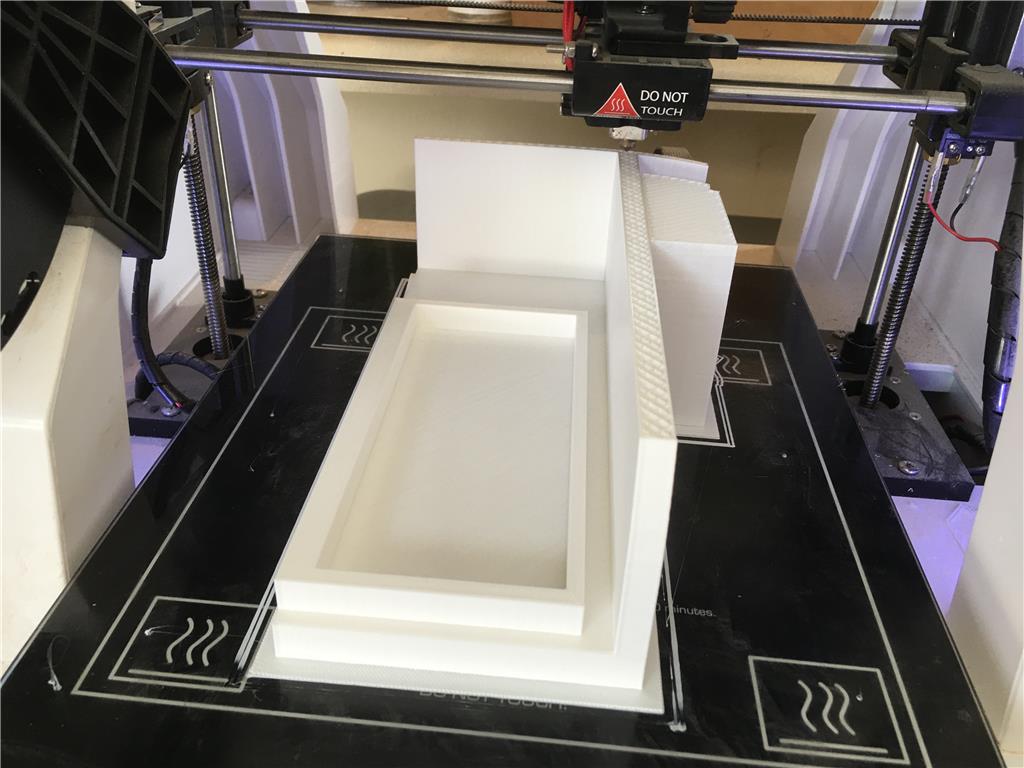

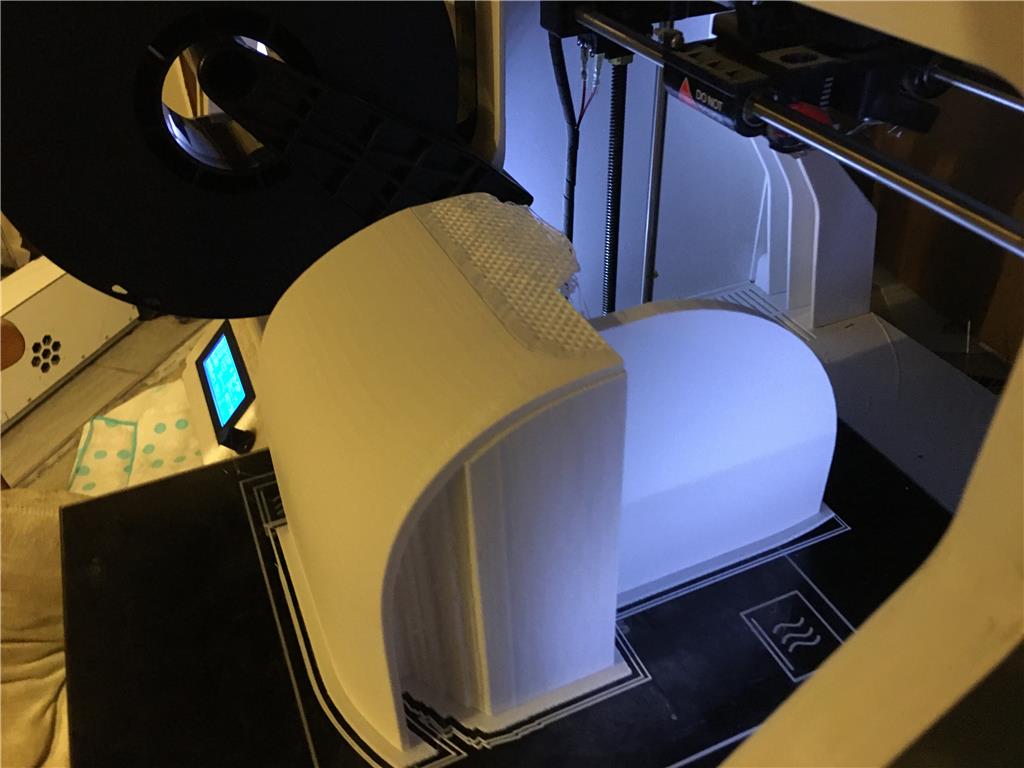

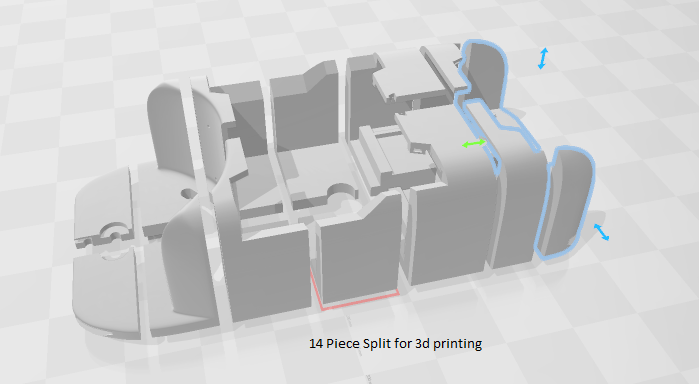

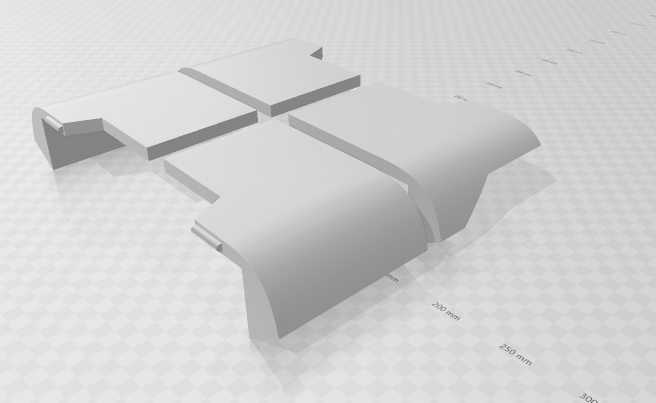

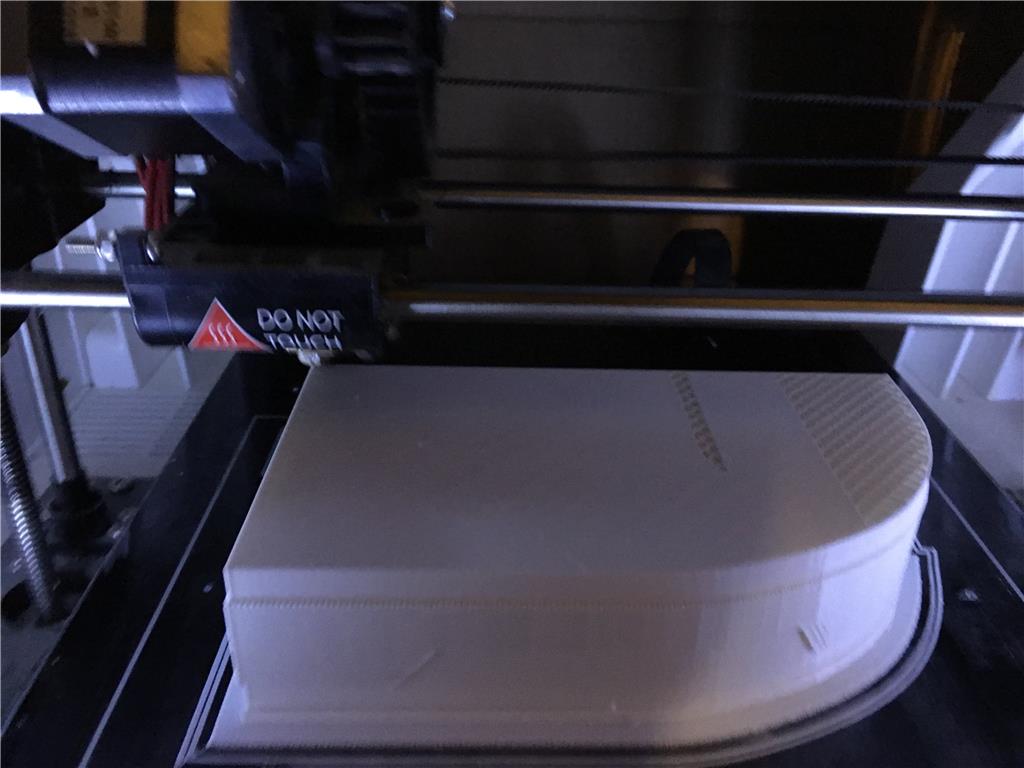

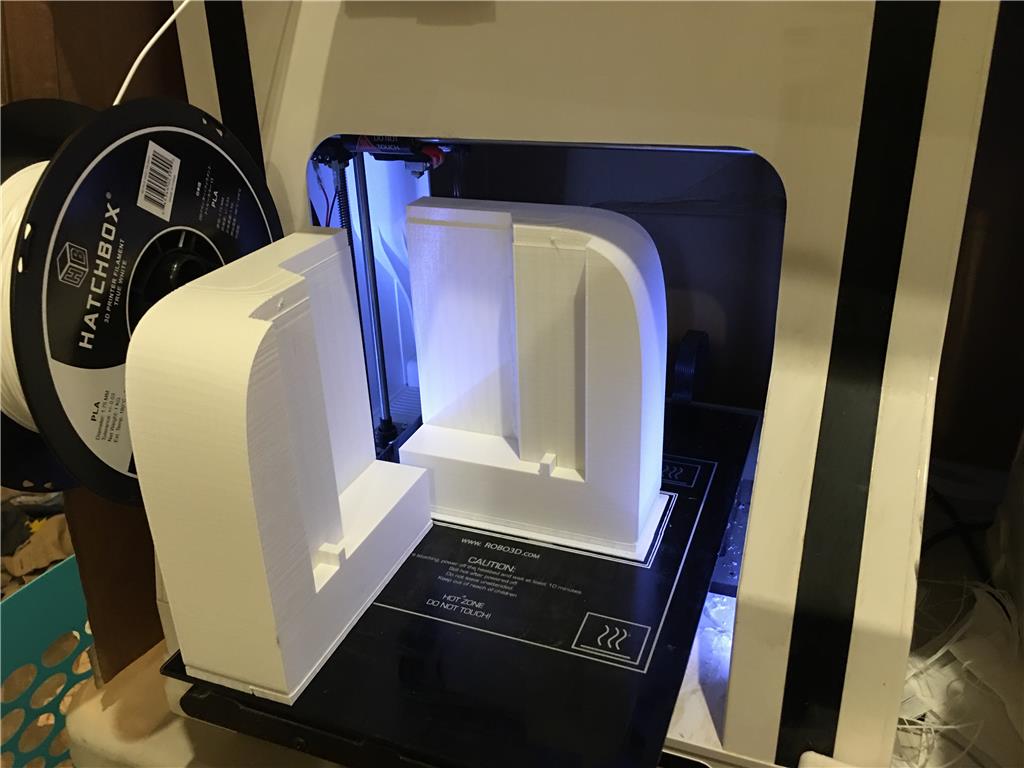

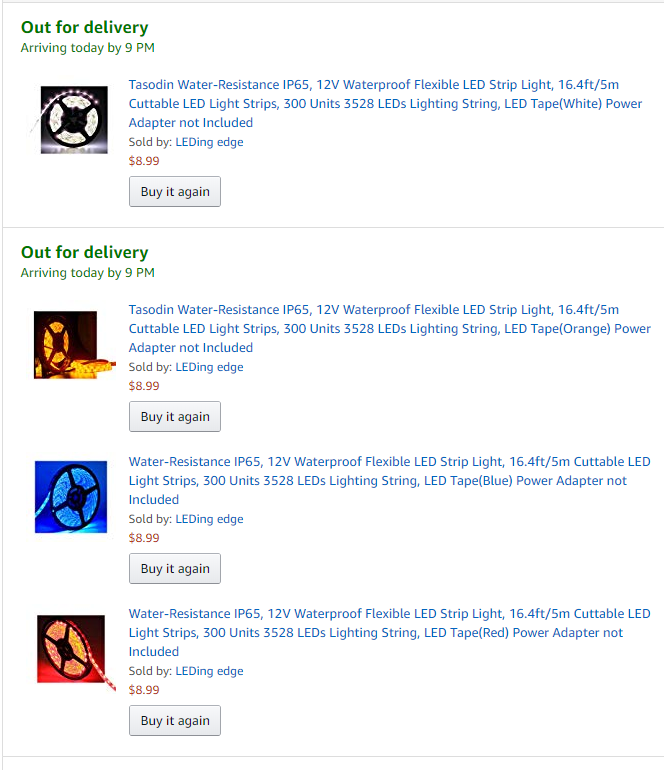

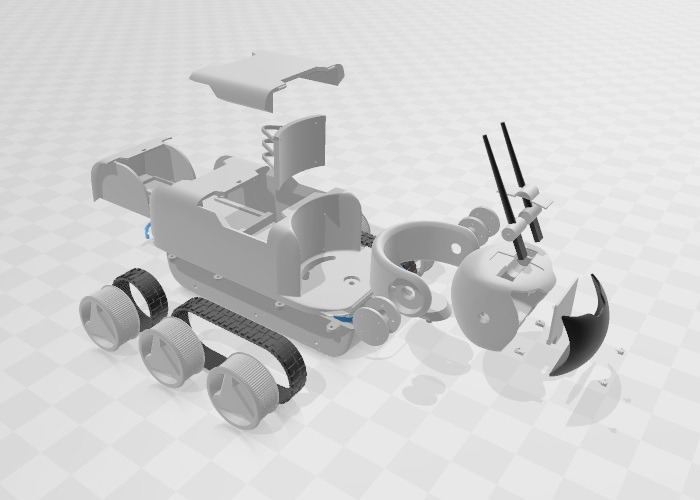

I just started two 30 hour prints. I cut the rear drawer and battery door in half and set the left and right sides to print on the Robo 3D printers. I have three Ender 3 pro printers in boxes that I will need to find time to assemble and setup. I need to take a few days to really buckle down and knock out my Scripting and coding class preferably before Christmas.

