tevans

Brazil

Asked

— Edited

Hi... During my experiments to transform everyday hardware in robot pieces, I came up with the need to build a very simple hand... Something. After trying a few desings, I created these very afordable ones, tha I would like to share with you...

Later I'll post a simple how to... Tevans

really cool! Very wicked

I'll add Tutorial status to this post once it contains some tutorial information

Sweet design

The clear three finger is exactly what I would like to use. When you get a chance could you post some more pictures and info. Thank you

Hi... while I'm putting together a video, here some pics of where I started from...

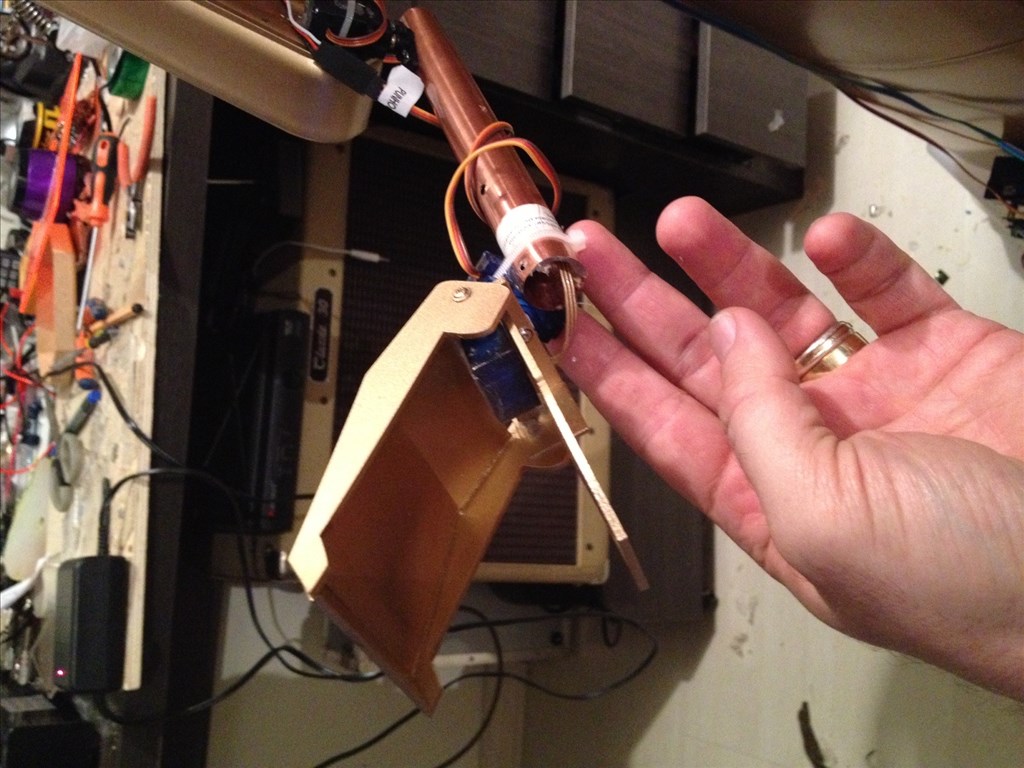

first some draft just to get into idea..

then I used a vector design software (idraw, corel draw, etc) to draw some parts, print on a piece of paper, and use it as mold to cut on balsawood... just to feel it in 3d.

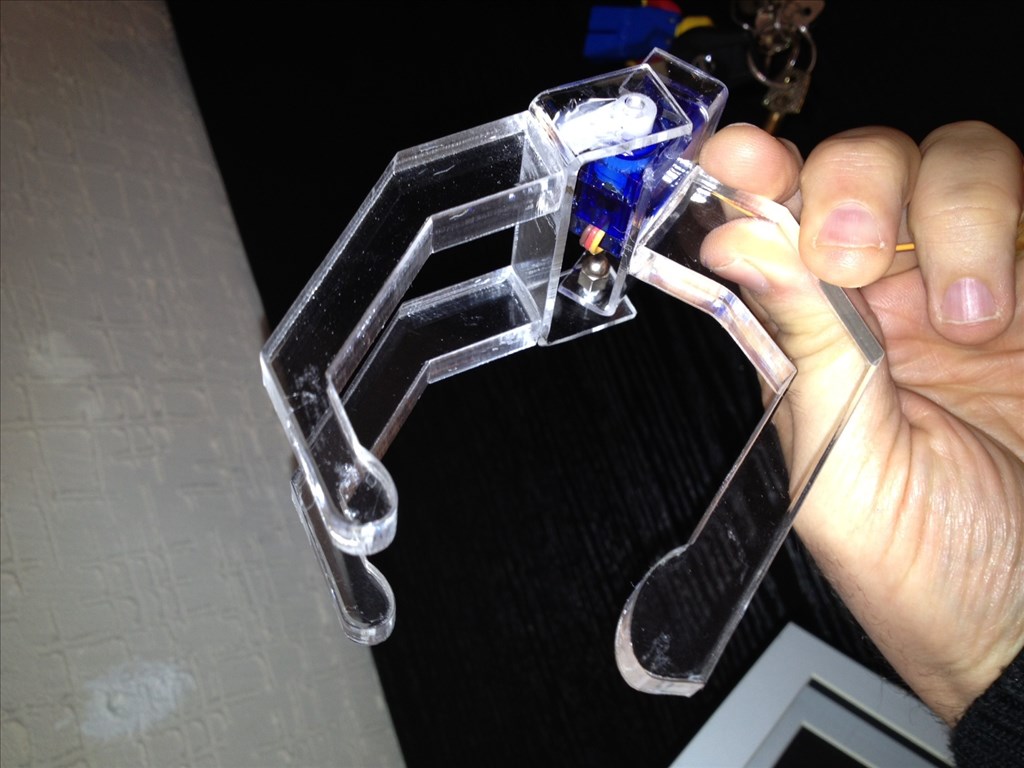

once I decided witch parts would work better, I had it cut from a sheet of 2mm acrilic

some superglue.. spray paint, a microservo (and other for the wrist) and.. that's it. My U$15,00 hand...

Then.. I used the same method for the three fingers... except that I cut myself the first prototype (cause it's easy to cut 2mm acrylic).

and finally I came up with this design... I sent that to be laser cut (the fingers in 10mm and the other parts in 2mm)

here the laser cut parts. U$10 for four sets...

the trick to bend some parts ? just use a little torch like this one and the corner of your table...

I'll try to show that on the video, later, ok ?

here is the pdf files of the parts.. use it as wish. I just would like to know if those were useful..

fingers10mm.pdf.zip

partsCLAW2mm.pdf.zip

Really nice job. Inspiring.

Alan

Awesome job!