Machine27

USA

Asked

— Edited

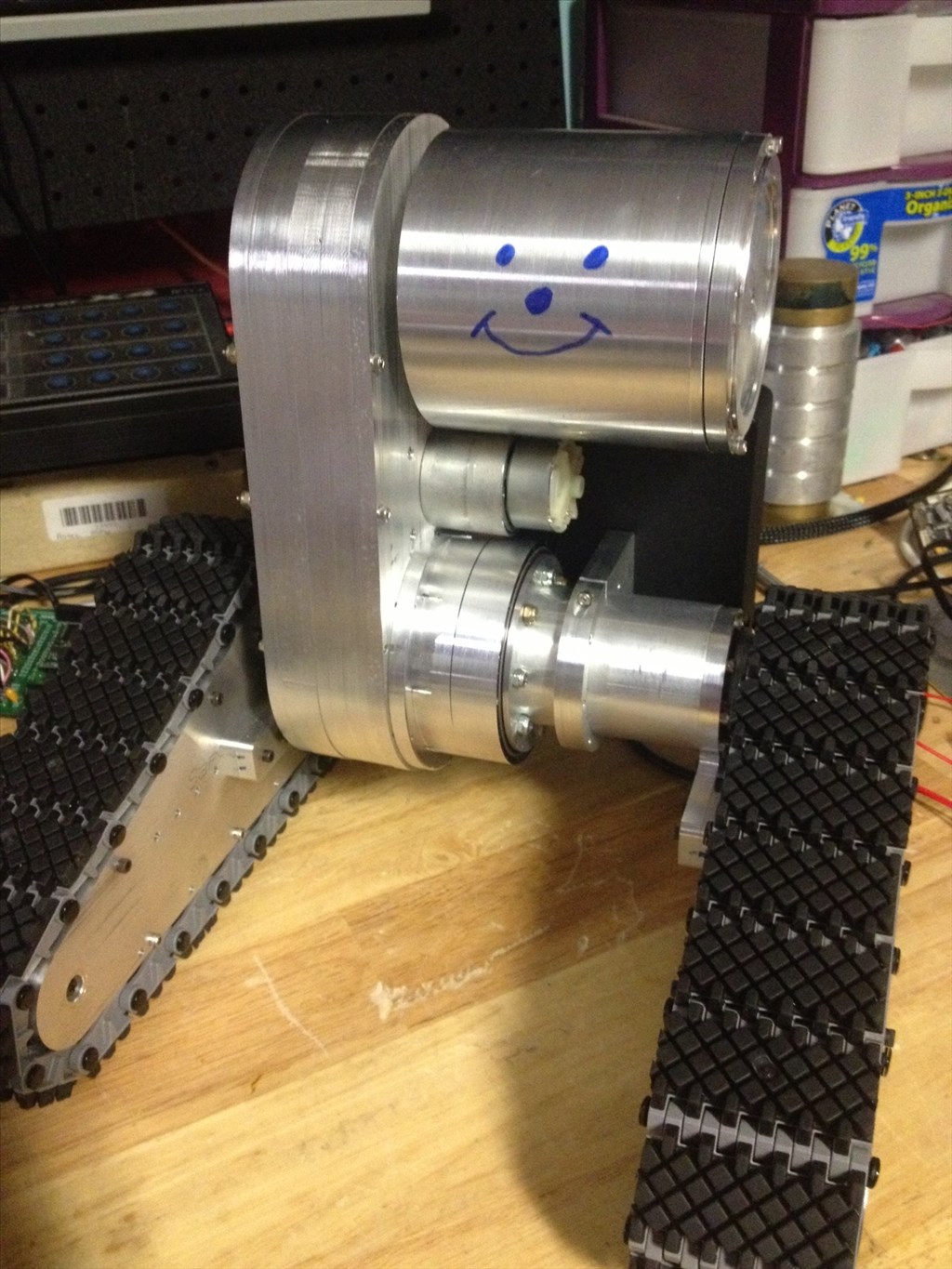

Here's the robot I've been working on. All the aluminum is CNC cut and turned out pretty nice. The tracks and sprockets are from Lynxmotion and the drives are Sabertooth and Pololu. I've been driving it around with a RC setup but look forward to adding the EZ-robot controller I just ordered.

The center section powers up and the (face) is timed via a timing belt with the center rotation point so the smile always points forward no matter the position of the center section.

The sharpie drawn smile is just temporary and as soon as I can come up with a face that's got some character and can support a sensor or two I'll make it and install it.

It's a little heavier than I like. The bottom is made Mic-6 aluminum. The plates are .5 and .250 thick. The .5 plates have been machined out to help with the weight. The motors are 42mm planetary units and work great. I drove the robot in my yard with remote control and found it would climb steep hills with ease. It has two 12v 4 amp hour Nimh battery packs. I used a Sabertooth controller but may change that out when I add the EZ-B as planned. As mentioned above, I'm trying to finish the smaller robot first. The larger Wall-e looking robot is one I built last year.

I say keep the sabertooth, it integrate well with EZ-B.

Got the EZ-B installed and after spending the afternoon at the computer store I was able to log in to the EZ-B.

I'm used to programming the BS2 so i'll have to start from the beginning on the EZ-B. Here's a picture or two. Sorry, no videos yet.

Finally got the EZ-B up and running on my drive tracks this morning. Lots of configuration as to what constitutes a "valid RC signal" was required by the Pololu drives. All was working well until I unplugged one of the servo plugs to recalibrate the oposite one still plugged in. After recalibration I plugged it back in only to miss the orientation of the pins. A load pop insued and my LM1084 5 amp regulator which operates the I/O according to the support video physically seperated from the heatsink in a cloud of smoke. I thought the fuse was supposed to blow first? Guess I was wrong on that one. I ordered more 5 amp regulators and was able to unsolder the old one. Another setback, Darn!

Ouch, I hate it when I do something like that. Good thing your handy and knowledge enough to repair it. I've found that the on line electronic suppliers like Mouser and Digi-Key have parts to us very quickly. I've received parts in as little as two days using regular shipping. Who do you use? I like Mouser.

As far as the fuse, it all dependson on if it will blow faster then the fault will damage the part or what direction the fault is coming from in respect to the part being damaged. All fuses have a delay wither they are fast blow or slow blow.

@machine that fuse isn't a fast blow , its a standard. They can handle a couple amps over for a while. Its called "burn time". The regulator may have gotten too hot too quick... Quicker than the fuse burn time. I don't have specs on the fuse only that its a mini blade type. If you want the highest level of protection you can use a F or FF rated fuse which can pop in a fraction of a second. Physically they look like a little thin wire on the bridge in the fuse.

I use Mouser and Digi-Key both. Both have given me excellent service. I'm hoping in a day or so to get the regulators in. The bot was just starting to get interesting when it blew. I still haven't worked out the head yet. The cylinder is proving hard to work with and give the bot some character at the same time. Has anybody seen anything that might work they can suggest to me?

I almost did this 2 days ago. Too bad, I was really excited to see a video.