Hi all,

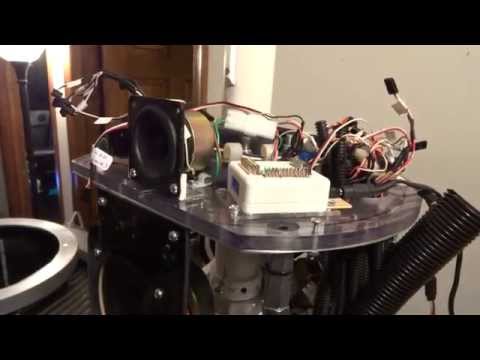

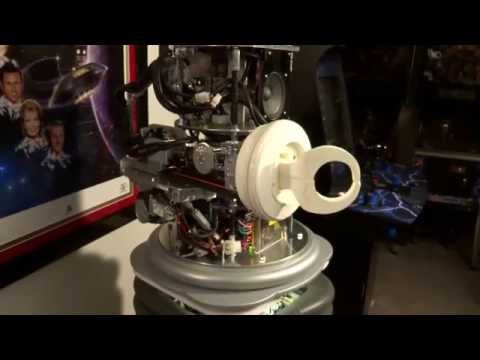

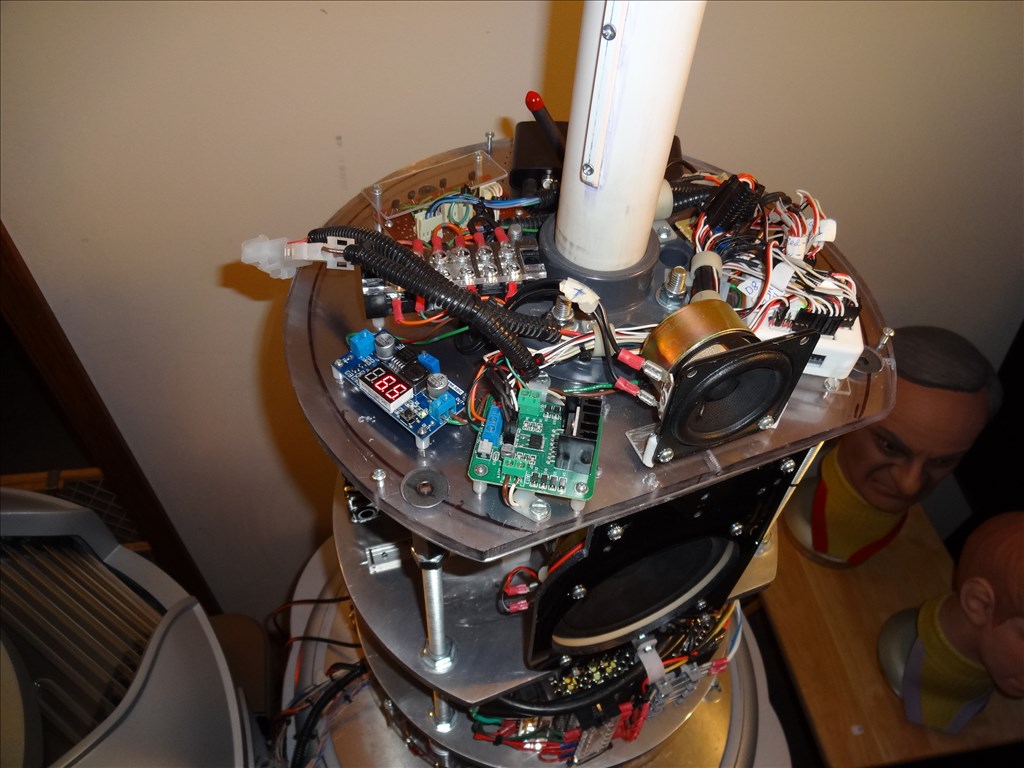

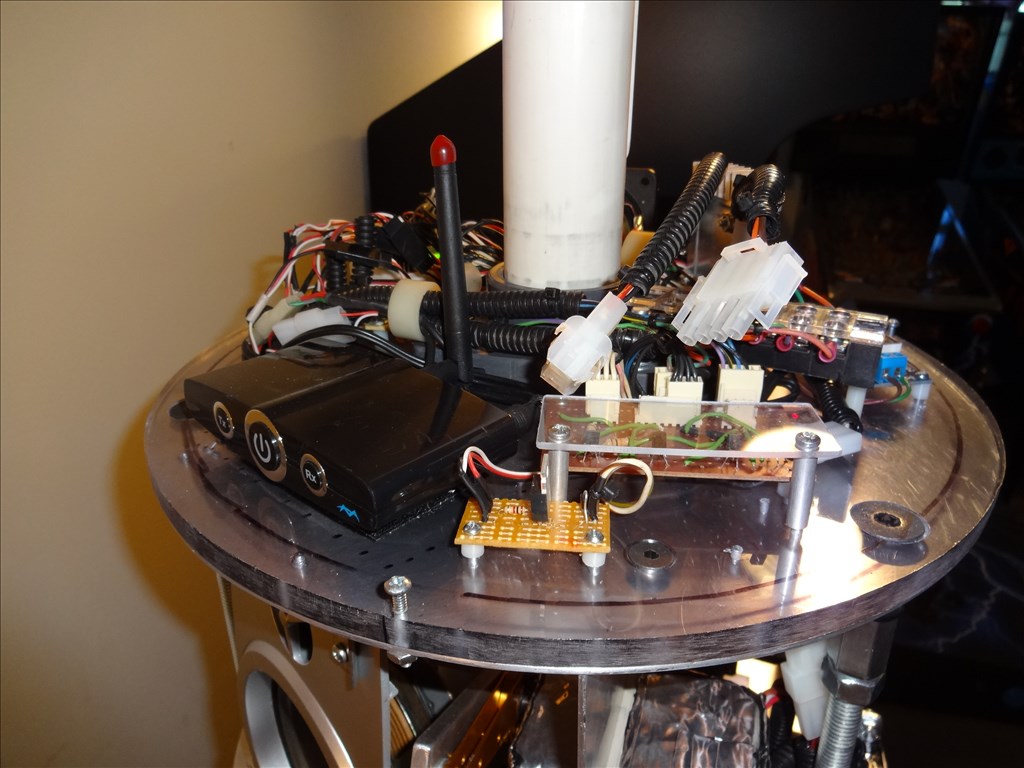

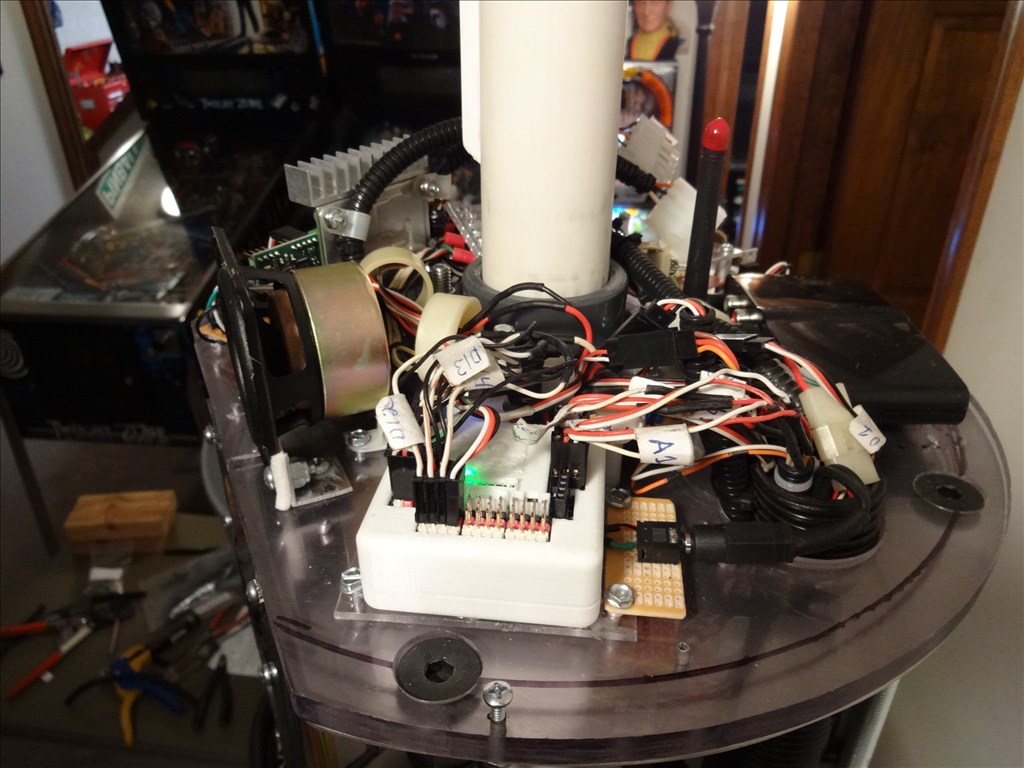

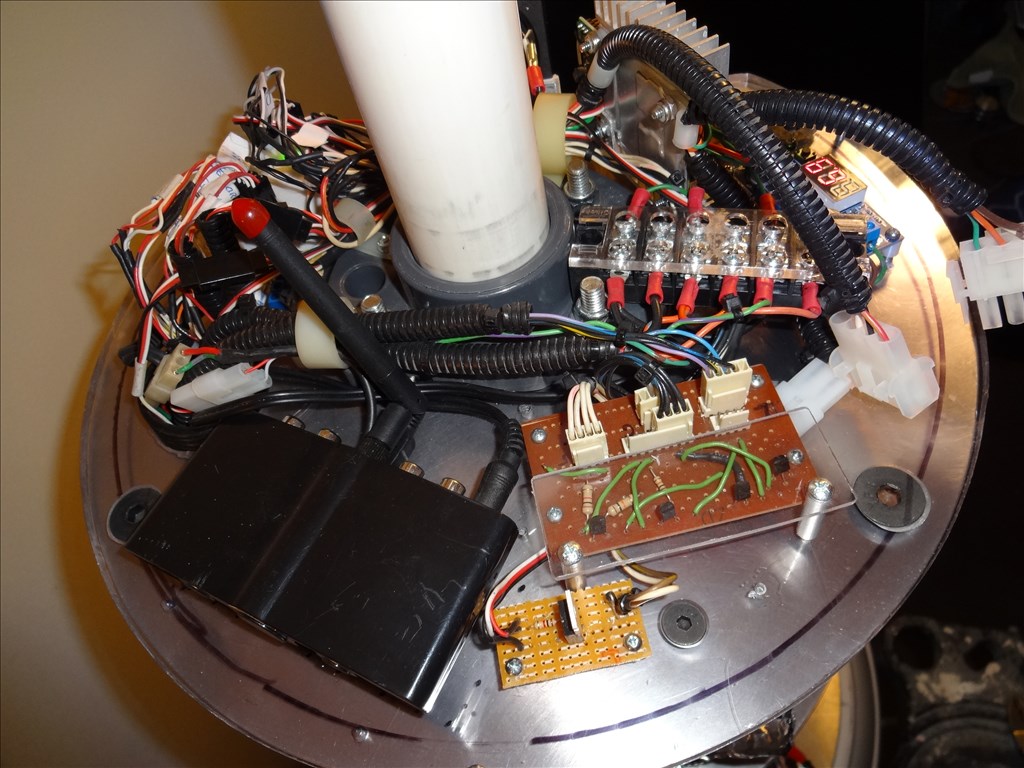

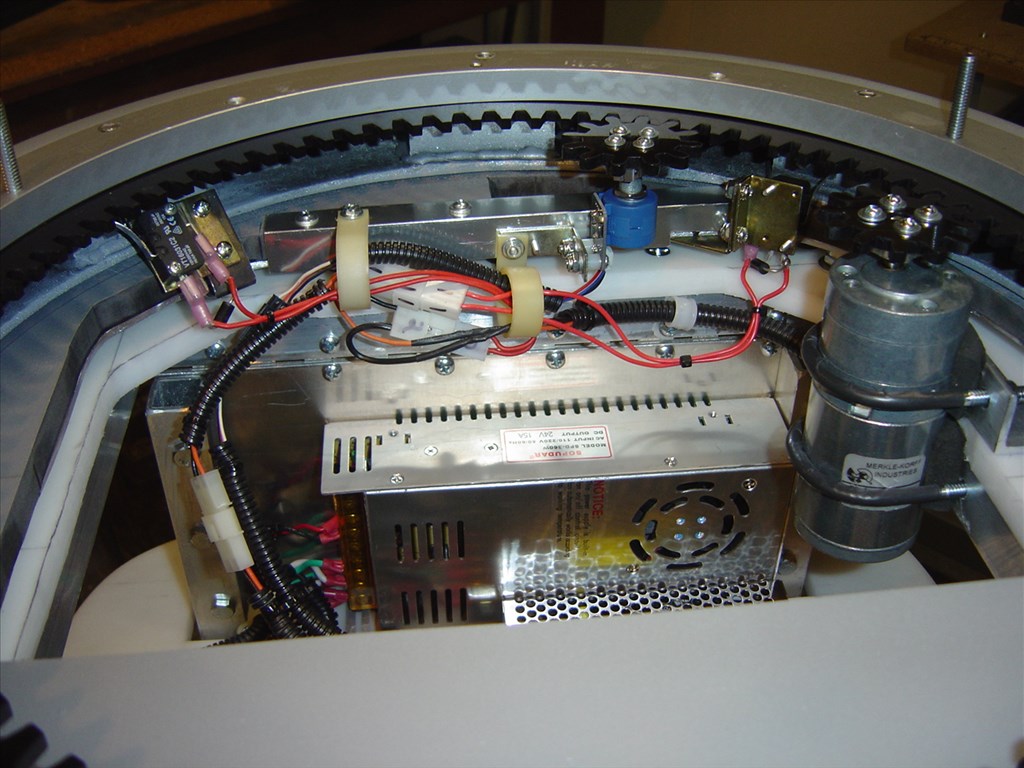

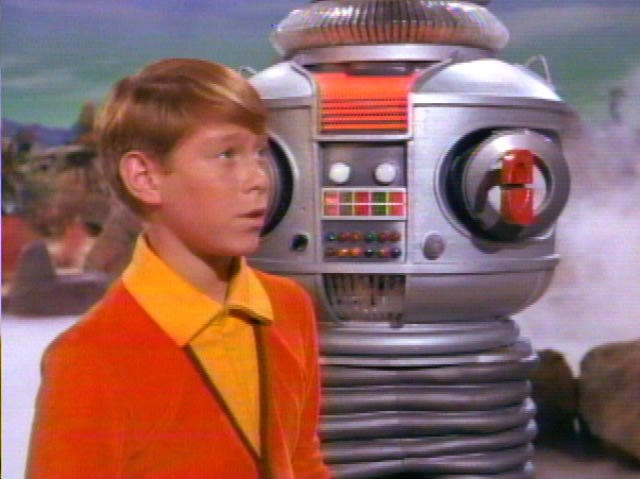

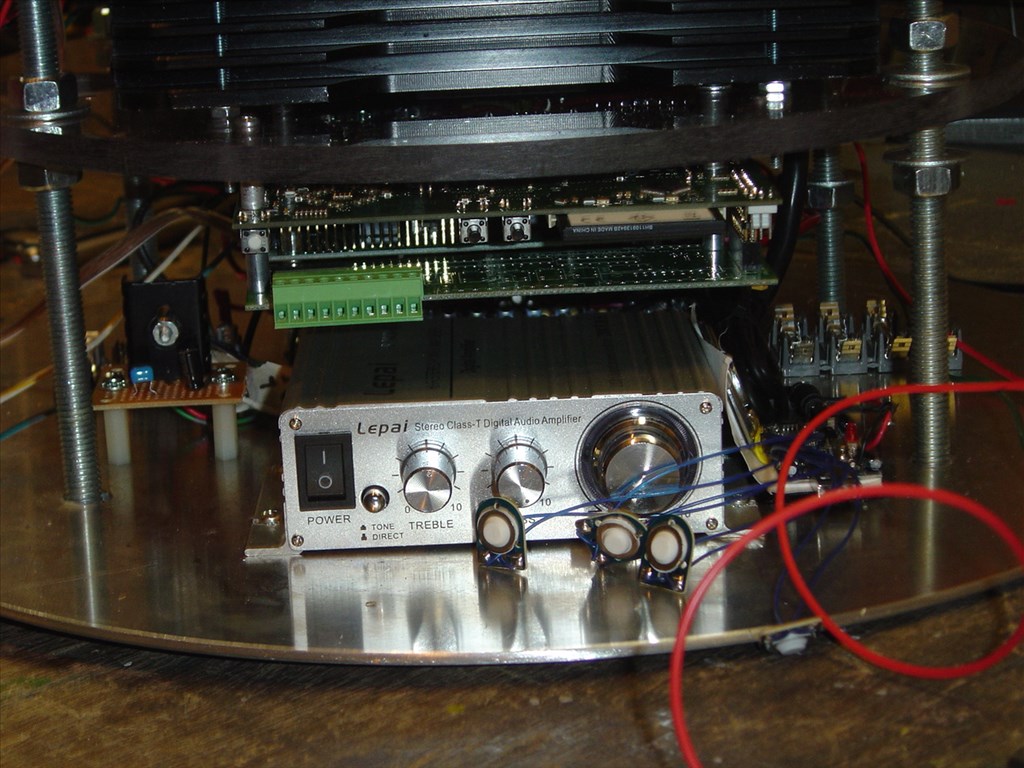

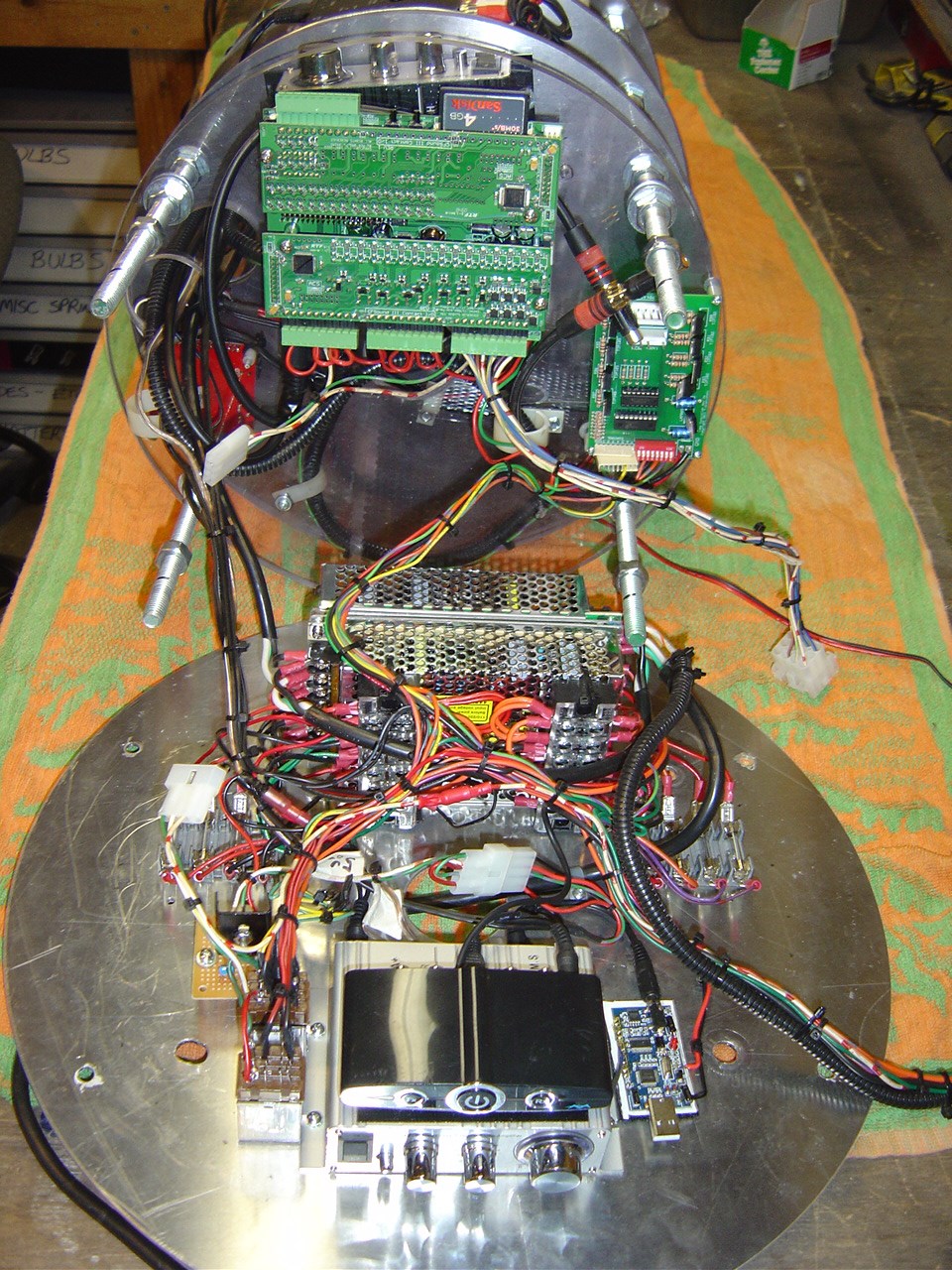

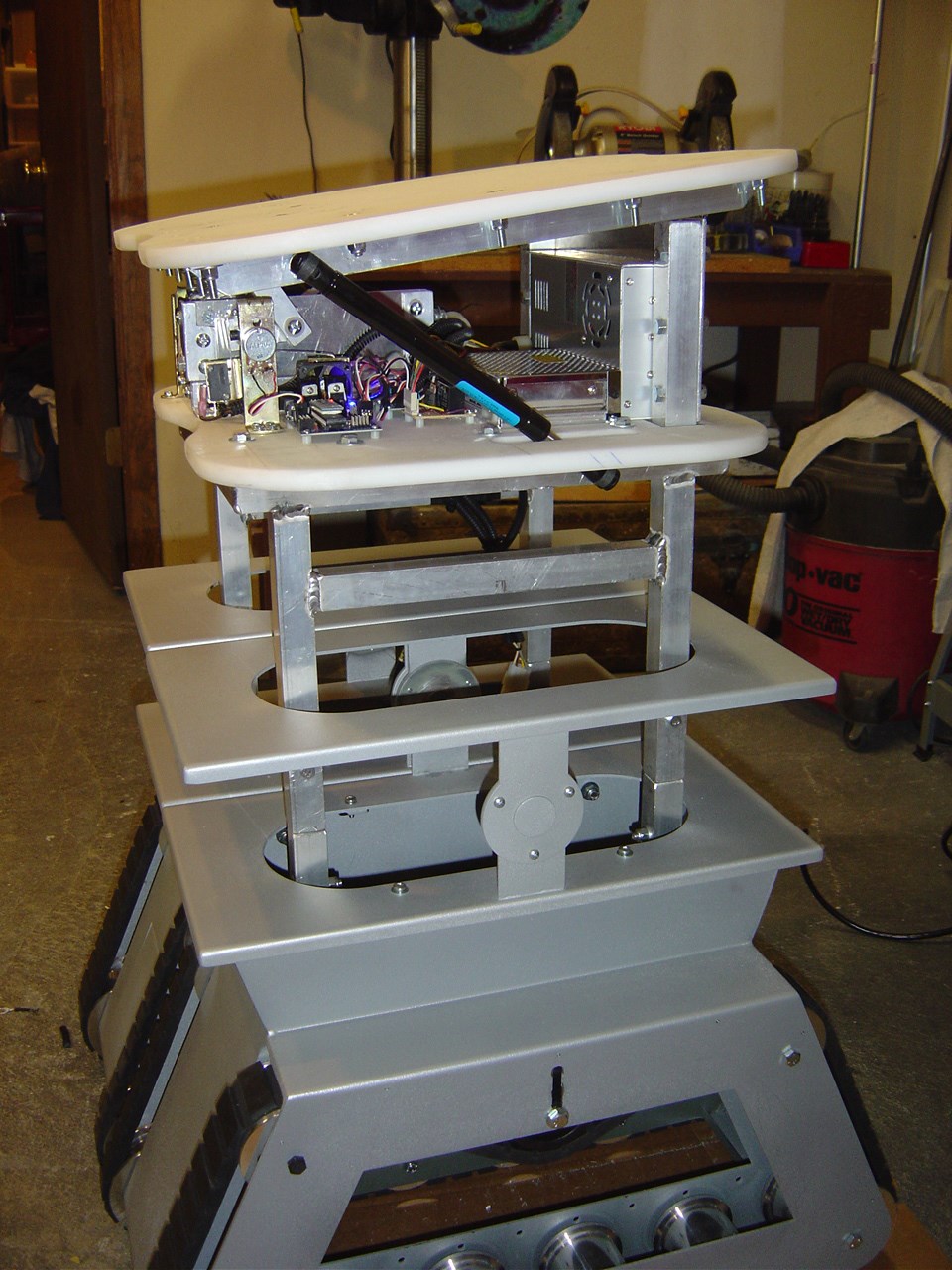

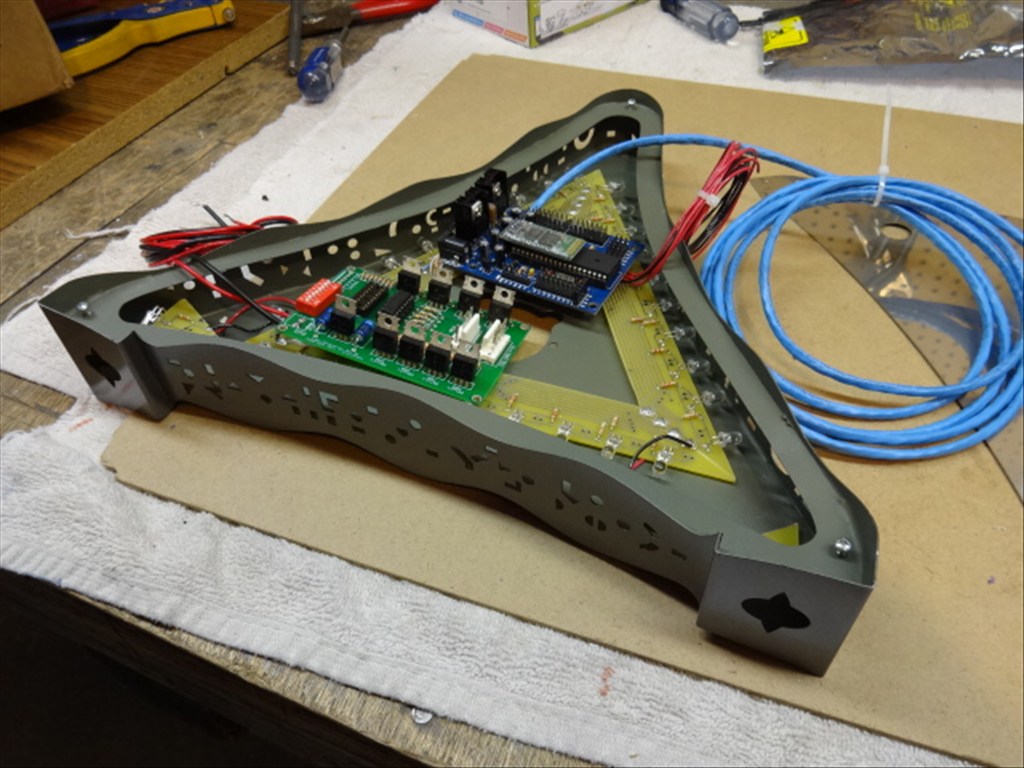

I'd like to share a video I just took of my full size Lost in Space B9 robot that's controlled by two EZ-B controller boards. Right now they are controlling limited movement and voice response of a few motors, lights and sound files played from a Sparkfun MP3 Trigger board. Although I'm just starting with the animation and have more building on the actual robot the result (mostly thanks to the EZ Robot controller board) is shocking. Please have a look at this (4 minute) You Tube vid and enjoy.

Please excuse some Technical camera lighting and sound issues. This is the first time I'd made and posted a vid online.

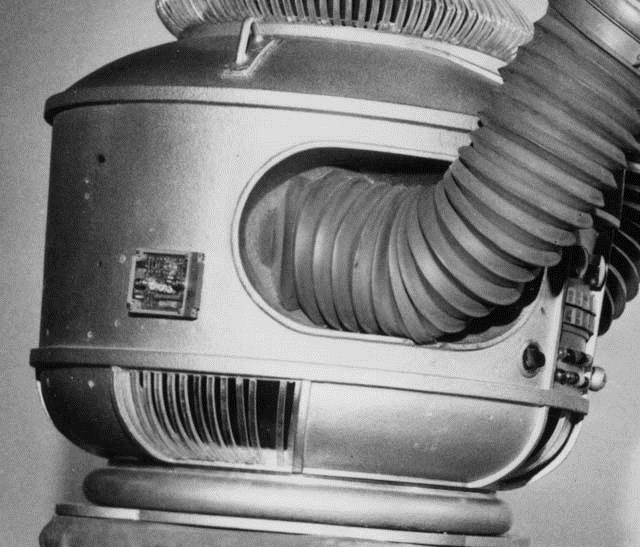

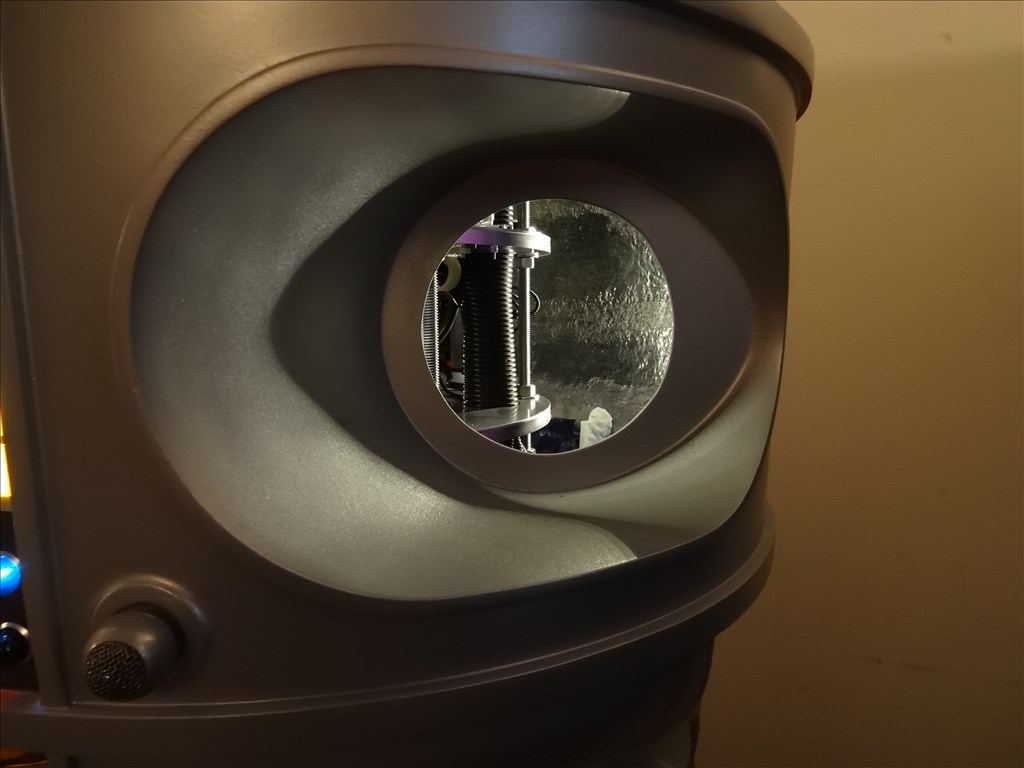

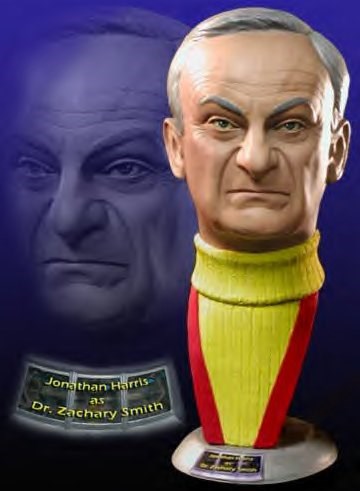

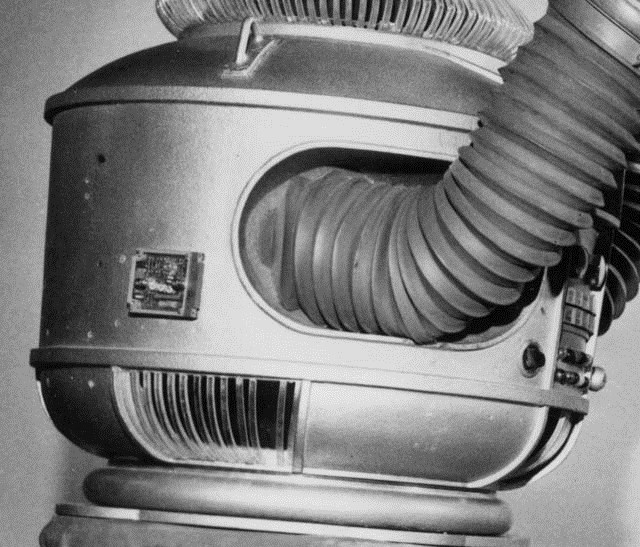

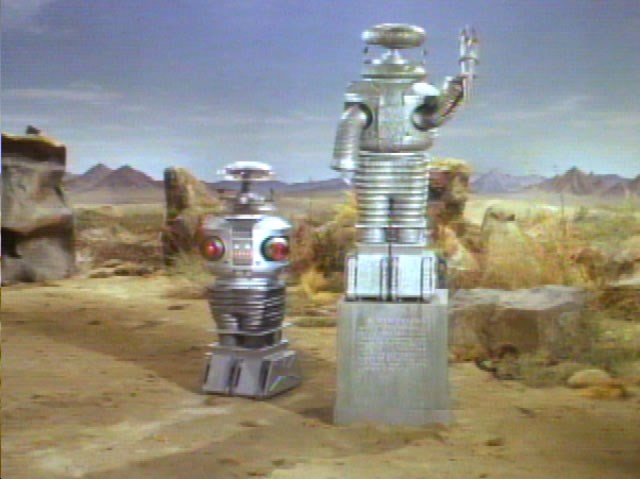

EDIT 8/2/13: Just realized I have no good pictures of how my B9 will look when complete. Here's one of the actual TV robots from the 60's TZ show Lost in Space and one recent shot of where I'm at with my build over 1 1/2 year after I started. Enjoy:

Thanks, Dave Schulpius

Other robots from Synthiam community

Ezang's Life Is Like A Tight Rope, Do You Agree?

Tachyon's First Robot

-635353562186322812.png)

Thanks cparks328 for thinking my B9 is good enough to show off. That means so much to me.

I never thought I'd have a robot like this. Without ez robot he would be just a floor display or a puppet.

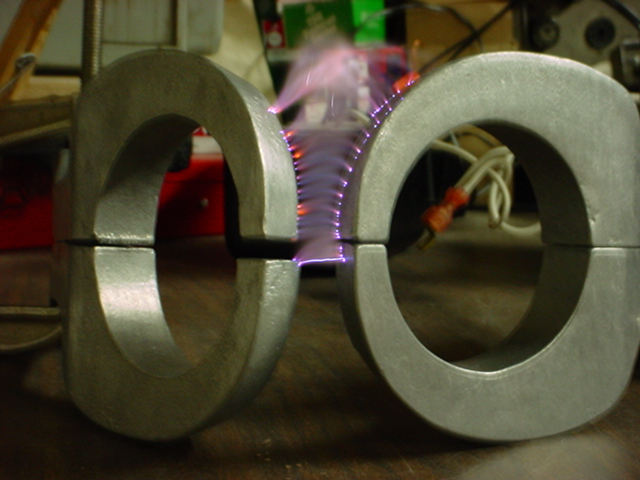

Hi Dave, went over your videos and loving it! I'm also building a full size B9. I've build quite a few full size daleks from Dr who but never a B9. I have a few parts already completed but still have a way to go.

Niko.

I love that EZ robot brings robots to life!

@Niko, I'm glad you enjoyed my videos. I wish I was better at making them but they were a hoot to do. Hope they helped you a little or at least got a good chuckle as you watched me fumble through them. I hope yo share your B9 build with us. I love watching robots being born I'm envious, a dalek is on top of my list of robots i want to make.

I'm envious, a dalek is on top of my list of robots i want to make.

@mcsdaver, I agree. It's great when you see one of these little guys spring up an live.

