Asked

— Edited

3D Print Jd Head

hi

has anyone printed a jd head?my question is ,how do you print the head on the printbed?

thank you

Related Hardware (view all EZB hardware)

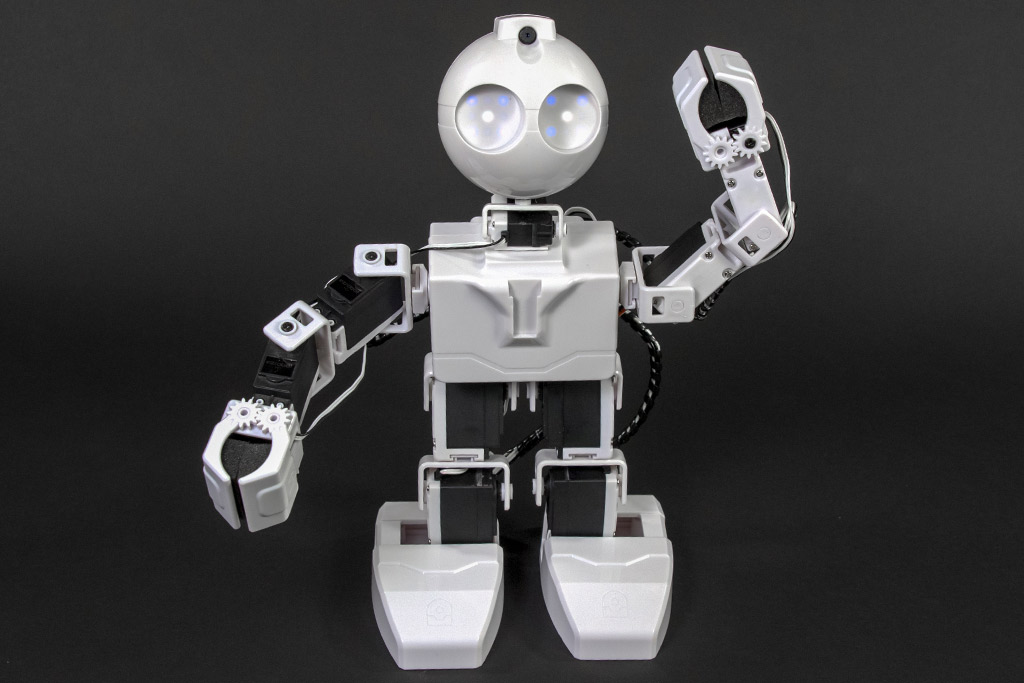

JD Humanoid

by EZ-Robot

JD humanoid robot kit - WiFi-enabled, 16 DOF with metal-gear servos; easy, fun, educational, available from the EZ-Robot online store.

Wi-Fi / USB

Servos

24

Camera

Audio

UART

3

I2C

ADC

8

Digital

24

Related Robot Skill (view all robot skills)

File Manager

by Synthiam

Displays files currently open for reading by scripts, shows only read-opened files, helps diagnose read/write locks and file access errors.

Looking good,

by the way, what happened to the Inmoov head you made?

hi

the head is stil on the shelf .

Hello @Nomad,

I was planning on uploading some more clips and adapters to Thingiverse. One of them was going to be a female-to-female EZ clip but I see you have already made one! I'm going to test it out tomorrow, if it works well would you be open to having me host on the EZ-Robot Thingiverse account? I will credit you of course

hi jeremie

sure you can . i think this is the file .

double-femaleClip.stl

Thank you @Nomad, I appreciate it!

hi averyone

i notest for some time now , my extruder gets very hot .so i replaced with a new one . and still have desame problem . today i figured it out . at one time i replaced the nozzle . same dia and 0.04 . thats when the problem started . there are two things that can go , wrong and heat up the extruder. first one using a nozzle with longer treath , that will , cause the bottem off the ptfe tube to crush so the filament can not go thru easy . second is the replace the nozzle with a shorter treath withs causes the filament , to leak in the heatblock and cause a blokkage . here's a picture ,see the yellow line , for cause number 2 the gap . the heat of the extruder should be some hand warm . if its hot you have a problem . to solve the problem . take off the nozzle and push , the ptfe tube all the way thru , then take out the ptfe tube all the way after cleaning. put the nozzle back in , and then the tube all the way untill it touches the nozzle . you can do this cold . use desame nozzles always . even if you print several days , the extruder should still be hand warm .

hi averyone

i gave jd a bow tie .

bowtie (1).stl

Hehe ! that is awesome. I love it ! JD looks so classy