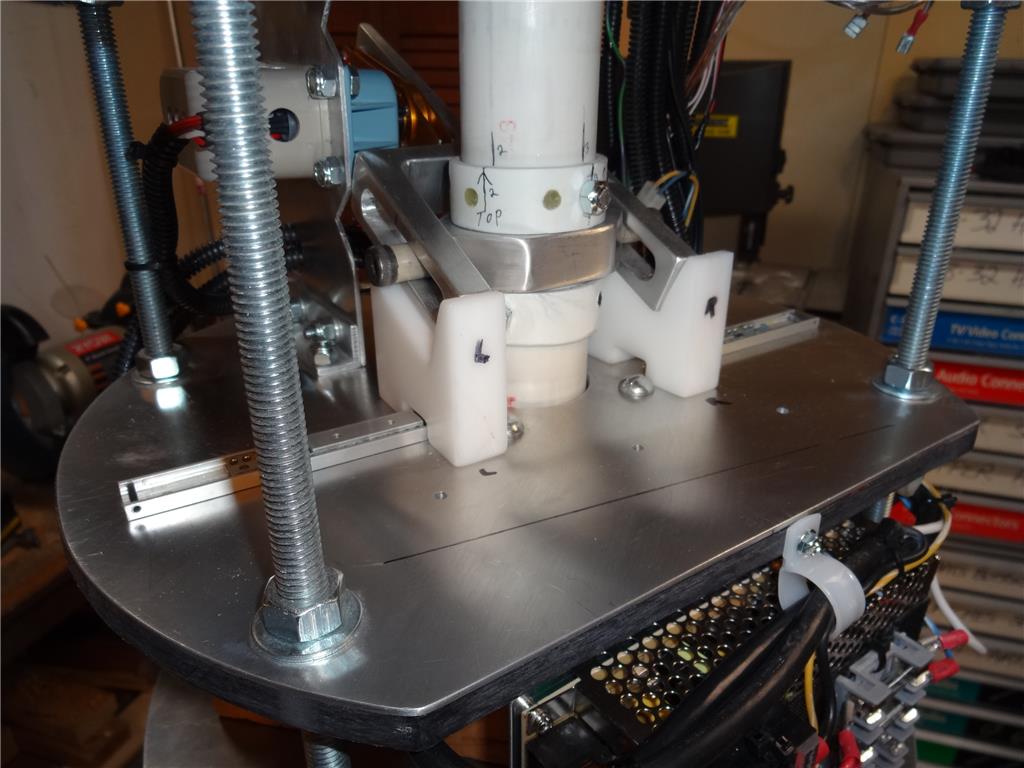

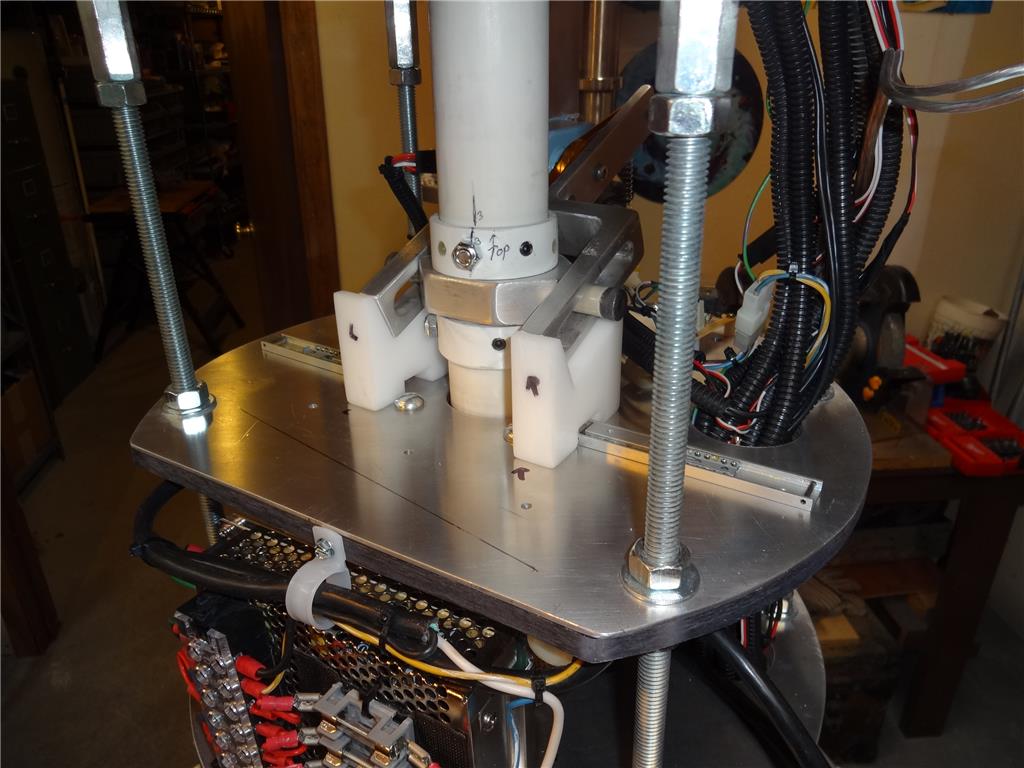

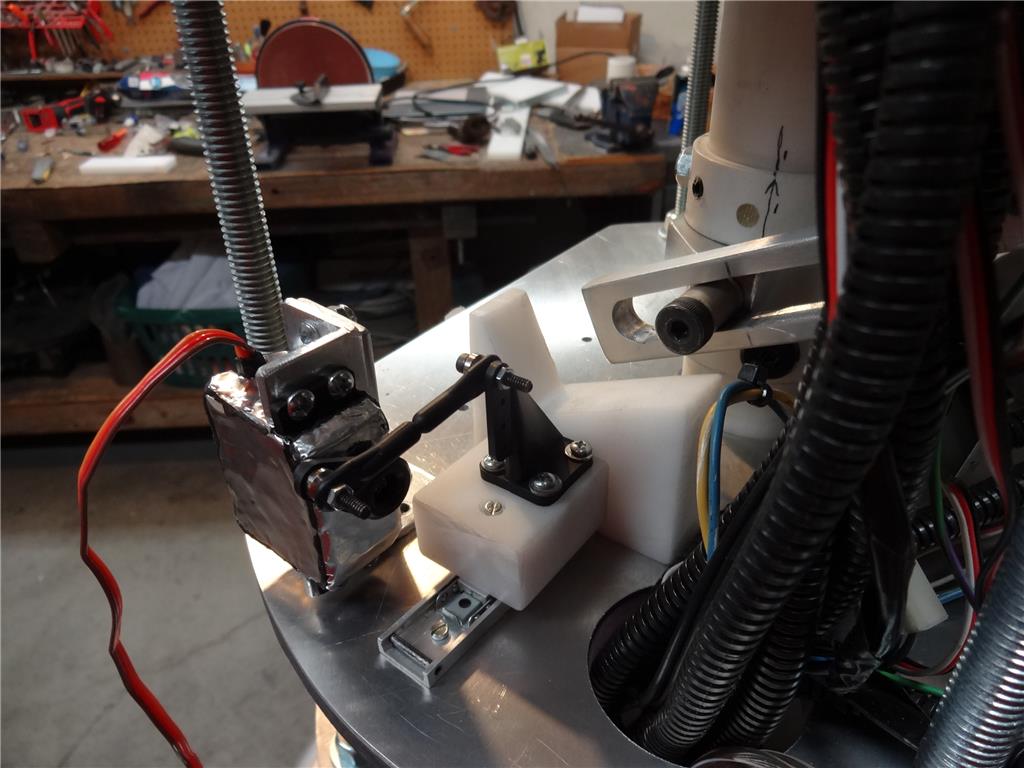

I need to find a material that will assist my bubble lifter servo lift the weight of my B9's finished bubble. It probably weighs about 5 lbs or more. Without a helper the HD servo I'm using now struggles to lift it and is slow to start moving upwards because of the weight. Up till now I've used a stiff spring as a servo helper but it was causing problems due to the way I had it attached to the lifting fork that is in turn attached to the servo and the neck pipe. The spring was attached to the front of the fork and pulling up on just one side causing binding of the neck pipe. I want to move it to the rear "handle" of the fork and perhaps make the tension adjustable somehow (adding a turnbuckle?). I also thought I'd like to use a different material other than a metal spring. Maybe a bungee cord and make it adjustable. The thing is, whatever I use I don't want the material to degrade over time or creep out of adjustment due to stretching. Does anyone have any ideas on what material I could use that would stand the abuse of wright, movement and time? I'll attach a pic or two of my present design (without any spring attached). Thanks!

Asked

— Edited

Hi Dave, I still am curious about a spring in the neck tube. Is it possible? My direction of thought is, you don't have to 100% remove the full weight of the head, just enough to get the servo load to be within it's best operating range. Maybe counteract some weight in the center (spring in the tube) and the rest which is adjustable on the fork. I am also curious about the slip fit of the tube on tube. Does sticking ever occur? I understand you don't want to do a redesign and build now. I am just throwing out opinions. I really enjoy your buddy.