Hi everyone,

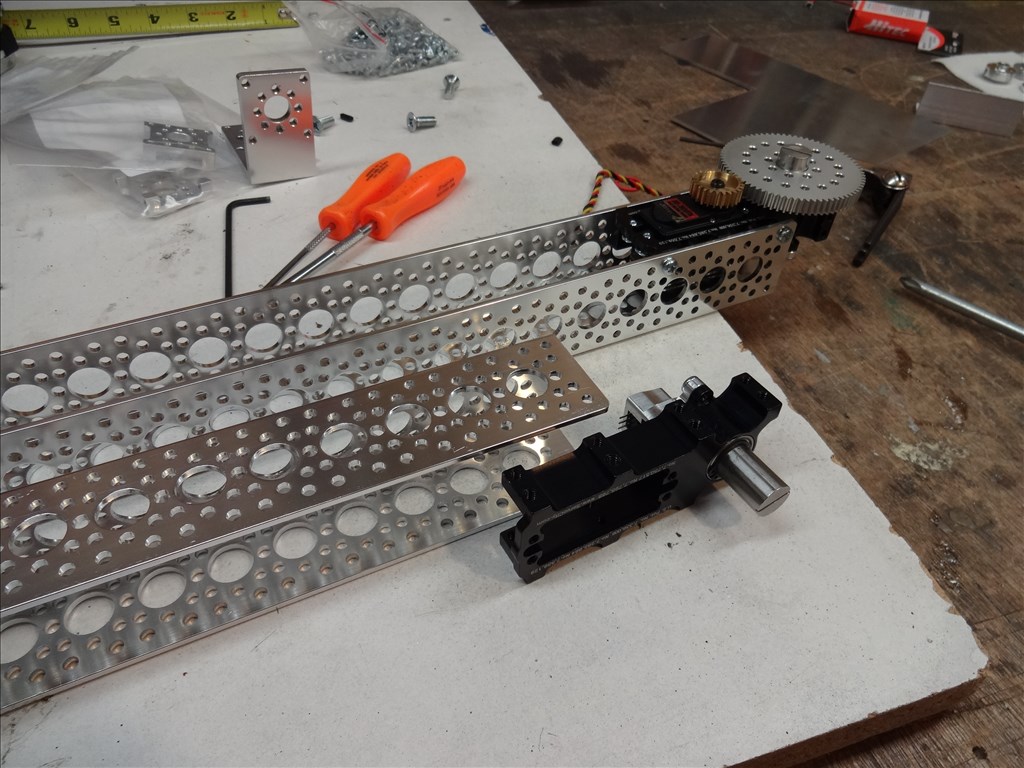

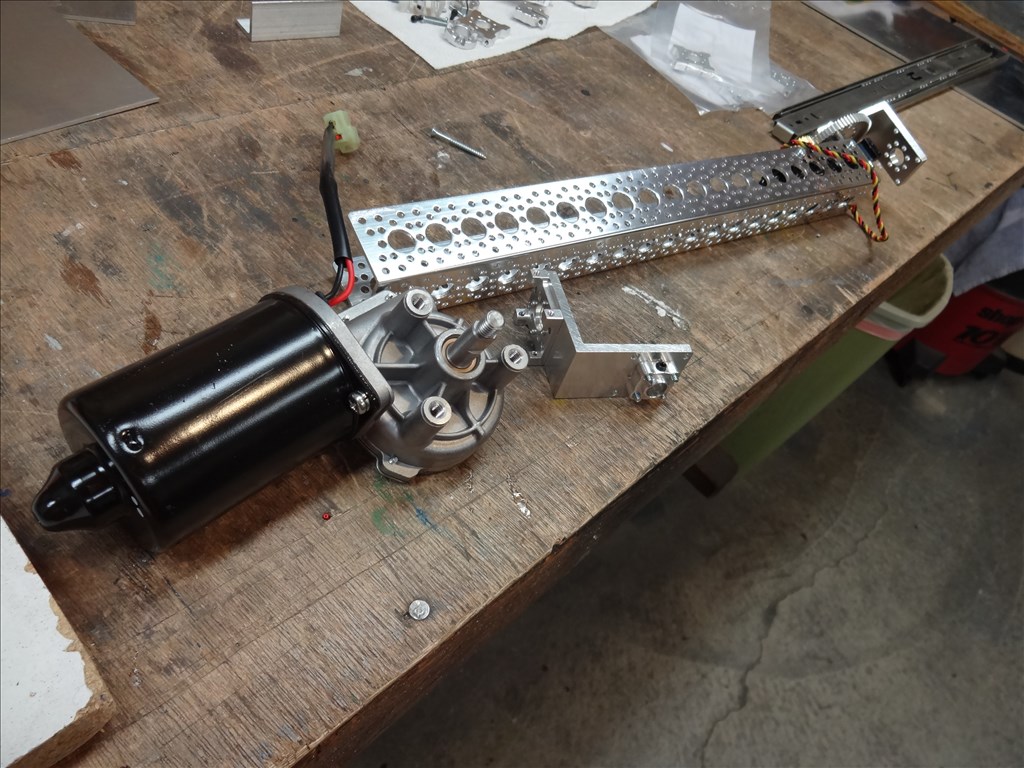

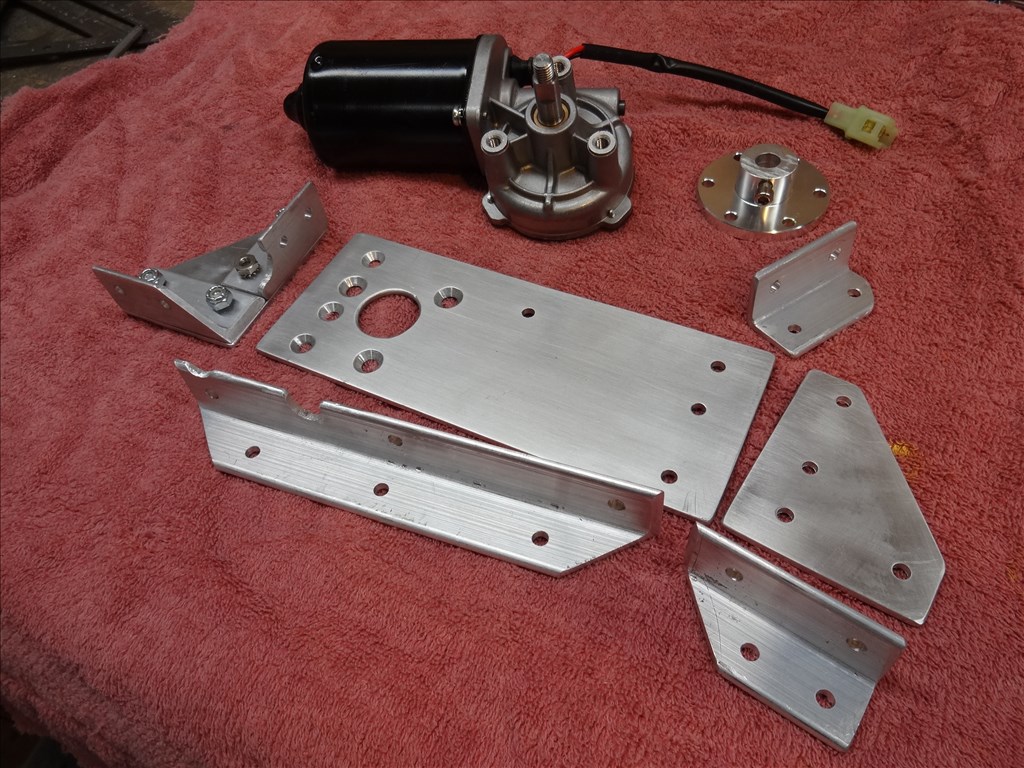

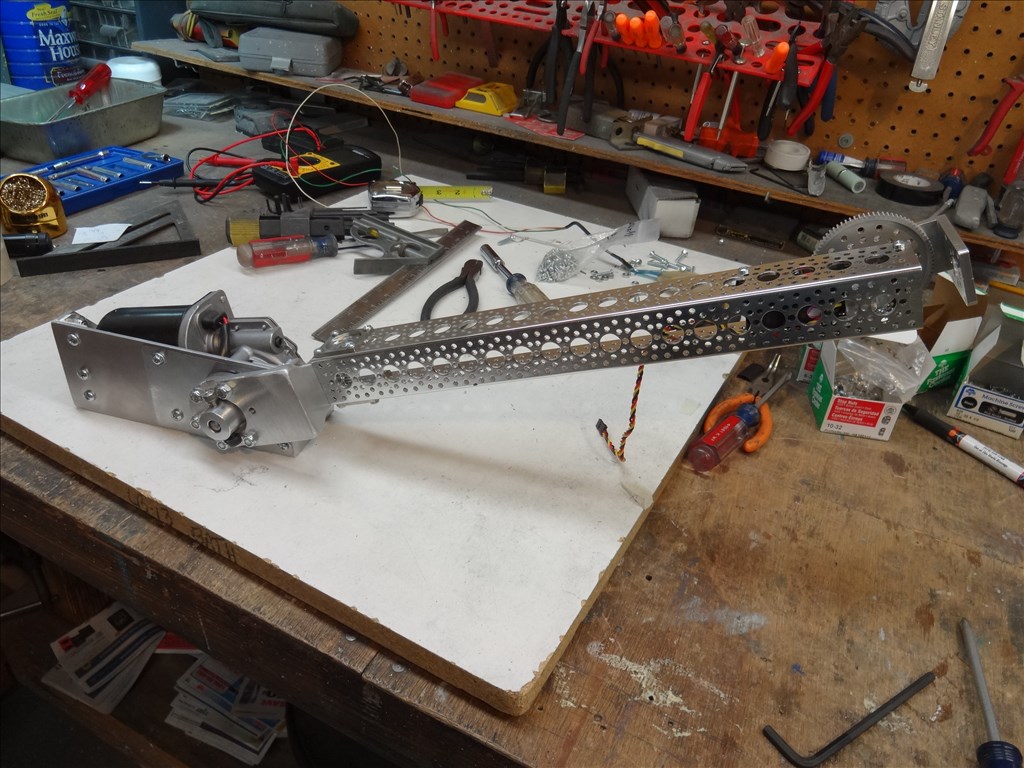

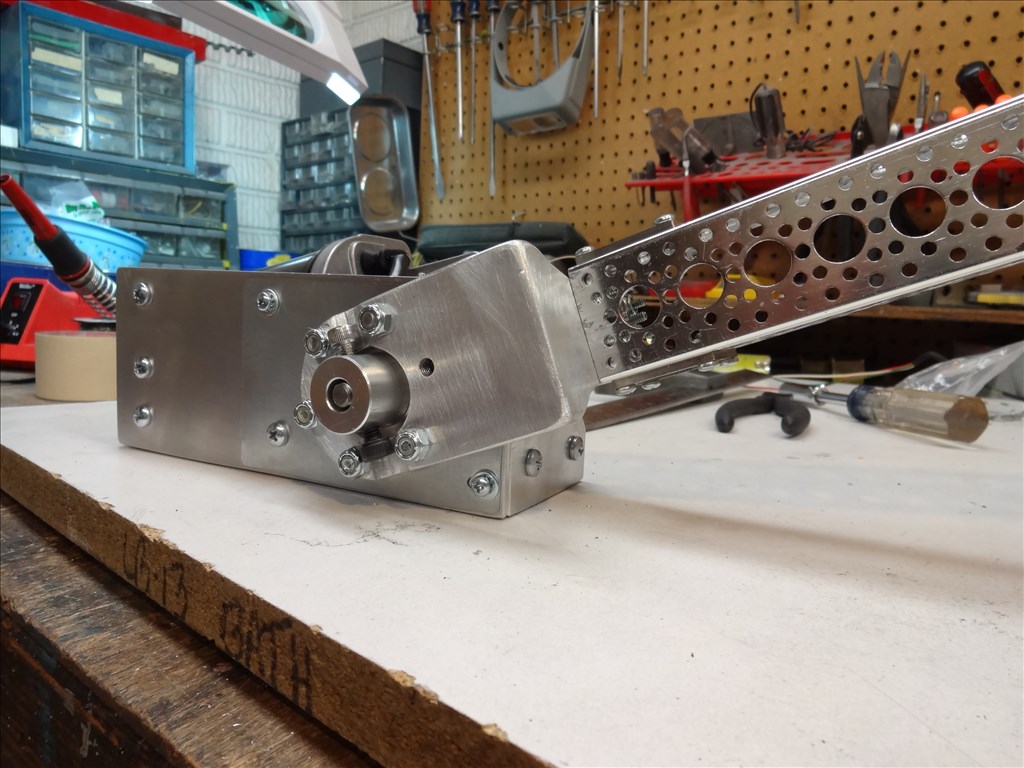

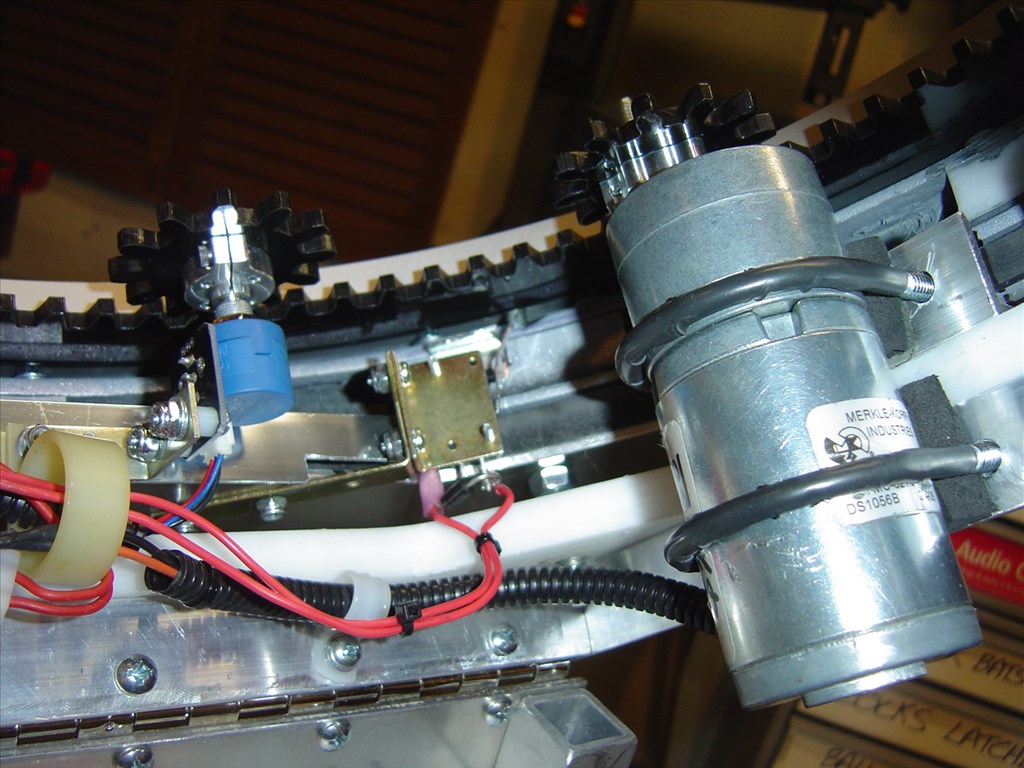

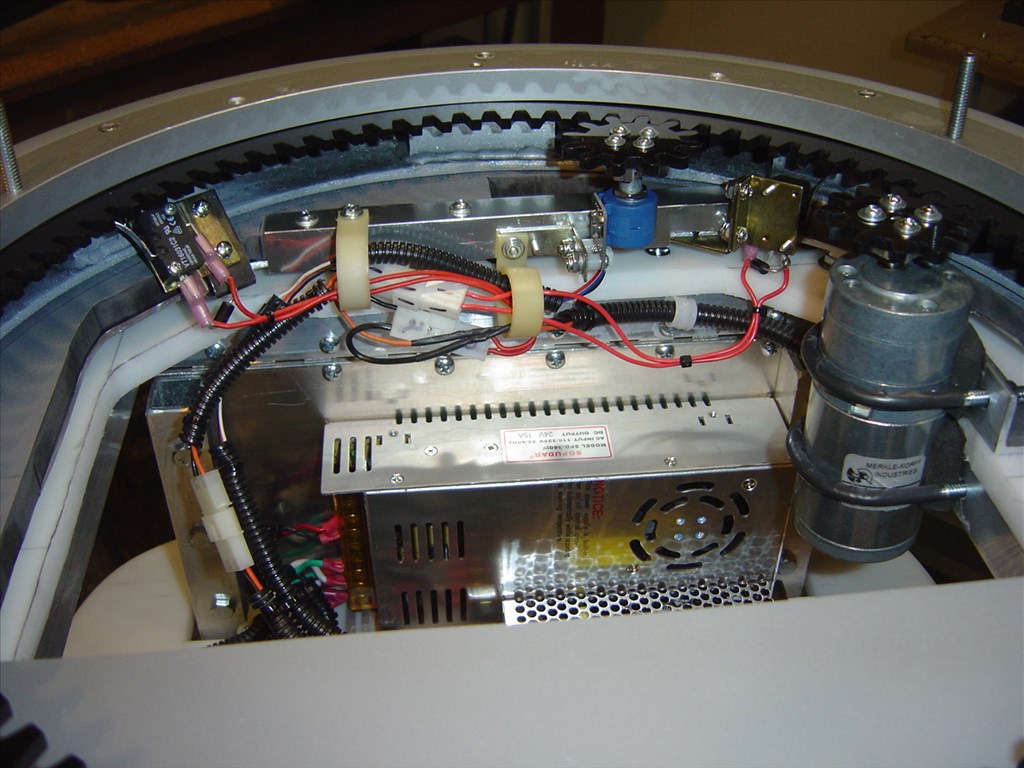

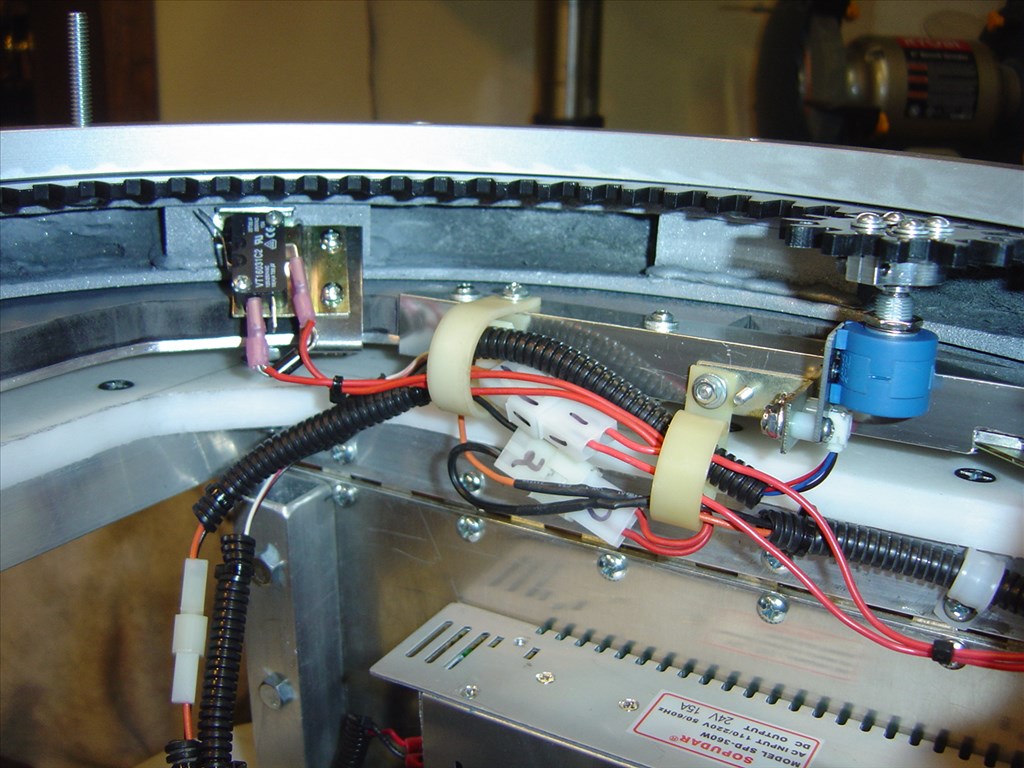

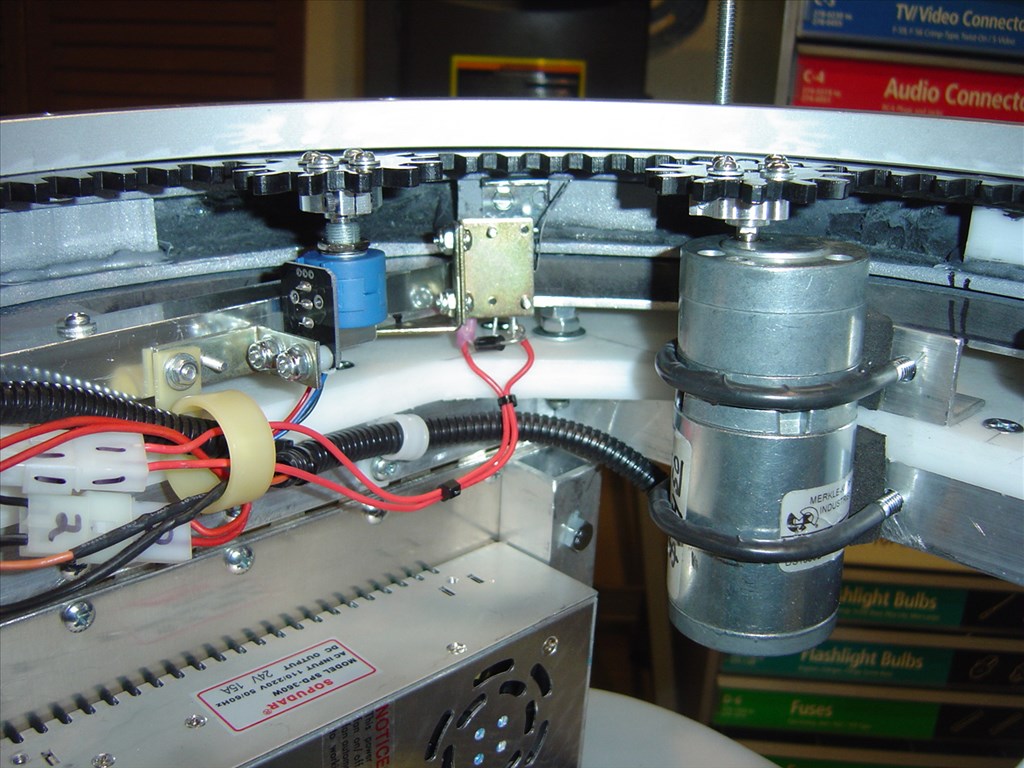

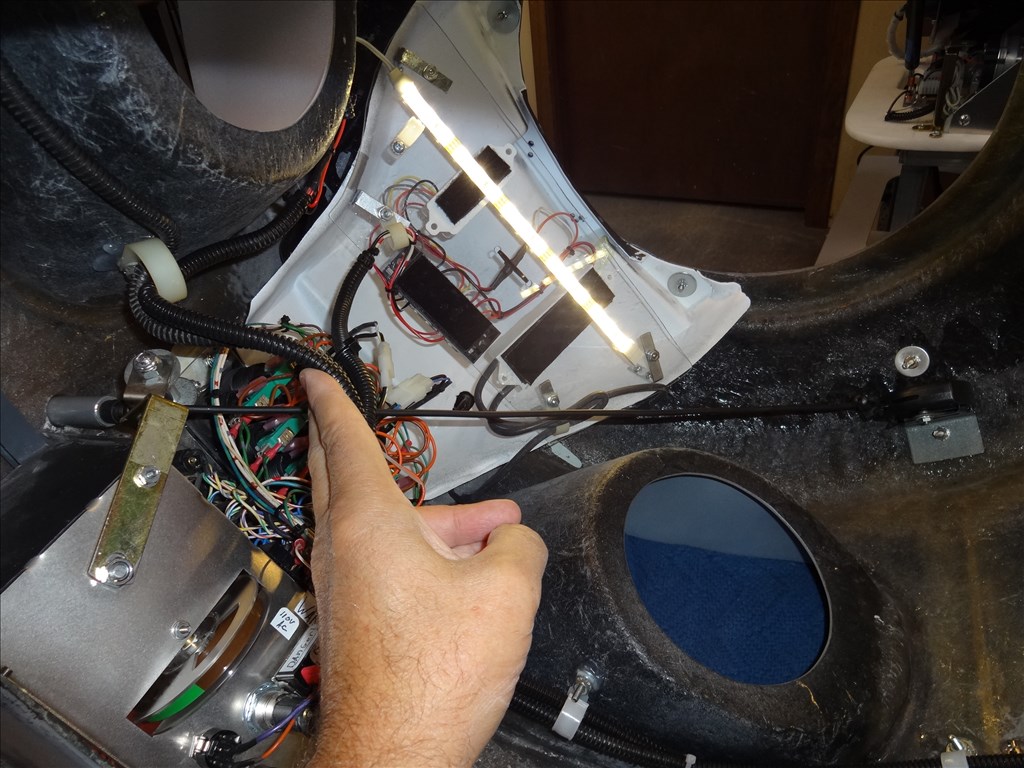

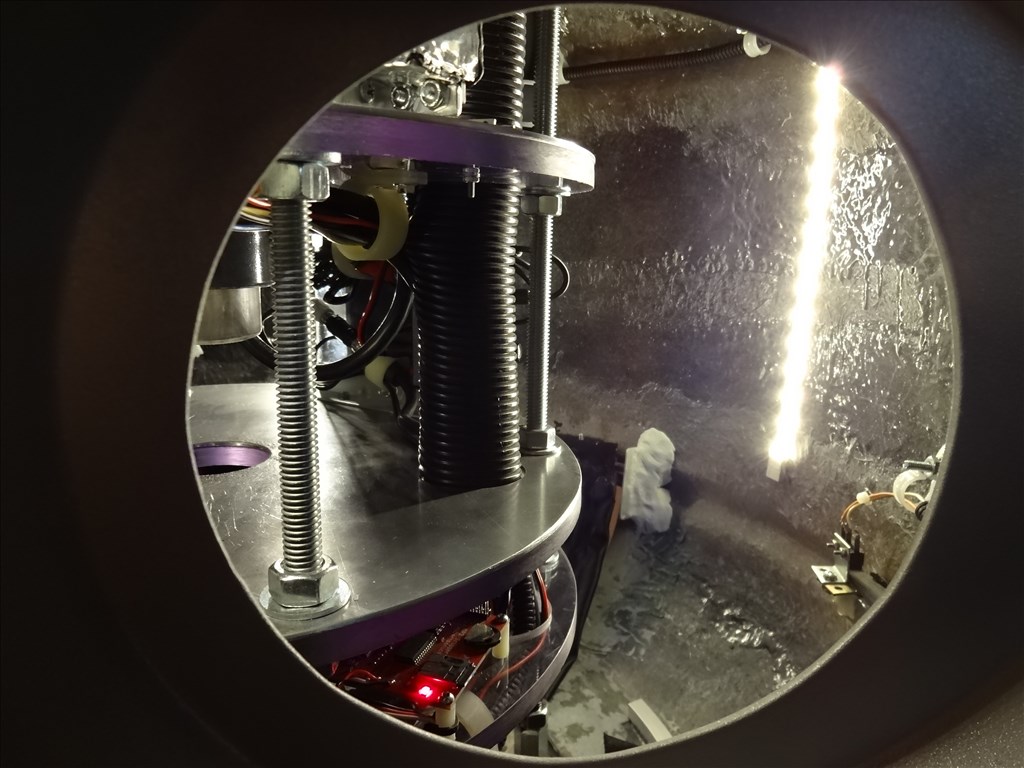

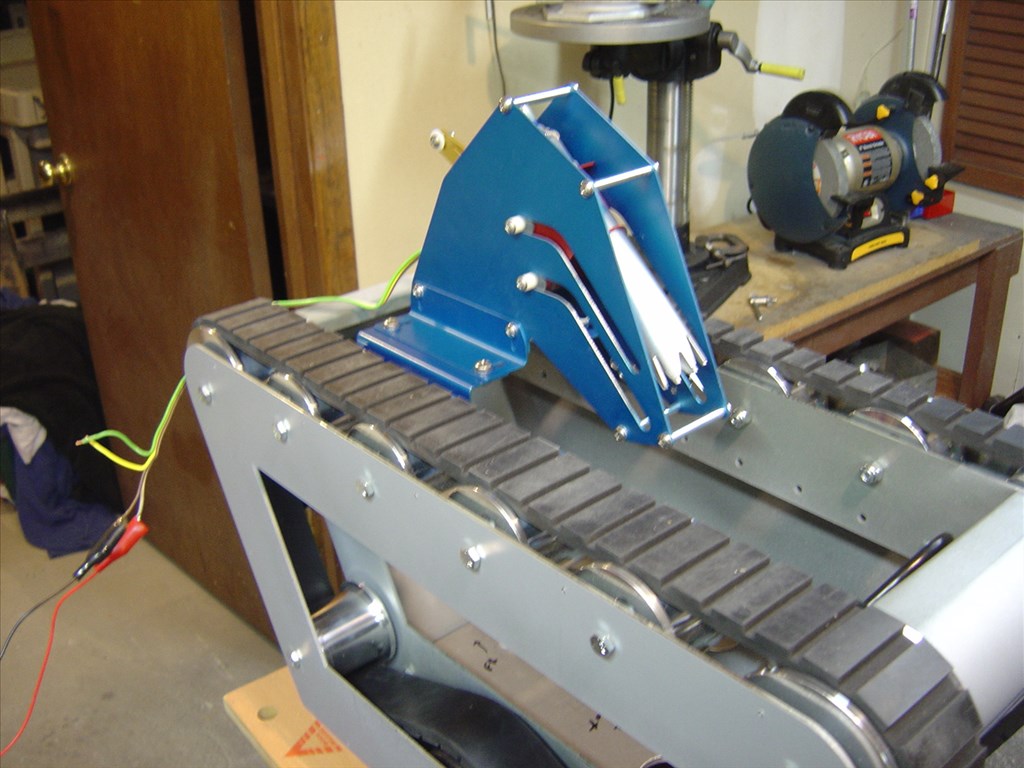

