Setting Up L298n H-Bridge This tutorial assumes only a single combined speed control for both motors. For independent speed of each motor the tutorial will be slightly different - See post #2 of this topic.

Assuming ports D15, D16, D17, D18 & D19 D15 Signal > Left Trigger A (In 1) D16 Signal > Left Trigger B (In 2) D17 Signal > Right Trigger A (In 3) D18 Signal > Right Trigger B (In 4)

D19 VCC > H-Bridge 5V D19 Ground > H-Bridge Ground D19 Signal > H-Bridge ENA & ENB

D19 Signal will need to be connected to 2 pins on the H-Bridge and the jumpers on the H-Bridge removed. I made a Y cable out of a couple of jumper cables.

Connect the positive of the battery to the H-Bridge VCC

Connect motor 1 to the Out 1 and Out 2 terminals Connect motor 2 to the Out 3 and Out 4 terminals

In ARC add a 4 Wire H-Bridge control and a PWM control.

Set up the H-Bridge control as the above D15 to D18 on LTA, LTB, RTA and RTB Set up the PWM control to D19

To use, set the PWM to 100% (or a lower value if you want it slower) - I have mine set to 100% in an init script that is run on successful connection of the EZ-B. Use the H-Bridge control and the motors should move.

Here is a project with both controls added, you can save it and merge it with your project (or open it and test the H-Bridge). It's also accessible in ARC by opening from the cloud.

Note: The PWM wire is optional. If you wanted to save a digital port and lose speed control you could connect any of D15 to D18's VCC to the H-Bridge 5V and any of the D15 to D18's Ground to the H-Bridge Ground. Keep the jumpers on between ENA and 5v and ENB and 5v.

If your H-Bridge looks different, they are pretty much all much of a muchness. A H-Bridge generally has 4 inputs to control the 2 motors plus 1 or 2 inputs for speed control. The same principle as above can be applied.

Signal wires from Digital ports to each of the inputs to control the motors. Generally labeled In1 to In4 or AIn1, AIn2, BIn1 and BIn2. Signal wires (this can be combined for 1 port if you don't want individual speed control from side to side) for the PWM or speed. Generally labelled as ENa and ENb. +5V or VIn is generally the 5V from the EZ-B Vm is generally the supply to the motors taken from the battery. Ground is always Ground, taken from any ground since it's a common ground.

A simple truth table for how the H-Bridge works.

In4 | In3 | In2 | In1 | Function

-----+-----+-----+-----+--------------

0 | 0 | 0 | 0 | Stop/Free Wheel

0 | 0 | 0 | 1 | Motor 1 Forward

0 | 0 | 1 | 0 | Motor 1 Reverse

0 | 0 | 1 | 1 | Motor 1 Brake

0 | 1 | 0 | 0 | Motor 2 Forward

1 | 0 | 0 | 0 | Motor 2 Reverse

1 | 1 | 0 | 0 | Motor 2 Brake

So to use that on the robot, setting digital to on (1) and off (0) as follows

In4 | In3 | In2 | In1 | Function

-----+-----+-----+-----+--------------

0 | 1 | 0 | 1 | Robot Forward

1 | 0 | 1 | 0 | Robot Reverse

1 | 0 | 0 | 1 | Robot Turn Left (or right depending on motor orientation)

0 | 1 | 1 | 0 | Robot Turn Right (or left depending on motor orientation)

0 | 0 | 0 | 0 | Robot Stop

EZ-B V4 Usage

With the EZ-B V4 there is a slight difference when connecting the L298n H-Bridge up in that the Vcc pins of the V4 have the same voltage as VIn i.e. if you supply the EZ-B V4 with a 7.4v 2s LiPo battery you will get 7.4v on the Vcc pins of the EZ-B.

The L298n H-Bridge, as previously explained has a terminal for +5V which, on the EZ-B V3 was fine to supply from one of the digital ports Vcc however with the V4 this is not the case.

Rather than supply the L298n with +5V we need to not connect this terminal and press the switch on the H-Bridge so that it uses it's on board regulators to provide its own 5V from the Vcc supplied.

All other connections remain as previously explained.

