jstarne1

USA

Asked

— Edited

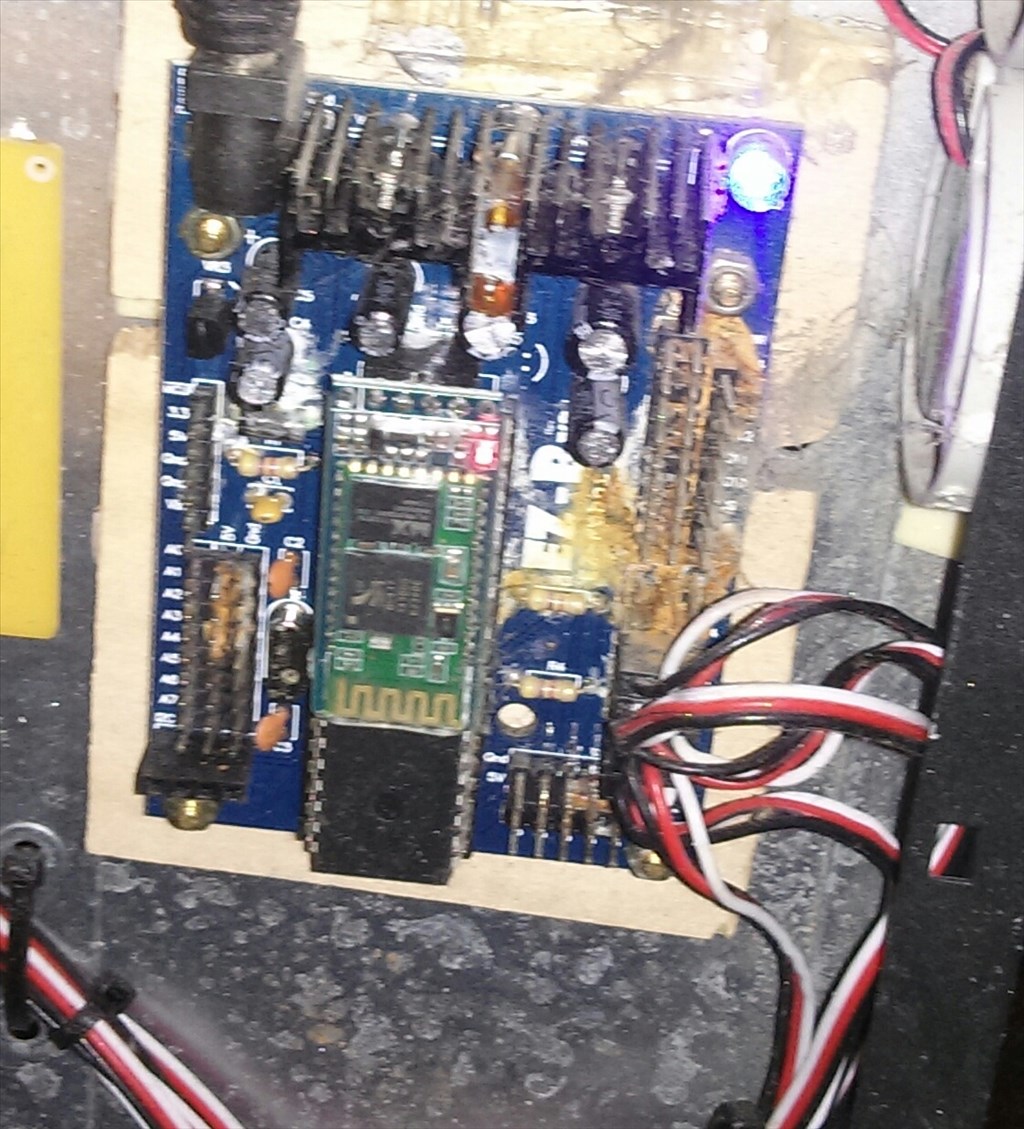

Hi guys just checking the saltwater controller for maintenance. Its been a few months and apparently the cooling fan has been pulling in evaporating water which has a small amount of salt. The EZB is still functioning I just need to power it down to clean the pins for preventative maintenance and then remove the cooling fan.

Hi Josh, I really think your making a mistake by not neutralizing the salt. I know you live down south and don't see what kind of damage salt can do to car metal. It's insidious. However maybe you have seen what sea salt can do. When I was down on the Gulf Cost after Katrina helping my daughters salvage as much as possible after their homes were flooded by surged Gulf waters I found many examples of salt water completely corroding metal even as soon as a few days after exposure. I found silverware that was completely covered and half eaten. Once the corrosion gets into the metal there is no way to stop it unless you change the cemetery of it. A good example is salt damage done to lawns and trees along roads up in the north states here in the USA. Once this happens there isn't much that can be done to bring them back except lay down gypsum. The calcium in the gypsum will displace salt residues and prevent further damage.