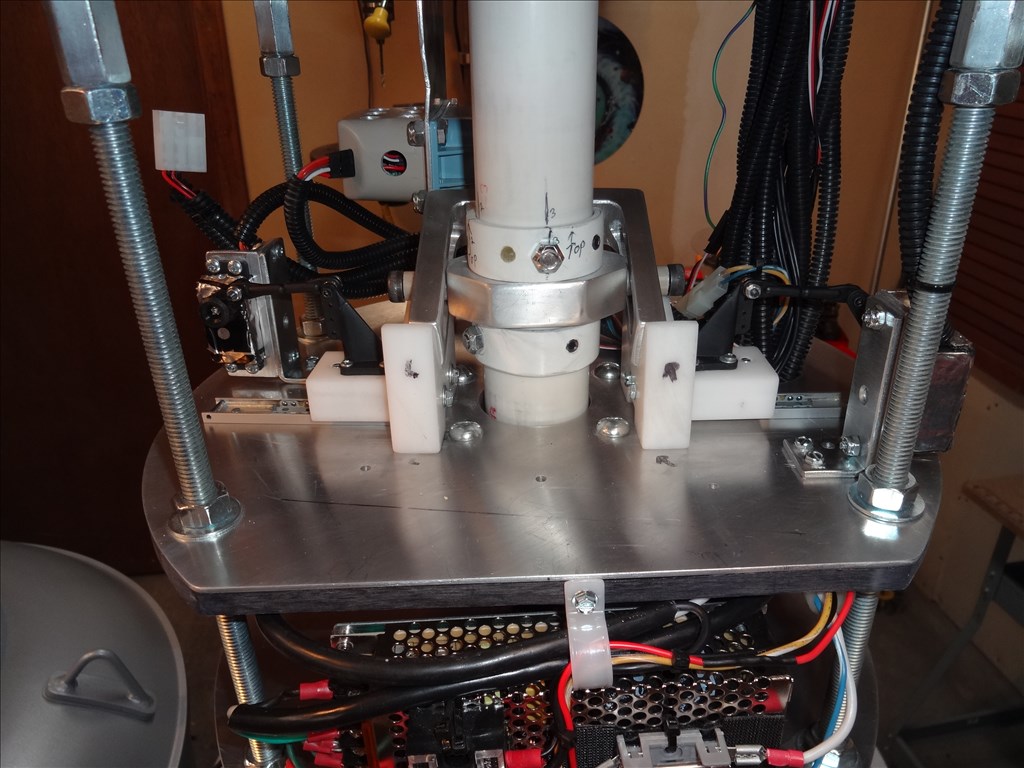

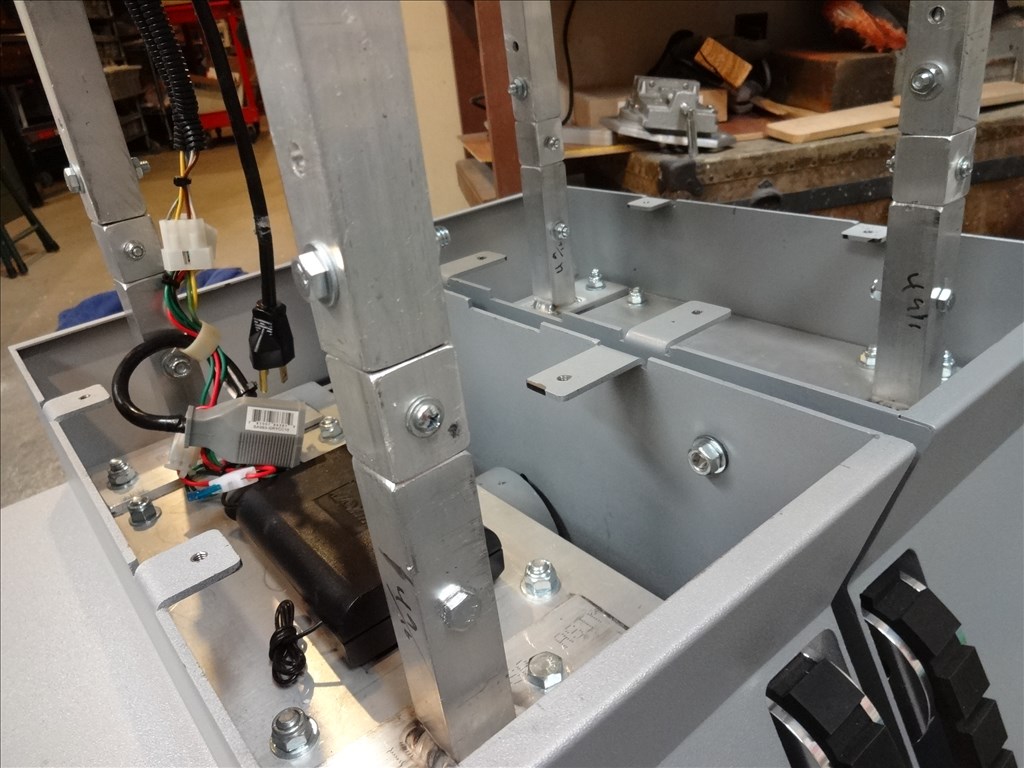

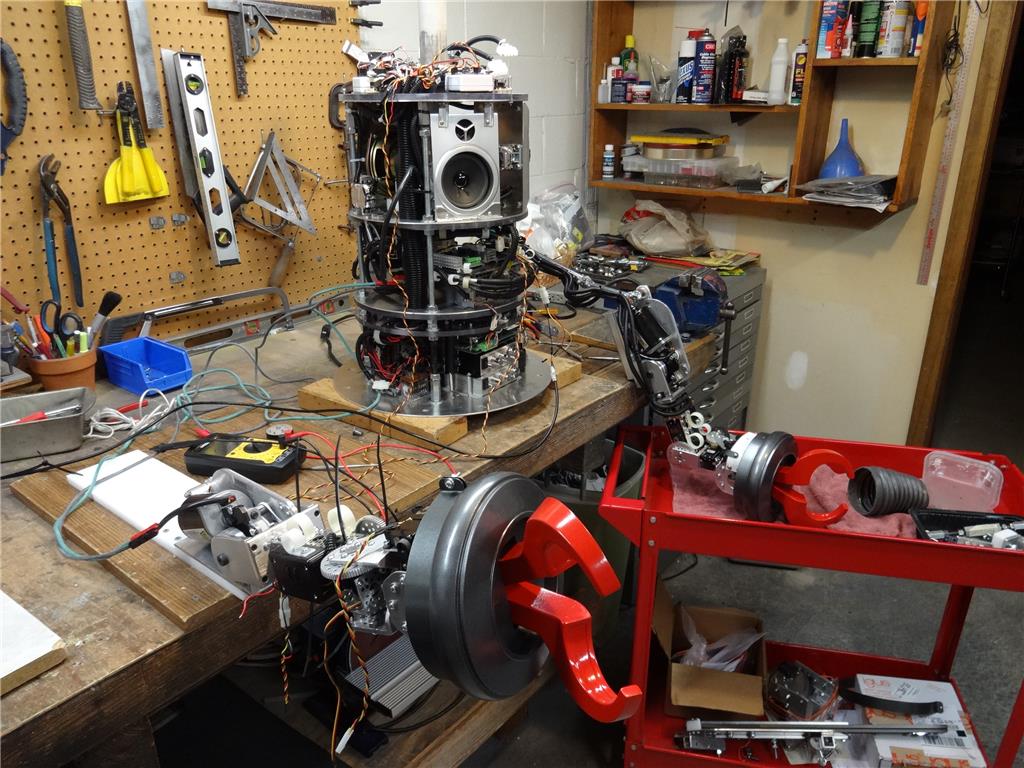

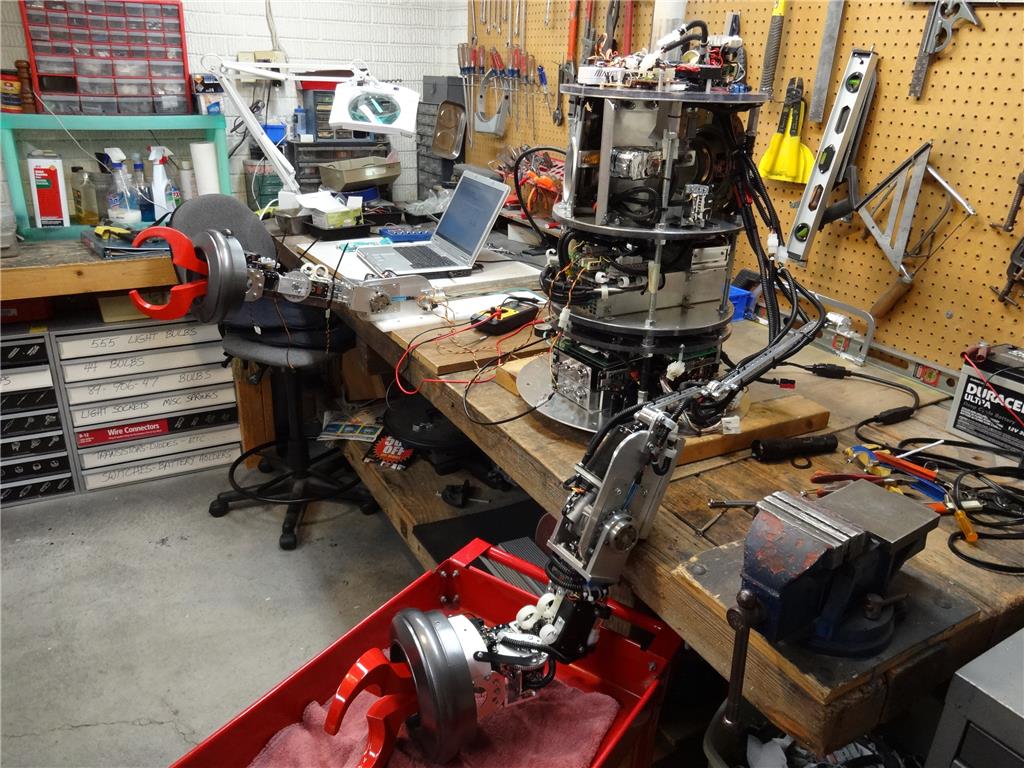

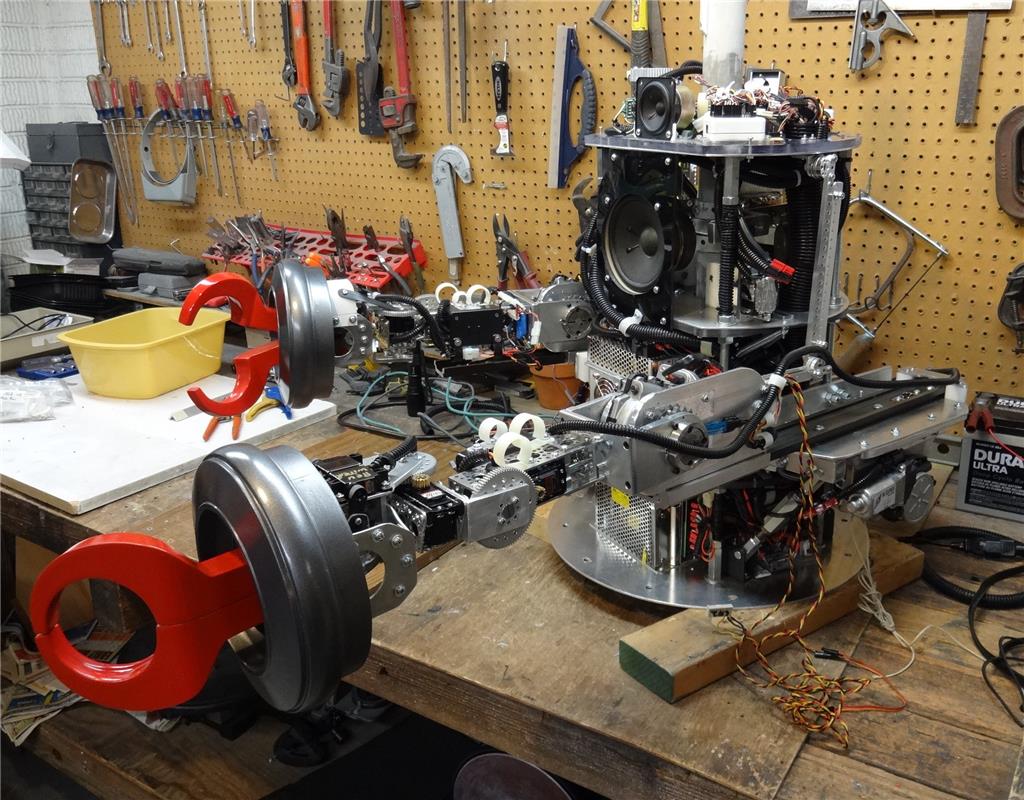

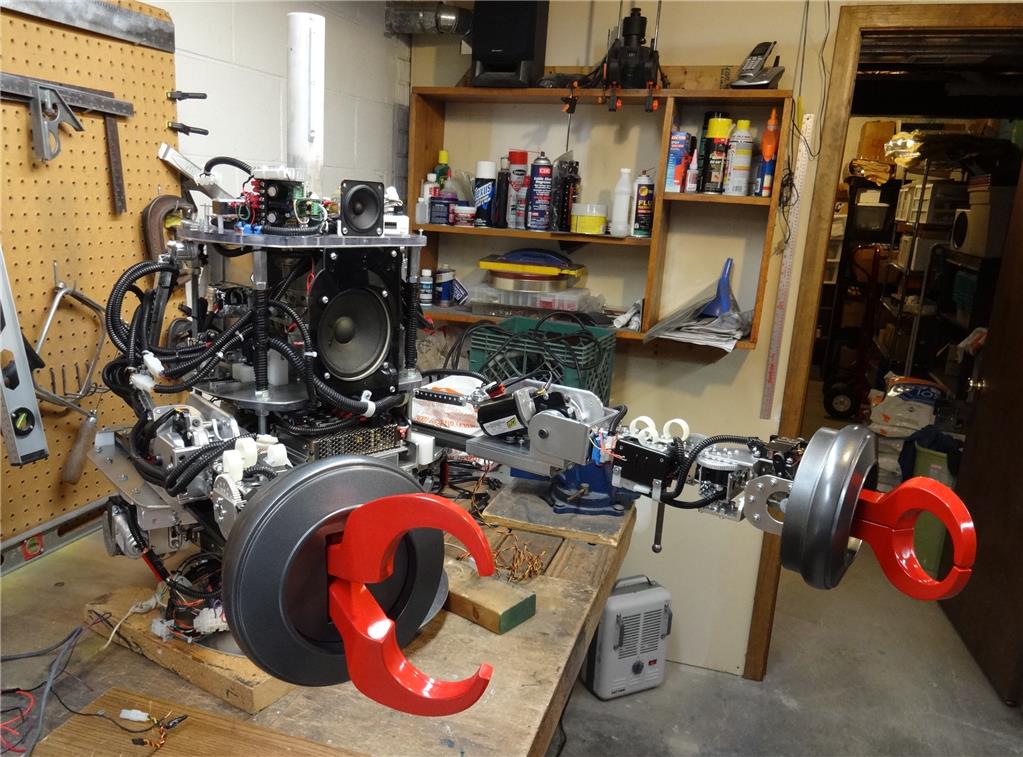

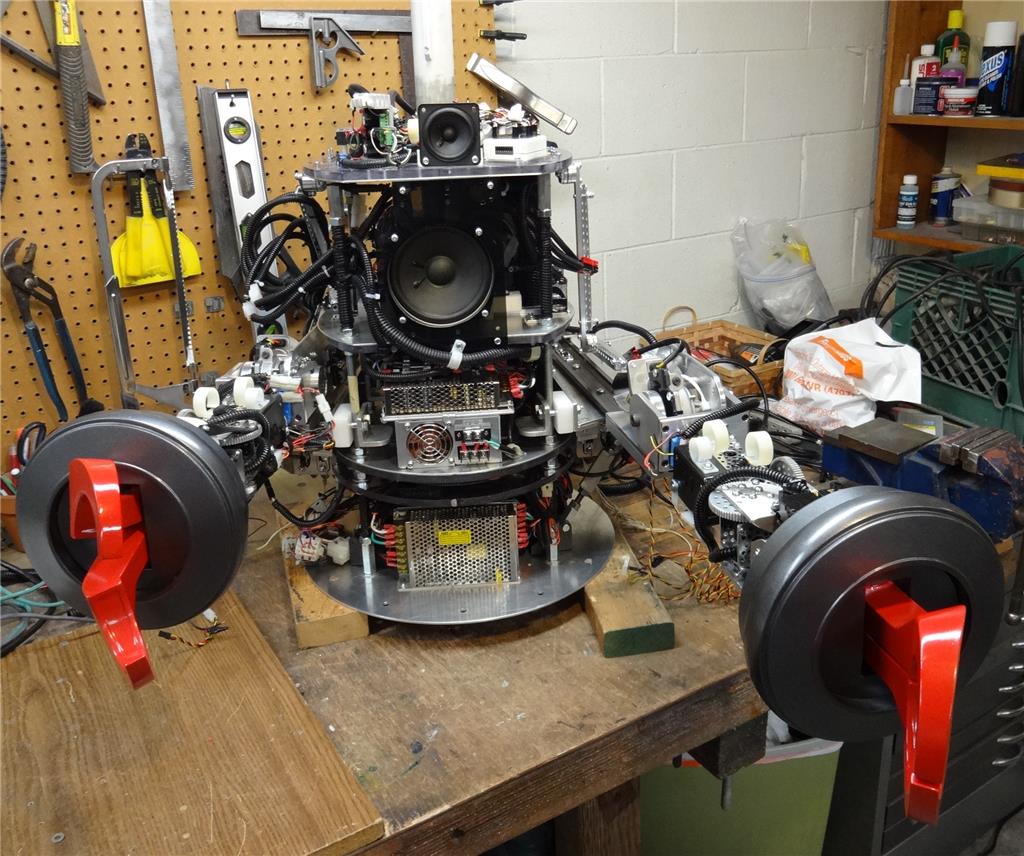

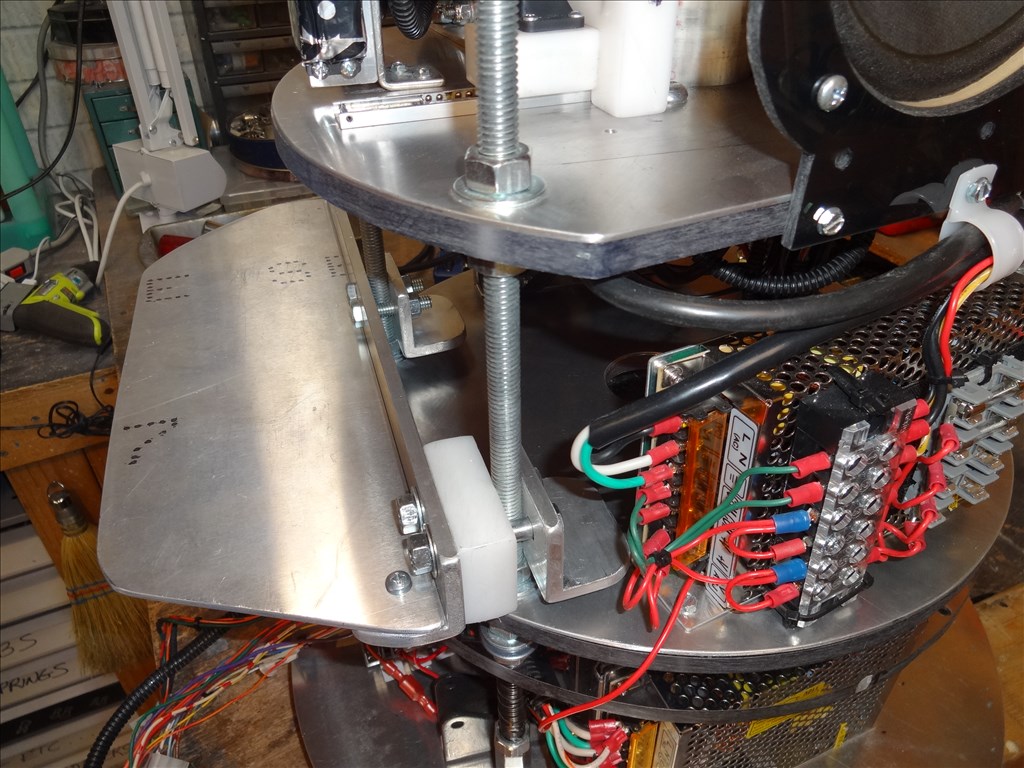

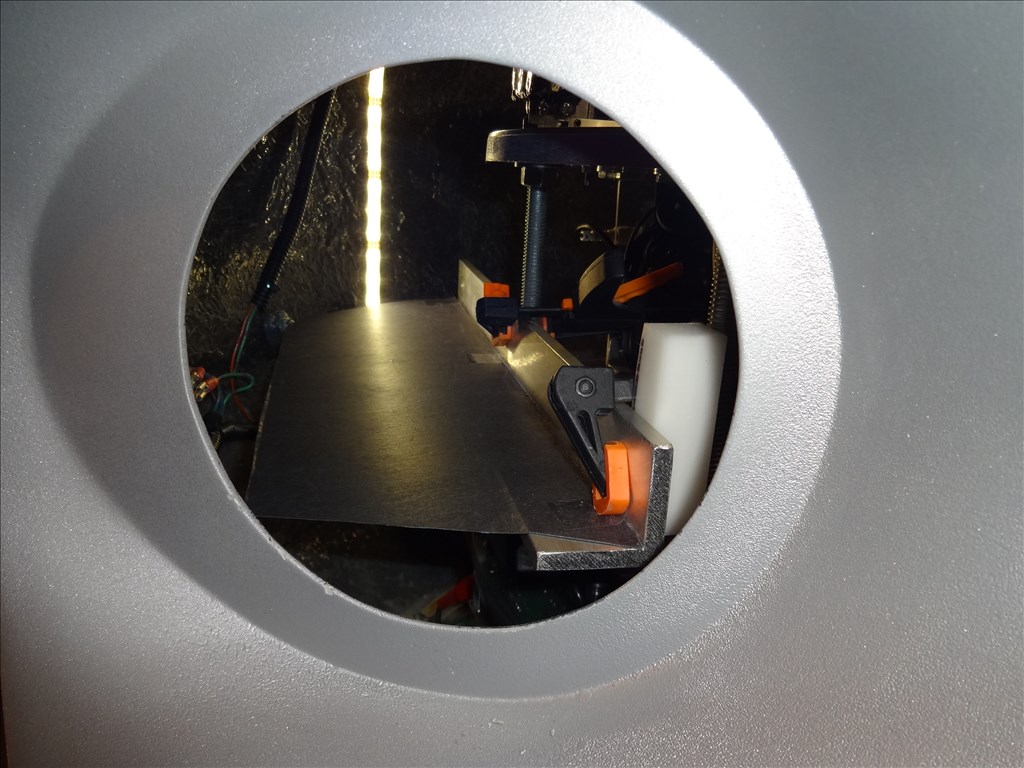

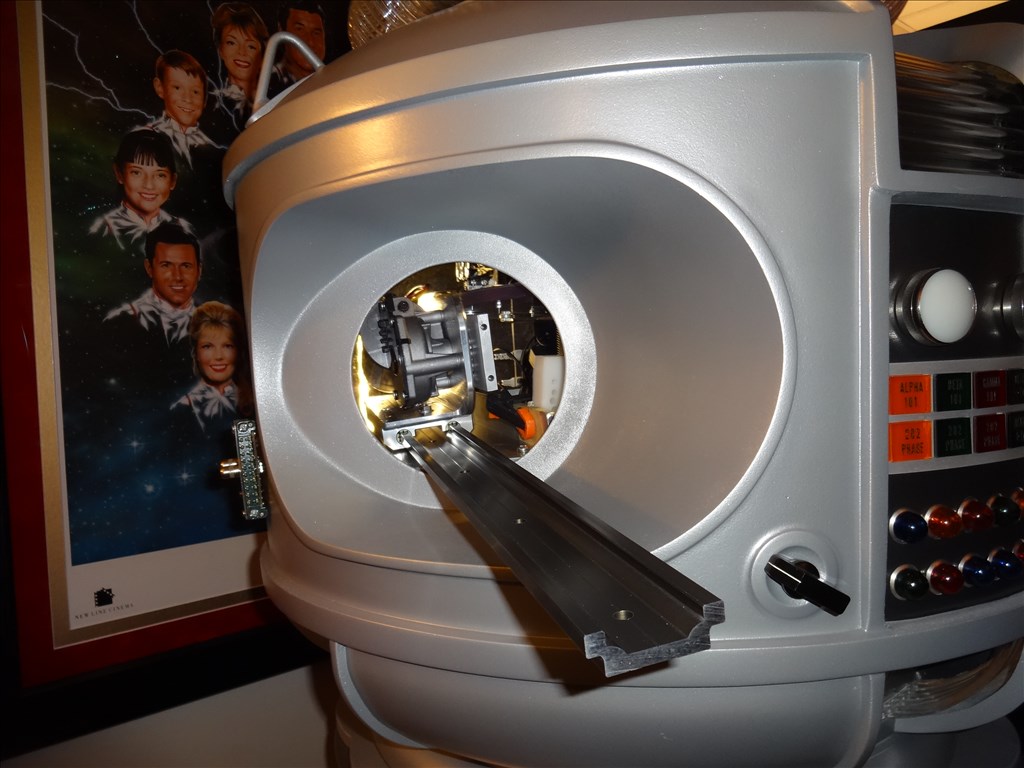

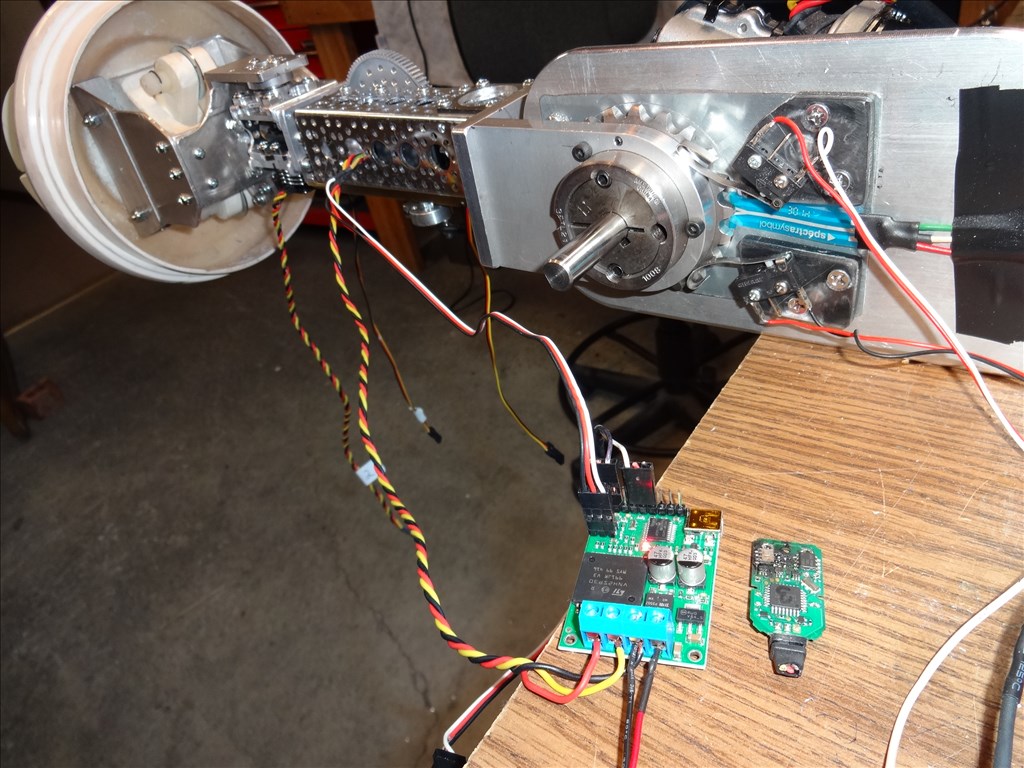

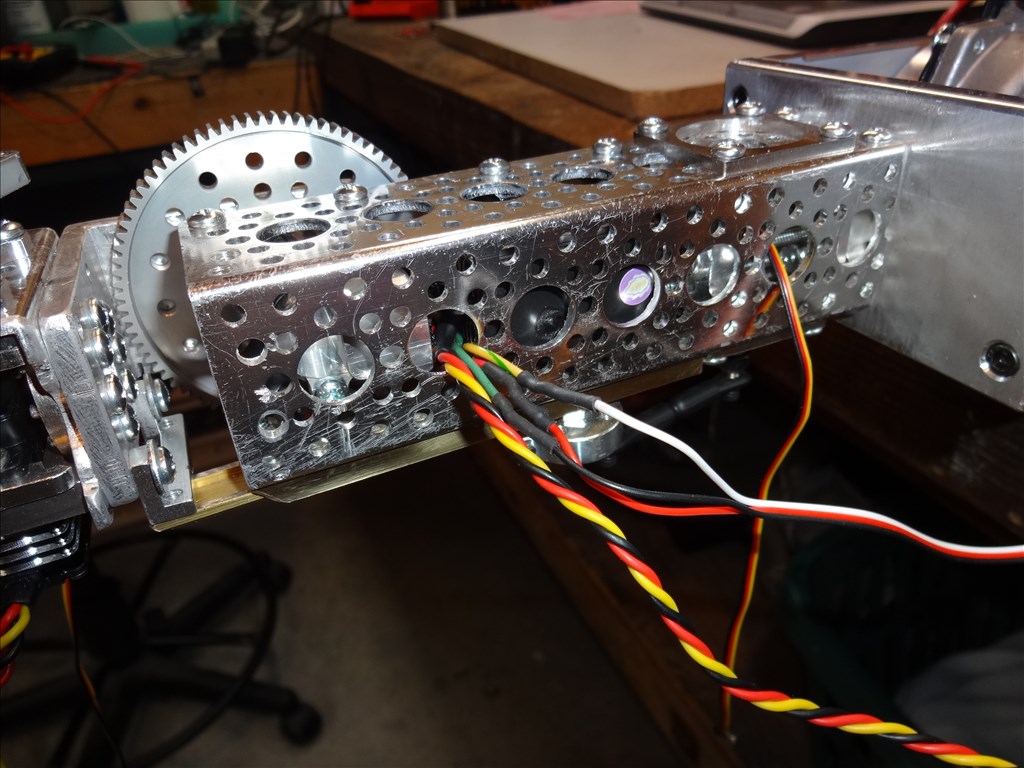