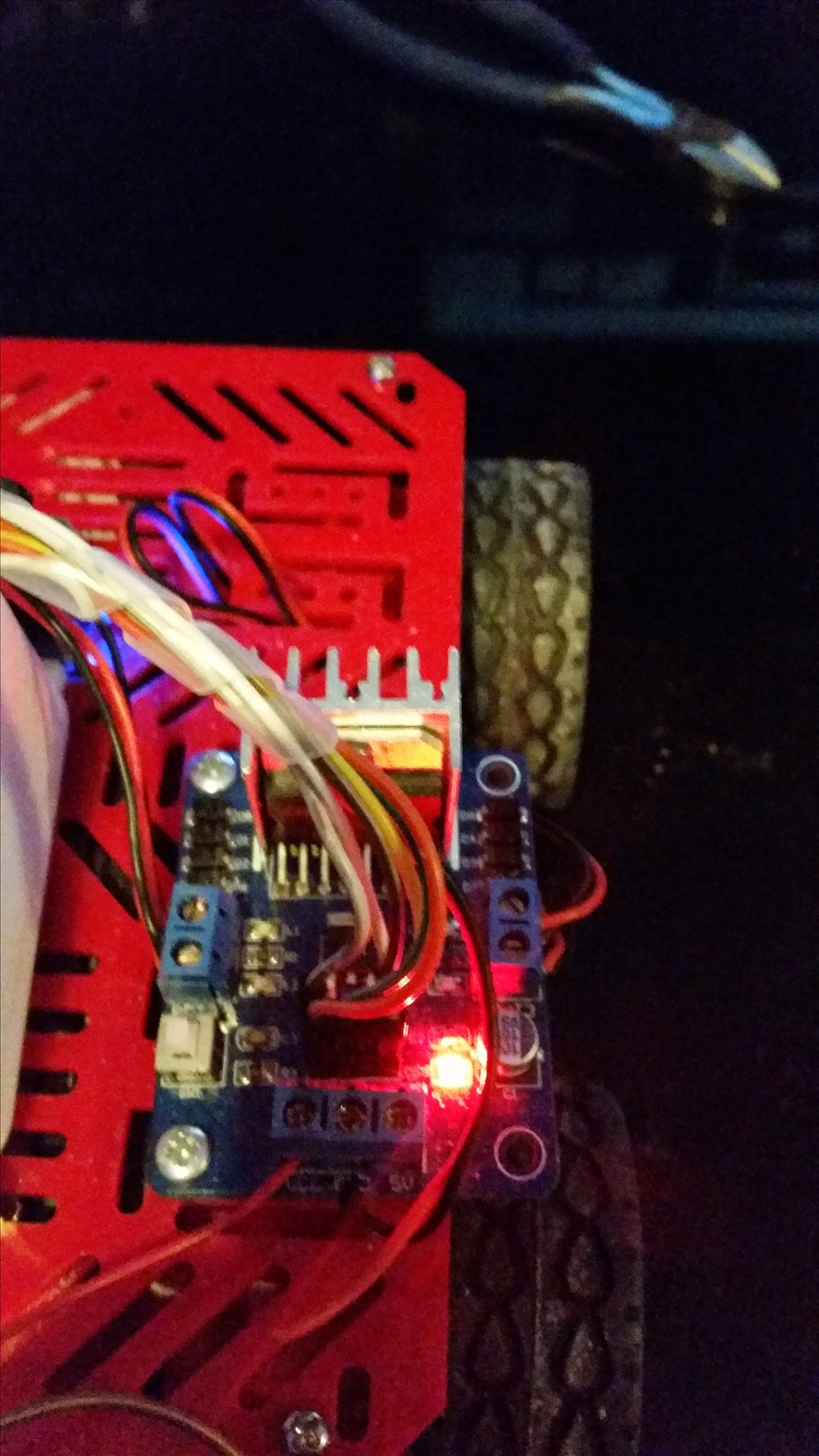

Pushing this button will enable the on board regulators. When enabled it may indicate so with a red LED.

On the EZ-B side, the connections would be pretty much as previously with the exception of the Vcc. On upgrading my test bot I simply disconnected the Vcc on the H-Bridge side so that my connections wouldn't require changing.

On the H-Bridge side, connections remained the same as previously however the +5V is disconnected.

That's all there is to it.

Update: 17/06/2014 (or 06/17/2014 if you write your dates wrong...)

Alternative wiring for a simpler method

The connections on the L298n are simply;

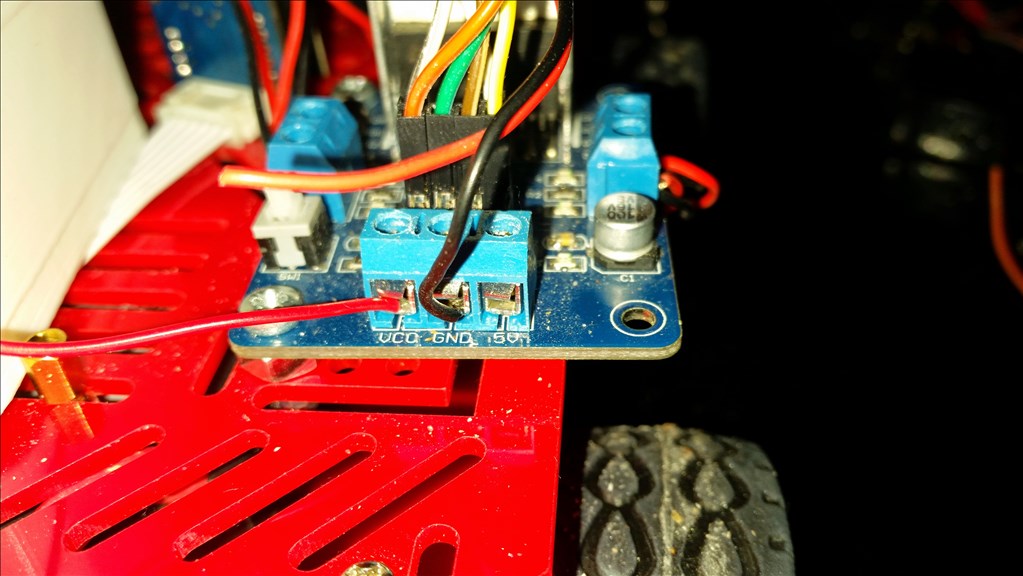

Vcc = Motor Supply Positive Gnd = Motor Supply Ground (ensure this is common if using more than one supply) +5V = Not Connected

In1 = Digital Port Signal (i.e. D8) In2 = Digital Port Signal (i.e. D9) In3 = Digital Port Signal (i.e. D10) In4 = Digital Port Signal (i.e. D11) EnA = Digital Port Signal (i.e. D12)* EnB = Digital Port Signal (i.e. D13)*

- EnA & EnB connections optional for speed control, If speed control is not required connect the two jumpers which come with the L298n to link EnA to the +5v pin to it's right and EnB to the +5v pin to it's left. If combined speed control is required (i.e. one speed control for both channels) a Y-cable can be used to connect both EnA and EnB to one Digital Port Signal (i.e. D12).

No ground or Vcc from the EZ-B to the L298n is required if you have a single source for both EZ-B and L298n or if you have a common ground.

You must make sure you press the switch to enable the on board 5V regulator circuit otherwise it will not operate

