Asked

— Edited

3D Print Jd Head

hi

has anyone printed a jd head?my question is ,how do you print the head on the printbed?

thank you

Related Hardware (view all EZB hardware)

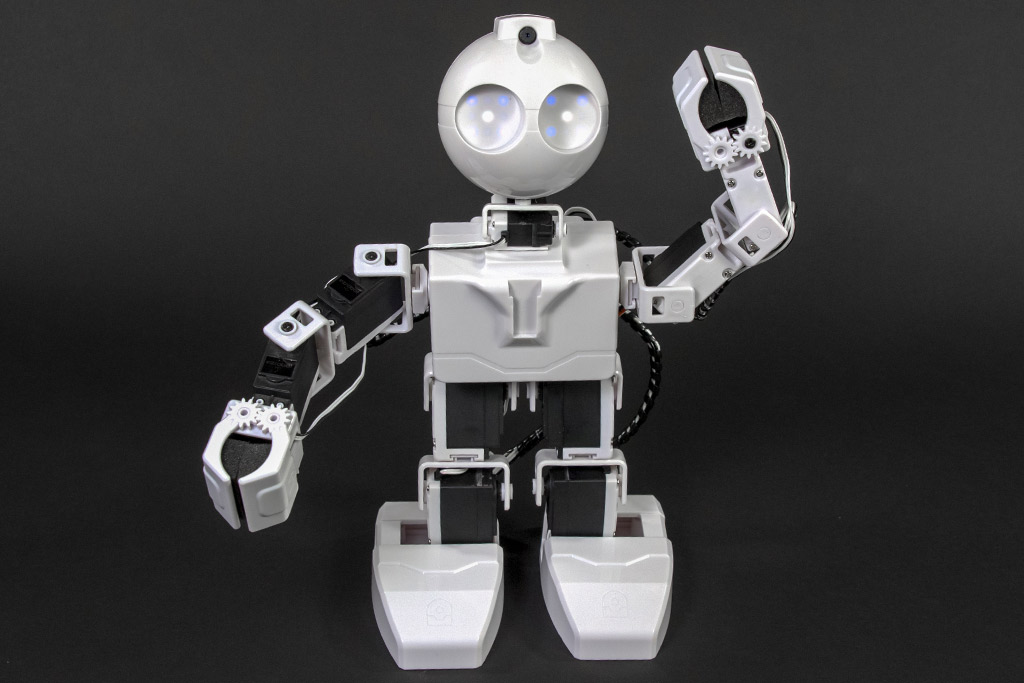

JD Humanoid

by EZ-Robot

JD humanoid robot kit - WiFi-enabled, 16 DOF with metal-gear servos; easy, fun, educational, available from the EZ-Robot online store.

Wi-Fi / USB

Servos

24

Camera

Audio

UART

3

I2C

ADC

8

Digital

24

Related Robot Skill (view all robot skills)

File Manager

by Synthiam

Displays files currently open for reading by scripts, shows only read-opened files, helps diagnose read/write locks and file access errors.

Brother, vent, vent, vent. I truly hope you and everyone living with you will be ok and have not been permanently hurt by this.

Are you going to build and enclosure like in the video you attached? Seems like the thing to do. You've said before that you live in a apartment building? Hopefully you have a way to vent the fumes outside. Maybe through the bathroom exhaust vent?

hi dave

yes i need to build something if wanna print more . i had no idea i was sick from printing . and i had two printers going . there chould be a warning when bying these printers . i put it up here for people who prints all night for days . be carefull guy's youre in the danger zone before you notest its the printer .

howdy folks

first thing. i had some problem with my extruder . filament didn go thru . as i learned to check the copper gear and it was worn out . you can if you dont have a spare lift the gear up or down to find a good spot .

here a picture worned gear . the middle of the gear is almost gone .

and so i placed a new one . and had some 70% improvement so not fully fixed. i was practise with some flex filament . and it was diff . but then i notest something els .

i learned when one thing is worned out replace the complete set . as seen picture below .amazing . the filament went thru the metal hole .

and now some good news . the test hand is almost done .

TADA

my first flex knokkels . temp 239 nozzle and bed 60 temp. standard speed ender3 pro . medium flex is skin color . the most importent i notest is , you have to adjust the spring from the , extruder very accurate . you have to do that with a raft . that gifs you plenty of time to adjust . flex is strecheble and , bent before its thru the extruder . its really adjusting by a 1/4 of a turn , and keep your eyes on the raft and the gear very carefull . when it start to , go wrong pinch the spring together and pull back the flex until the knob is out and adjust 1/4 . of a circle. you have to keep this doing aslong the flex goes constant , smooth thru the extruder . i had to try about 5 times .

flex filament

now have some rest and making bagage am going on holiday tomorow . DUH.

here a short video . from the hand .

https://www.youtube.com/shorts/cgwHdjULjag

Wow, you must really run that printer of yours to wear it out like that. LOL.

That Flex seems to work amazing for that hand. I wonder how it will stand up to ware as the joint gets bend back and forth over time.

Have fun! Don't forget to vent that printer.

hey dave

well we will know howlong the knokkels last . i was surprized that the ender3 pro , could print flex . normal is only for . PLA?ABS? and PTEG . another problem is will the fingers go back in srand position .

thanks

solved the finger back to position .it needs a little spring . yellow arrows is a tiny space for the spring to sit .

and a short video how the finger retracts . i tested a random spring .

https://www.youtube.com/shorts/j6ZxX9W9WOY

goodmorning all

i woke up and instant i wanted to print . haha problem nm 1 filament got stuck in the nozzle . okay set nozzle temp 255 and you can pull out the filament . then came THE axcully problem that cause all other problems .and that is the complete , block were the nozzle sits was loose ,thinking how i gonna solved that ? after some time , i saw the light .see picture . the below roller has an axel thats out of center . when you use L-wrench and turn to left or right you put back good tention on the top 2 roller . and that was the main problem of bad always diff prints . level the bed after that .