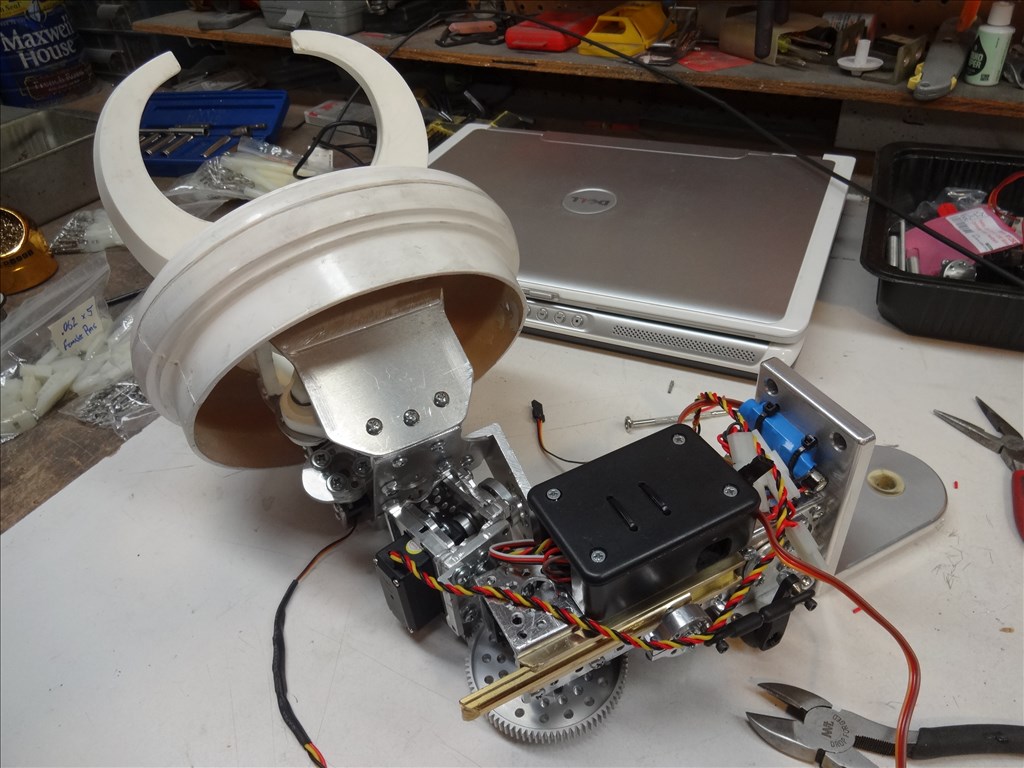

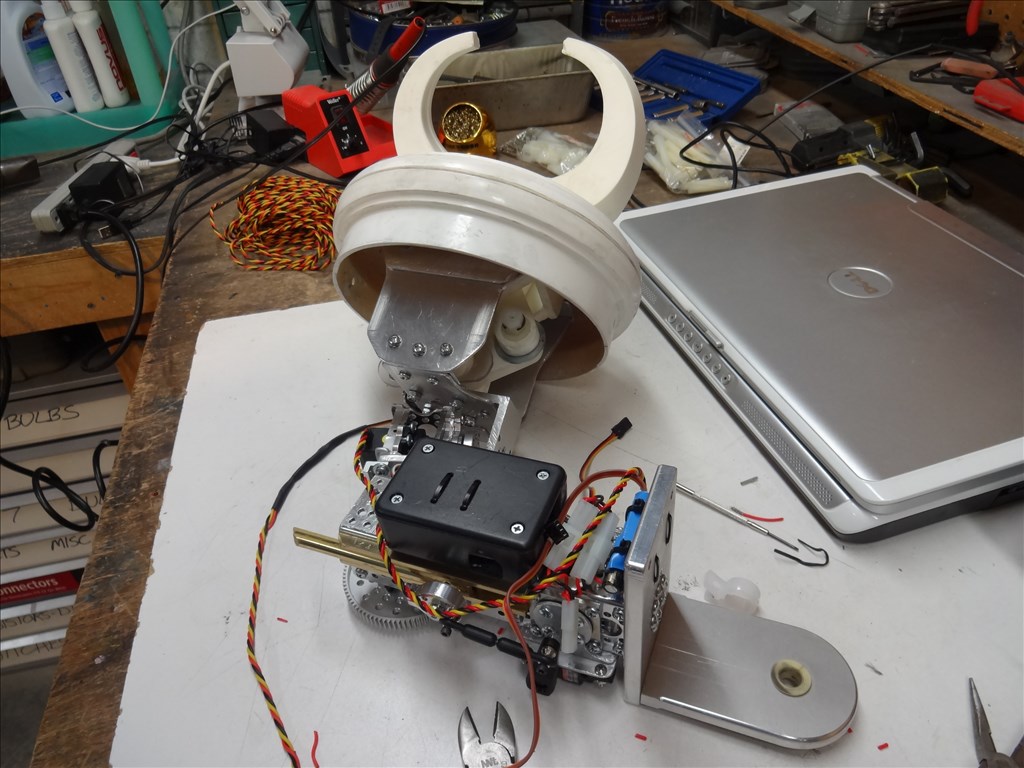

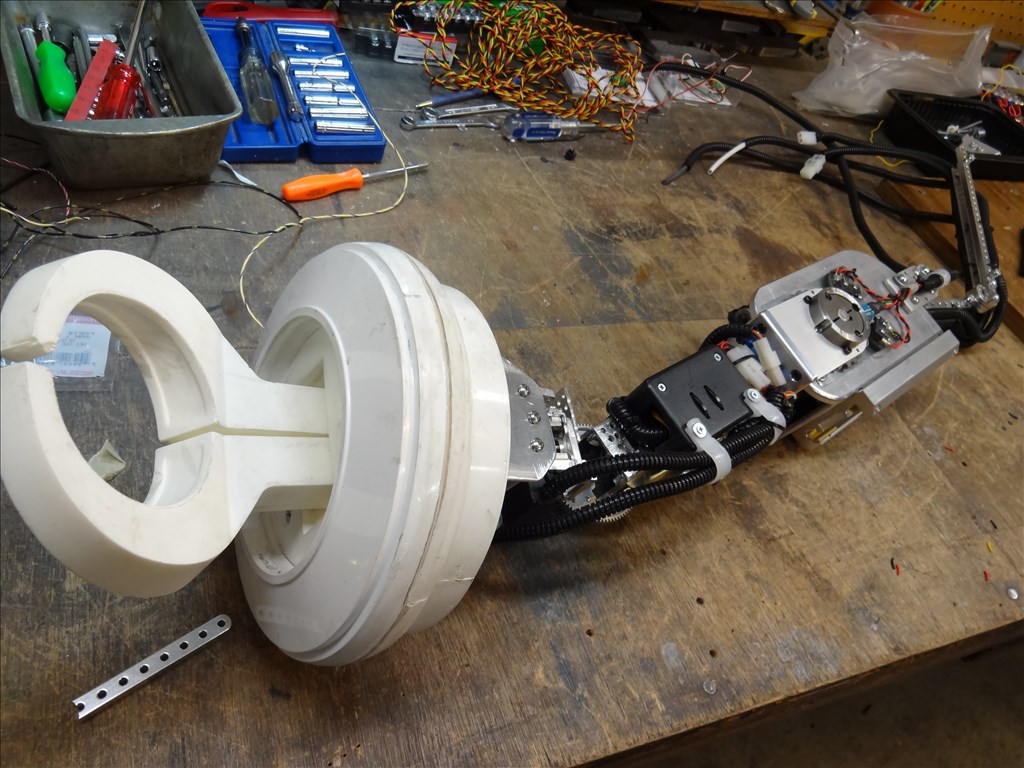

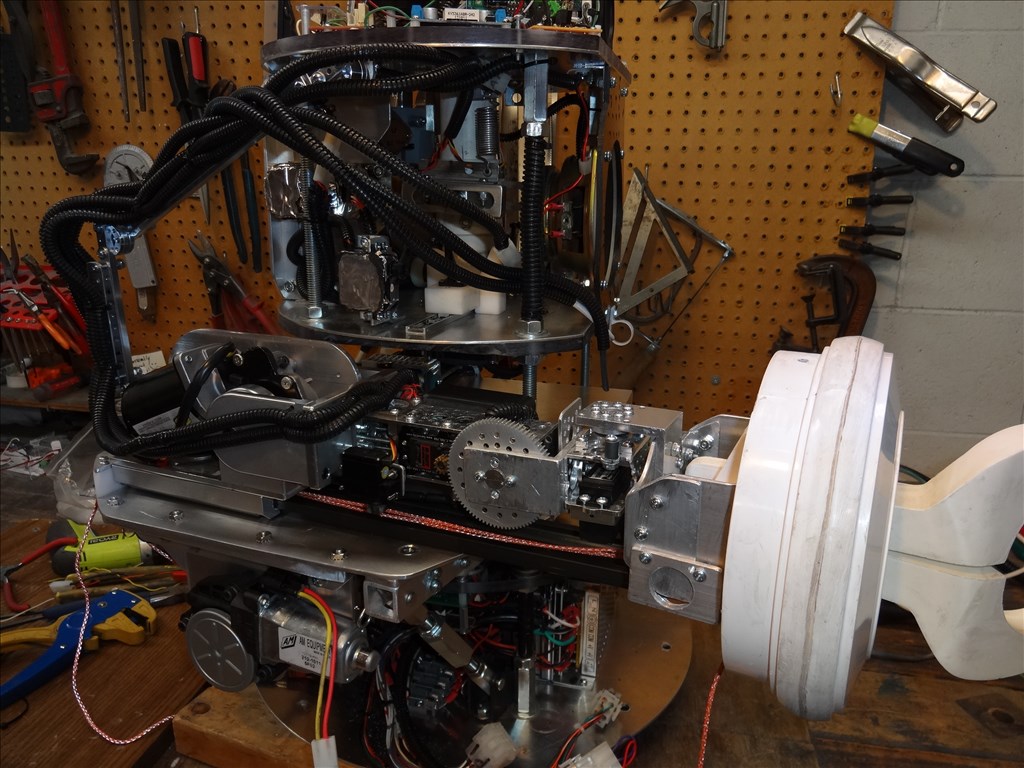

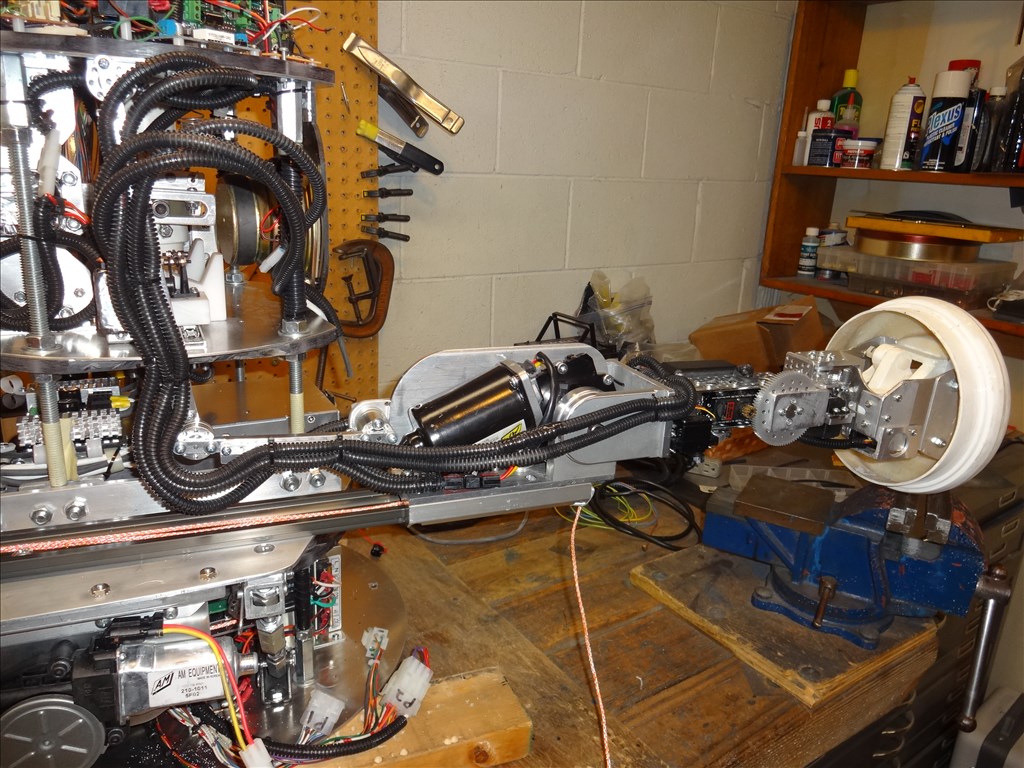

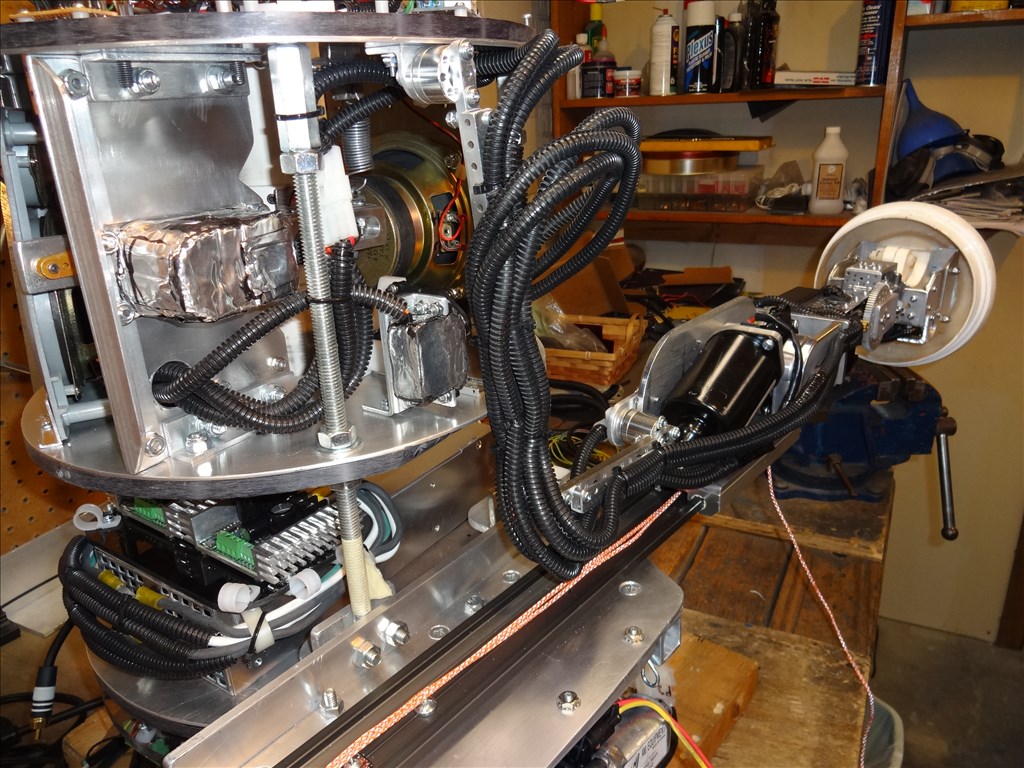

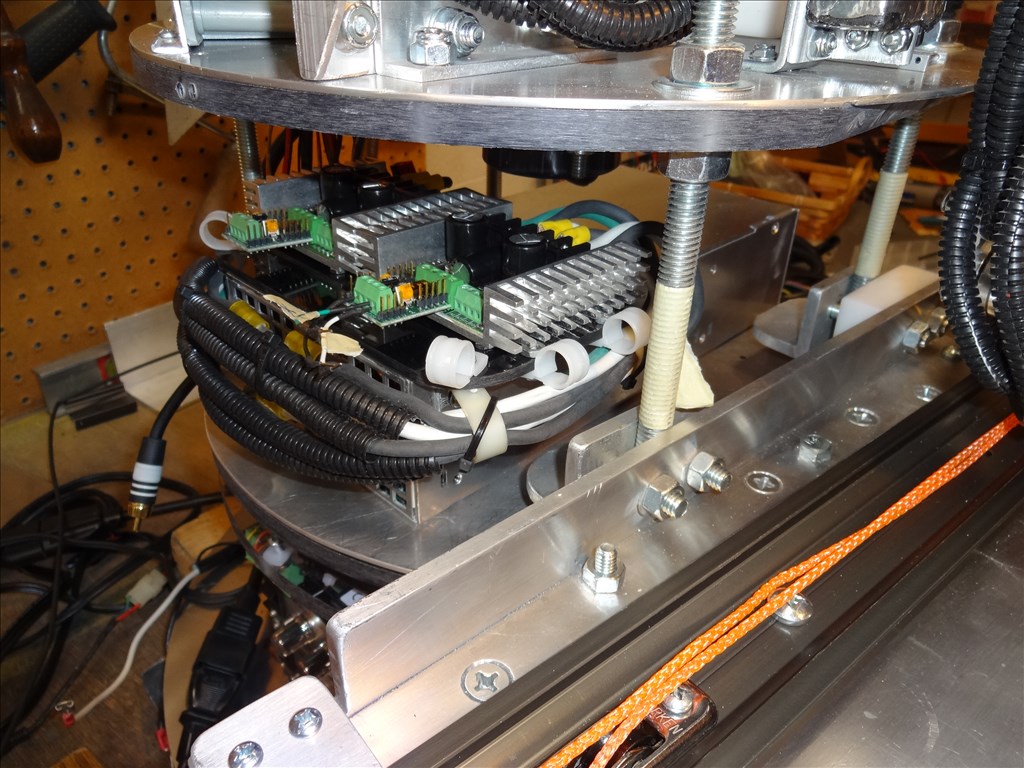

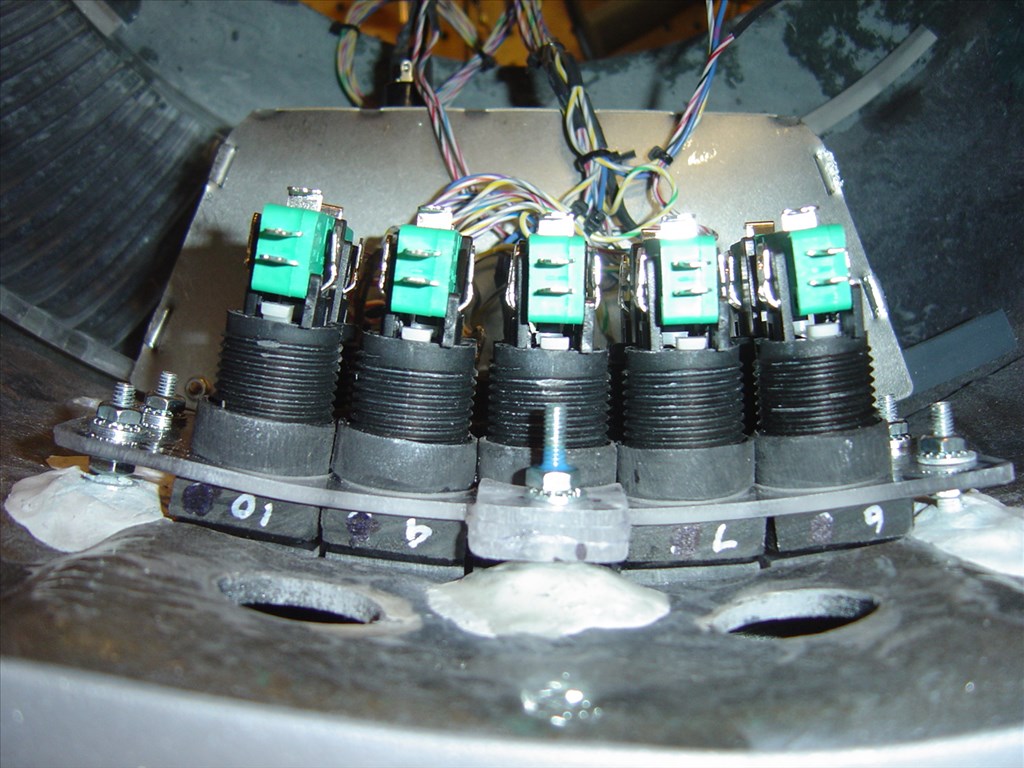

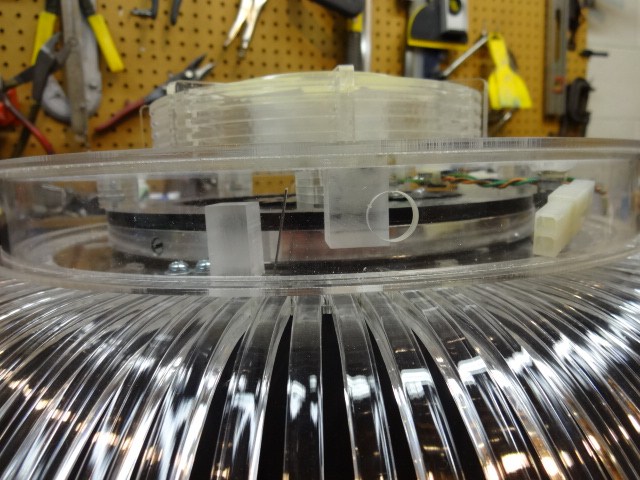

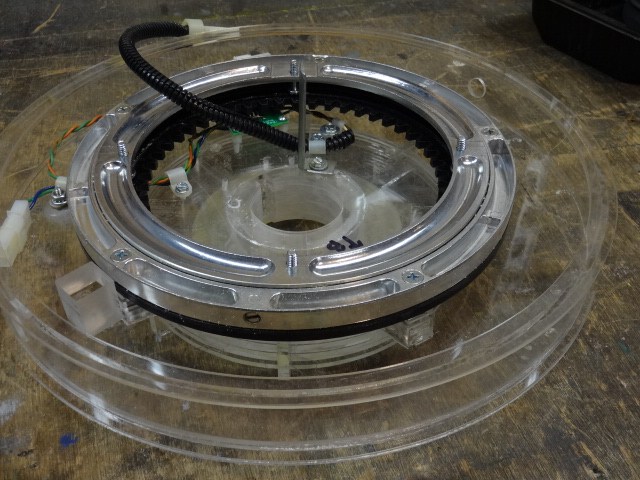

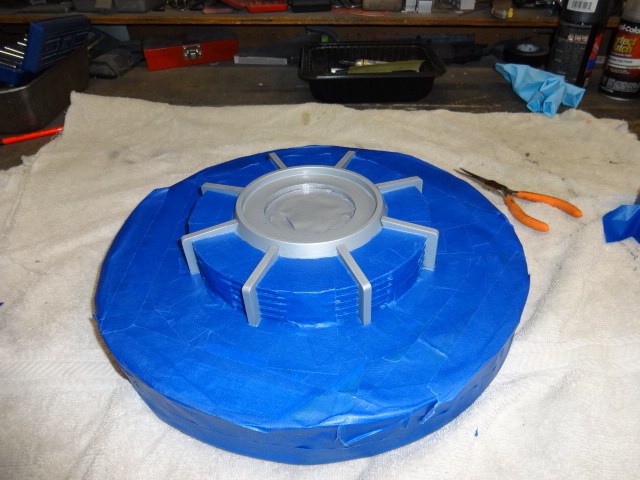

It's been awhile since I posted anything on my progress. It's been a busy and fun summer at home and at the day job but I have managed to make some good progress. Anyone still following knows I have the main robot practically complete (minus some improvements and updates planned). I've been working these past few years (yes, I wrote years) on designing retractable and nicely articulated arms. I succeeded nicely I think with the first one and have been working on and off this summer copying it to build the second arm (mirror imaged).