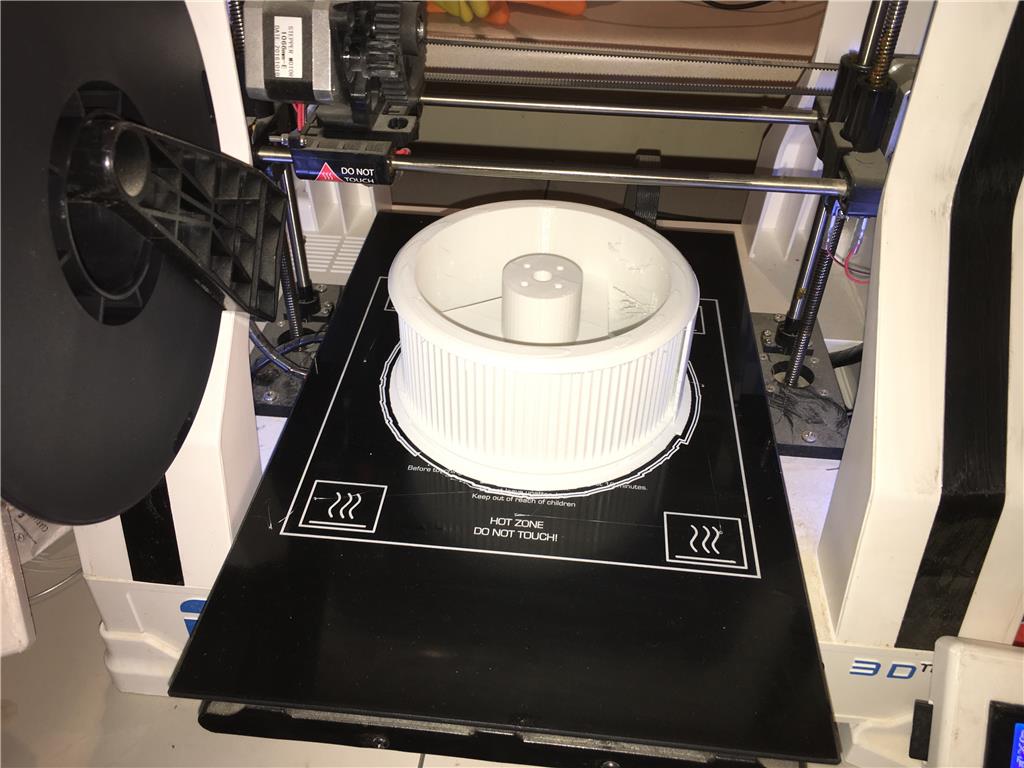

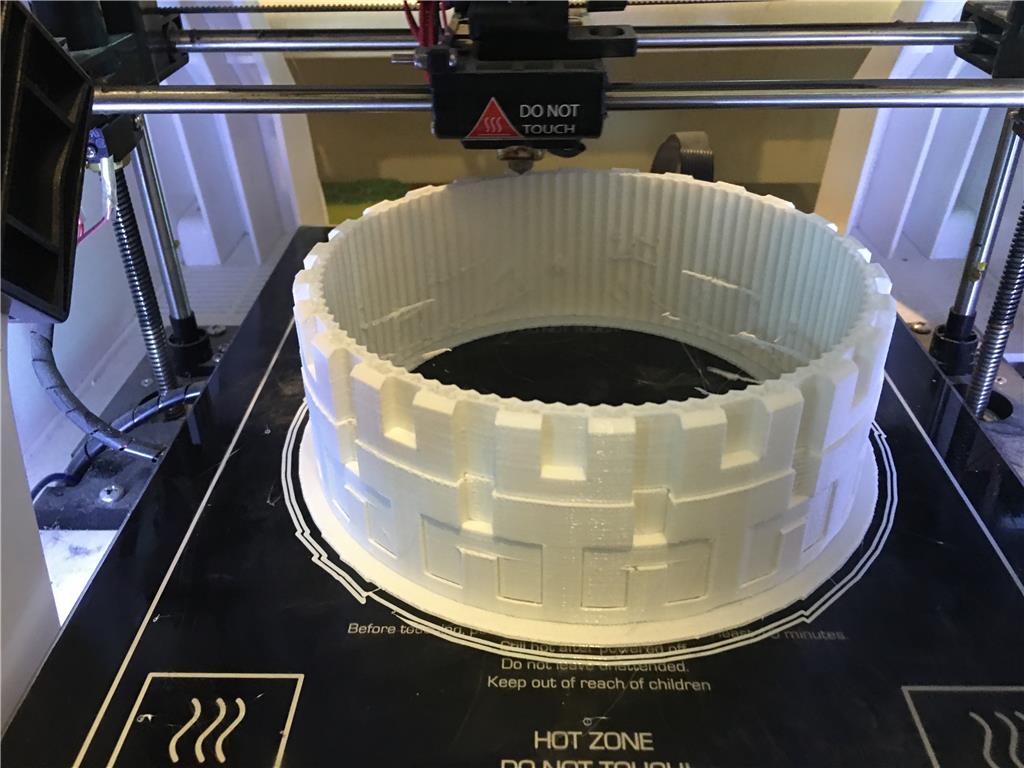

the rear drawer and rear body cover are 36 percent printed and they are looking excellent! Based on the time printing so far it will be tommorow sometimes before these two are done.

