Asked

— Edited

Hey everyone. I'm currently in a pickle. confused

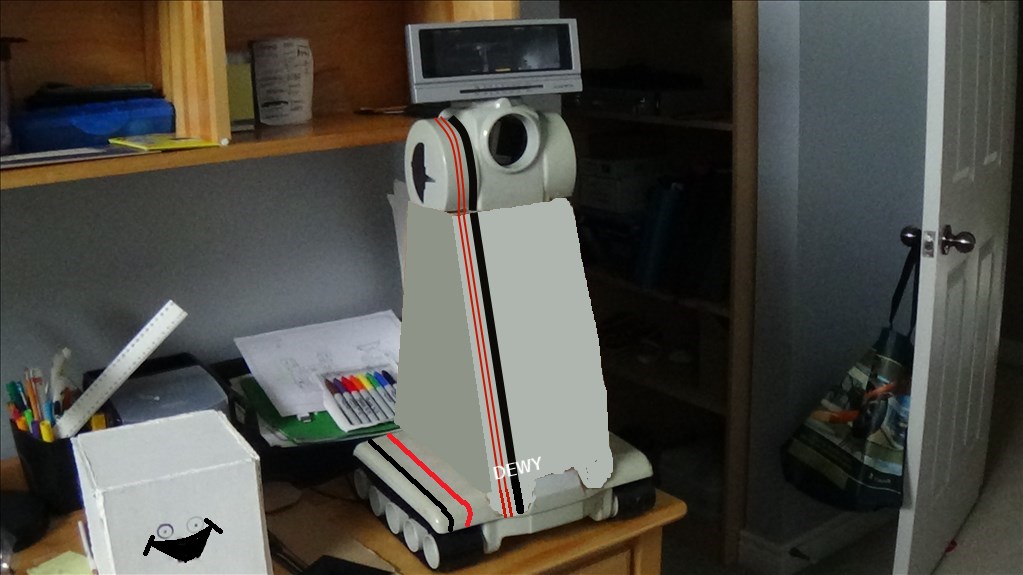

I'm currently trying to find a way I can smooth out Dewy's body at edges and so on.

Video:

Paint scheme:

Any ideas are welcome.

Thanks, Tech

Part of the challenge is you have different media - you have plastic, cardboard and hot glue (I think). If you had plastic to plastic you could use a plastic epoxy.

I would probably lean towards a skin - total covering of the cardboard media.

I like the brown paper skinning idea but I have to spray paint it, so it might not work.

The trash can might be better, but I'm not sure how I'll explain the amount of wasted glue to my parents.

Thanks Justin.

I'm still open to other ideas though, just in case someone happens to have gone through the same ordeal.

Fibreglass the whole thing would provide the best outcome however fibreglass work is messy, smelly and can involve a lot of sanding down therefore insane amounts of dust.

"Bondo" is easier to smooth out however may crack while curing.

PVA glue and scrap paper can produce pretty neat finishes. A combination of that plus bondo/fibreglass once dried may be a compromise.

There are other products out there too which could help. "Smooth On" could be painted on to do exactly what it's name suggests.

Oh, ok @Techno....I thought you were older, it sounds like you are younger though. Probably half those ideas I suggested (like the fiberglass) are bad ideas for a younger person. Here is my revised advice.

Or leave it the way it is. It doesn't look that bad to me and a good coat of paint will probably do wonders.

I think I'm going to redesign the body anyways, cause it appears by aligning skills are bad.

Let's put it this way. When the base is straight, the top of the body is off by 5-15 degrees. So, looks like I'm redoing the body. I'll look for garbage cans but if not I'll take special care in using cardboard.

One idea I got a little while ago, was to put clay into the holes and crevices and then seal/glue them in.

And as a note, I am thought of as older, for many reasons.

@technopro , if you have access to a fabric store then you will have easy options for fiberglassing. Using a stretchy polyester you can tack it in place on one end with glue then stretch it accross the void and glue to the other side. Then mix up about 4 ounces of resin . You can use many kinds of resin. The easiest to work with , cures in 5 minutes and very little odors is alumilite plastic resins. You can buy about 16 ounces for 20 dollars from hobbylobby craft store. I like using indoor friendly materials so i dont piss off women in my life or the neighbors.

If you want to go this route i can walk you through step by step easily.

Here is sort of a work in progross pic doing the method i was suggesting on my cars dash to mold in a 6.25 inch center channel speaker and tweeter. The pink is bondo on top of the resin.

beforeduring

After