Asked

— Edited

3D Print Jd Head

hi

has anyone printed a jd head?my question is ,how do you print the head on the printbed?

thank you

Related Hardware (view all EZB hardware)

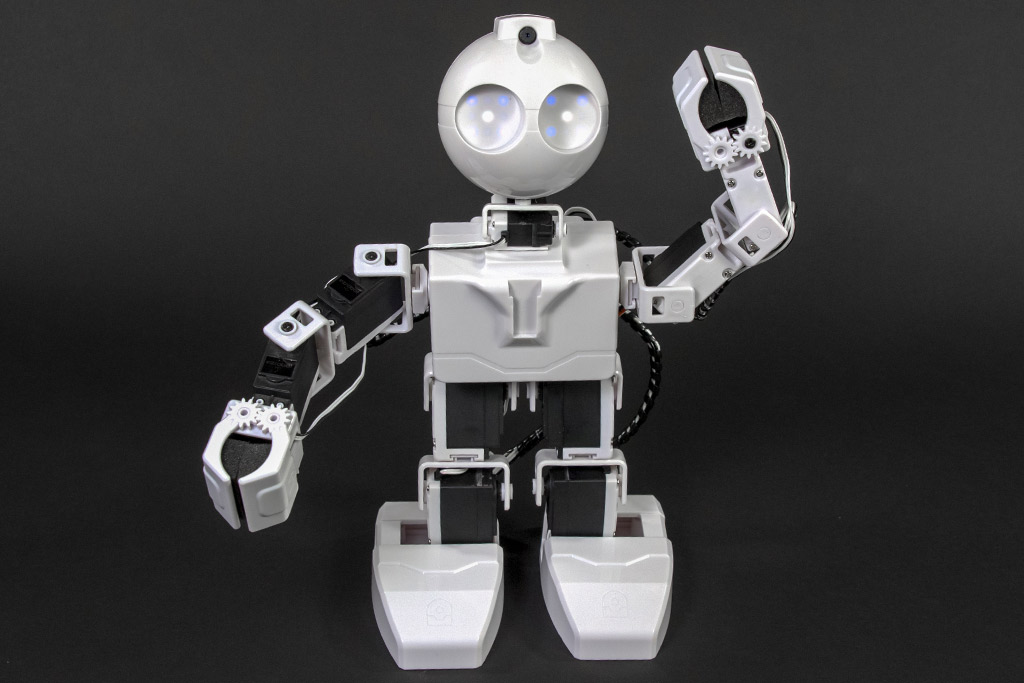

JD Humanoid

by EZ-Robot

JD humanoid robot kit - WiFi-enabled, 16 DOF with metal-gear servos; easy, fun, educational, available from the EZ-Robot online store.

Wi-Fi / USB

Servos

24

Camera

Audio

UART

3

I2C

ADC

8

Digital

24

Related Robot Skill (view all robot skills)

File Manager

by Synthiam

Displays files currently open for reading by scripts, shows only read-opened files, helps diagnose read/write locks and file access errors.

okay i have printed my B9 hehe.tomorrow i will print the transparent parts.

Dave snuffleapagus is gonna love that! If it was a bit bigger, you could add servos and an iotiny

hi dj

i dont have a big printer for the size mini servo's.but i can make it bigger.

i forgot i dont have pla transparent.so made it red.i can scale up to 350 size in cura .

@Nomad 6R Hi I like your B9, very nice if you are thinking of printing transparent parts I recommend using PMMA filament it is very clear. print slower and hotter, and you can finish with acetone fuming just like ABS, for a great finish. How long did it take to print your B9?:D

thank you for the tip.i saw a video about fuming.the printing of the little B9 a few houres cant say excacly howlong.

i forgot what is the recomended speed for PMMA ?i am doing the grippers on scale 350 in cura ,it takes 3.40 houres

@Nomad 6R For fuming I use a metal paint can and I put paper towels around the insides held on with a couple of magnets. then wet the towels with acetone put your print in the can on a small piece of wood in the bottom and put the lid on. I do this outside as the acetone is very strong. use a test piece to test for time check every 10 minutes. for printing I print at 60 and the extruder temp is 240 deg. for clear parts do not use any infull if you can/