Hi All

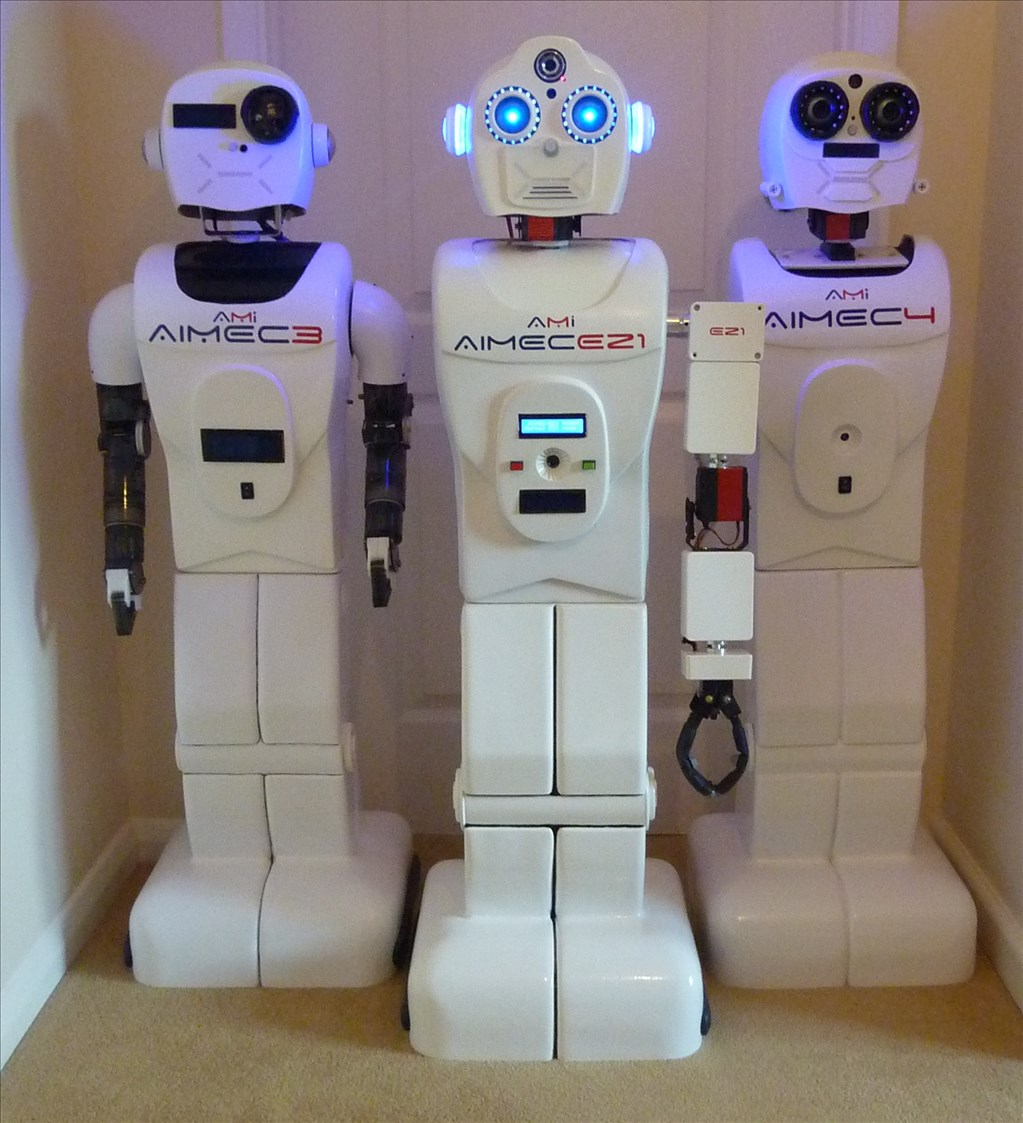

Introducing the AIMEC:EZ1

We are in discussions with DJ to produce a special version of our AIMEC (Artificially Intelligent Mechanical Electronic Companion) robot for the EZ-B, this will be a very advanced robot that will be made available in kit form, which will probably be by the end of this year.