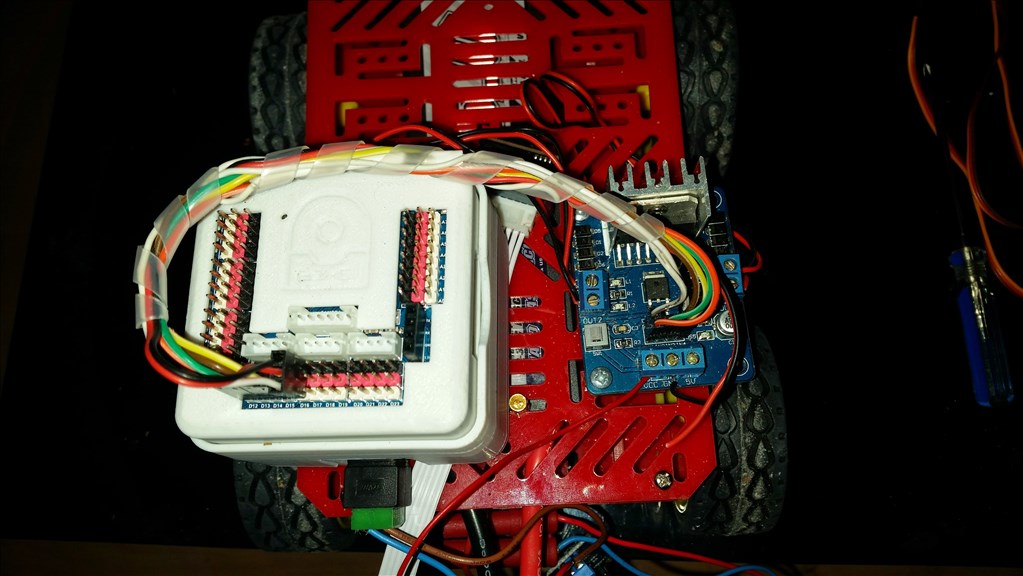

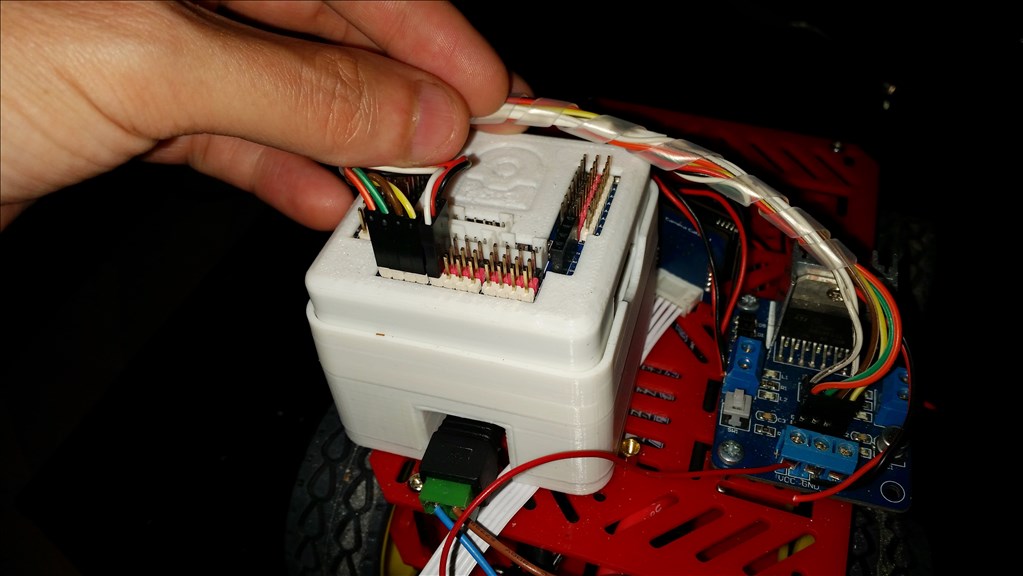

Some photos (I'll change them once I get chance to edit and tidy them up but no idea when I'll get the chance so here's the unedited ones).

