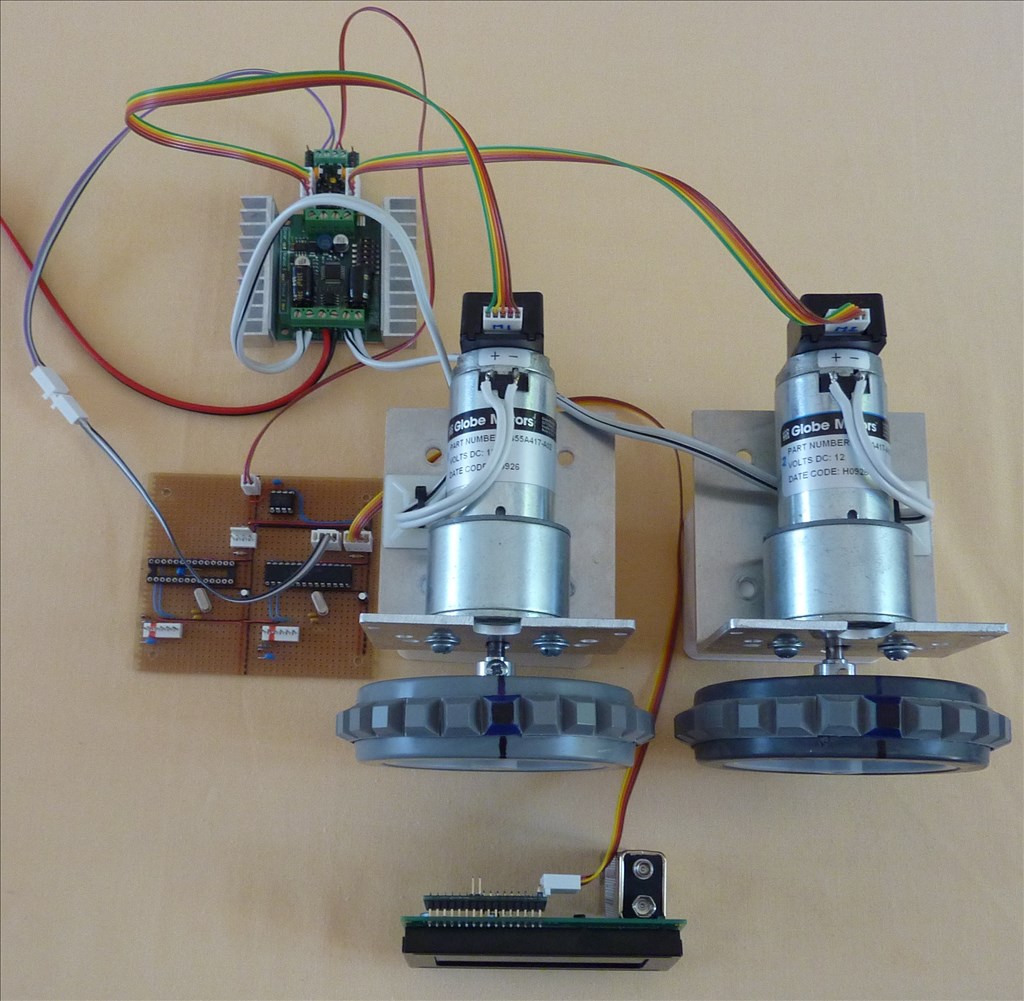

This is a video to show you guys how good the Kangaroo/Sabertooth motor controller combo is!

Dave, this video starts by showing the ramp-up - full speed - ramp-down algorithm that I coded on the PIC microcontroller, you will see how GET_POS is read and controls the ramping up/down. The ramp-up and ramp down rates can easily be change via a variable. When I get my V4, I will port the algorithm over to an EZ-B script for those that want it.

The second part is to show you folks how important encoders are, here you can see the incredible synchronising that the Kangaroo's auto-tune PID has. I have sent it precision movement (distance) commands for hours with barely no loss of motor synchronisation which means that you can build a robot that will accurately move in a straight line and move/turn to the exact distances that they have been previously programmed/taught. I use this for accurate room mapping and having pre-learnt routines which enable my robots to move from one room to another or to a particular room location.

Matt, its not the magnet power thats the issue, its the number of clicks (pulses) that the encoder gives per single wheel rotation. Your magnet sensor looks (to me) to do only 4 clicks per rotation where the units we use are 64000 clicks! The errors from such a low res encoder are substantial and I am not even sure that the Kangaroo will work properly with this low click count.

You could improve resolution by cutting say a larger disc and gluing as many small magnets as you can around the discs edge making sure there is enough magnetic separation so that moving the disc across the hall effect sensor gets a stream of clean pulses. If you put the magnets too close to each other then the hall effect will just see a continuous signal.