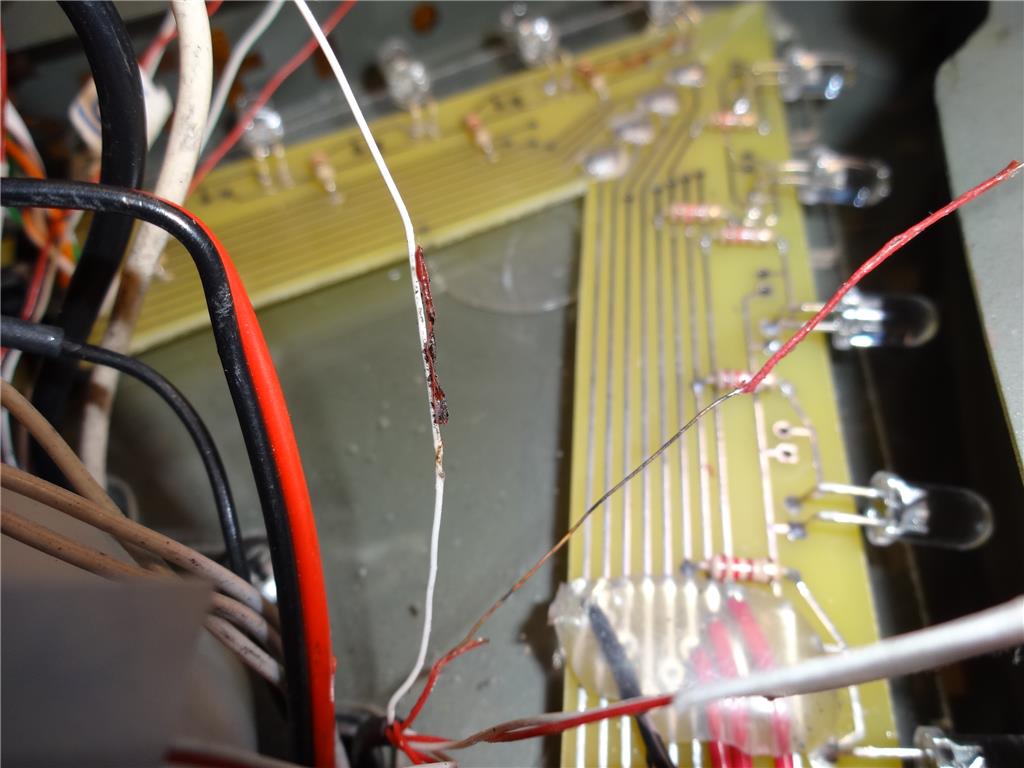

The building process o the second arm has been a relatively easy but honestly it's been an annoying process. To necessarily make it exactly like the first arm, but mirrored, I've had to disassemble almost the whole upper part of the robot to get the the first arm. Then I had to take it apart to use as a jig and pattern. I hate taking apart precision things I've spent so must time building. Luckily I built it with maintenance and replacing parts in mind . It was still a pain in the butt and has some very tight tolerances. Also it needs to go back together exactly right or it won't work right. Needless to say I was a little nervous and it bothered me to see my arm sitting in a pile of parts in a tray. However it's turning out to be a good test on its durability and ease of maintenance. It went back together fairly easy without anything breaking and is just as strong as before I took it apart. Best part is that is still works like designed.

