Hi All

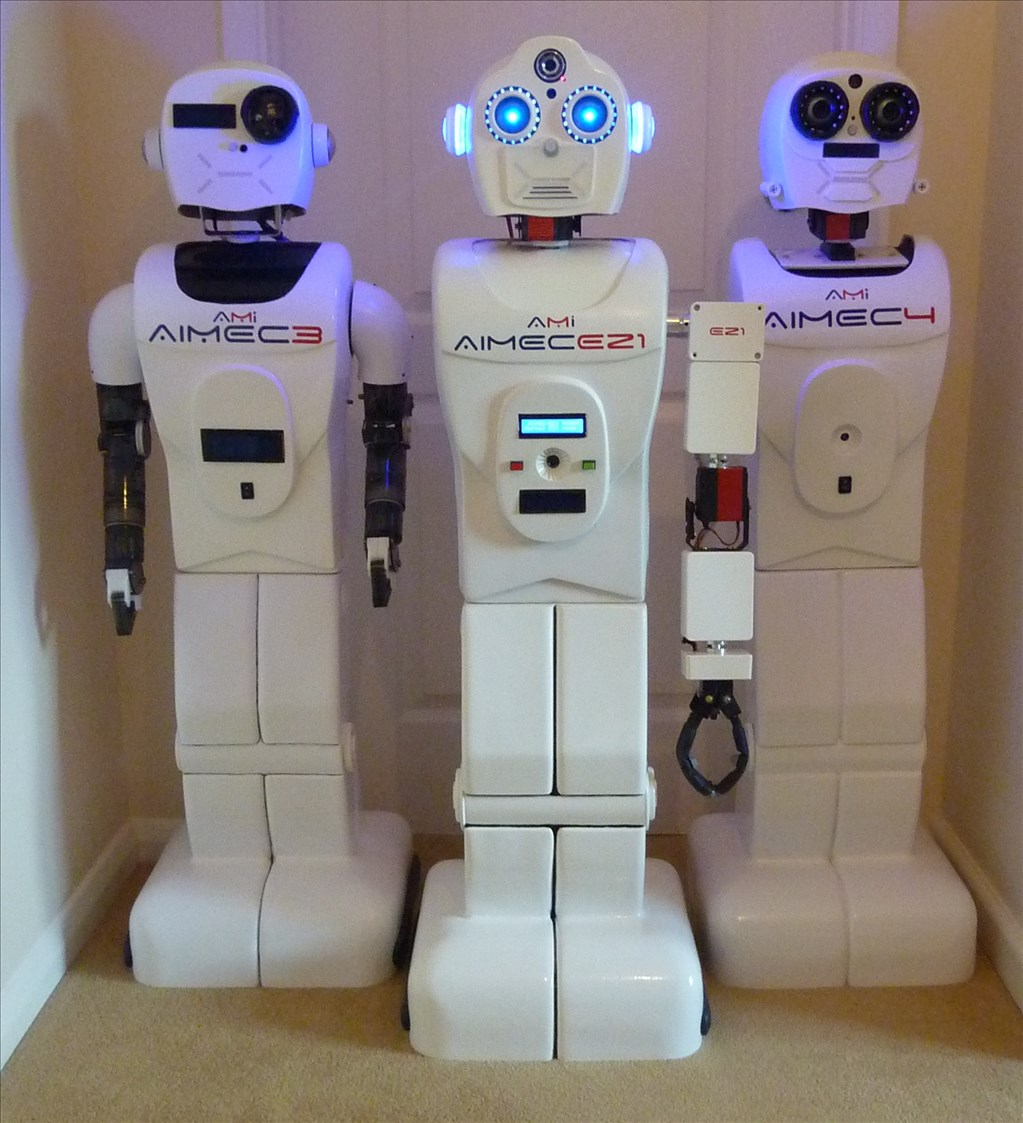

Introducing the AIMEC:EZ1

We are in discussions with DJ to produce a special version of our AIMEC (Artificially Intelligent Mechanical Electronic Companion) robot for the EZ-B, this will be a very advanced robot that will be made available in kit form, which will probably be by the end of this year.