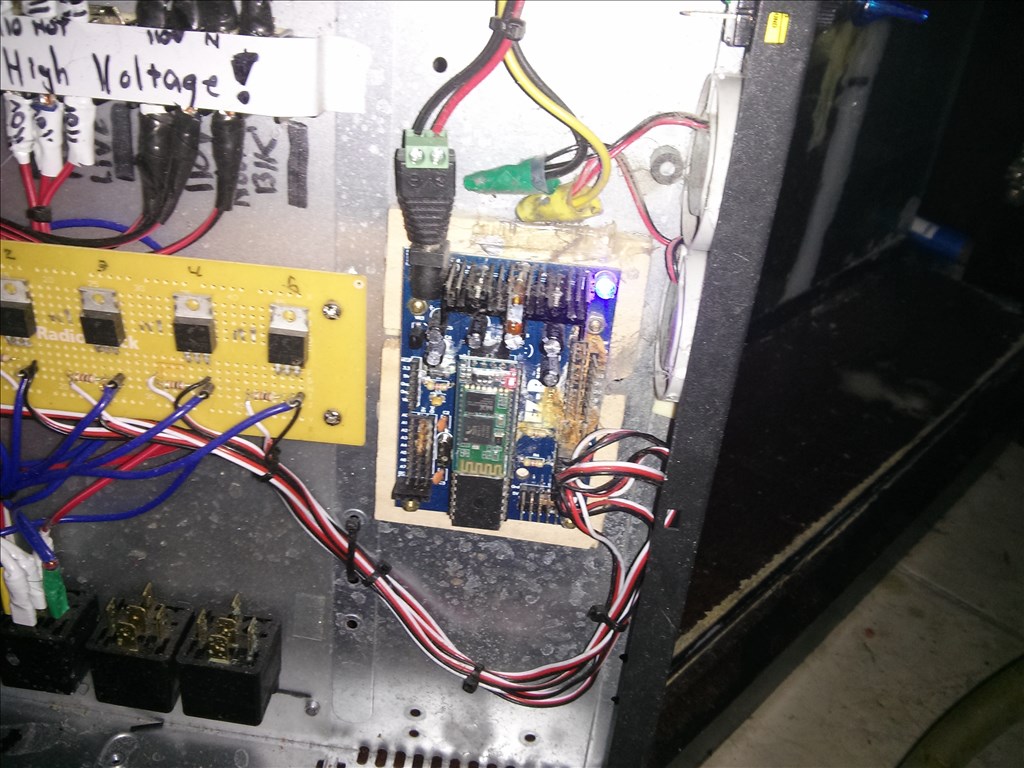

Without going into a chemistry lesson and really pissing you off, you need to completely remove the salt or chemically change it or you board will fail in a few years. If your lucky the alcohol removed all the salt. If not the salt in still hiding in a few spots (probably under the header pins) and corrosion will start up again. Or the salt has already started eating into the traces and alcohol will not wash that out. It will keep eating away till the board fails. Here's a picture of what that looks like:

There are several ways to stop even this advanced corrosion. In addition to the alcohol bath you need to use either vinegar, baking soda or ammonia. I've neutralized more then a few boards that looked as bad as the above and they are still working after many years.