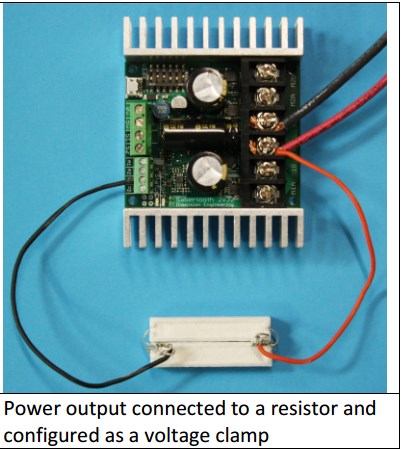

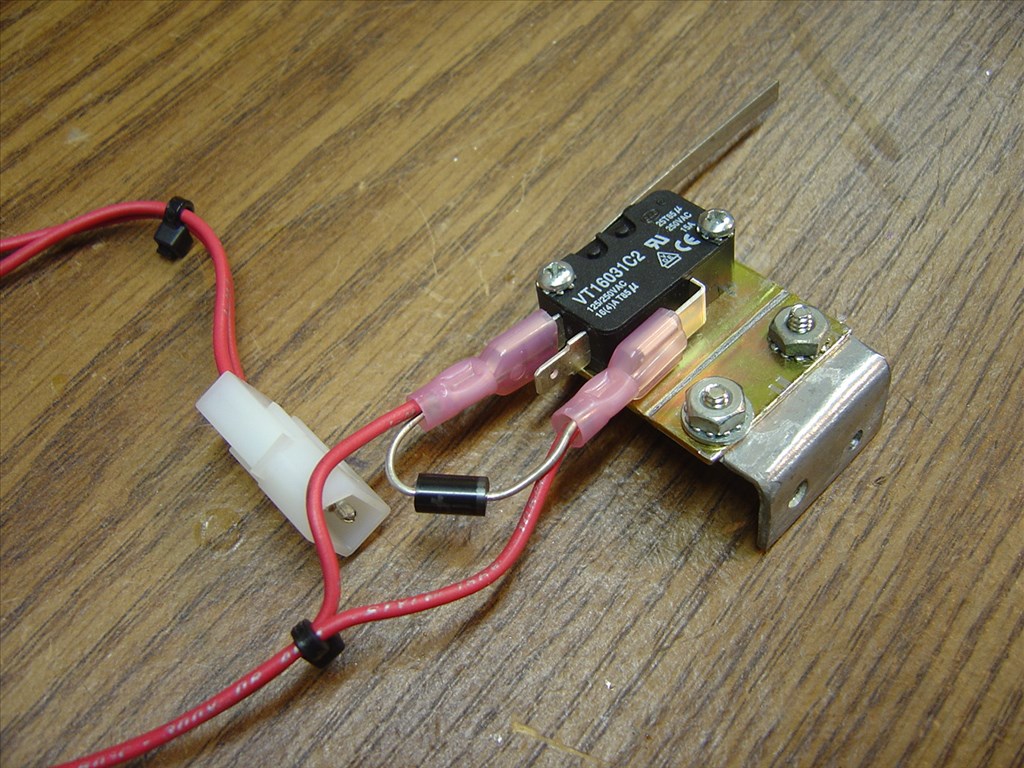

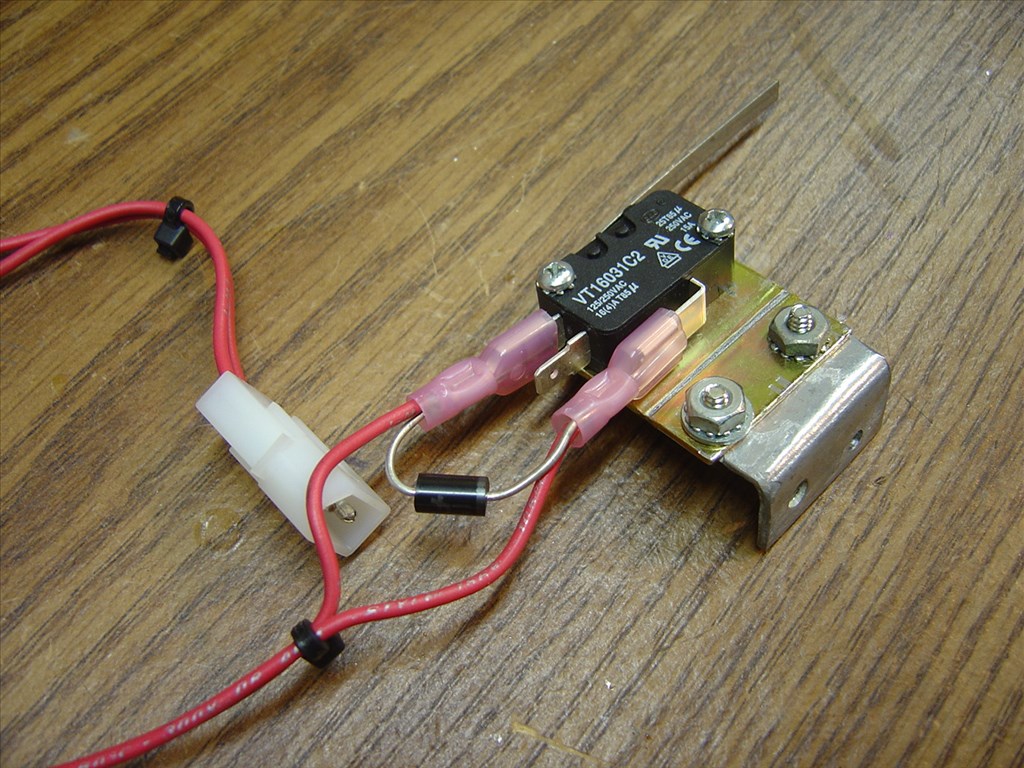

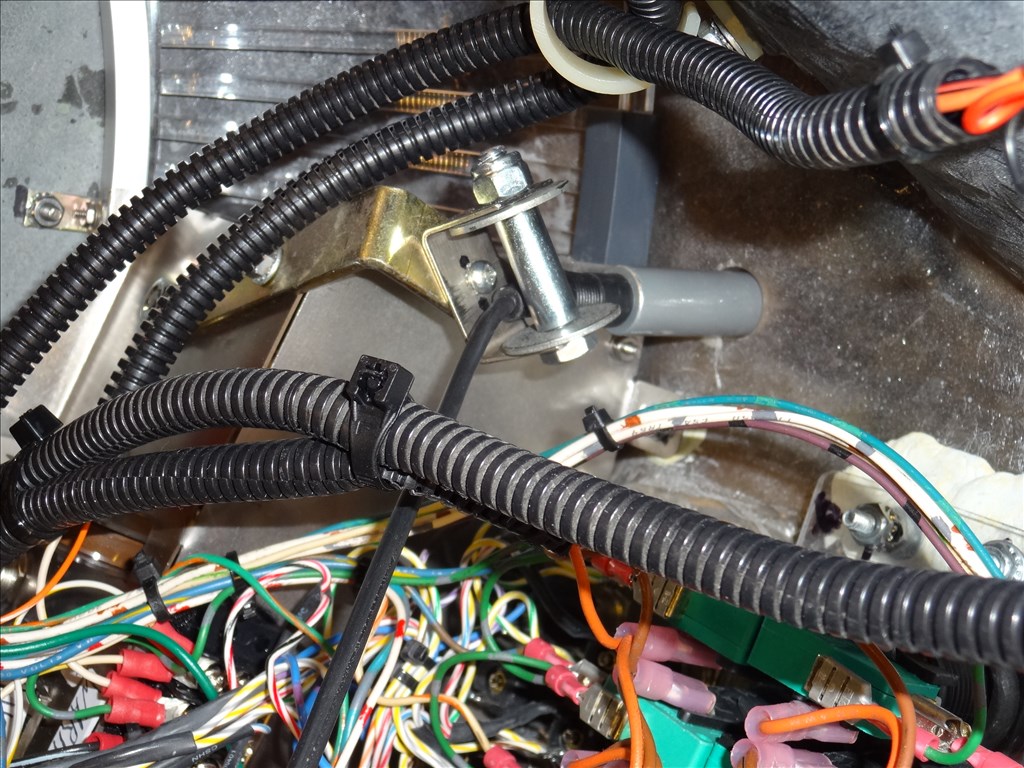

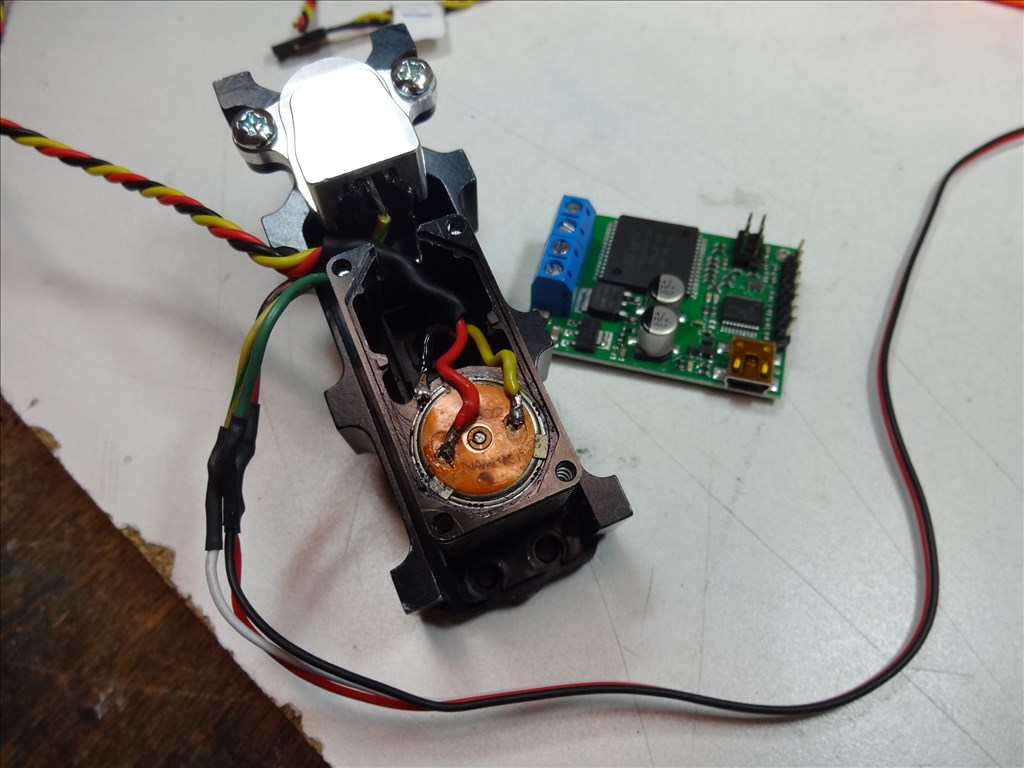

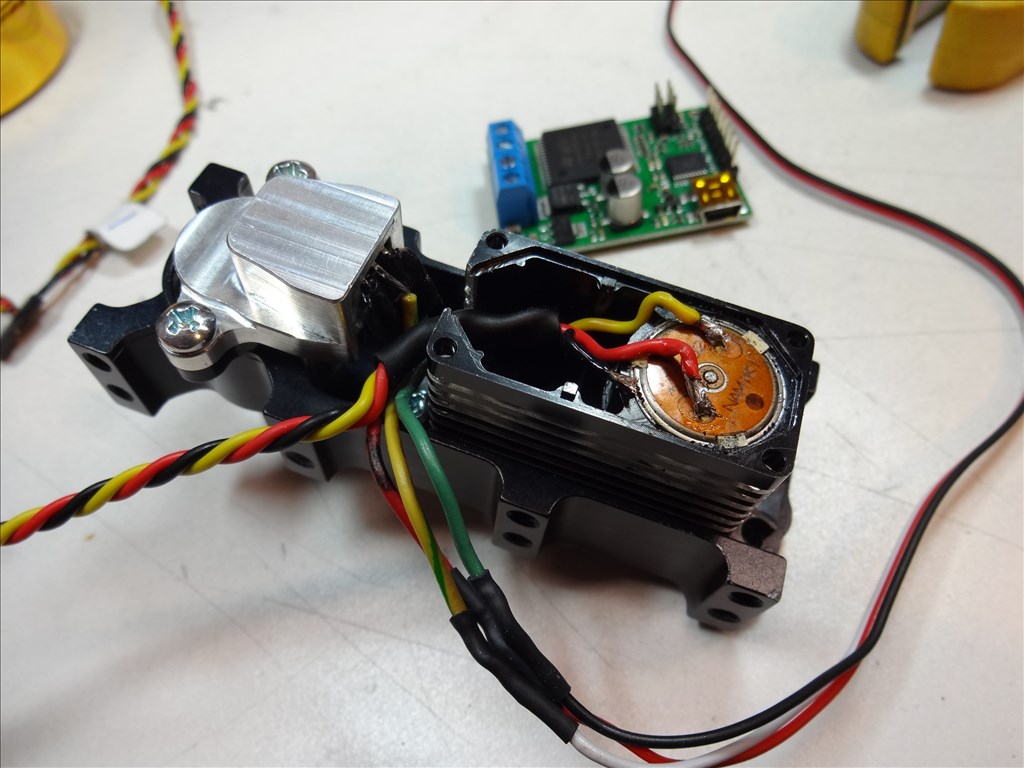

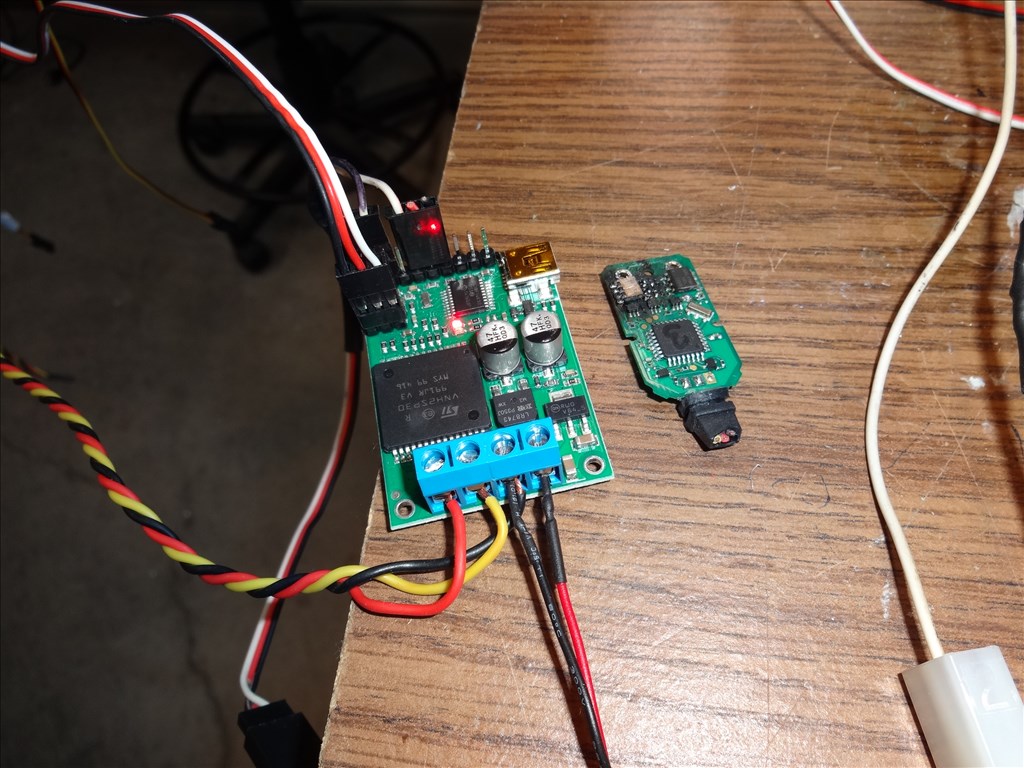

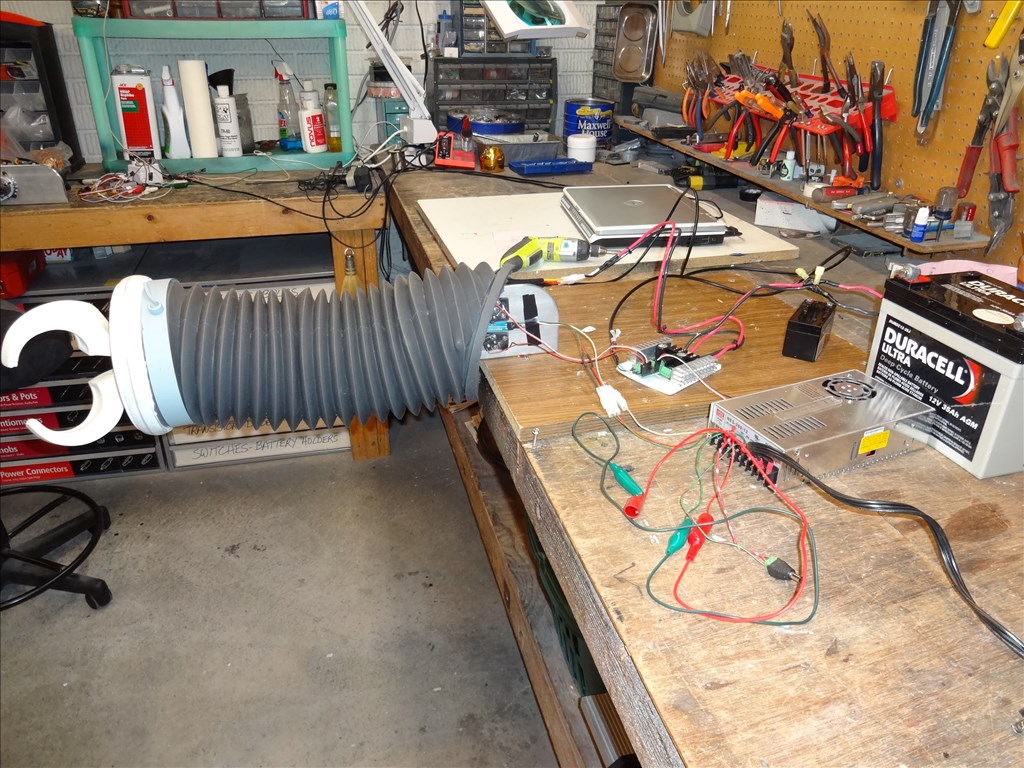

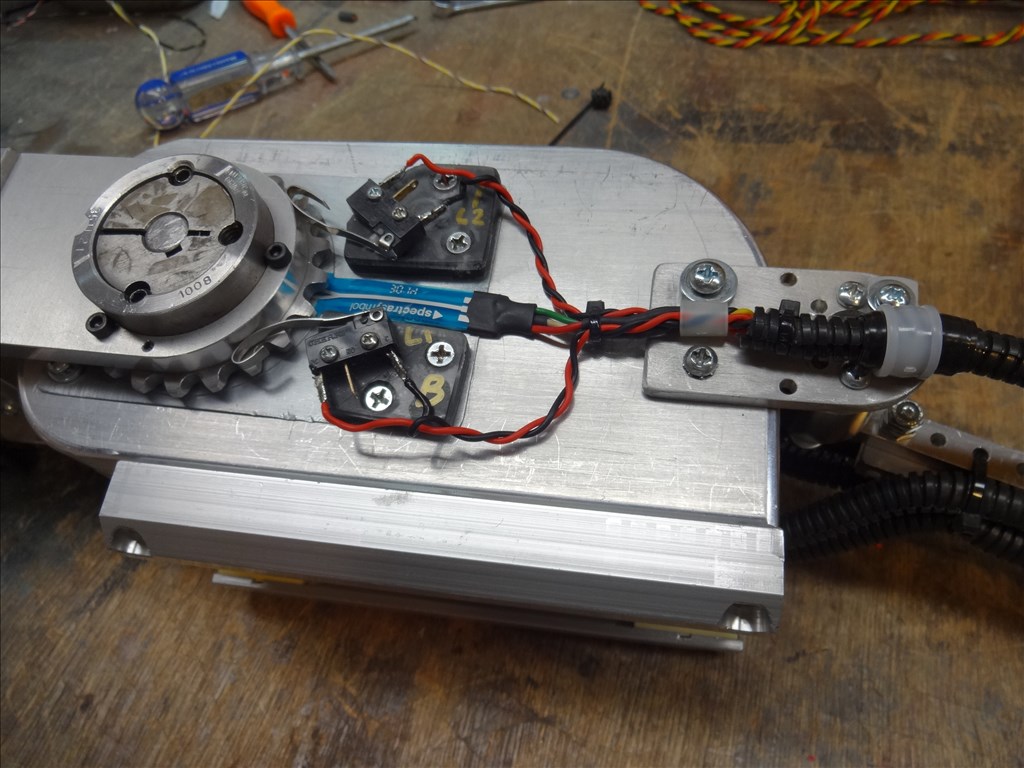

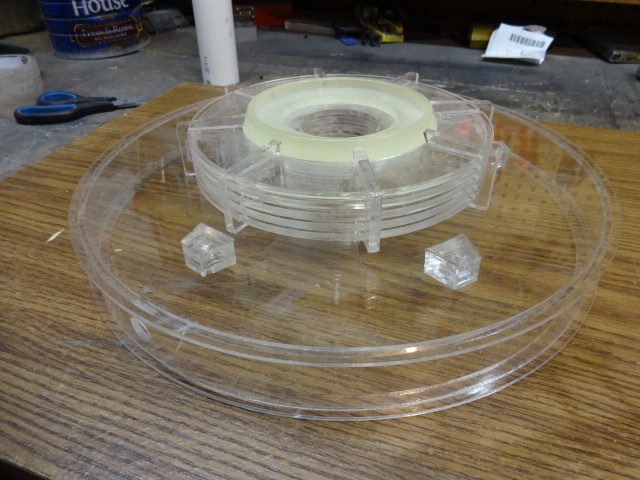

LIke I said building the second arm has been simple. I hit a delay when I started working on the control system. I'm using the second side of the Sabertooth 2X32 with a Kangaroo X2 daughterboard I'm controlling the first arm with to add position and speed control. My feedback device is a paper thin and pressure sensitive Softpot. I thought I could just copy over all the setting I had spent weeks to manually tune from the first arm to the second. No such luck. When I did the second arm is jerky with no ramping. The Kangaroo's auto tune feature is totally useless for my setup. The AT works great for loads in tight or next to the motor but for heavy forward acmetricial loads like my arm It fails every time. I need to shorten the arm by taking off the heavy wrist and claw section then I'll get a successful tune. However that tune is useless when I replace the forward load. It is good for a baseline tune I can work from so that's what I did. For the past 2 weeks I've been working a few hours a day adjusting the settings with the DE software in the Kangaroo. Mostly the PID Coefficient settings. It's not an easy task as one setting will through another out of whack. Added to the flustration is the Roo doesn't have three PID settings as you'd expect (P, I and D) it has six or 7. Each one has a gain and a reset coefficient to