Asked

— Edited

Hi! This is my first post here!

I have built a robot before using the arduino, but now really want to make something useful. As you can see in the video, my last robot didn't really do much, it was just REALLY big!

So I am going to try an make a DSLR 360 robotic panorama head, controlled by a smartphone.

The robotics part, I am pretty sure is more than possible with ezrobots hardware / software. But would it be possible to trigger a Nikon d750 with the EZ-B v4/2?

EDIT: The final thing is pretty much done! See the videos of it working below.

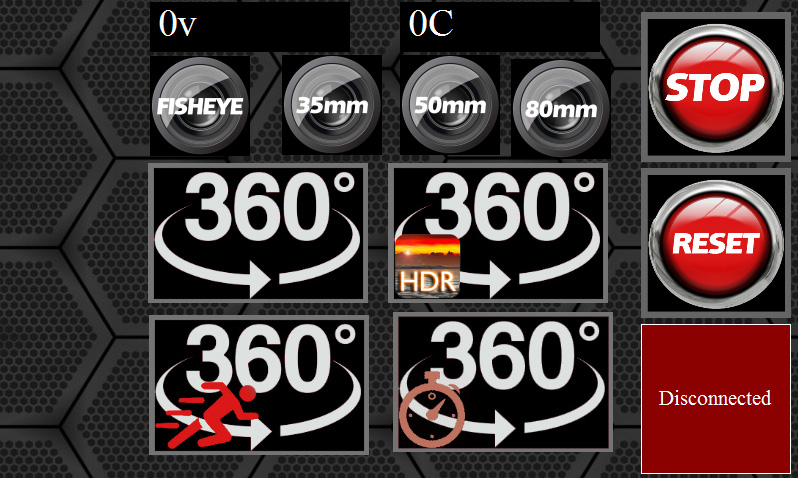

And here is the mobile phone app interface.

Ok cool, thanks. That's really good to hear.

Sorry about the double post. I am the new guy haha

Anyway.. I plan on attaching the magnetic sensor (pot replacement) on the turntable itself rather than in the servo.. I can get more of a direct reading then. Not sure it this is a good idea or not.

I will have to add gears for the pitch and yaw mechanisms as the camera and lens are about 1kg. The load will be about 5cm from the fulcrum for the pitch. My RDS3115MG servos I will modify, have 17kg/cm @ 7.2v. I figure, if I gear it by 6x, I should have enough torque and be safe not to overload it.. It will hopefully hold in position nicely too. It will be a lot slower though.

That's a good idea, to move the pot. That way you can increase the torque for sure.

Oh! I didn't see your post about the winch servos!

That's even better And they are weatherproof too..

And they are weatherproof too..

Because I am based in South Korea, it can be hard to find decent stuff at a good price, especially imports! But I found a HS-785HB 3.5 for $10 cheaper than USA sites

Thanks dude! Great help!

Spent last weekend doing some test prints / designs / ideas..

So I have adapted a servo with gears to run 370 degrees. I wanted a bit of overshoot for the 360 degree pan, just to be safe.

I just moved the pot so it is now geared. I will do a smaller version this weekend.

I printed this one in PLA as hear it is better for gears. Any ideas on printing gears in different materials? What is best in your experience?

Here are two other vr panoramic heads I made. The small one was the first, for a go pro hero 4 black.

The larger one is for my DSLR.

They snap incrementally into place manually - but only for one lens. The DSLR is set up to snap into 16 positions around 360 degrees and 4 positions on 180 degree for the vertical. Only for a 50mm lens.

Both printed in ABS.

So if I want to change the lens, I need a new base for snapping positions.. This is why I am making a robotic one instead..

I thought I would use this thread as a log for my progress if that's okay?

I got my delivery on Monday! Had a play with it and made a simple app on my mobile to move a servo. Seems to work great!

Got to say, that was the easiest setup I have ever had! Thanks!

Looks like I might end up buying the mini one too as I really don't need all the features / outputs on this beast! (At least for this project anyway)

Hi! Totally use this thread for your progress - it's a good place for it because it tells a great story

Looks like it is coming along well!

Cool thanks.

Because of other commitments, I'm giving myself 8 weeks to finish this! Should be fine, as long as I don't need to order any parts from overseas. Will definitely need some advice when it comes to the coding though..

Will post some more progress after the weekend