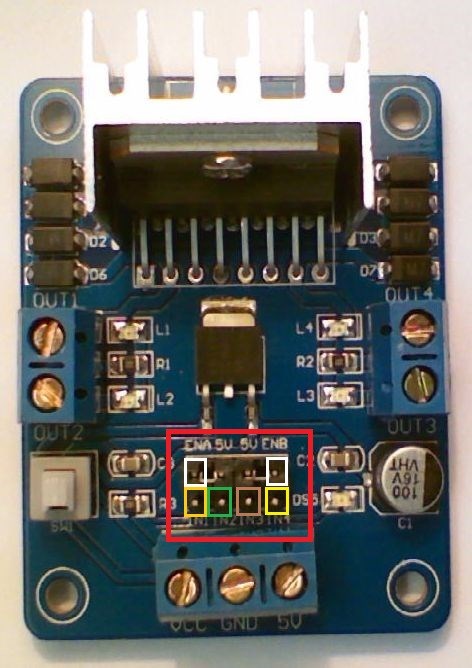

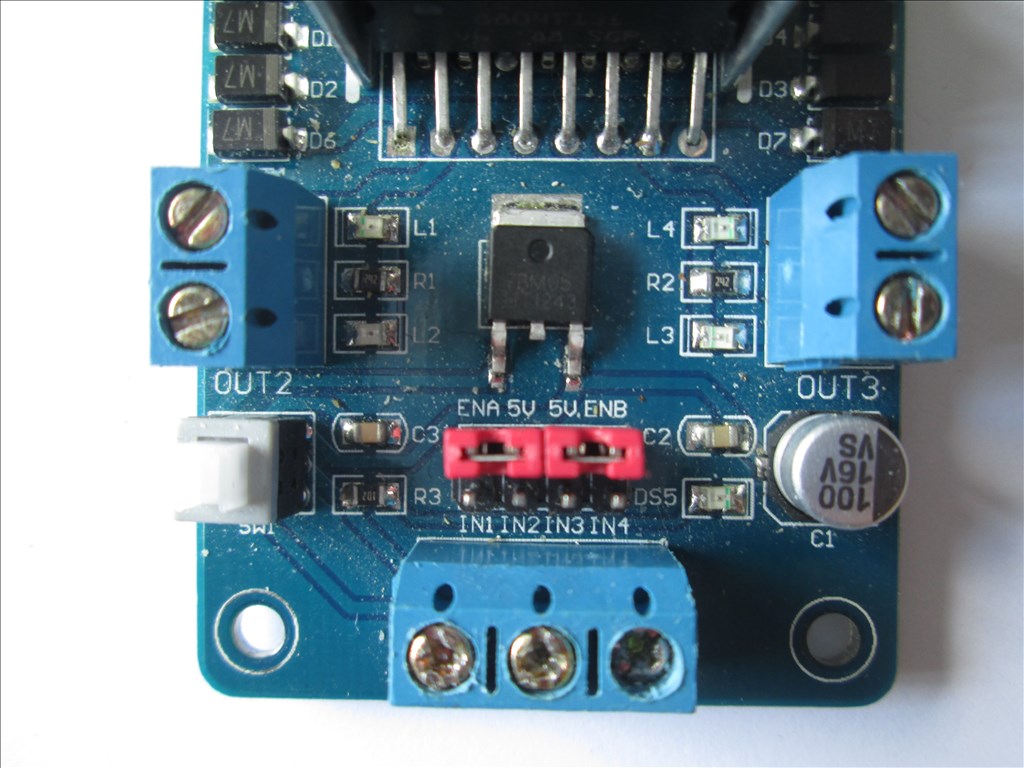

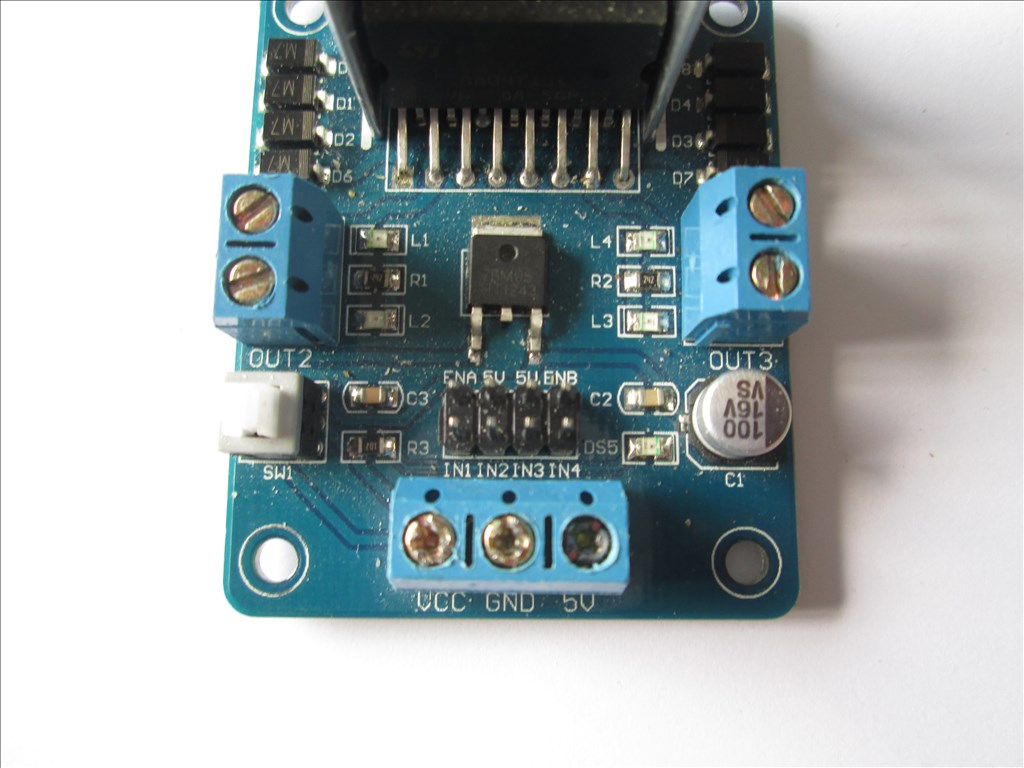

The L298n in it's stock state

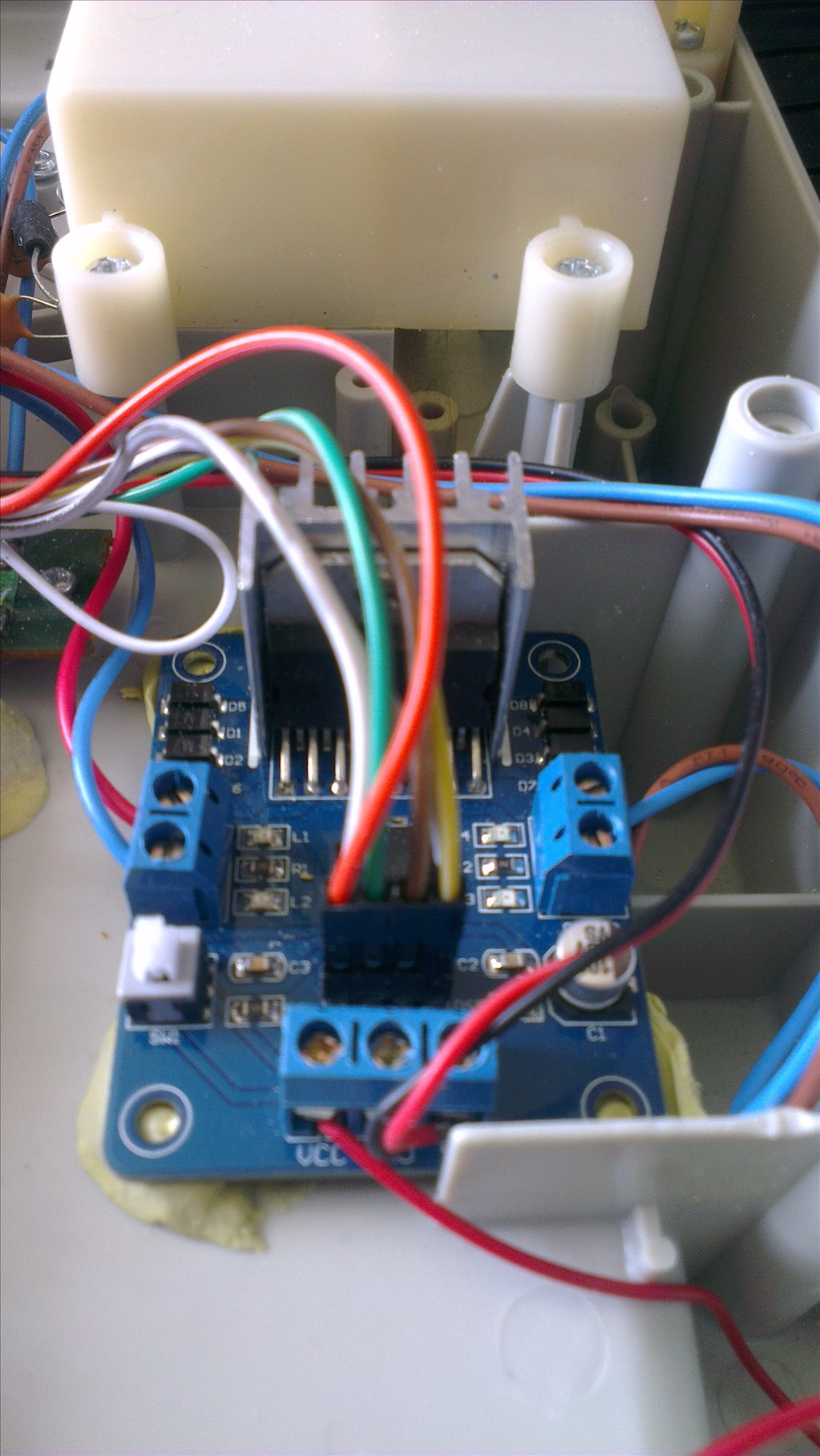

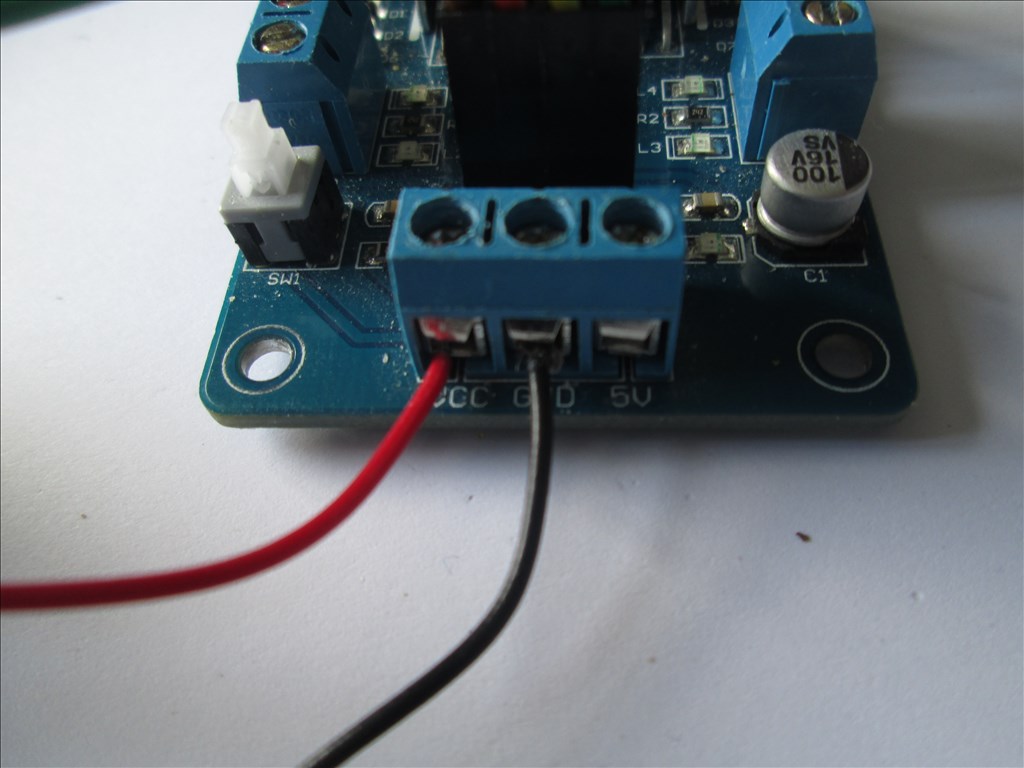

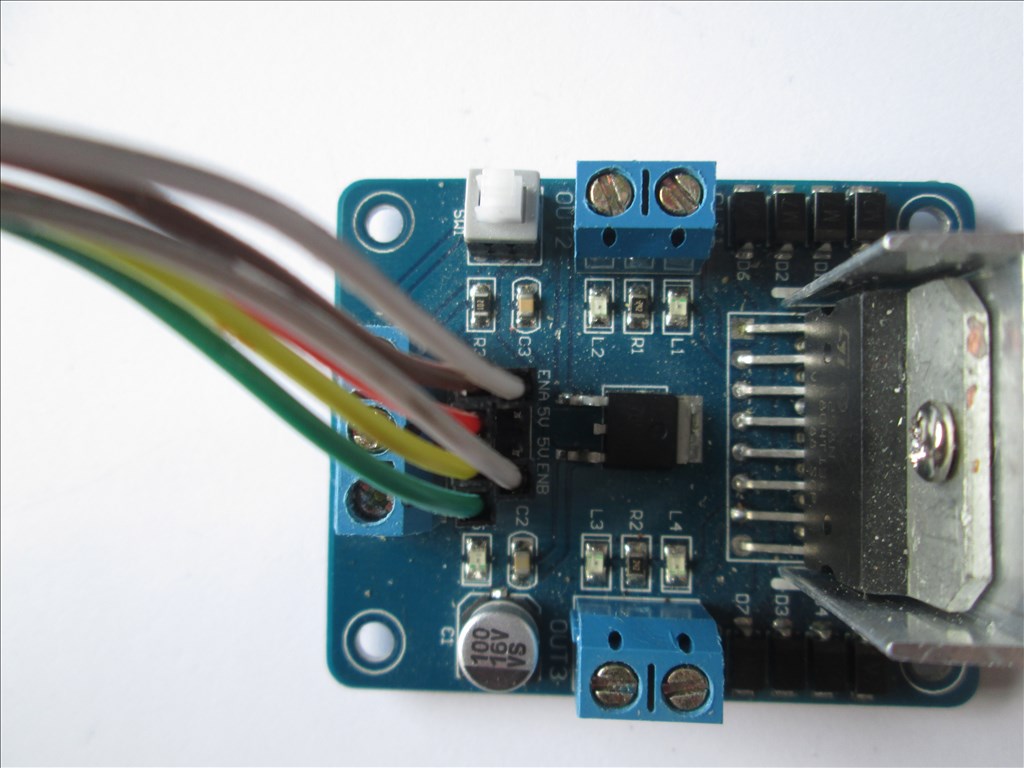

The L298n wired power connections

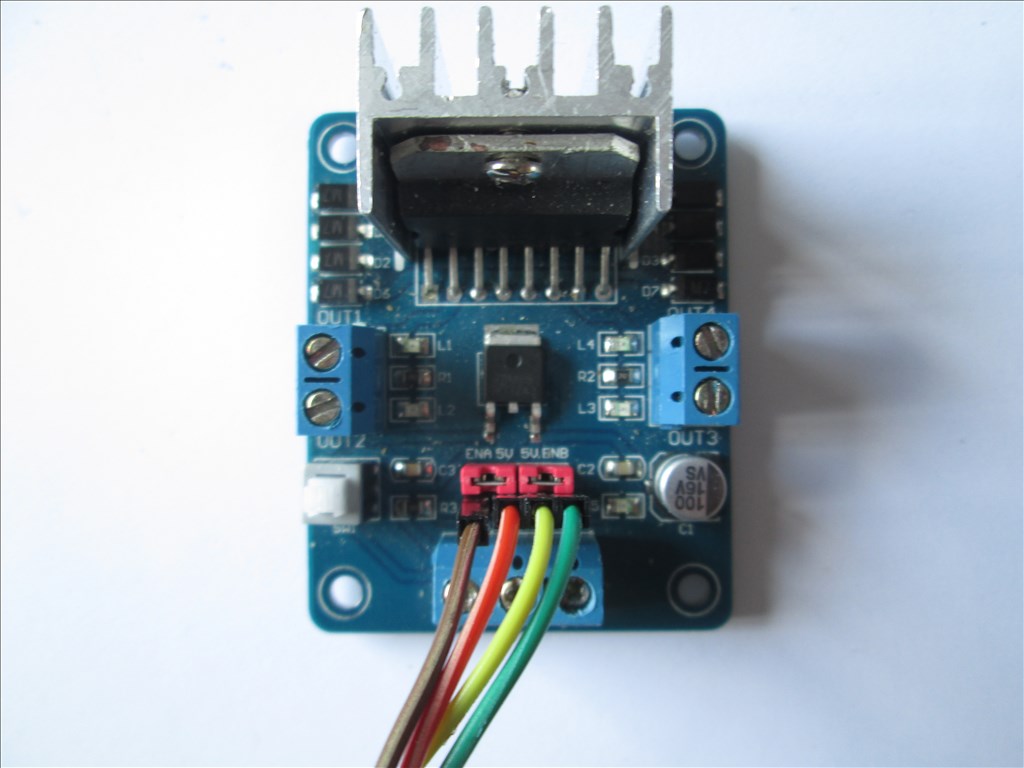

The L298n wired for no speed control

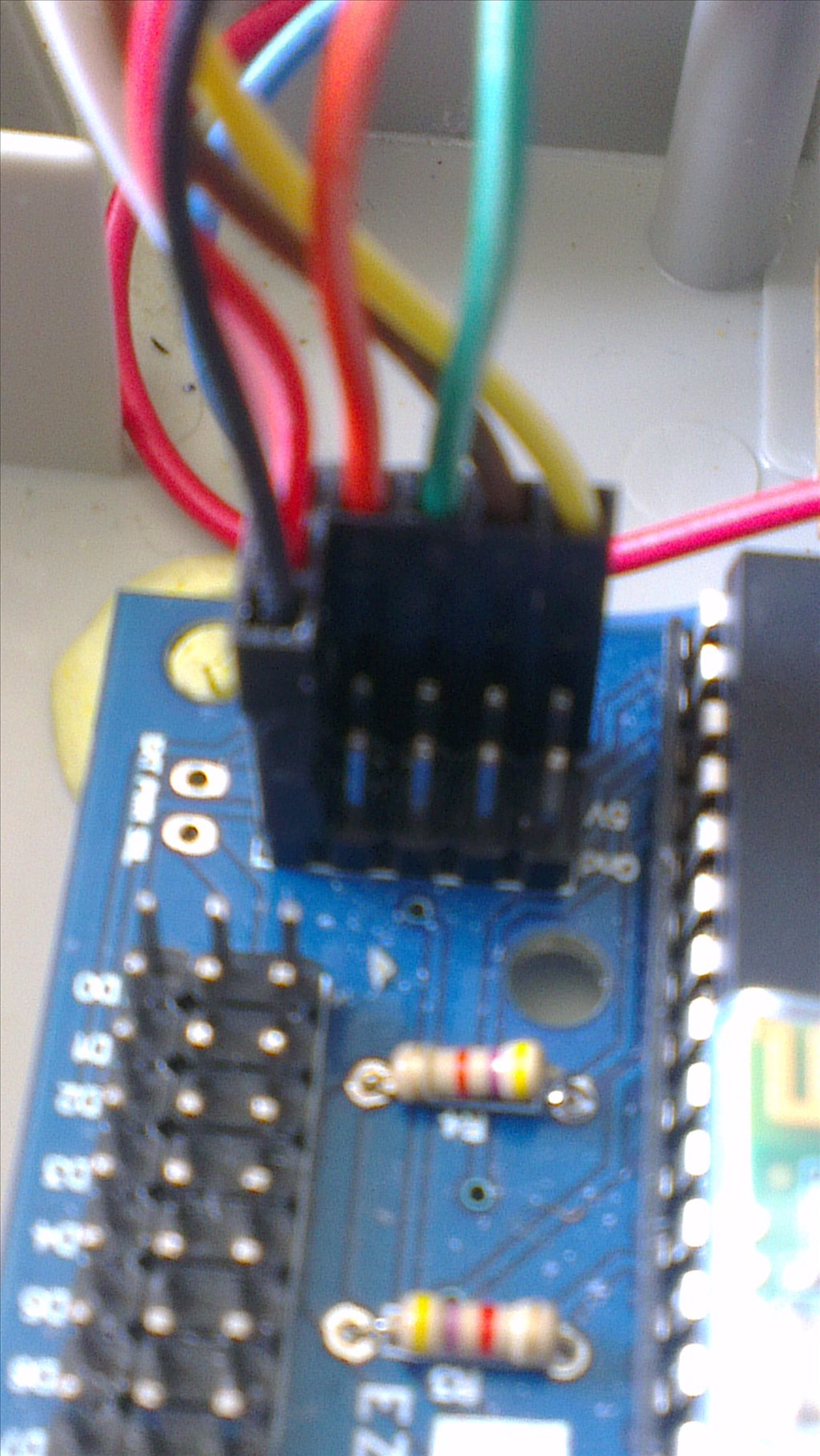

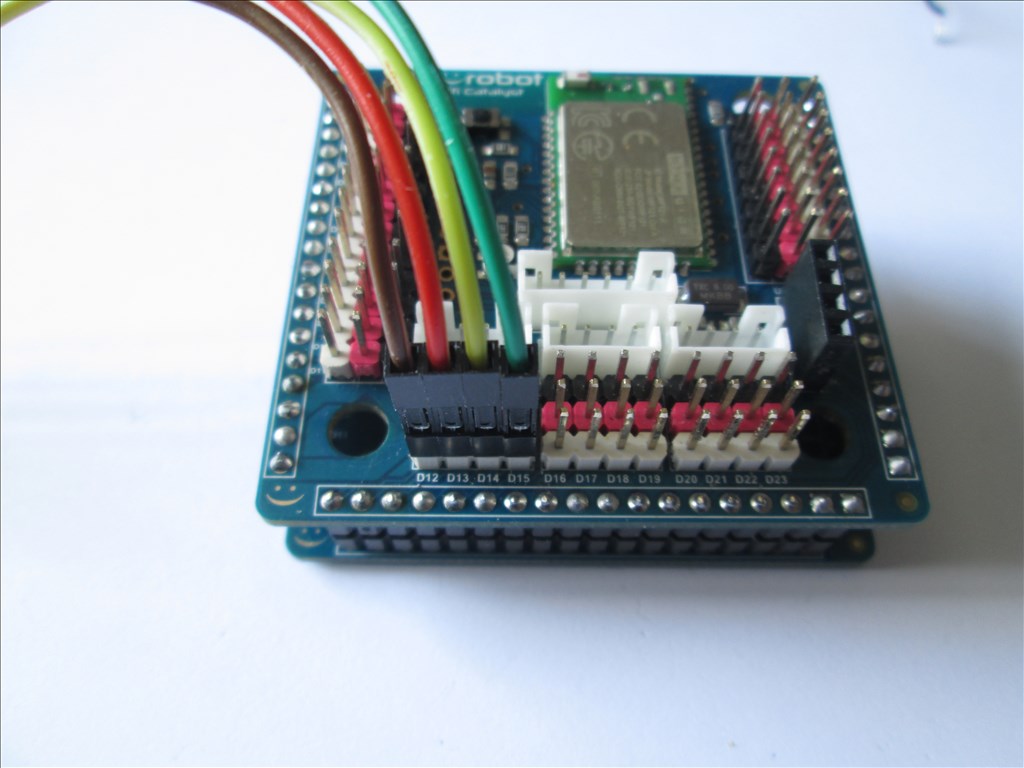

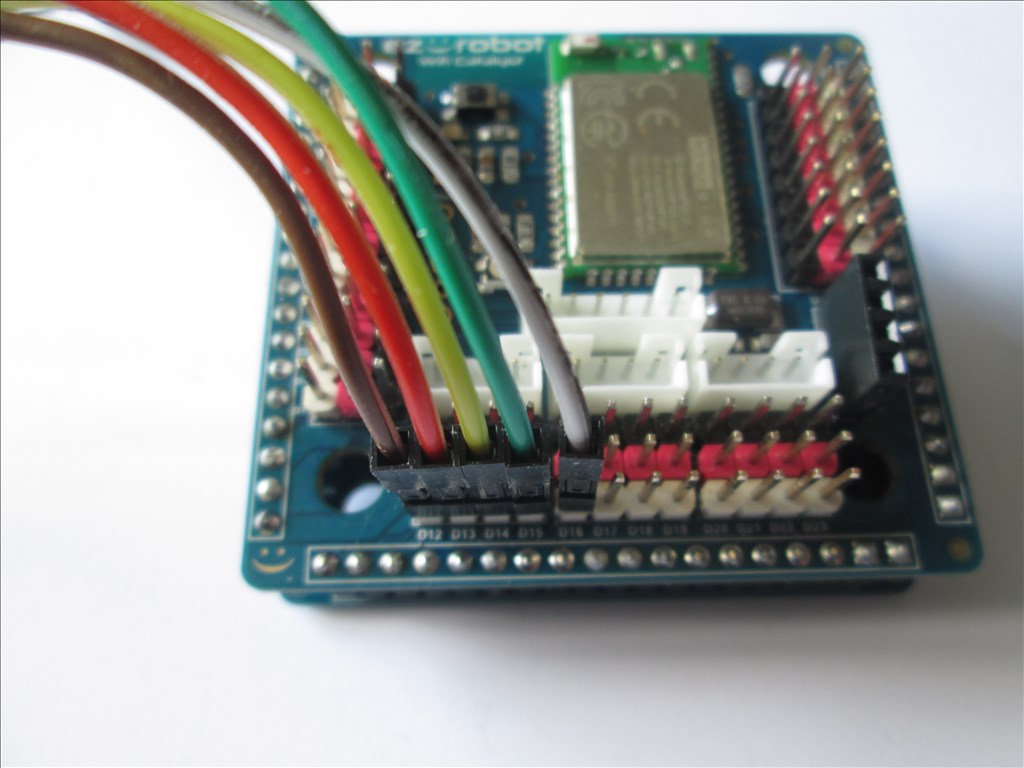

The EZ-B V4 wired for no speed control

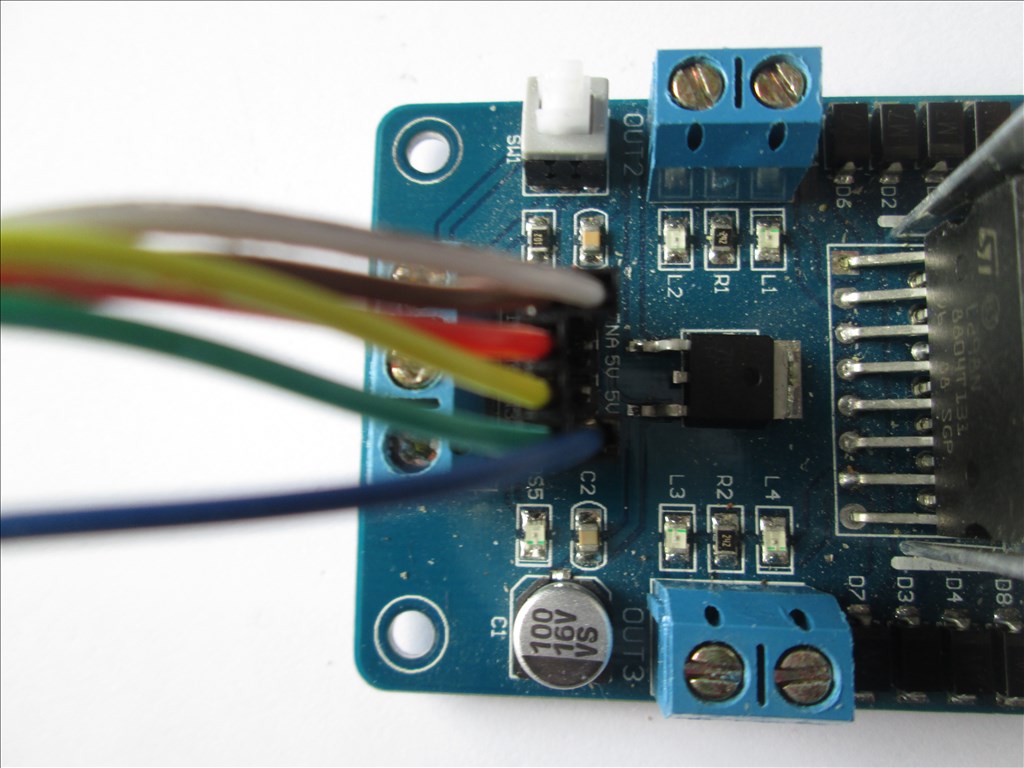

The L298n with the jumpers removed

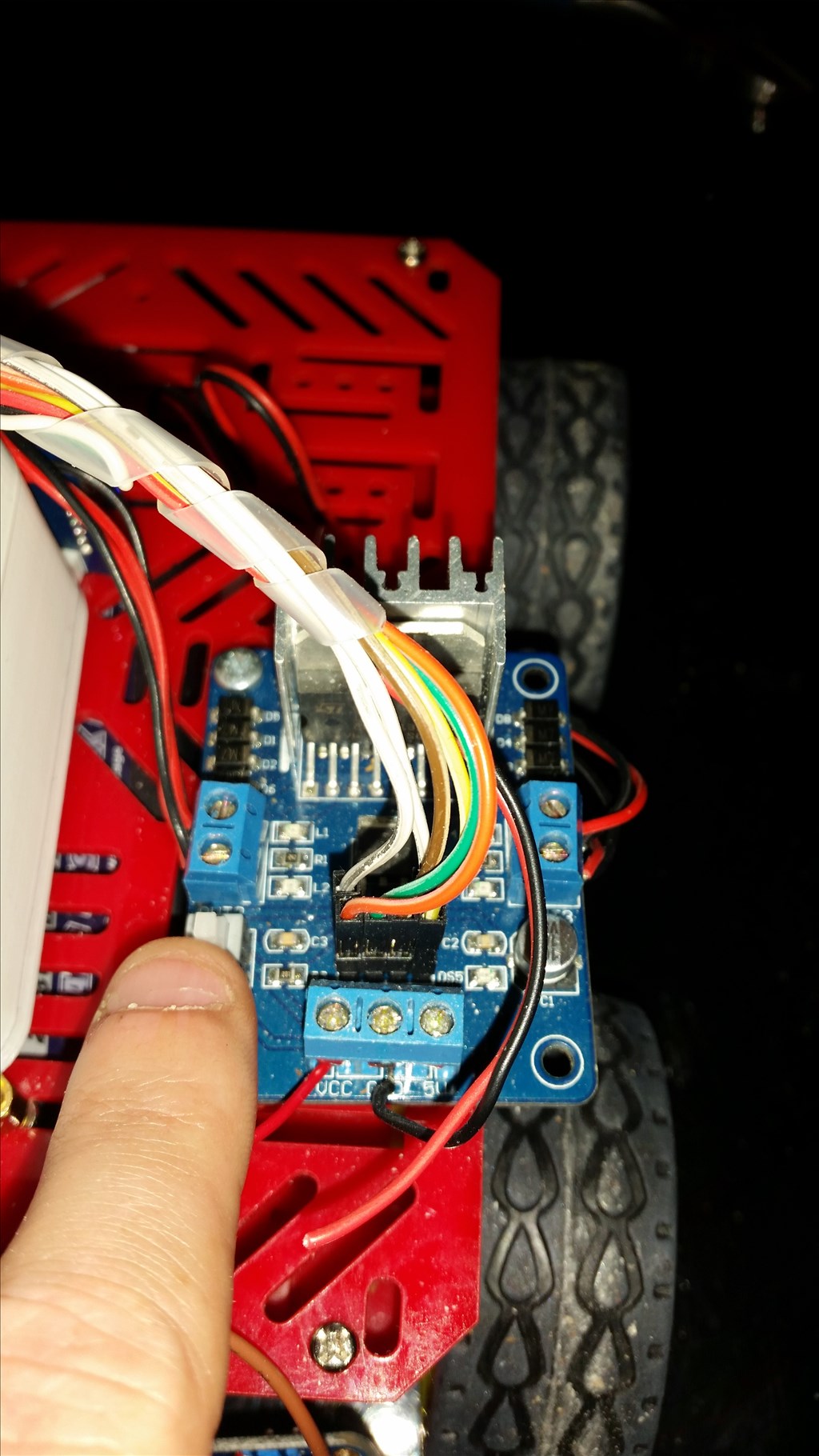

The L298n wired for common speed control (1 PWM adjusts the speed of both channels). White wires is a Y cable, 2 to 1 with the 2 at the L298n end