Some history, the first AMI (Applied Machine Intelligence) robot was the AIMEC:3 which is a "hyper-tech" toy and we were very close to licensing this design to a large US toy manufacturer, but the deal fell through. Our most advanced robot is the AIMEC:4 which is still in development, this robot has advanced voice recognition (Dragon 11), face recognition and eye tracking and object recognition the robot has an advanced Ai core and is capable of self learning. When we came across the fantastic EZ-B system that the genius DJ Sures produced we immediately thought that it would be really cool to make a EZ-B version and this is what we are currently developing the AIMEC:EZ1. This robot is the development platform for a ground breaking robotics kit that we plan to sell to the general public, for the first time a highly advanced robot will be available (in various versions) at a price that hobbyists would be able to afford.

I have been building robots for over 30 years and some of my designs are recorded on Cybernetic Zoo

https://cyberneticzoo.com/?p=2280

https://cyberneticzoo.com/?p=3984

On our team we have the brilliant model maker (and engineer) Steve Cole (Articole Studios) https://www.articolestudios.co.uk/ who is also a member of this forum @ukrobotman, with Alex Cole on 3D design and (the incredibly talented) Mike Hodgson on software development. I am doing mechanical, electronics and sensor designs and firmware development for support PIC microcontrollers that enhance the EZ-B boards operation over the I2C bus.

We are all looking forward to working closely with DJ and his team in the new future!

Tony

-- Conceptioneering Ltd - Inventors of the Award Winning Cube World To see Product Innovation - visit our website at www.conceptioneering.co.uk To see Robotic Innovation - visit our website at www.appliedmachineintelligence.co.uk

@Toymaker,

I can't wait to see how this goes! Do you have the preliminary dimensions worked out? Will it be wheel driven?

Welcome to the forum Tony, I can't wait to see what you have in store for us

@rgordon

The height of the EZ1 is approx 3ft 9in (114cm), the EZ2 which is the version that will go on sale will be a bit smaller and a different shape.

Due to the size of these robots locomotion is by wheels, this is for 2 main reasons, firstly with robots of this size it would be hugely expensive to make them bipeds (walkers) and our whole concept here is to make our robots affordable. The second very important reason is that our robots use odometry to calculate where they are, while this is possible with wheeled robots its very tough to do on bipeds. Here is the AIMEC:4 locomotion system the encoders on each motor have 64000 counts per wheel revolution, so all drive movement can be accurately measured, note the tires are specially designed to limit wheel slippage which can cause errors with odometry, the motor controllers use PID for accurate movement and this also enables them to move in straight lines.

In the EZ version we are developing a custom PIC that will handle all this, so the EZ-B just sends commands down via I2C and the locomotion PIC does all the rest, this saves I/O and reduces the load on the EZ-B so it can be doing other cool stuff!

Rich, your Hearoid is looking great with the brain, nice job!

Tony

Conceptioneering Ltd - Inventors of the Award Winning Cube World To see Product Innovation - visit our website at www.conceptioneering.co.uk To see Robotic Innovation - visit our website at www.appliedmachineintelligence.co.uk

I love the arms on the Aimec3, it looks like they are similar to my plans for the Hearoid if my 4th attempt using the original arms doesn't meet my standards. The shoulder covers look great and I hadn't thought of making them look that way (in fact I was struggling to figure out a way to hide the joint).

I can see me taking a lot of inspiration from those

Yes, the brain has given the Hearoid a whole new lease of life and added the minor details to make it that little more realistic. I can't thank you enough for the brain idea or the brain. While I loved the old face it had the new one is so much better.

@Toymaker,

I have to ask.....Is there a ball park price range? Will they cost more than a $1,000?

Thanks for the fast response

Rex

What is going to be the apprx price that you will be shooting for on the diferent models?

Hi folks, I thought I would also introduce myself. I am Steve and am working with Tony on our new Robot Kit Project. We can't say to much about it at this stage but you guys are going to love it. The EZB will be the core of the programming and the bodyshell will be in a composite material. Keep your eye on this page as we will be announcing things on this thread! Regards Steve www.articolestudios.co.uk www.articoleprops.co.uk

Yes , pricing is important as we already loved what you have