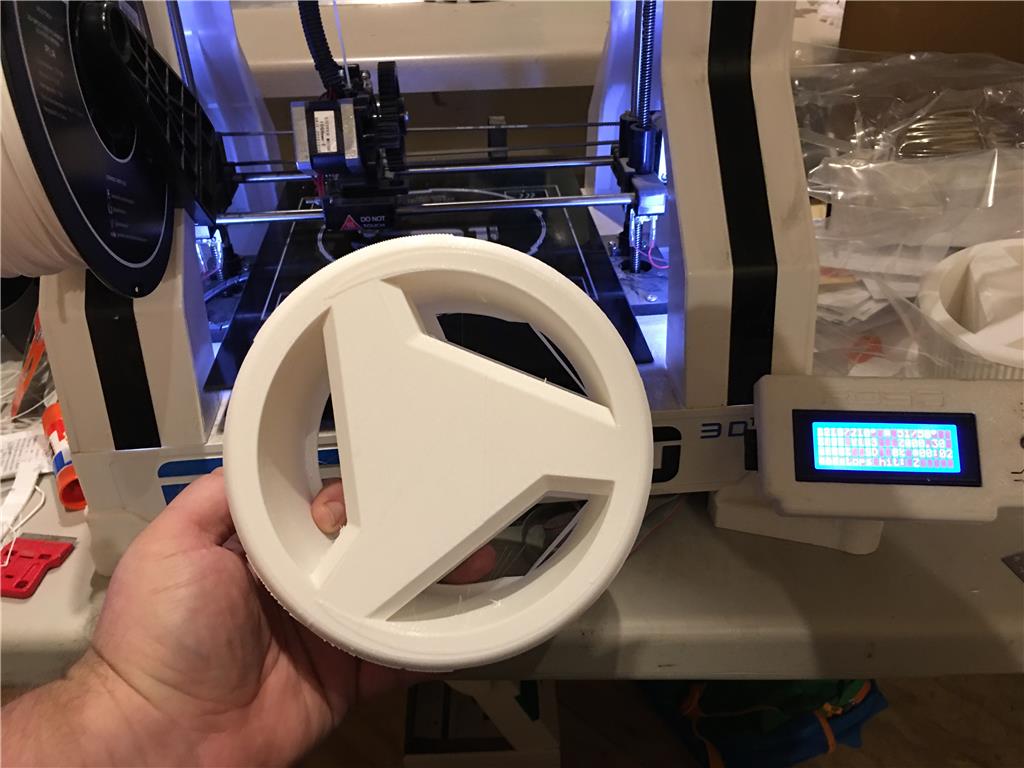

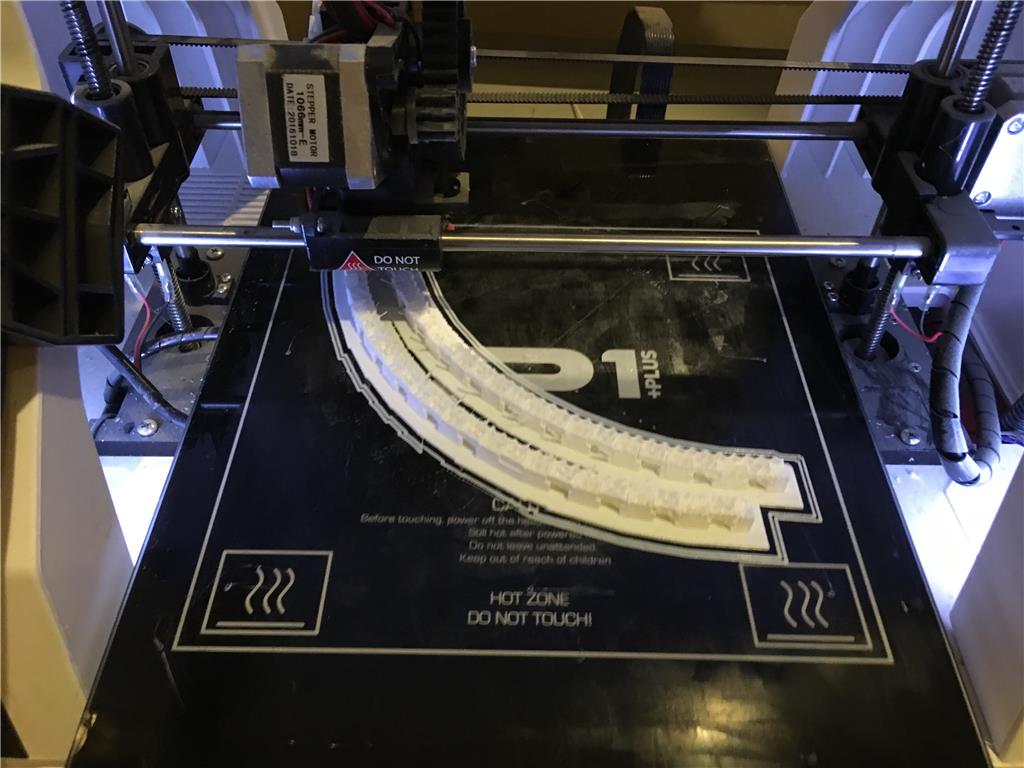

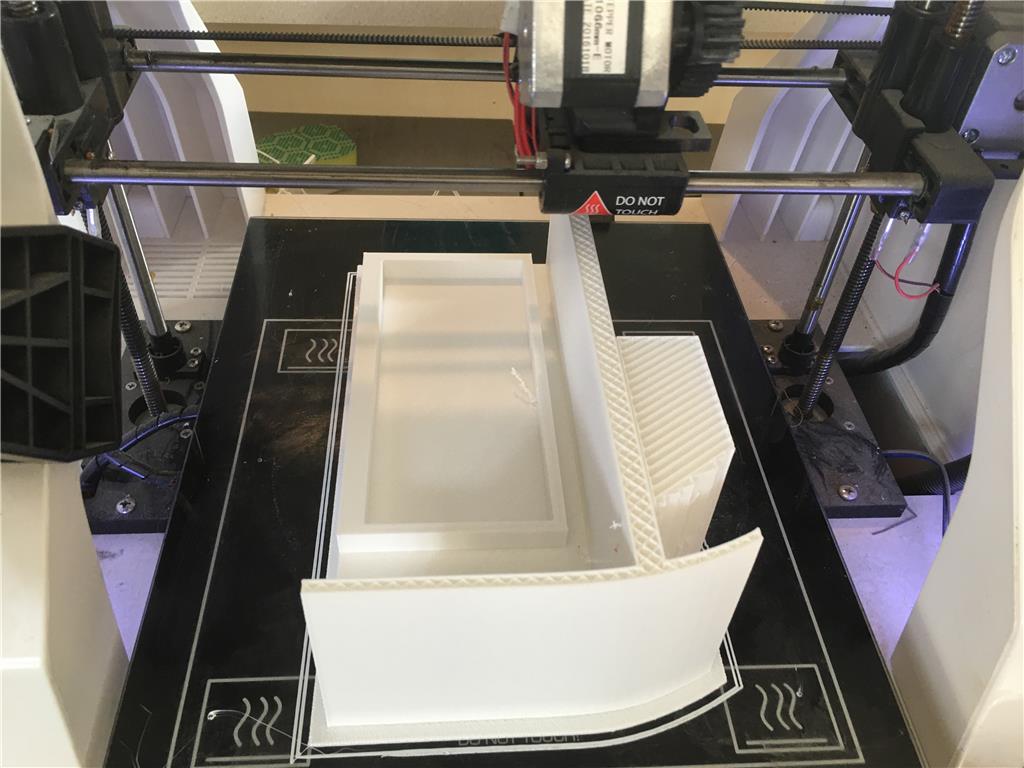

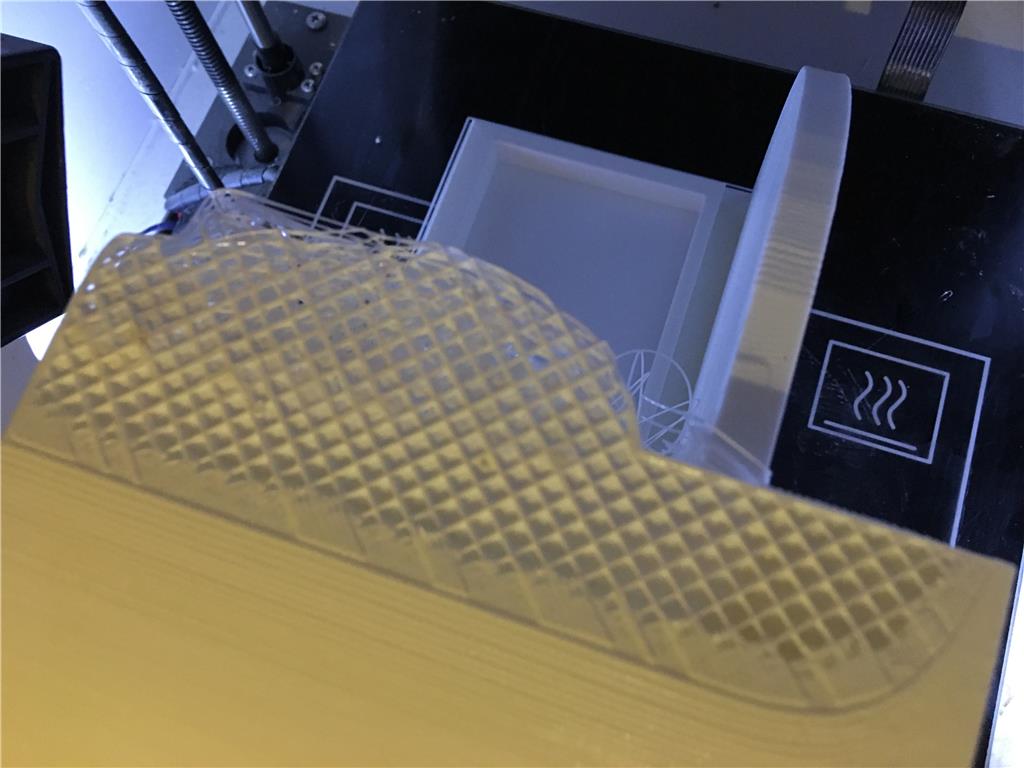

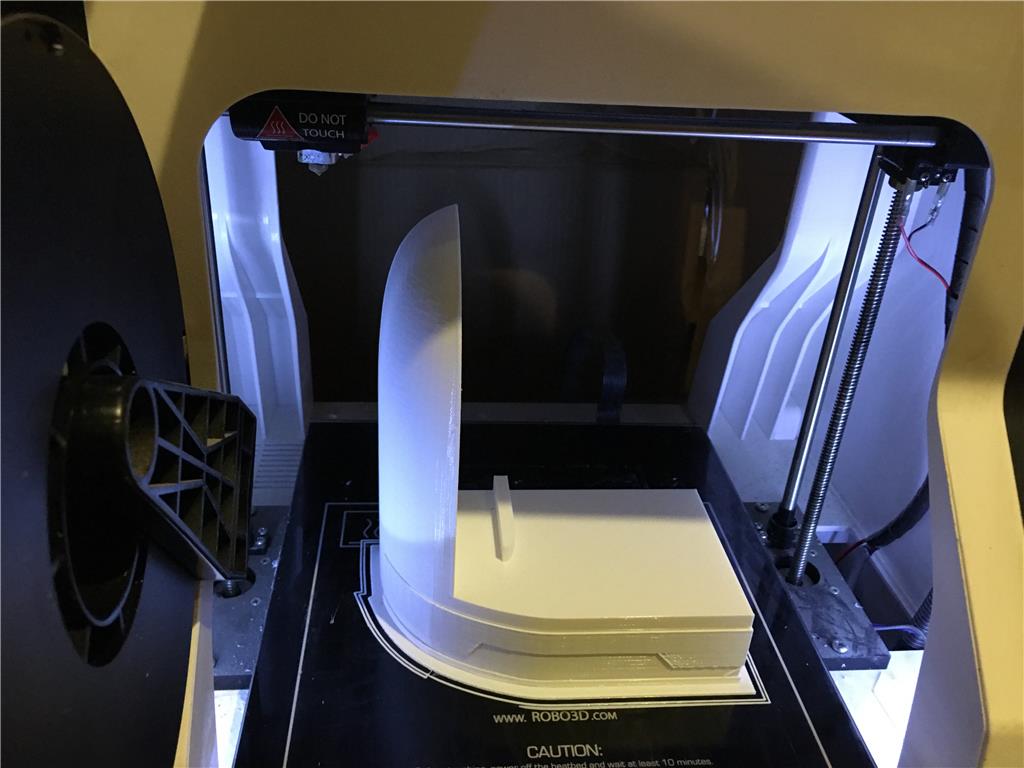

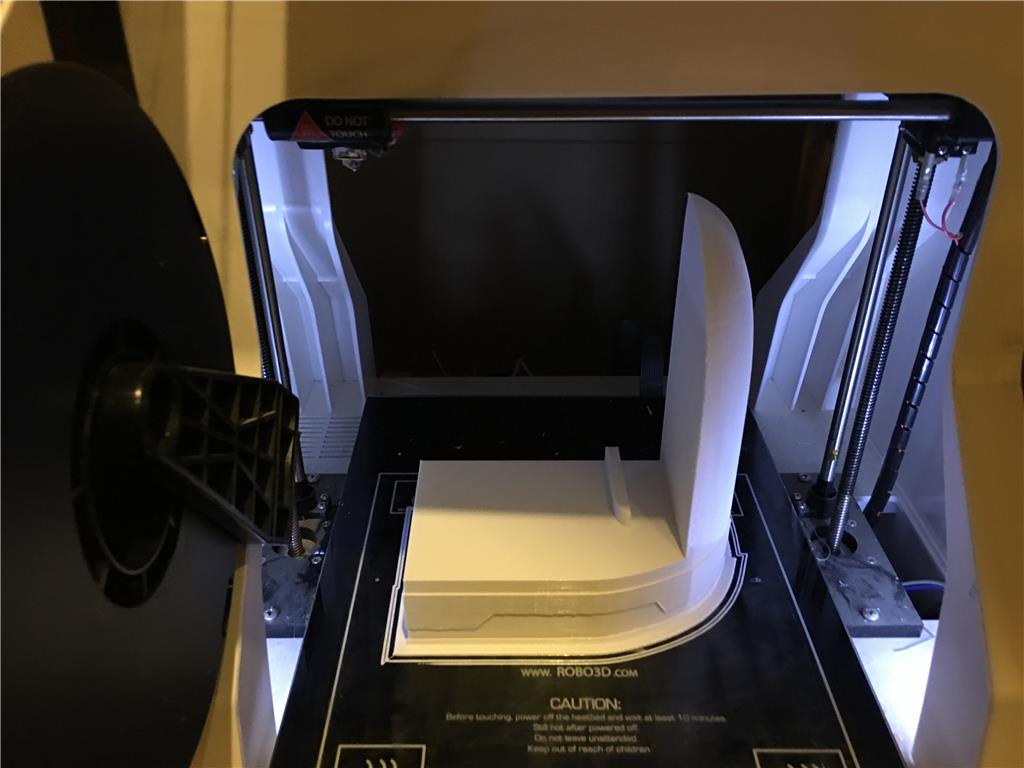

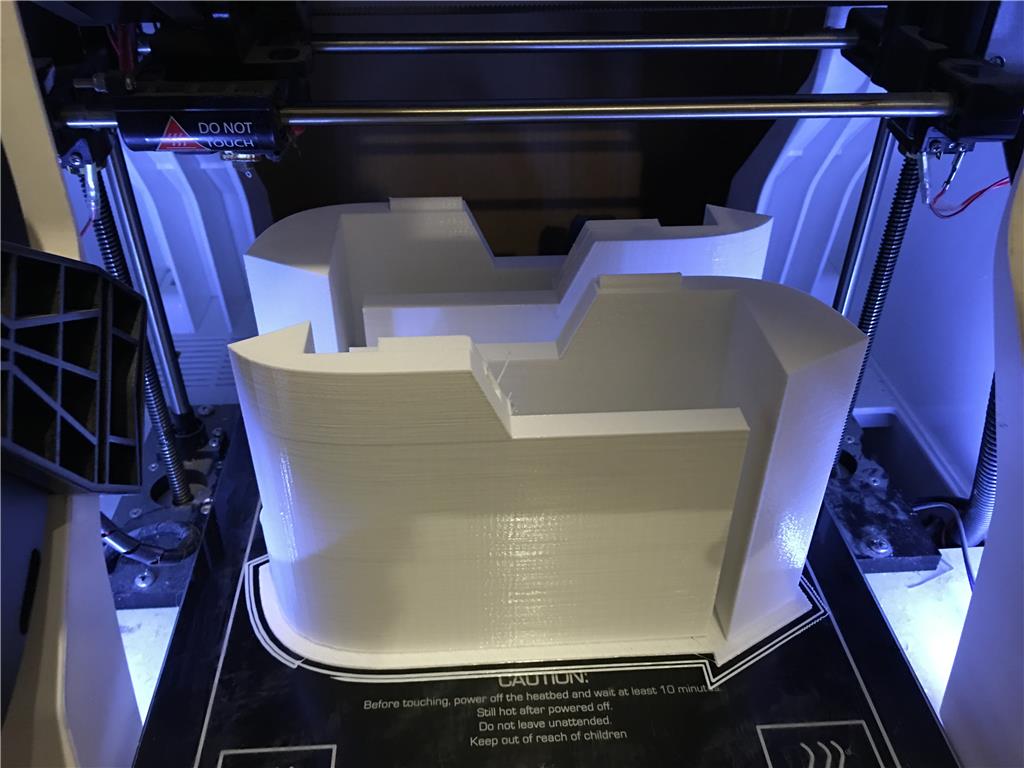

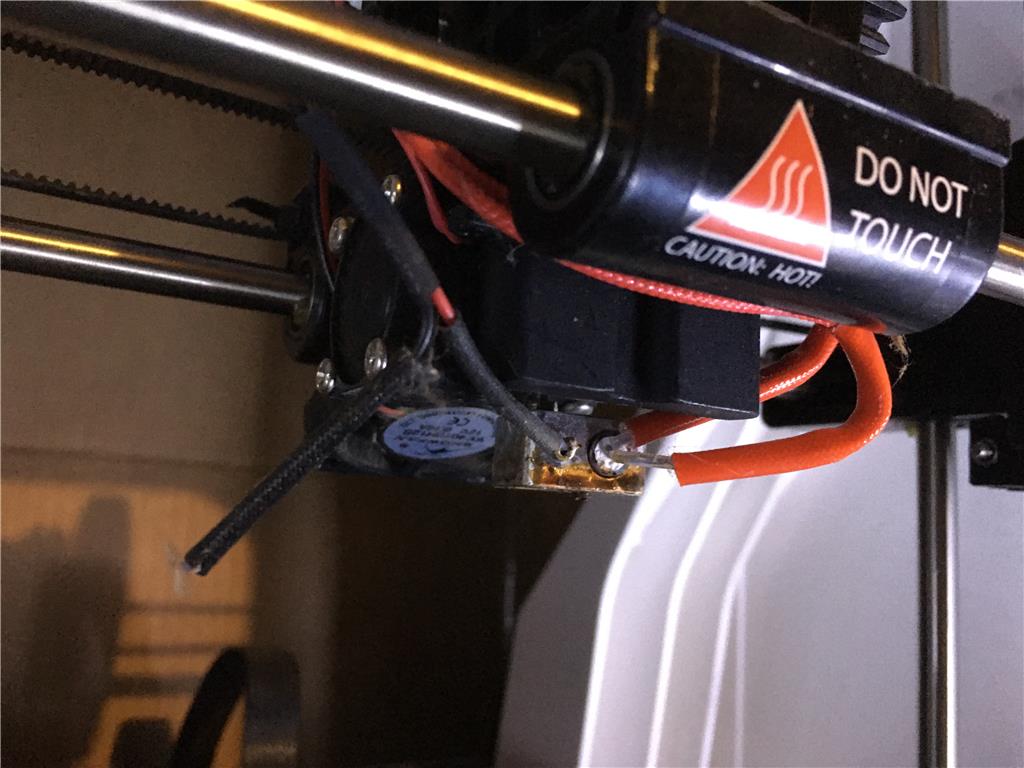

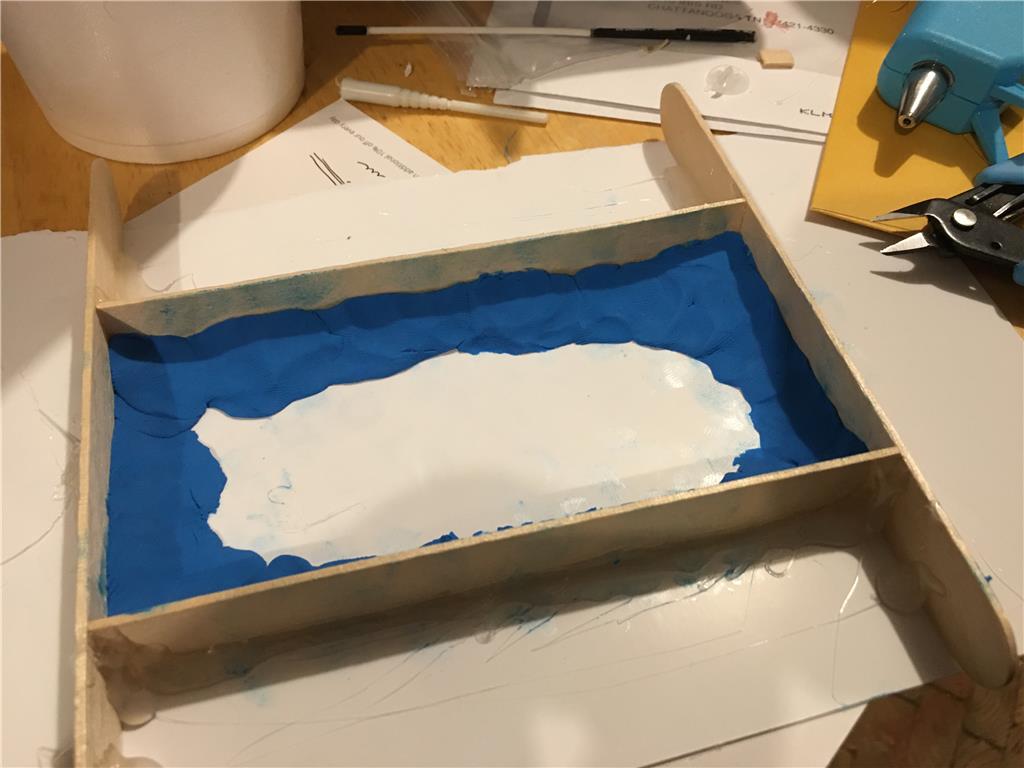

Yuck, my first misprint for the project. All of a sudden the nozzle was caught on a piece of the support that broke away from the bed I think. I put together a Janky card board draft black to wrap around the back, sides and top of the Robo printer and I will try agian.

Super Janky draft shieldAre you printing with PLA or PETG? I am printing with PETG and I find its very tar like and sticky compared to pla. It gets on the nozzle and eventually collects and deposits on your model as a blob, which then cools and creates a high spot on the print, which of course the nozzle comes back to hit on its next round about. I got in the habit of taking a straight razor to the balck build up on the nozzle before a print. Seems to help alot.