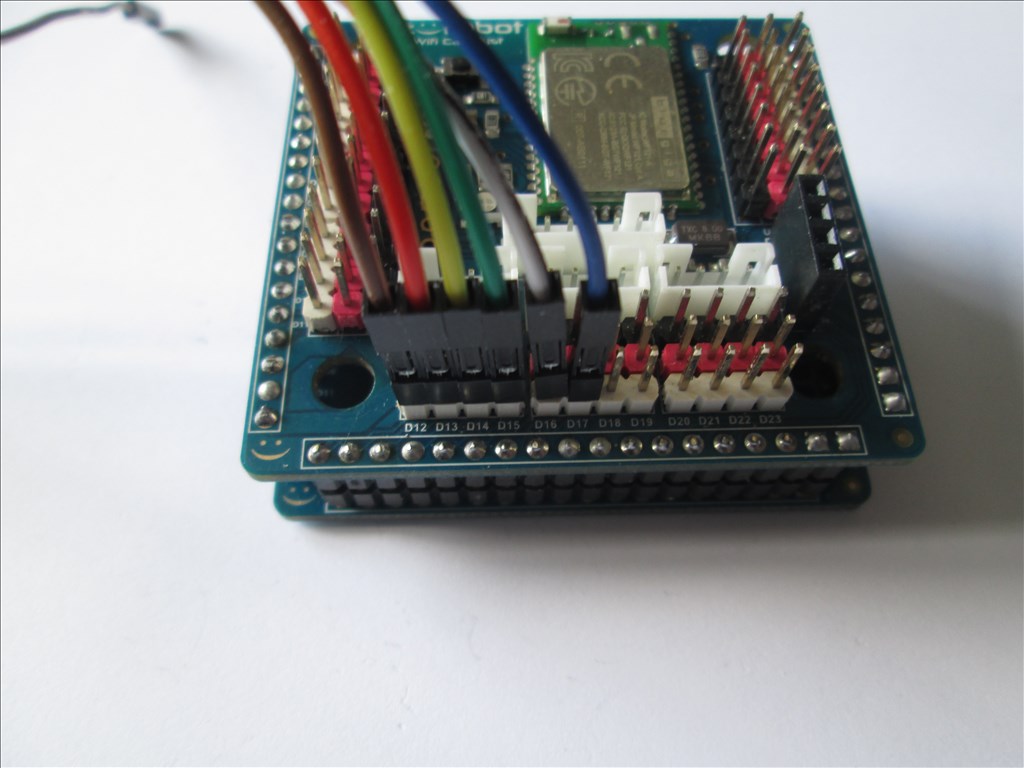

The EZ-B V4 wired for common speed control (1 PWM adjusts the speed of both channels). White wire is a Y cable, 2 to 1 with the 1 at the EZ-B V4 end

The L298n wired for independent speed control

The EZ-B V4 wired for independent speed control

Independent Speed Control

As in post #1 however with some slight alterations as follows;

Assuming ports D15, D16, D17, D18, D19 & D0 D15 Signal > Left Trigger A (In 1) D16 Signal > Left Trigger B (In 2) D17 Signal > Right Trigger A (In 3) D18 Signal > Right Trigger B (In 4)

D19 VCC > H-Bridge 5V D19 Ground > H-Bridge Ground D19 Signal > H-Bridge ENA D0 Signal > H-Bridge ENB

Connect the positive of the battery to the H-Bridge VCC

