Machine27

USA

Asked

— Edited

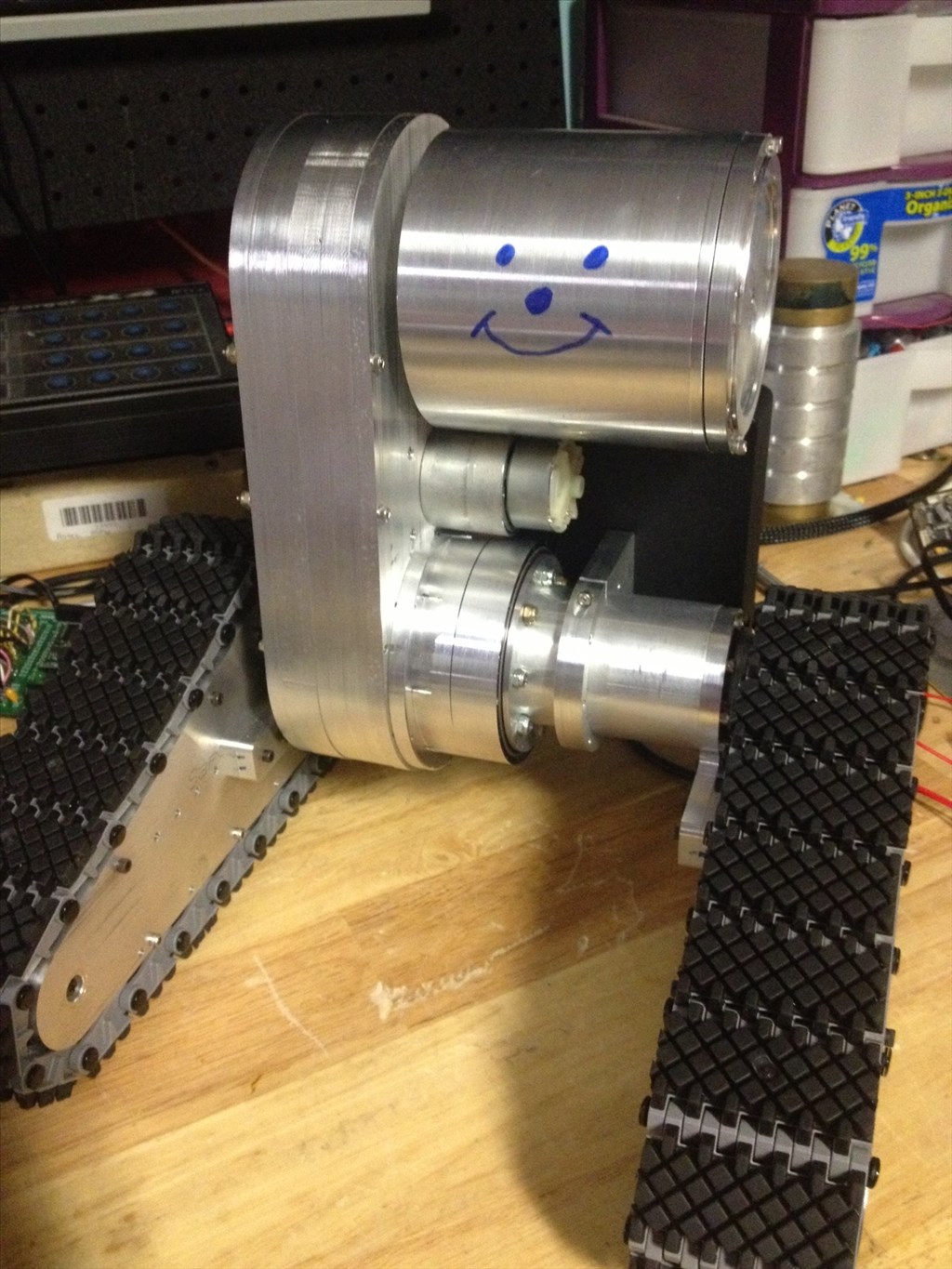

Here's the robot I've been working on. All the aluminum is CNC cut and turned out pretty nice. The tracks and sprockets are from Lynxmotion and the drives are Sabertooth and Pololu. I've been driving it around with a RC setup but look forward to adding the EZ-robot controller I just ordered.

The center section powers up and the (face) is timed via a timing belt with the center rotation point so the smile always points forward no matter the position of the center section.

The sharpie drawn smile is just temporary and as soon as I can come up with a face that's got some character and can support a sensor or two I'll make it and install it.

Waw, unbelievable cool ! Very nice work, congratz!

Very cool

I love the look of fresh aluminum. Something about shouts "Manly".

The battery box has been added. It contains a 1400mah 11.1v lipo and three Pololu drives. I machined out the back of the black Hammond box and laser cut new panels to give me a bit more depth. Before cutting out the panels, I also drew in a feature that allows me to plug into the Pololu 18-7 drives and make program changes without opening the box.

I'm still watching for Fedex with the new EZ-B controller. The drives will plug right in just as if I were running servos.

Cool! Can't wait to see a video!;)

@Dave..not just the shiny aluminum but also the mega treads on the tracks!..looking forward to the vid as well

Awesome design, very original. It looks like a swat team/ military robot.

Manly men building manly things!