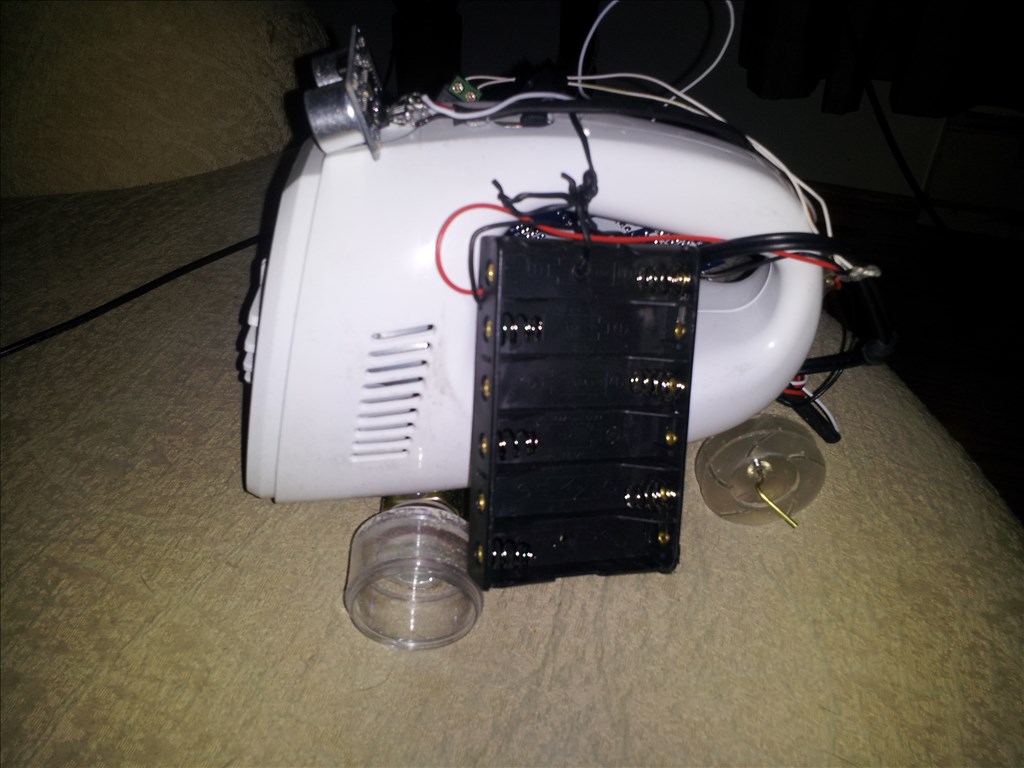

This is a WIP of a cycloidal gearbox with a reduction ratio of 40:1. It is driven by a Tarot 4108 brushless motor, in theory it should have almost zero backlash...

By Mickey666Maus

— Last update

Other robots from Synthiam community

Derrick's First Bot

Build an autonomous vacuum with EZ-B: control DC motors, H-bridge, servos and sensors; camera tested with Synthiam ARC...

Gotrobbed's The R7 Droid Project

Build an R2-style R7-M1 droid using EZ-B to control motors, sounds, Xbox wireless, camera eye-tracking, voice...

Bhouston's Inmoov's Touch Sensors

Build DIY touch sensors for robots in Synthiam ARC using foil tape on an ADC port and simple scripting.

Good find!! I will take a look!!

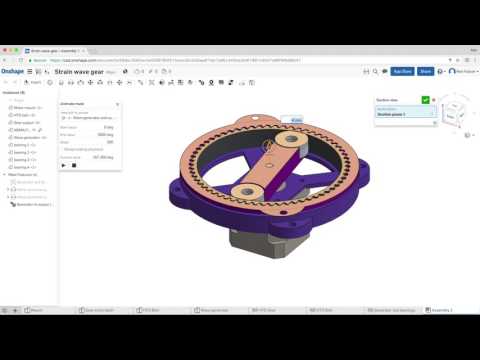

This is another take on a strain wave gear, it works with a belt! I am not sure if this is the better choice over a printed one...but it would surely offer all the needed material properties needed for that part!

This is a nice take a a 3d printed strain wave gear, but seeing the noise and vibration makes me afraid that it might be better to stay within the cycloidal realm of gearboxes?

What do you guys think?

So I got the gearbox setup with the encoder working...it is actually less vibration than expected, I will make more stress tests under load!

Looking good so far!!

Also ARC integration is super easy!!

Nice job! What did you print your parts with?

Its all ABS...

What was the approximate cost for the parts?

Looking forward to your torque testing.

I used an Odrive and the recommended controller from their site...

The motors and bearings were ordered from China, do quiet cheap but as we all know...its a waiting game!!

I think the cost should be less than 150 per joint!!

But a 3d printed gearbox still is a 3d printed gearbox after all...lets see how it'll hold up during some stress tests!!