Connect motor 1 to the Out 1 and Out 2 terminals Connect motor 2 to the Out 3 and Out 4 terminals

In ARC add a 4 Wire H-Bridge PWM Movement Panel control.

Set up the H-Bridge control as the above D15 to D18 on LTA, LTB, RTA and RTB Set up the Left PWM control to D19 Set up the Right PWM control to D0

This now enables independent speed control for each motor and analogue speed control/movement through the Joystick control.

Frequently Asked Questions

Q: Everything is set up but when I move forwards the robot turns and when I turn the robot moves forwards, what have I done wrong? A: Simply put, one of the two motors is running the wrong way, probably due to the mounting position or polarity. To fix this you have two options;

Q: My robot moves in reverse when it should move forwards and moves forwards when it should move in reverse, what's up with that? A: You have your motor polarities backwards for both motors. You can fix this in one of two ways;

Q: When I turn left the robot moves right, and when I move right the robot moves left, how do I fix it? A: Your left trigger and right triggers are back to front. Again there are two options to fix this;

Q:How hard is it to solder the stuff rather than use a jumper kit? A: That depends on your soldering skills. The In1-In4 and ENA and ENB pins are a 4x2 pin header with 0.1" spacing. It would be like soldering direct to the EZ-B. Chances of bridging pins would be very high. That said, DJ shows it being soldered in the EZ-Robot tutorial for this. So yes, it is possible to solder rather than use jumpers depending on how well you can solder.

Awesome Tutorial Rich, thanks for sharing!

Thanks for the info. How hard is it to solder the stuff rather than use a jumper kit?

That depends on your soldering skills. The In1-In4 and ENA and ENB pins are a 4x2 pin header with 0.1" spacing. It would be like soldering direct to the EZ-B. Chances of bridging pins would be very high.

That said, DJ shows it being soldered in the EZ-Robot tutorial for this.

So yes, it is possible to solder rather than use jumpers depending on how well you can solder.

Great write up Rich!

Great write up. thanks for sharing your knowledge. j

Thanks for the nice comments everyone. And it's a pleasure to do these, it's the whole "give a man a fish/teach a man to build a robot that fishes" thing.