Some history, the first AMI (Applied Machine Intelligence) robot was the AIMEC:3 which is a "hyper-tech" toy and we were very close to licensing this design to a large US toy manufacturer, but the deal fell through. Our most advanced robot is the AIMEC:4 which is still in development, this robot has advanced voice recognition (Dragon 11), face recognition and eye tracking and object recognition the robot has an advanced Ai core and is capable of self learning. When we came across the fantastic EZ-B system that the genius DJ Sures produced we immediately thought that it would be really cool to make a EZ-B version and this is what we are currently developing the AIMEC:EZ1. This robot is the development platform for a ground breaking robotics kit that we plan to sell to the general public, for the first time a highly advanced robot will be available (in various versions) at a price that hobbyists would be able to afford.

I have been building robots for over 30 years and some of my designs are recorded on Cybernetic Zoo

https://cyberneticzoo.com/?p=2280

https://cyberneticzoo.com/?p=3984

On our team we have the brilliant model maker (and engineer) Steve Cole (Articole Studios) https://www.articolestudios.co.uk/ who is also a member of this forum @ukrobotman, with Alex Cole on 3D design and (the incredibly talented) Mike Hodgson on software development. I am doing mechanical, electronics and sensor designs and firmware development for support PIC microcontrollers that enhance the EZ-B boards operation over the I2C bus.

We are all looking forward to working closely with DJ and his team in the new future!

Tony

-- Conceptioneering Ltd - Inventors of the Award Winning Cube World To see Product Innovation - visit our website at www.conceptioneering.co.uk To see Robotic Innovation - visit our website at www.appliedmachineintelligence.co.uk

@toymaker What about the questions on software and EZB I HAD posted?

@Tony I can't wait for the day that robotics is in the curriculum. I'm currently toying with the idea of starting up some kind of after school club for robotics - I have no clue how though lol (all ideas/suggestions welcomed). But I'd love to see these in the class room, kids building it and programming it, I can see it being one of those "fun lessons". When I was at college the "fun lessons" were those which involved programming (Pascal & Assembly Code) and debugging.

The cost is always going to be an issue. You need to make money but also need to have it affordable while keeping the standard to a high quality. I don't envy you on that task (I do on all other tasks though!)

The guy who never sleeps RICH lol

I KNOW toymaker needs to make a profit and costs will be a issue,a idea and may be you are using it get most parts made by china.

I know every one usa hates parts made in CHINA mostly because it takes away jobs,may be the rest of the world too.

IDEA on shipping if you come to a maker faire in usa you can sell some there and no shipping costs,plus people at the faire will mostly likely want one.

6 AM HERE IN SUNNY FLA

AND another idea for me since i travel a lot and love london and england i can easy pick up there and only pay customs fee,and baggage fee

Here is a first look at the EZ:1 (development robot) with its 5 DOF arm under the control of an EZ-B (and ARC).

Now I want to ask you all your advice, you can see that I get the dreaded servo noise when the arm is under load. I might be able to help this with "damping" springs but I do not think I can totally get rid of all the servo noise here.

The shoulder is a "home brew" power servo that has a whooping 200Kg.cm torque, but as you can see its this that makes most of the noise! My question to you all, is this noise acceptable on a hobbyist level robot (also for educational level) or do you think its unacceptable and I should design a new one from scratch? I have an idea of designing a screw driven high power servo, where the screw should hold position without drawing power or making any noise, I could produce an 8pin custom PIC as the servo controller cct, what do you all think?

Thanks in advance for all your comments.

Tony

I have no sound at the moment so I cannot comment on the sound level, I'll watch it again later when I have sound and post what I think. Although I wouldn't expect a silent robot, the noises from servos, motors etc. are all part of what a robot is. Look at the films with robots in, look at Titan, sound effects of the motor noises are added in.

Rich

I tend to agree with you on some motor noise, but this servo motor noise is pretty excessive from the high power shoulder servo and seems too loud to me and may be annoying to people. I look forward to your further thoughts when you been able to see the video with sound.

I am wondering if you are going to change to a ball screw design wouldn't a liner actuator work better. With a ball screw you either need a break or constant power to hold its place.

I see what you mean about the noise now. If you are able to adjust it then I would say now is the time. Moving noise is all fine but holding noise, at least in my humble opinion, should be a minimum.

Springs to aid the arms and sound proofing may help but a worm/screw method would be more effective.

To be totally honest, I wasn't satisfied with less noise in Melvin's arms.