A more simple homemade encoder would be a disc with many holes precisely drilled around the edge then use a photo-interrupter circuit (LED with LDR, photdiode etc) to read the click count.

Hope this helps

@Tony, well it has been an unproductive robot week here, one of those hurry up and wait weeks. I get my finished wheels back tomorrow and am going to purchase new encoders. I wonder if you might take a look at the two I'm considering or suggest an alternate if you have a moment? I'm considering the US Digital E2 or E3 encoders. They make several models but they aren't giving them away so I'd like to keep potential cost as low as I can. These are easy to mount and fit my shaft (5mm) under the brake cap. E2 E2 encoder

E3

E3 encoder

I'm not sure what to put for CPR and want to get the right part since they are relatively expensive.

Thanks in advance Matt

Edit: I'm going to ask this of anyone who has used the kangaroo because I've had three emails into dimension with no responses this week. My dip pins on the sabertooth are 1&2 off all else on. On the kangaroo I have 124 off 3 on. I had a different setting 1,3,6 on the s tooth when it was running alone but I think these settings are what I need to perform as in your video. Problem is, I am not getting the software to see a sabertooth/kangaroo. Are my dip switches wrong or is it necessary to have the encoders attached for describe to recognize the kangaroo? I have the wiring from the kangaroo to usb correct and the sabertooth is powered up and connected to the kangaroo.

Matt

I've found DE's customer support is less then helpful and slow to respond.

For the Kangaroo to work you need a feedback device like a pot or encoder attached to both the motor shaft and the Roo and also have had a successful tune. That may also extend to being able to use the setup software but not sure.

Dip Switches; You have dip1 set to Analog. To use it with EZB you need to set it On. This will pit it into digital mode. You have dip set to analog feedback. This is for use with a pot feedback.If you are going to use an encoder you need to set it to On.

You have dip set on now and that is for position. Off if for speed like when you are turning an axel of a car. Roo's dips shouldn't keep you from accessing the setup software. Your Sabertooth dips are set properly.

Well I finally got my new encoders in the mail today but now i'm waiting on a different usb delink to get the kangaroo to talk to the computer, apparently the one i bought doesn't like to talk with the kangaroo. I think the new encoders will work nicely, I bought these:

encoders

more than I wanted to spend but I need them to work like Tony's video. I am now looking into a way to make the converter board I posted about or a similar pic type board work to make the robot perform send and receive serial. The waiting is the hard part. One of those things where you can't complete one thing because you're waiting on another. I only have a limited window to complete my project so i'm hoping to have a win soon.

I'm not sure when my v4 will ship but i'm a little concerned i'm going to have to buy another component since i'm using two 12v batteries in parallel connected to the sabertooth/kangaroo combo.

I guess there isn't much of a question here, i'm just checking in while I wait and wondering if anyone has had more luck with their projects.

best Matt

@mdeming1, The price on that web link you pointed to says these encoders cost about $90 each. Is that what you paid? How and where did you order these?

Also what is the shaft hole size and how and where do you plan to mount these?

Thanks for any info you are willing to offer.

Dave

Dave, they cost around £29 here

uk.mouser.com/ProductDetail/Avago-Technologies/HEDS-5545A14/?qs=RuhU64sK2%252bvm%252b6S8JdyXfw==

You can get them already installed on a very high quality and high torque motor from Zagros for around 129 bucks.

www.zagrosrobotics.com/shop/item.aspx?itemid=639

For high resolution they must be mechanically connected to the motor shaft itself, if you connect the encoder after the gear train (where you would attach the wheels) then the resolution will obviously be much lower.

Hope this helps

Tony

@Tony, you're just a treasure chest full of information and help. People like you make this stuff fun and interesting and very doable for schmucks like me !

I didn't know what else to buy as my wheel shaft is 17mm but at the rear of the wheelchair motor where the brake used to be, the shaft is 5mm. From what i've read online several people have placed encoders in this spot so i'm hoping i'll have some luck. I think even a little feedback will help achieve what i'm trying to as long as I can get the bi-directional feed. My main worry was shaft size (fitting my motor) but i'd probably buy the all in one motors if I had to do it over.

Hopefully my usb-delink will arrive tomorrow and i'll be able to update firmware or something on the kangaroo. I've asked a friend to see if he can make the i2c board I bought work to communicate bi-directionally with the v3. I'll keep you posted if anything comes of it. Waiting is the pits.

Matt

PS: I bought the encoders directly from us digital, you can choose your options on each encoder and they make several, some cheaper, most more expensive. Just email them and they will email an order sheet. I got mine very fast and they were very responsive to all emails.