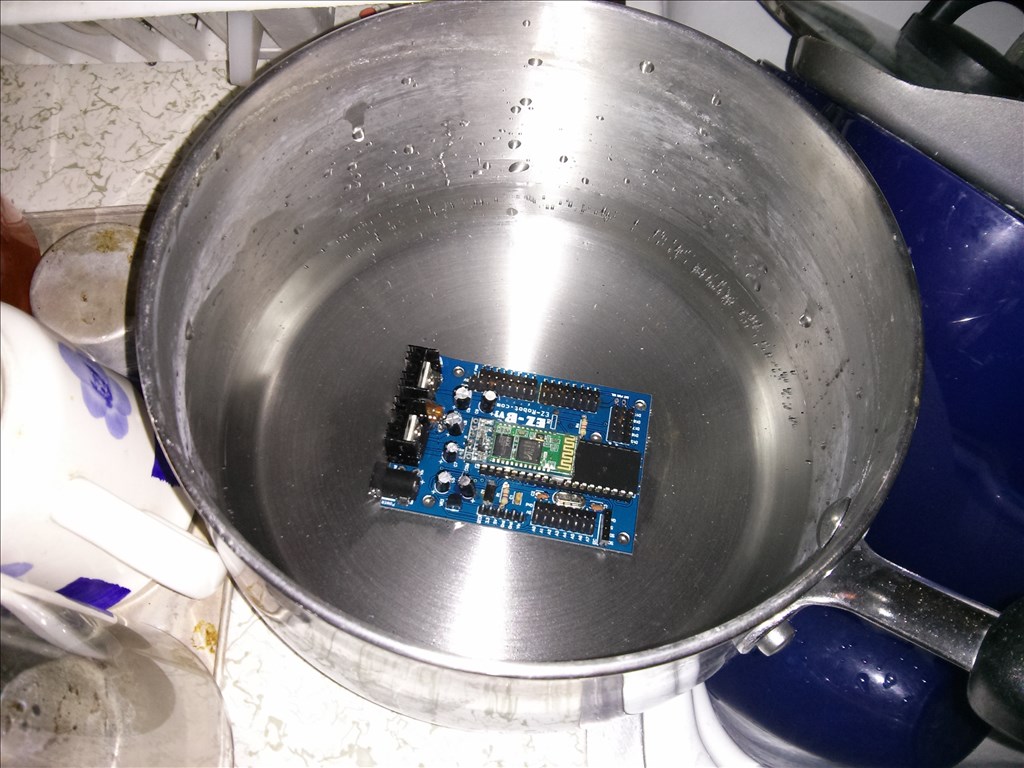

Also do not be afraid to use water on your EZB board. Water will not harm it (I'm not so sure about the sealed Bluetooth unit though). I've been placing old dirty electronic boards in the dishwasher and using dish washing detergent as a soap for over 10 years now with no ill effect. The important thing is to make sure the board is dry before you turn the power on. I always blow it off completely with my air compressor and let it sit overnight in a dry area before I reinstall them. Also it's important to not let the static from the compressed air harm any sensitive IC chips. Keep yourself grounded when handling it. I know the IC chip on EZB is static sensitive.

The only thing I would not apply water to is boards with relays that are in a plastic dome or other sealed daughter boards. There is no way to dry these unless you drill holes or take off the domes.

Hope all turns out well for you Josh. I'm just trying to help and keep any problems from occurring down the line. With any luck what you have done already will be OK. I'm just really anal and don't like problems to pop up down the road.

OK so its soaking in vinager right now and I will rinse in a few minutes with alcohol.

One resistor needs to be replaced as it was too corroded to make a good solder joint.Awesome advice Dave on corrosion control thanks so much!...Josh your vinegar bath needs a few baby cukes thrown in ..OR ...start making french fries ..Weird how places in some states dont provide vinegar as a condiment?!...I guess its an English thing. Not even counting a french canadian add on of gravy and cheese curds (poutine) I am sure Dave knows all about cheese ,coming from Wisconsin!

..Weird how places in some states dont provide vinegar as a condiment?!...I guess its an English thing. Not even counting a french canadian add on of gravy and cheese curds (poutine) I am sure Dave knows all about cheese ,coming from Wisconsin!

Yes, everywhere I go in the world they seem to know about the "Cheese Head" nick name. I love cheese but never had vinegar on it. Ick. Now, I do love vinegar on spinach. Yum.

I love cheese but never had vinegar on it. Ick. Now, I do love vinegar on spinach. Yum.

Back on subject; I've found it difficult to desolder parts that have been corroded. To keep from destroying the solder pads I usually make sure to use liquid flux and melt a little new solder into the joint before doing the desolder. However I've always done this on old corroded boards that are 20 - 30 years old that has seen a lot of miles on them. A new board like the EZB that has this corrosion may be a lot easier to desolder.

Gotta luv recycling!..I am always looking for cast out electronic equipment for gears and components and desoldering is a necessary skill

you forgot the tolerance code: BBROYG But Violets give willingly.

that's the way I learned it.

OK so its a 4.7kohm resistor and I stopped by RadioShack to pick some up. I tried to solder it on with the new lead free solder and that stuff was constantly attracted to my iron and didn't flow well. It just wanted to bead up. So I went back to get some 60/40 solder and tried again. Does anyone know when this resistor goes directly to son I can be sure I tested it correctly? It does power on and blink like normal.

You may already know this but: If you put your digital tester on Resistance setting and the proper range, then measure across the resistor you should get the proper reading........ most always. However I have gotten different readings on resistors (rarely) both in and out of circuit. I've found most of my false readings on resistors in circuit will happen when another resistor is in parallel with it. Your readings will not always be spot on. Usually they very + or- 5% as noted on the specs of the resistor. Check the specs of the resistor. If outside of the stated range then the resistor is bad.

I also like to do a continuity test from the component I installed to where the traces go and also to traces and parts around it to see if there are any problems.

Just another tip on soldering; If possible don't cut your lead to far into the solder pile. I see you've cut it way down on the backside of the board. This could cause micro fractures and cold joints. I know, sometimes the pile is just to big however if possible leave a little of the component lead outside of the solder pile. Also it's a good practice to clean the left over flux from your board with flux remover when done soldering. This may sound a little anal but It both looks better and keeps shorts & bleed over to other circuits from contaminants down to a minimum.

Other then that it looks great! Nice job!

Dave Schulpius