Thanks for the interest and thought you're putting into this Andy. You have some good ideas here. However, if I understand what you're suggesting, I can't have anything attached or in the neck pipe itself other than a couple floating electrical wires going up to the brain. It needs to float independently of the servo lifting it up and down or anything else. The reason is that the neck pipe needs to be able to move in 4 directions; up, down, and rotate back and forth. The back and forth movement is provided by the radar that the pipe slides through above. The pipe has a key attached that slides through a slightly larger keyway in the radar. When the radar turns, it grabs the key on the pipe and turns it along with the bubble attached at the top at the same time. This way the bubble and brain at the top of the neck tube turns at the same rate and direction as the radar and also is able to move up and down.

There is no sticking. There is a PVC ring attached to the neck pipe that rests on top of a floating aluminum collar that in turn slips in oblong holes in the lifting fork. You can see this all in my first post of this thread. The PVC plastic to aluminum is very smooth. Of course there is a little drag I'd like to get rid of. If I keep this system I would like to add something to virtually eliminate that. I was thinking of something like an omni wheel or roller bearings. I think what would work better is a flat piece of self lubricating tribopolymer. Basically a self lubing peace a plastic. This product is mind blowing. Igus sells plastic bearings made from this stuff. It's the same material that I'm using in the bearing in my robot's arms. After hundreds of operations there is no wear at all and the joint glides like they are on ice.

