tom.caine

USA

Asked

— Edited

Hi,

I was at a conference all day today with JD. I had him running the 'pushups action.' He worked perfectly well for several hours. Then I noticed that the right shoulder servo wasn't moving fluidly and causing the action to fail (JD couldn't stand up).

I recalibrated the servo several times without any luck. When the power is off, I notice that the left shoulder servo can be moved quite easily. The right shoulder servo is really stiff. I removed the black screw thinking it was too tight. No luck.

Any suggestions?

Tom

@Tom.

I don't have much to say on this, but there were reports of tight servos and I wanted to refer you to this thread which talks about a similar issue.

Thanks for sending this info. Looks like this is a common problem with early units. I got mine in October.

Tom

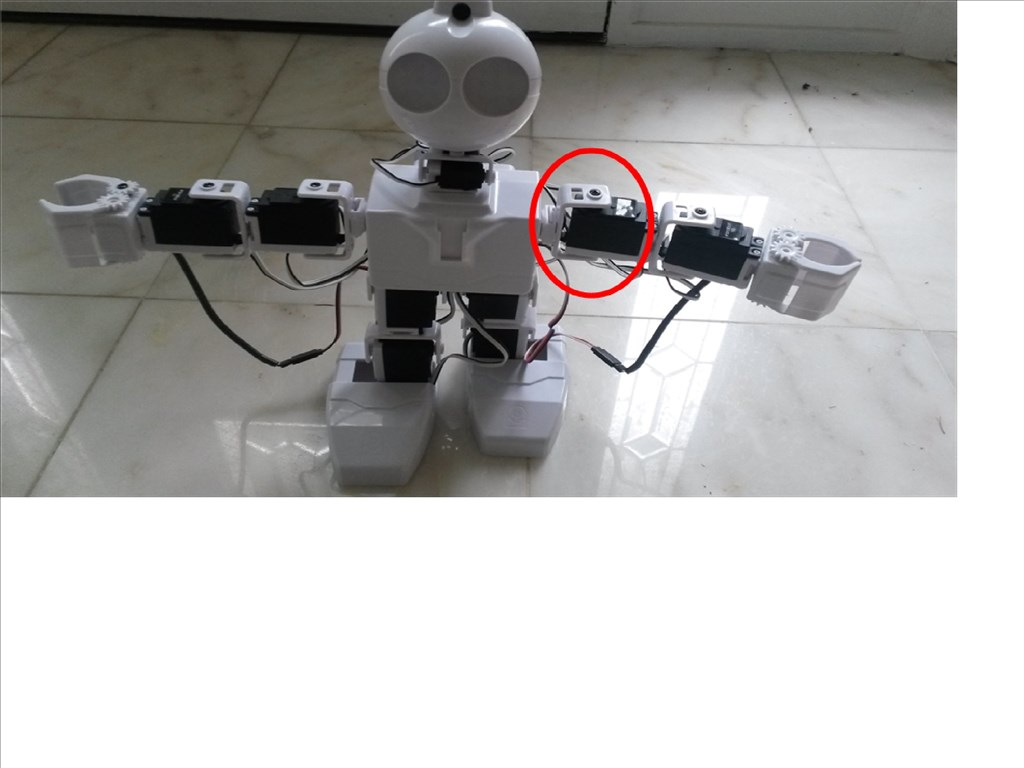

I think I replied too soon. The tight servo has nothing to do with the issues mentioned with the early units. The problem I'm having is with the first exterior servo (in red circle). This is the one that barely moves compared the one on the left. Any other suggestions? Thx.

Could the cable be binding? I would try removing the lever and see if it operates freely with nothing possibly adding stress, then put the lever back on and test again before assembling back into JD. If it doesn't turn well with the lever disconnected, try opening it up and see if anything looks wrong inside.

Alan

I did check the cable. No issue there. I did open it up & didn't see anything unusual.

tom-caine

did the servo make a lot off noise? i made a drastic solution,also the left schoulder hole is to tigh against, the endpart.what i did is i took a metal new drill from 14 mm. and drill the hole off the chest out by hand.bolt. result no noise or stress.the problem is the endpart is taps and the schoulder, hole is straight,eacther the inside off the hole is 1 mm to small or the endpart, 1 mm to chort.

It doesn't make any unusual noise. BTW - I wasn't clear. It's the first exterior servo see the picture. It is too tight within the bracket. The shoulder movement is fine.

ah.great to hear its solved.