Asked

— Edited

hi all

is there anyone that can make me an stl file,the cost here in belgium to make an stl,is very high+cost material and chipping.also you dont get the stl file, companies says its there property.you dont have to do it for free ,but i , dont want to spend to much on it.

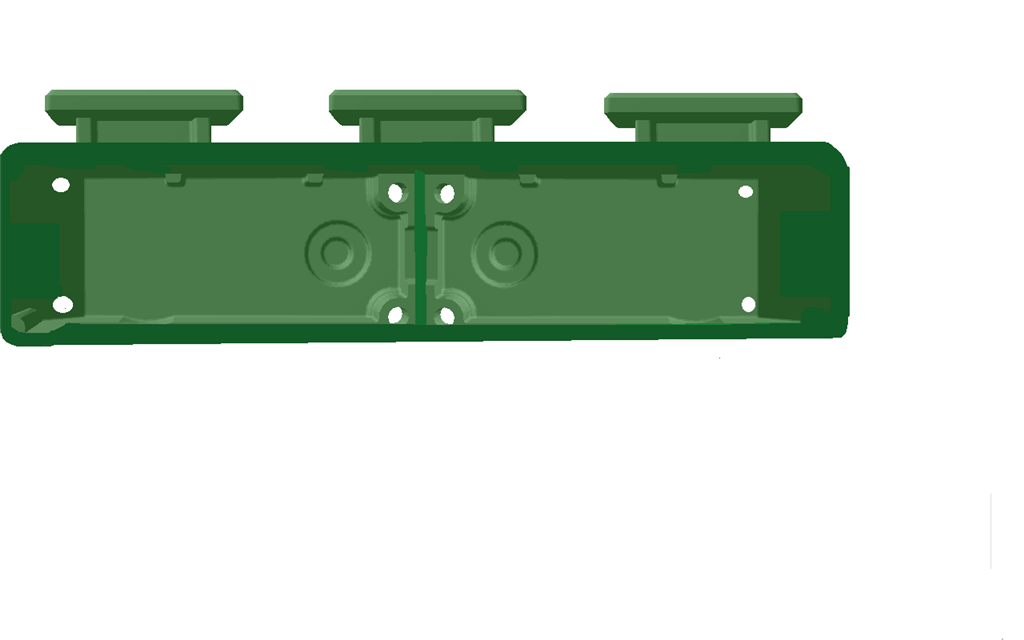

what do i want is a hip case ,similar like the neck part jd,but for 2 big servo's. the ones we use here ,lever servo's.color case is white.i want to give jd , some freedom more ,to be able take side steps.

the servo's comes together with no end piece where normal a screw sits. on top servo,here are some pics.

thank you

Patrick, in the US, almost every city has a Maker-Space with 3D printers and other tools that you can use for a reasonable membership fee and thr price of materials. Also many public libraries have 3D printers that will print for a small fee plus the cost of materials. You may want to research if there is anything similar in your area.

Alan

here they are chops too .but they ask to much money for a small part. more then 150 euro is way to much.and most friends i know,cant make an stl file. and you dont get the stl eather,its companie property.

I'll whip something up for you

dj

thats very nice of you.do you have any question for me?

no - i understand what you're looking to do.

thank you

got my new camera yesterday jd head.works really well. and i saw new ARC new rgb motion,awesome.

I have a few more finishing touches to do - and the bracket, which will have a female clip so the block isn't necessary.

thats a cool design.i did earlier with my bioloids the same ventilation. with testing them servo's they never get to hot and die,i tested them for 4 houres, long without moving the horn,thats the highest heat you can make. pinokio is a fully jd now,he's waiting for his hips. thank you for doing this.