@Dave, I like your linear actuator train of thought just a little spendy. Is there a way you could mount the camera showing the bubble going up and down on that tube. From your Photos and video, it's hard to see if that PVC pipe moving up and down. I seen it for a split second on your last video just a little shaky. A compression spring I was talking about would be like comparing to a ball point pen.

But it sounds like you have a good game plan and I do like your videos. Good luck!

Thanks for the reply Dave. I understand more clearly. The radar unit complicates the internal spring idea. The waist movement rules out the counterweight concept. Anti-Gravity units aren't available... Yet.... (Filling the Bubble with Helium is out of the question) We will keep thinking.

Here's a good shot of the neck tube going up and down through the radar as it moves. Note that the bubbie is not mounted so there is no load on the bubble lifter servo. You'll see it at about the 2:42 mark:

Ignore the EZ Robot problem I'm talking about. This was my issue, not EZ Robot

@Dave, first off thanks for the good laughs every time I watch you talking to B9, It's great!

Are all of your EZB's ver3 or do you have a mix?

This is an old Video. I've upgraded all to ver 4.

Ok, I was woundering, you got me

I still love your videos when B9 is talking back to you

Anyway, I think you've given up on the compression spring that's only thing I can think of besides the linear actuator. Besides that I'm not sure if they make an inside diameter of 1 1/2 or 2 inches however round your PVC Tube.

I'll let you and the Masters figure that out, anyway love the videos.

Cheers