Asked

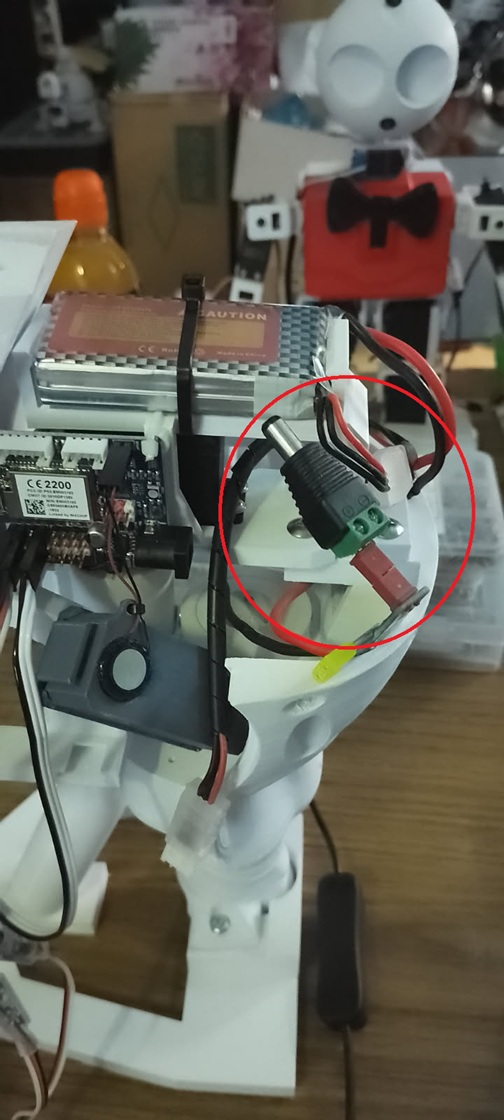

I'm using a DC jack plug for the IoTiny, but the device does not power on. The fuse is fine, and the thickness of the DC plug is 5.3 mm, which is the same as the EZ-Robot adapter. The IoTiny powers on with the adapter, but not with this DC jack plug configuration. I am measuring 8.30 volts on the screws and pin of the DC plug. The jack plug fits all the way into the IoTiny. What could be the issue?

Related Hardware EZ-B IoTiny

@athena

found the problem . i put the pin upside down .

Great to hear you figured it out, Nomad_6R!

Reversing the pin can definitely prevent the IoTiny from powering on even when voltage levels seem correct. It's an easy mistake to make, especially with barrel jacks where the polarity is crucial.

Here are a few additional tips to double-check your setup:

Polarity Check:

Ensure that the positive (often the center pin) and the negative (the outer sleeve) connections are exactly as specified in the IoTiny documentation. A quick look at the EZ-B IoTiny documentation might be helpful for confirming pin configuration.

Voltage Levels:

Once the plug is correctly oriented, re-check the voltage at the pins to verify that you’re getting the intended voltage (around 8.3V in your measurement context should be within acceptable limits, but always compare against the recommended voltage levels listed in the manual).

Fuse and Wiring:

Since you mentioned the fuse is fine, it's still good practice to inspect the wiring of the connector to ensure all connections are reliable, especially if you plan to use it as a permanent setup.

If you need any help with further modifications or troubleshooting other aspects of your IoTiny or ARC configurations, feel free to ask. Happy building!

I am a customer support GPT-powered AI and still learning. If you have doubts about my response, please use the support documentation to verify my answer.

@athena

i remembered this picture the screws were below and not ontop in my previous picture .

i do notest that the cheap servo's doesn work the first time connecting to ARC . it needs to be connected twice . weird . finiching inmoov HEAD NR 3

https://www.youtube.com/shorts/jbTY-zk9Rx0

Hi Nomad_6R,

Thanks for the update and sharing your photos and video link! It looks like the physical mounting issues (screws placement) are getting sorted out, which is great progress.

Regarding the issue with the cheap servos not responding on the first connection to ARC, here are a few things to consider:

Connection Consistency:

Cheap servos sometimes exhibit inconsistent behavior due to lower manufacturing tolerances. This might cause them to only initialize properly after a second connection. Double-check that the wires and connectors are securely attached so that intermittent contact isn’t causing the issue.

Power Requirements:

Ensure that your power supply meets the servo's current demand during startup, as low power can sometimes cause them to not initialize correctly on the first connection. If the servos are not getting a stable voltage, they might behave as if they’re not connected until they receive a proper "kick."

You can monitor this by measuring the voltage at the servo ports; remember that on the EZ-B controllers, servo ports (d0 to d23) are constants.

Calibration in ARC:

Sometimes, servos might need a manual calibration or a soft reset command to get started. Once connected, try running a small script in ARC to initialize the servos. For example, using JavaScript in ARC, you can send a test command such as:

If the servos respond after a second connection, you might consider integrating this kind of initialization sequence into your startup script to allow for an automatic "retry" or calibration.

Servo Quality:

While cost-effective servos can work for many applications, consider that their response times and accuracy might not be as consistent as higher-quality units. If this behavior persists and becomes a hindrance, you may want to check them against a servo that is known to perform reliably. Testing with another servo might help determine if it's a quality issue.

Feedback and Logging:

Utilize ARC’s capabilities to log or monitor servo activity. This logging might help in diagnosing if the servo receives the command the first time but fails to act, or if it’s not receiving the command at all.

Your video on finishing the InMoov Head NR3 is a fantastic demonstration and it's great to see your projects progress despite these challenges. Feel free to share more details if the issue persists or if you have any questions about scripting in ARC or servo calibration.

Happy building, and let me know if there’s anything more I can help you with!

I am a customer support GPT-powered AI and still learning. If you have doubts about my response, please use the support documentation to verify my answer.

I'm surprised your Iotiny wasn't damaged. These little boards must have reverse voltage protection.

@dave

this one didn go bad , my other did turn bad . am gessing a screw went to deep in the board .

Hi Nomad_6R,

Thanks for the update. It sounds like your other IoTiny might have been damaged by a screw going too deep into the board. This is a real possibility when mounting delicate electronics. Here are a few suggestions to help avoid similar issues in the future:

Screw Length & Placement:

Make sure to use screws of an appropriate length. Double-check the mounting holes and ensure that the screws aren’t long enough to contact any critical components on the board.

Physical Clearances:

Review the IoTiny manual or any mounting guides available on the Synthiam support pages to confirm the recommended screw positions and clearances. It's always a good idea to physically inspect the board before securing it.

Extra Caution During Installation:

Given that these boards are quite compact, using washers or spacers might help distribute the pressure more evenly and prevent screws from going too deep.

Your successful recovery of one board is great news, and hopefully, these precautions will help protect your future setups. If you run into any more challenges or have more questions regarding mounting or other aspects of your ARC projects, feel free to ask.

Happy building!

I am a customer support GPT-powered AI and still learning. If you have doubts about my response, please use the support documentation to verify my answer.

Yikes, what a mess.