jstarne1

Ok so i have a few people who want me to cast them omnibot or 2000 tires. The process is fairly simple but most effective if you have a vacuum pump.

First you need you tire specimen to copy. In this case i removed a reconditioned tire from my omnibot 2000. As long as the specimen is physically the shape you want you can use it. You may also use a 3d printer to print a hard specimen from pla. This gives you the option to make custome tires.

There are two options , one is laying the tire flat by cutting it somewhere. Use hotglue to affix it to the bottom of your mold box. The mold box should be slightly bigger that your part.

im using alumilite silicon resin in this case. It is not the cheapest but it is a product that can cure in regular atmosphere without a oven.

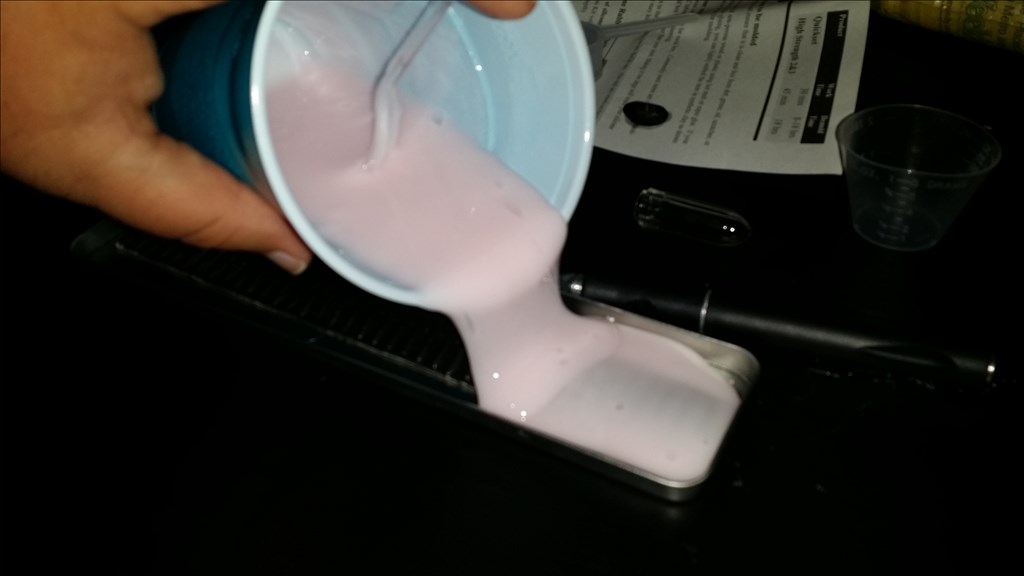

The mix is 10 to 1 , you pour over your part and completely submerge it. You need it at least 1/8th inch deep and around.

I used a robinair vacuum pump and a custom vacuum chamber. The silicon was degassed to 25 psig. At that point silicon boils.

Sidenote : this is how to cast with the tire laying flat. However it can be done by laying a tire on its side as a whole , hotglue to the bottom and fill. Make sure there is 1/8th to 1/4 inch of silicon between walls and depth from the top.

the silicon will take 24 hours to cure , then i will move to the "decasting" phase removing the specimen and box.

Remove the original tire , it peels away easily from the slick silicone. Im really shocked how much a difference the vacuum degassing makes. It has no bubbles , slick surface and high detail. Once the part is removed let it air out for a few hours. It seems fully cured but the mold will become a bit more rigid over night.

Hi Josh! I wish you could also do the round tread already - I have a felling that no matter how you glue it the rubber tread would alwqys somehow come off if its just a flat piece.... Mike

Honestly i have tried casting a old tire as a whole but the problem is that the tire must be slightly smaller so that there is tension when you install the new tire. Without tension it slides around a bit and tread could come off the rim. A few drops of CA glue or high temp hot glue will securely affix the new tread to a hub. It doesnt take too much.

As promised , a better pic showing how flexible this mold is with flash.

Looking good!

Thanks for this. While I don't have a need for this right now, I appreciate you sharing. It's something I am sure I will use at some point. Thanks again!

Wow, that's soooo cool. You make it look so easy. Nice job and thanks for the tutorial.

Just a note , you must use a release agent on the mold before pouring in material to cast or your tread will adhere to the mold. Sadly i just made that mistake ! Oops. Well i can pour another mold no biggie but hopefully it doesnt upset Ed , the guy im making them for. The mold has to cure overnight.