It is PLA

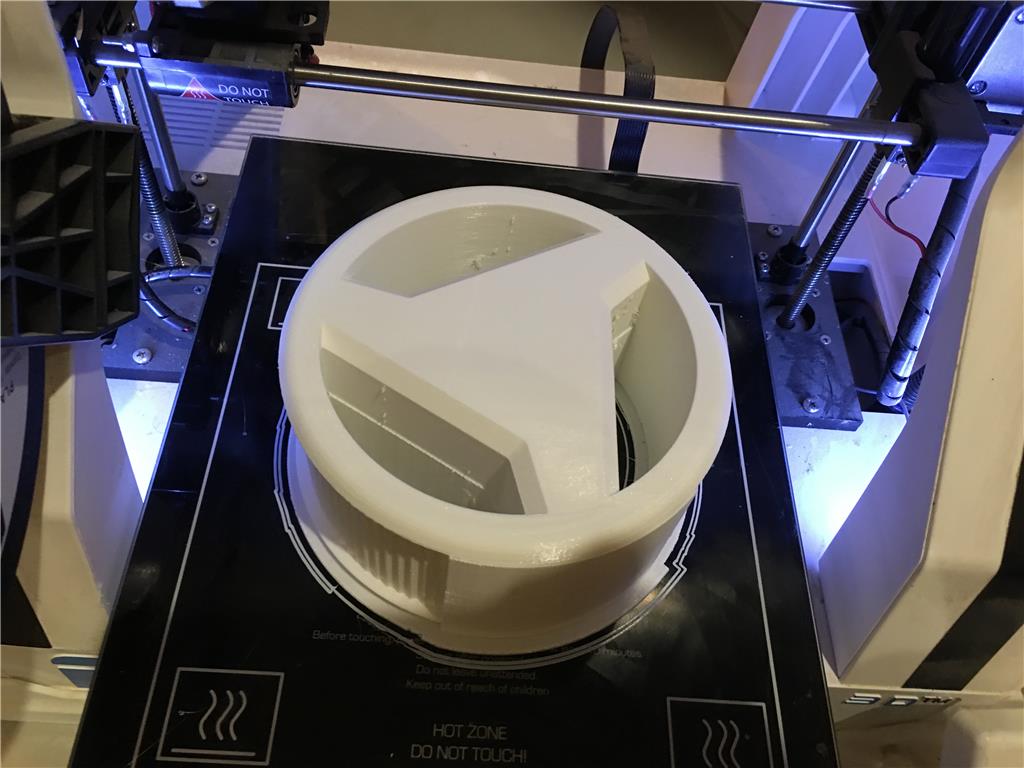

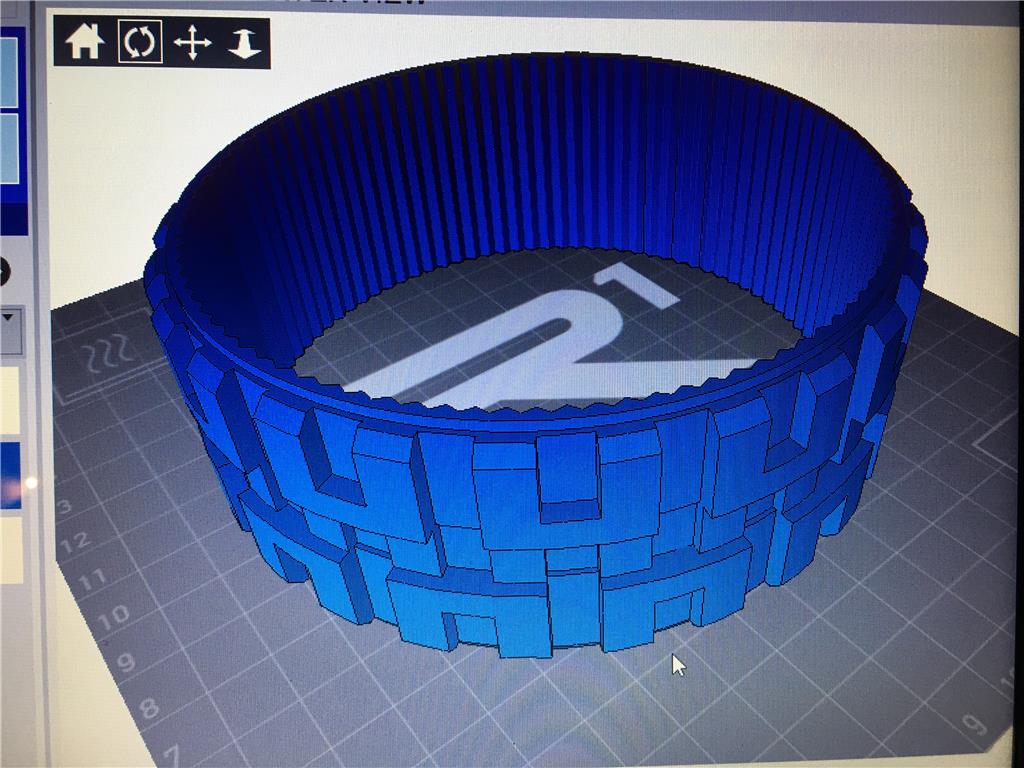

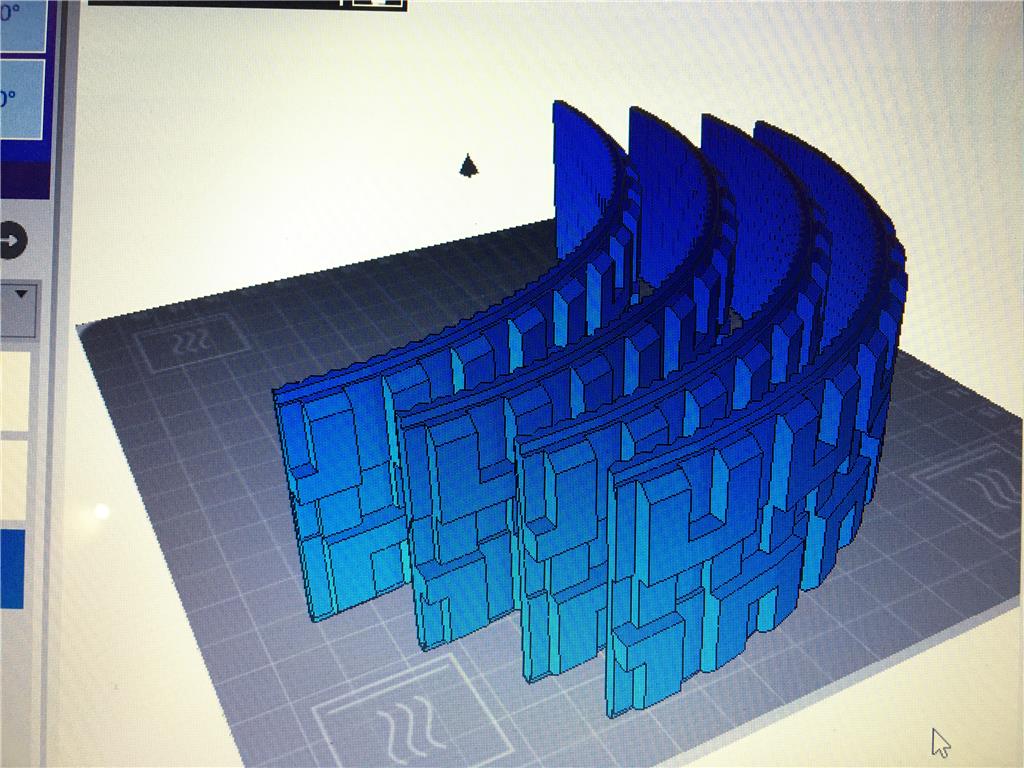

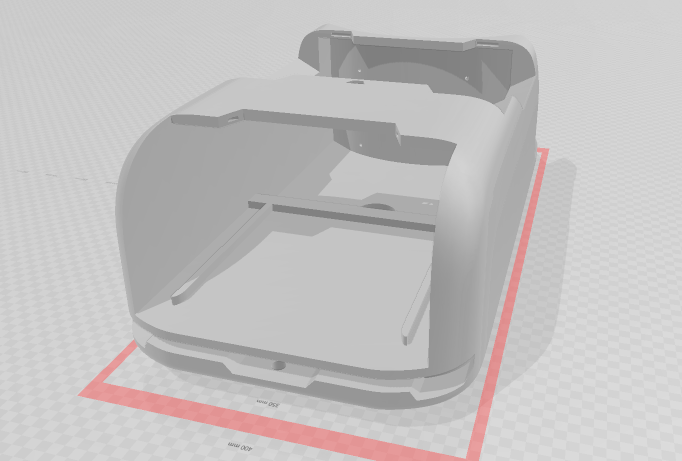

well the other print failed to and it was my oversight that caused it. I didn’t realize the slicer did not generate adequate support for the top layers overhang. I believe I will switch to using Simplify 3D as I already bought their license a while back but I have not used it recently . I used the oem supplied matter software from Robo 3D for this botched job.

