Asked

— Edited

Hi! This is my first post here!

I have built a robot before using the arduino, but now really want to make something useful. As you can see in the video, my last robot didn't really do much, it was just REALLY big!

So I am going to try an make a DSLR 360 robotic panorama head, controlled by a smartphone.

The robotics part, I am pretty sure is more than possible with ezrobots hardware / software. But would it be possible to trigger a Nikon d750 with the EZ-B v4/2?

EDIT: The final thing is pretty much done! See the videos of it working below.

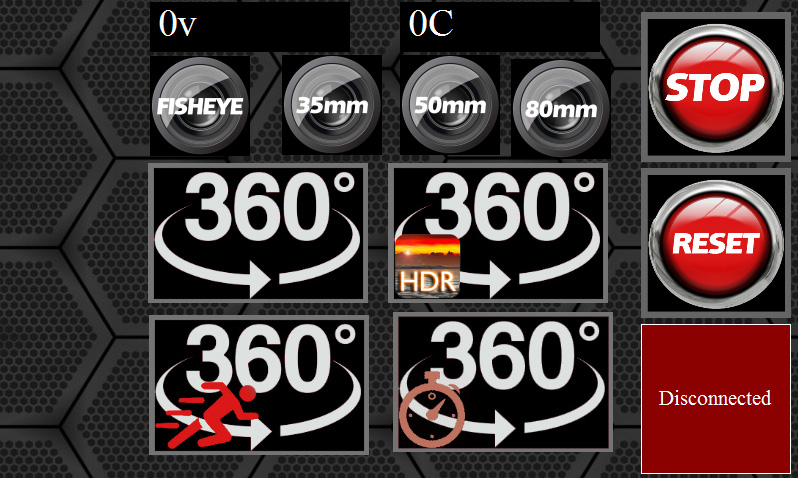

And here is the mobile phone app interface.

Can you guess what it is?

Busy designing and printing the mechanism for panning.

So, after this build of the 360 degree panning system, with a modified digital servo, I have realised that if I want more accuracy of the positions, I am going to need another solution.

It has the power due to the gearing. However, in the software I am using to make a 360 vr panorama, I can save a template, so I don't need to stitch the images semi-manually every time. For this to work, I need pretty good accuracy as the software expects each image to be the same incremental angle for the template. Really useful feature.

So my next attempt would probably be using steppers with H-bridges to control them.

Here are a couple of threads about using steppers with the EZ-B.

https://synthiam.com/Community/Questions/5028

https://synthiam.com/Community/Questions/6183&page=2

Alan

Yeah - a continuous rotation servo wont' give you the accuracy because I suspect you're triggering the servo ON/OFF real quickly to get small steps. However, due to inertia, the gears will continue to move even with the tiniest of pwm pulse.

You will have much better luck with the winch servo. Because you can specify degrees of accuracy and the servo will hold the position.

I actually moved the pot to a gear. So the servo isn't continuous. I am going to give it one more try, using a different gearing setup.

Thanks for the links to the steppers Thetechguru! It will be really handy if I do go that way..

I do have a few 12v 380kg/cm servos that do 1.5 turns laying around too. (Overkill much?) I really dont want to use them for this as they are 1lb per piece! Also going up to 12v just complicates things. Don't want to risk losing fingers either haha!

Back to the electronic drawing board >__<

Ok awesome! I managed to get more accuracy now for the pan axis with a modified servo. (The link to your modified servo (continuous rotation servo) happens automatically - can't see how to stop that ~ but it still isn't one of those lol)

My gear system for the pot was a little loose, so redesigned those gears. Much tighter fit now and I can't move / wiggle the pot gear manually with my fingers.

So now that tricky bit is out of the way, I can work on the next axis. This one needs more torque as will be lifting over 1kg at 4cm to 5cm ~ depending on which lens.. These servos are 17kg/cm so if I gear it to a 3:1 ratio, it should have 51kg/cm ~ that comes out at 10.2kg of torque at 5cm.

Update.

So I spent the weekend printing and assembling. Got a first prototype working. The only problem I am having is my wobbly tripod head! The actual panoramic robot is really rigid. I have printed a new tripod head that is much stronger, but the weekend is over and have no time to fit it tonight.

To add extra stability to the two axis, I used some massive thrust bearings. Seems to do the trick.

At the moment, it is all printed in PLA, just 1.2mm walls and 20% infill. Not sure if this will be up to the task for long-term use, so when I have everything right, I will print it again in ABS, 100% infill.

All that is left to do now is to design and print a detachable electronics housing / battery holder. It should balance it out nicely too. Then print the adjustable camera mount. Should have the camera on there by the end of next weekend!

So here is a video of the prototype in action. I used a cardboard box in place of the camera.

What a contraption. Very cleaver. Love it. I can see this has been a lot of work and brain power on your part. Nice work!

Your design looks very solid and the servo movement is so smooth. Sweet! However what are you going to do about the wobble your tripod is adding to the mix? I would imagine if your software is expecting a smooth transition from shot to shot and your shooting quickly you would want the pan to be exact. Is there a new quality tripod in your future?