Asked

— Edited

3D Print Jd Head

hi

has anyone printed a jd head?my question is ,how do you print the head on the printbed?

thank you

Related Hardware (view all EZB hardware)

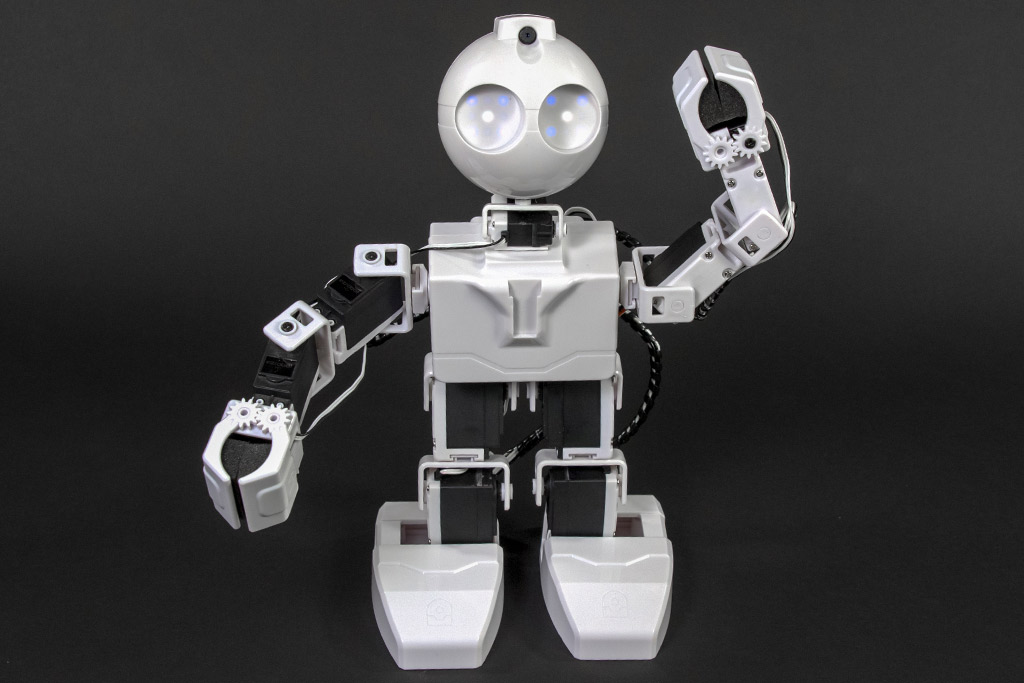

JD Humanoid

by EZ-Robot

JD humanoid robot kit - WiFi-enabled, 16 DOF with metal-gear servos; easy, fun, educational, available from the EZ-Robot online store.

Wi-Fi / USB

Servos

24

Camera

Audio

UART

3

I2C

ADC

8

Digital

24

Related Robot Skill (view all robot skills)

File Manager

by Synthiam

Displays files currently open for reading by scripts, shows only read-opened files, helps diagnose read/write locks and file access errors.

here is a pic with error message.

seems pic below is not correct.

try the print without the raft. there is an error and I am not familiar with your printer screen, not sure what I am seeing. reset the Printer to DEFAULT SETTING you may have entered a setting that is not correct for your printer. I print from my Computer using a USB cable using a very good Program called Simplify3d. If the data flow to the printer is interrupted for even a second it can lose it's position and start printing in the wrong position. if you are using a Mem card in the printer to print from format that card and reinstall the .stl file. if you are using a usb cable remove from computer and printer cable and switch the ends. check to see if you have the cable near a high voltage source like it's power supply and move the cable away from this. even shielded cable can loose the data flow with an electrical pulse. remove all the stepper motor cables one at a time and reseat on the controller card. check your ground connection.

hi nallycat

i found this video with all settings for ender-3 and with your tip off setting speed lower.it works. i cant paste video's here? but as seen in pic above ,the numbers 500 chould be 2500x2500x100x25. now the robot is assembled and now comes the flaws in the design.lol:( few things to adjust.

hello nallycat:D

question ,how can i reduce some support on my 3d prints? if thats a good idea ? i al using cura 4.5.0

@Nomad 6R I do not use cura with the program simplify3d I can put the supports where I want, or reduce the amount of support material I don't know if cura has this capability. but usually I just reposition the part on the build plate, as long as the object does not have an overhang of more then 45 degree it can be printed without support, the change I made to your part that I checked for you. I sent it back to you on it's short side. there was an angle to the rest of the part but it was under 45 degree. and could have been printed without support one overhang at the top may have been rough at the bottom. another way of saying you don't have to print flat. sometimes printing from a corner for example only puts support to hold the part in that position. that may reduce the support material.

new actuader,is that a servo

did you print this? EzAng

no no i think they are newest servo's.