Asked

— Edited

3D Print Jd Head

hi

has anyone printed a jd head?my question is ,how do you print the head on the printbed?

thank you

Related Hardware (view all EZB hardware)

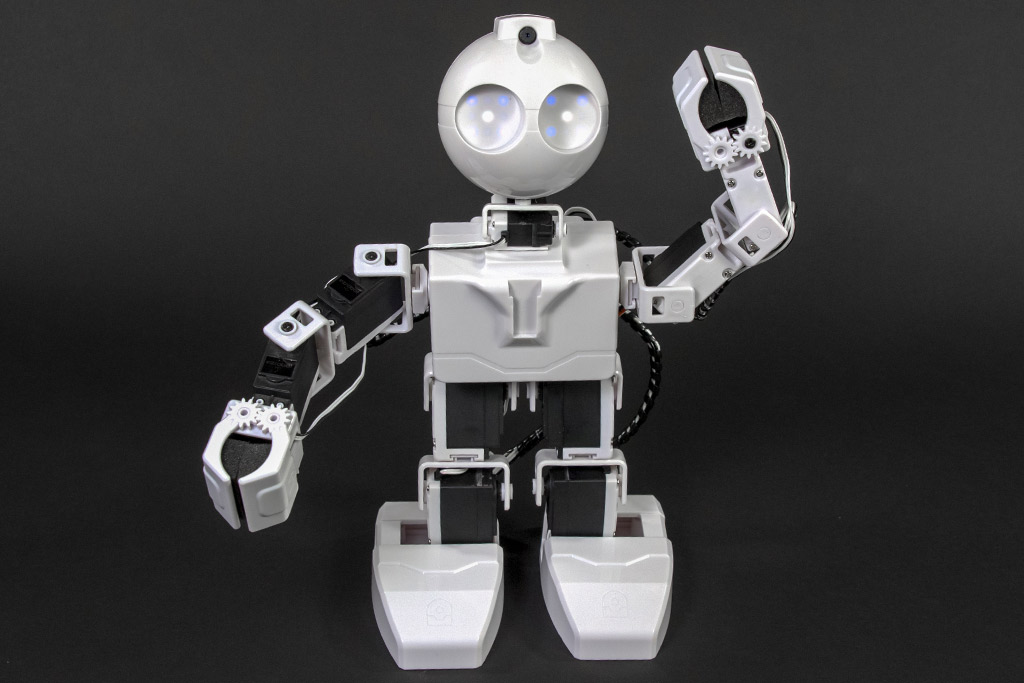

JD Humanoid

by EZ-Robot

JD humanoid robot kit - WiFi-enabled, 16 DOF with metal-gear servos; easy, fun, educational, available from the EZ-Robot online store.

Wi-Fi / USB

Servos

24

Camera

Audio

UART

3

I2C

ADC

8

Digital

24

Related Robot Skill (view all robot skills)

File Manager

by Synthiam

Displays files currently open for reading by scripts, shows only read-opened files, helps diagnose read/write locks and file access errors.

hi ezang

you have to ad the male or female end part .

send.zip

Thanks Nomad,

I will try them out

the micro servo goes in the cover complete . dont take the back cover from the micro servo off .

how to get very strong 3d parts .wel this guy in the video knows it . i tested the settings and my parts looking very nice and are alot more stronger .

Thanks Nomad. That was really interesting. I don't 3D print but I enjoyed that and learned something.

I really want to get into 3D printing someday soon. I can see how it could help me build better stuff. However, I'm having a hard time moving away from old ways. I'm kinda old school when it comes to building something. I'll grab some aluminum or polycarbonate, a bandsaw and drill press and start measuring, cutting and shaping.

I have a hard time sitting down and taking the time to put a design into a CAD program or onto paper to plan it first. I should try to move away from this a little and get the process out of my head. That may keep me from having to rebuild things two or three times to get them to work. LOL! I make so many brackets by hand to mount components. I've always thought that if I could do the process in software first and then 3D print them, This would be so much better. However till recently I felt that 3D printing was still not to the point that it was easy to understand, implement with good results.

Then there is the final print on areas that need to look smooth. Resolution is very important to me and I hate the finishing process that would need to be done to make a 3D printed surface look smooth. I understand there are methods to make this process easier and the printers are coming now that print in higher resolutions. I think these printers and software are just about ready for someone like me to make the jump into this world.

I really think it's the way of the future for building things. I saw a movie recently where there was a spaceship that crashed on Mars. They needed to get to the base that was set up for them before they got there. The needed to 3D print the parts they needed for the damaged equipment so they could survive. This makes so much more sense then trying to carry parts you think you may need into places you have no way to get them.

The big thing I dream of doing with a 3D printer (other then make small parts and brackets) is to start printing a full sized Robby the Robot from Forbidden Planet. I've found that there are high quality STL's of this life sized robot. I couldn't imagen how long it would take to print the pieces for something like this. I can seeing me having to buy 2 or three printers! LOL

hi dave

i like to modified parts and make them stronger . her's an excample . fragiel trigger from a AR15 . i made it thicker in TC and see the result . you will have some errors and forget some things withs is very annoing. but doing is again makes you mentally stronger . the feeling when , your print is sucsesfull is awesome . but you have to learn bit by bit . the creality ender3 pro is the best for beginners . and use glas bed . also remember when you mod a part most likly you have to adjust more .

reinforced trigger . top has 1 mm spring in it .

if you have stl's from robbie . i have time enought to have a look at it .

hi

printing a riffle is not so very robotic . but its a great way to understand 3d printing. all the stuff that can go wrong , what you forgot to ad . it similar like what iphone did . you take designs from others and modified them . ask the designers or mention his/her name , in your design . so they get the credit . here sofar my design AR-15 . with scope and org viser . i used a door spy funny . now soon there will be no door spy availble in stores just kidding i hope .

just kidding i hope .

you can still use the org viser and its adjustble in hight . you can see thru , underneed the top rail and use it .

is someone wants to try this .i send you a folder for free . also other type's are availeble for free . if you can let it work , you can 3d print . also needed are springs , bolts and nut . i dont want to place the folder here cause its a robotic forum .

here some more pictures .

you can take off the scopen and top rail . its changeble .