play with. Then other settings like deadband and exponential come into play. There are three different deadband setting including a position and a speed deadband! AHHHHH! LOL. Anyway the good news is just last night I made a breakthrough and have it moving relativity smooth. Hopefully I just need to balance a few setting to dial it in.

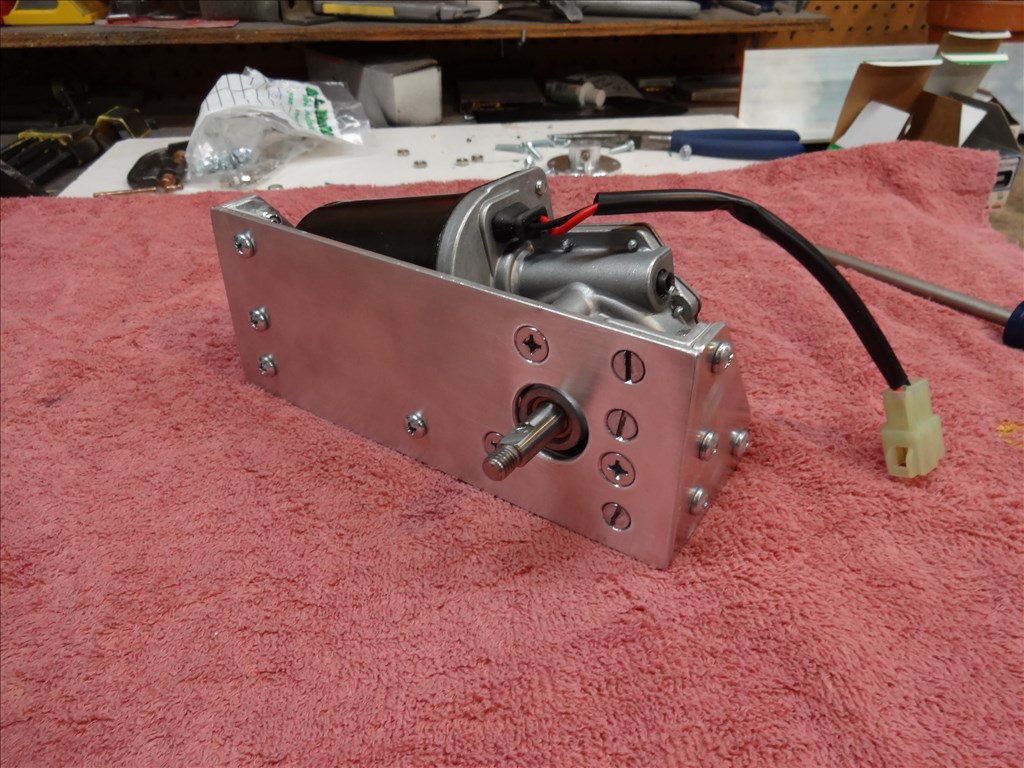

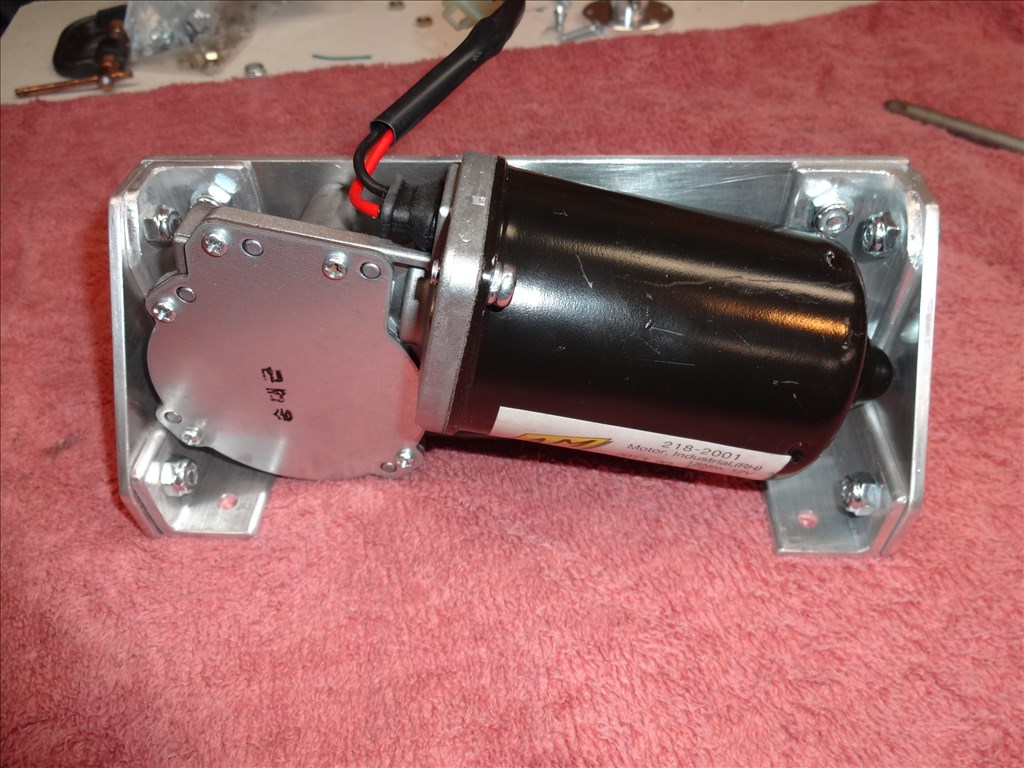

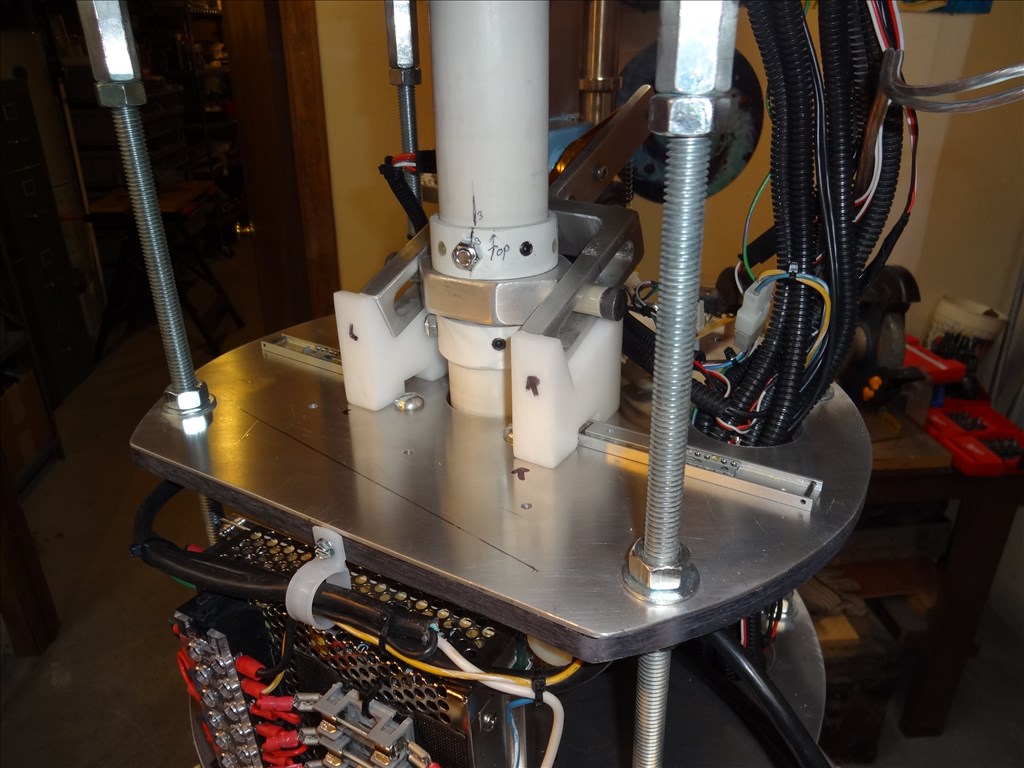

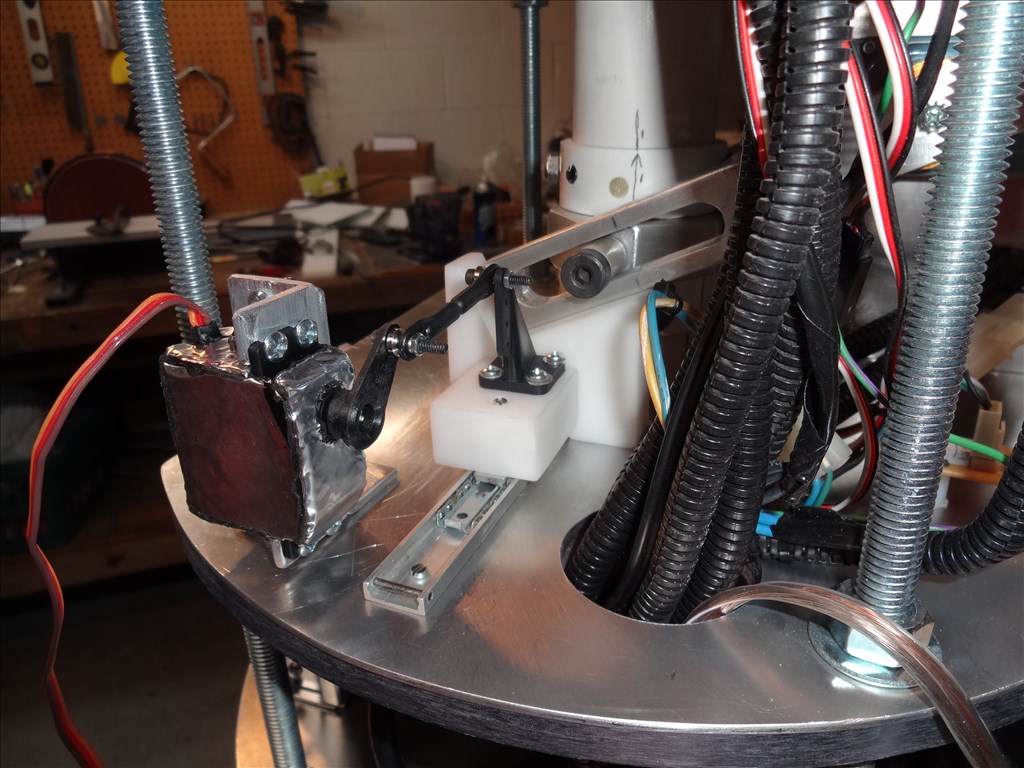

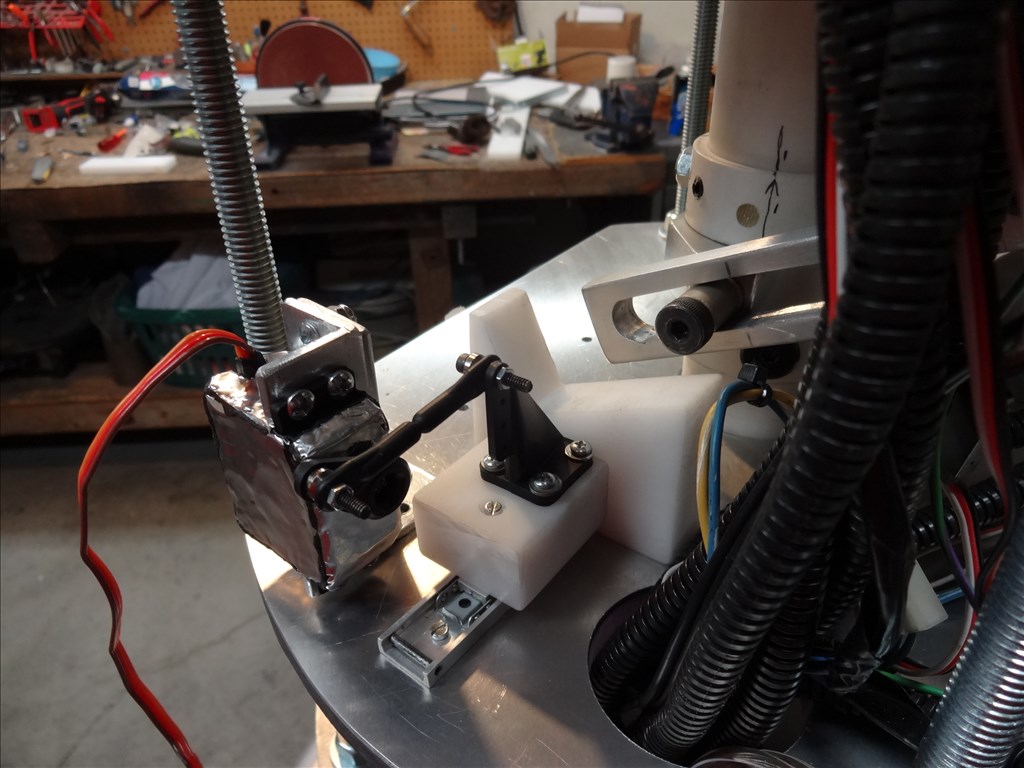

I thought I'd post a couple pics of my second B9 arm being tuned. No vid yet because like I said above, at this point I don't have it tuned properly. When operated it kinda looks like a drunk with the DT's. LOL.

Armed and Dangerous!

Dave, Your robot already is a great achievement, but more than that, I admire your determination to build your dream robot to completion, and not quitting!

Thanks for the support Steve. Much appreciated and needed. I've been adjusting this thing for hours today and am making very s..l...o....w progress. This must be a lesion in patients some higher power is trying to teach me. LOL.

Actually I read an article that said PID settings for motors looks easy because it usually only has three settings. However when you go to an automated factory or other places that have motorized equipment you'll usually find many poorly tuned motors. Seems it's not as easy as it first appears and I'll attest to that.

As always, great work Dave! Beautiful engineering on your robot.

PID is a nightmare even with just 3 values - we are working on a new algorithm that does away with the need for PID completely in the EZ:1 robots locomotion system this does needs a DSP PIC though!

Tony