jstarne1

USA

Asked

— Edited

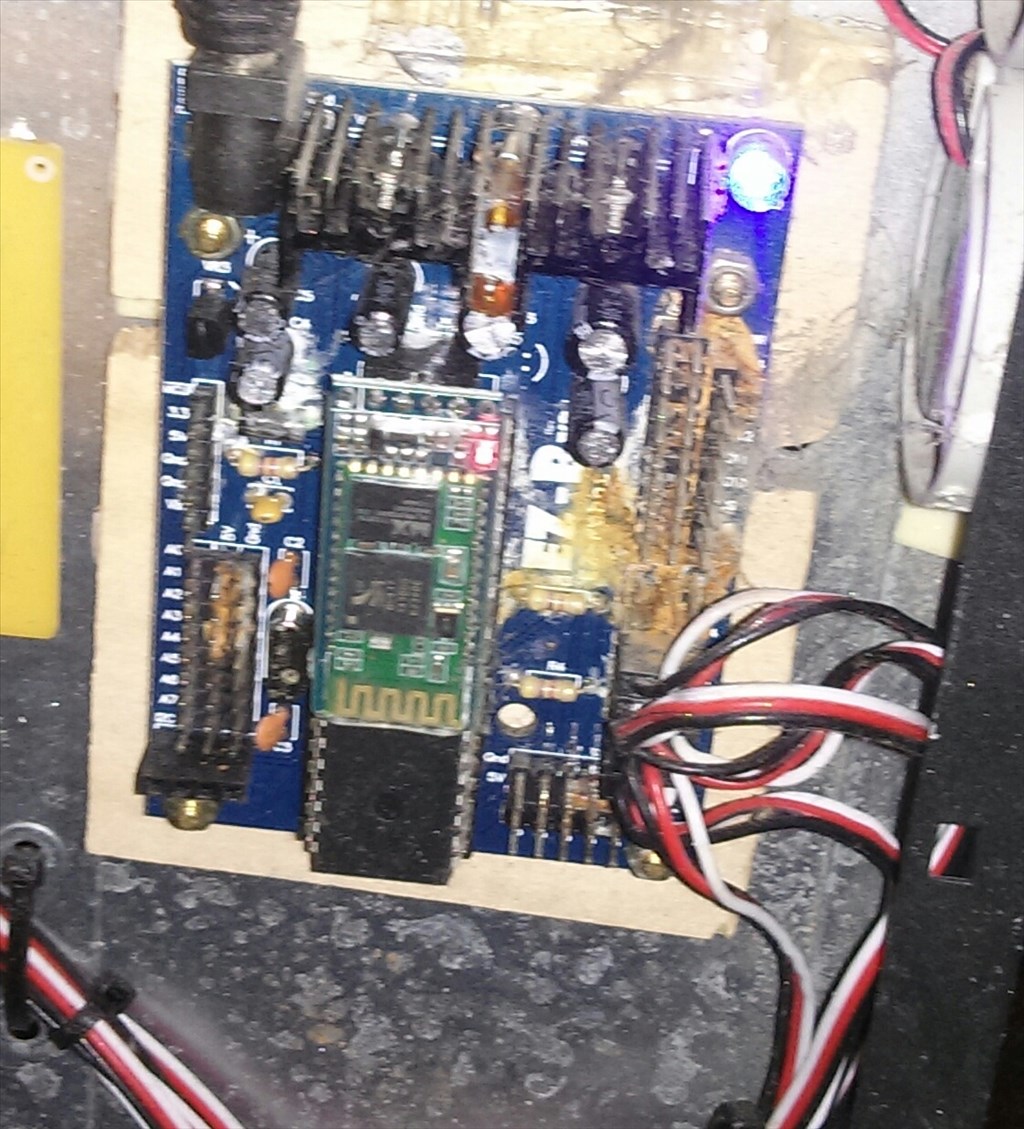

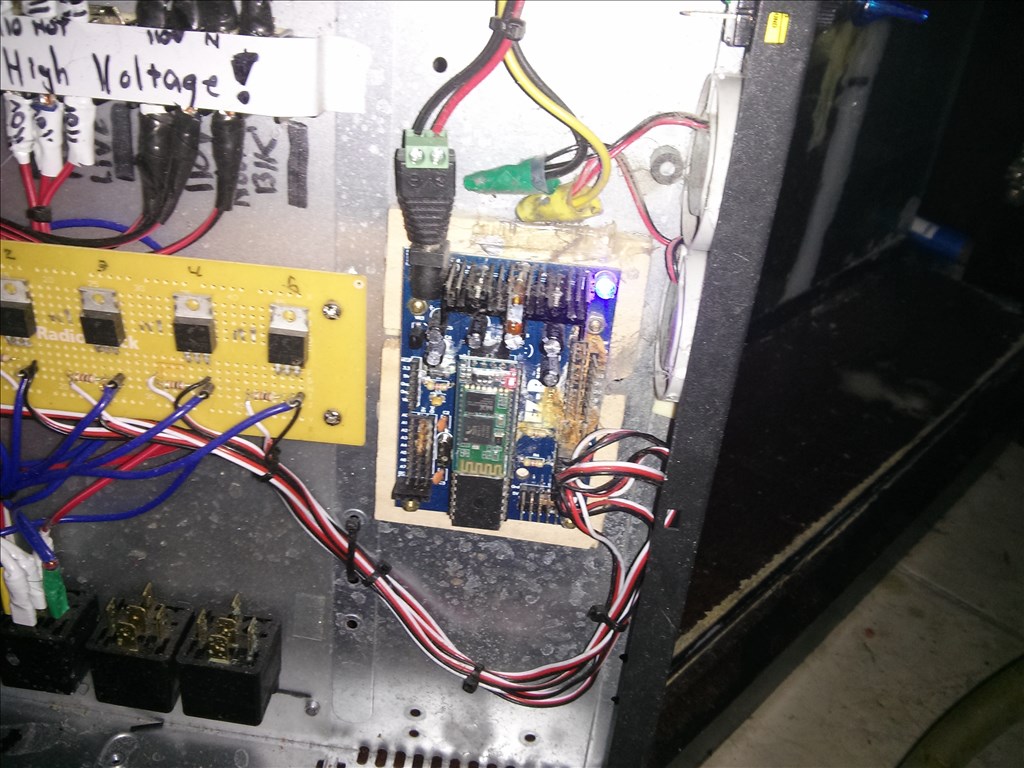

Hi guys just checking the saltwater controller for maintenance. Its been a few months and apparently the cooling fan has been pulling in evaporating water which has a small amount of salt. The EZB is still functioning I just need to power it down to clean the pins for preventative maintenance and then remove the cooling fan.

Anyone gave Ideas for this, for a "electronic safe " cleaning method.

Remove all power then use a soft tooth brush and rubbing alcohol. Use compressed air to dry.

Eeeeew nasty! Lol. I think I would take a toothbrush and scrub away.

OK I will take some 90 percent rubbing alchohol and clean it well. If they doesn't do the trick I will look into electrical connection cleaning solvent. I want to try the least invasive approach before a solvent. I will pick some up tommorow and record the progress and results for others who may need to clean up a ezb for one reason or another.

Yes, clean it up with the alcohol but you also need to neutralize the salt. Once it gets onto the board like that you will never get it off and all you can do is chance the chemistry to keep it from continuing to eat away and do damage. So,after the alcohol scrub, rinse off in tap water and and follow with scrubbing with clear vinegar. Rinse with clean water and repeat the process a few more times. Blow dry with compressed air.

If you do it like this all should be good. If you just wash it off without the vinegar it will just keep eating away even though you can't see it.

Edit: last liquid on the board should be alcohol. This will help remove most of the water.

OK so alcohol - vinegar- alcohol - air...

I'm going to video this. If something explodes at least it will amuse someone

Ya, that's it. Can't wait to see the vid.