in short I need to take care that proper supports are generated and I don’t thing the stock software is cutting it.

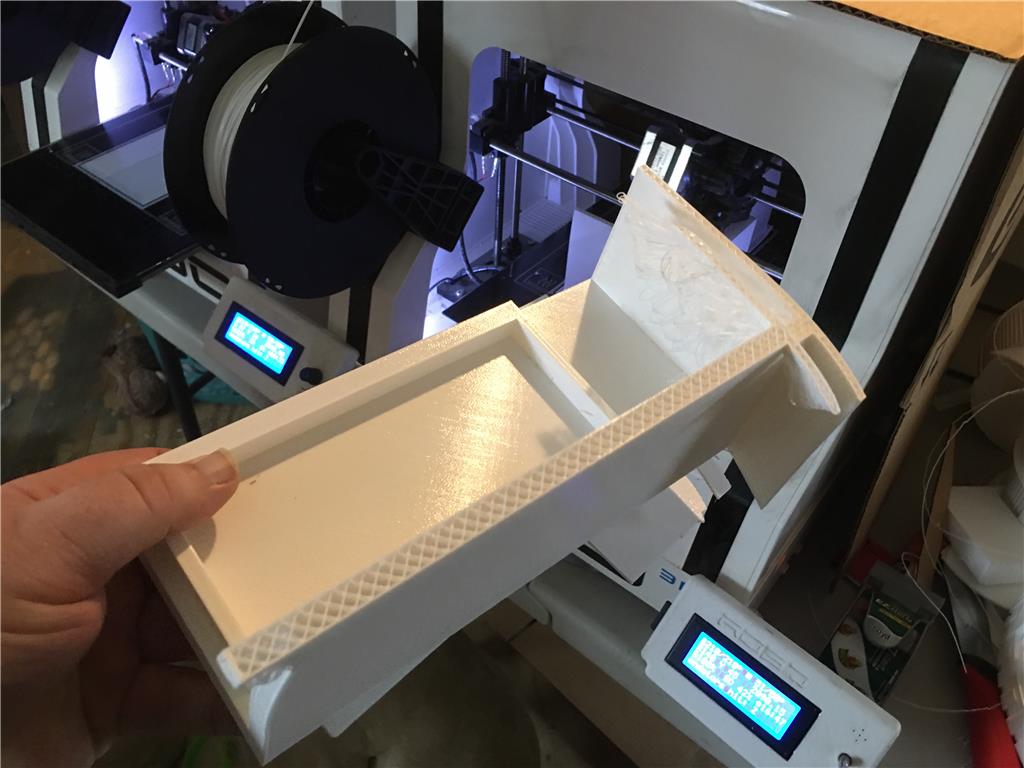

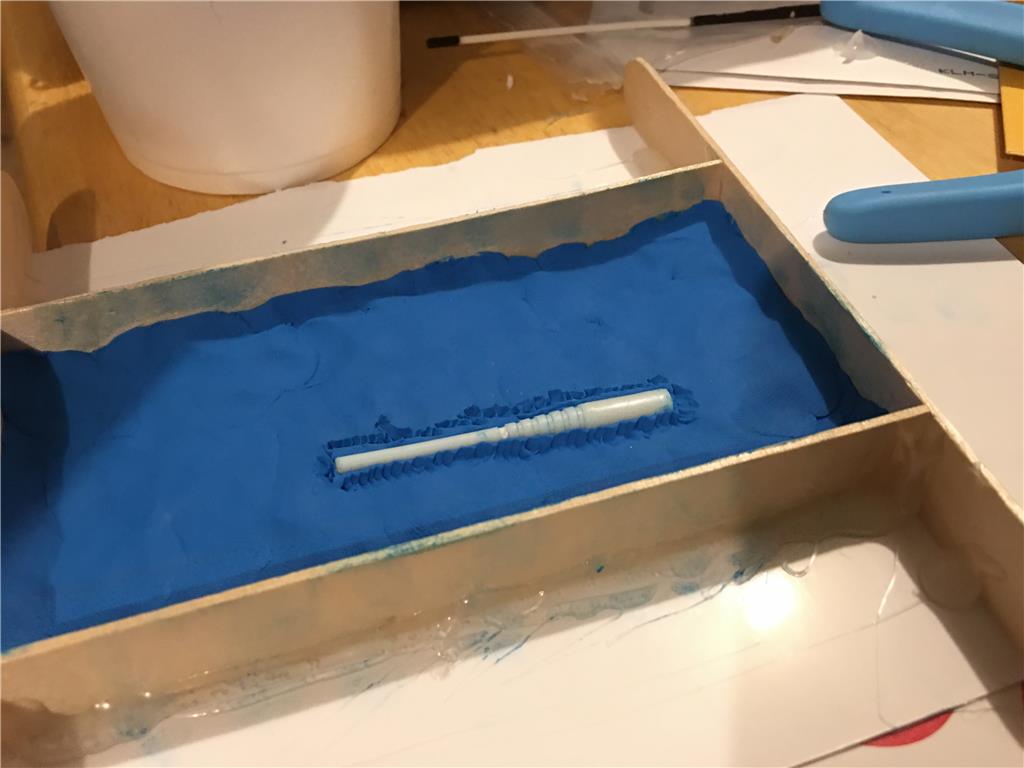

So , moving on and doing what I should have done to begin with.. I installed Simplify3D on my laptop. It immediately sliced with the correct supports in place. I have a license from a few years ago, I wonder if their are any improvements or good reasons to buy a new license? I will start those prints over after I get off work today and we will see if we have some winners.