Asked

— Edited

Hi! This is my first post here!

I have built a robot before using the arduino, but now really want to make something useful. As you can see in the video, my last robot didn't really do much, it was just REALLY big!

So I am going to try an make a DSLR 360 robotic panorama head, controlled by a smartphone.

The robotics part, I am pretty sure is more than possible with ezrobots hardware / software. But would it be possible to trigger a Nikon d750 with the EZ-B v4/2?

EDIT: The final thing is pretty much done! See the videos of it working below.

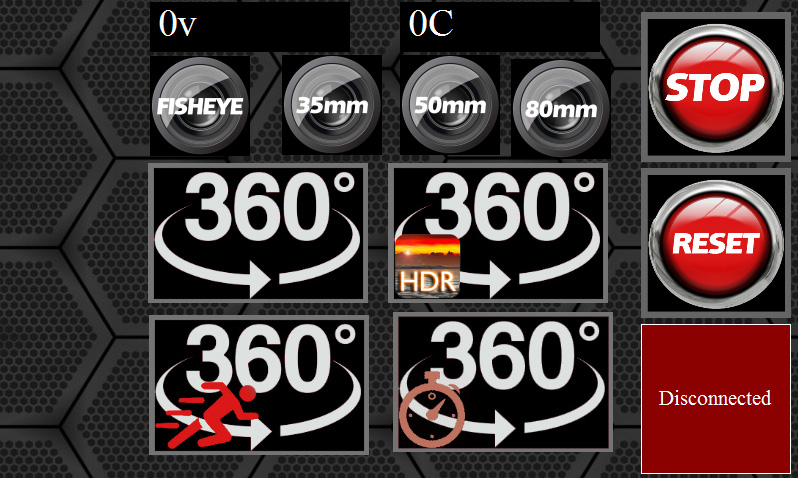

And here is the mobile phone app interface.

Do you have any specifications on what is required to trigger the camera? I see from some searching that it can use an IR or cable release, but we would need to know what the cable does. If it is simply closing a switch, should be pretty easy to do with an EZ-B digital port and probably a transistor. If it is more complex, then so would be the solution.

The EZ-B can't directly do IR, but there are probably solutions for this too (A robot gripper holding an IR remote control aimed at the camera is a down and dirty way to do it. Crude, but effective).

Alan

Mostly the button is a simple switch - which you could do with a solidstate relay. It would be pretty easy to create the whole thing!

EZ-Robot's video guy made a pretty neat rig for time lapse, but he used a go-pro

Brilliant!

So I could actually make it refocus first too by using two relays. By the looks of it anyway. I found someone made one for a Canon. The jack is a simple stereo jack and the same in the Nikon.

So there are enough pins on the EZ-B v4/2 to do this. Perfect.

Many thanks! I really appreciate the quick responses!

For greater control and to have 360 degree capabilities, I am thinking of using something like this for the pan motor. What do you think? Compatible with ezrobot hardware?

https://www.01mechatronics.com/product/supermodified-v30-rc-servos

Here is how they would suggest you connect it to the Arduino. So would it work with the EZ-B v4/2? If so, what are the equivalent pins to the ones shown on their website?

Thanks!

https://www.01mechatronics.com/support/gettingstarted/testarduino

Hey, no double posting threads tsk tsk

tsk tsk

Yeah those servos will work. They have serial or i2c connectivity. So you can choose either one or the other. In practice, the serial/uart is much easier to work with. Use the SendSerial() EZ-Script command and voila!

Just have to take a look at the manual to see what the commands are to move the servo.

Oh, according to: https://www.01mechatronics.com/support/gettingstarted/testarduino

They say...

So that will be the easiest! Simply get the servo and ask for it to receive standard RC/PWM between 1-360 degrees. Voila

Although you can use the servo that Jamie Young uses with his BB8. It's called a Winch servo and that is easier to find.

This winch servo has 1260 degree rotation! That's awesome: https://www.robotshop.com/ca/en/hitec-hs785hb-servo-motor.html

And here is another winch servo that is cheaper: https://hobbyking.com/en_us/sail-winch-servo-13kg-0-7sec-360deg-55g.html

That's what you need