smiller29

USA

Asked

— Edited

MRB1 (My Robot Buddy V1) Project

Welcome to my MRB1 (My Robot Buddy V1)

I have removed the post because it was corrupted somehow and all the pictures and formatting was lost.

This post needs to be deleted.

I pulled out some old shoulder joint gears I had and spun em up by hand and found the reduction to be 12:1 on the stock inmoov. A little surprised. So now I kinda think it will be undergeared and not have enough torque. We'll see, those servos are monsters but it's still a servo. The motors inside are only so big. Inmoov arms cry out for BLDC motors/encoders with 3:1 reductions like James Bruton uses in his projects. The $$ will build up.

Perry, I figured it would be at least 3:1 or maybe 4:1 but did not think it would be 12:1. Well I think this will be the general design below. I will have to remove the Pistonbase out of the torso because that will not be use anymore. with the new design I am working on.

The last change it needs will be a second mounting bolt or maybe I will just use the one and pin to lock it. I need to think about that.

Let me know what you think!

Did you calc the gear ratio or are you guessing at it? You I can't quite count the teeth in your rendering so I couldn't calc it out. I still think you will have a ratio problem but let's see. 12:1 should be the target if you want a stock speed. I found it to be a balance between speed and torque in my designs with speed losing out due to torque constraints. Are you planning a different method to raise the arms at the shoulder joint? Your solution looks rather deep and will interfere with the stock screw jack method.

Looks like you are having fun. Reminds me when I was putting tons of time into my inmoov. Was a fun time. There is still tons of innovation left in the platform.

Small gears are 12 teeth the ring gear is 36 teeth. I will not be using the screw jack in this design the next part in the design will replace that. I am going to use the same concept... more to come! I need to order some filament so I can print some parts.

I have so much to complete still and I am jumping all over. I printed the new hand and got a few HS-40 servos to test the design so finger crossed on that. The FUN JUST NEVER ENDS!!!!

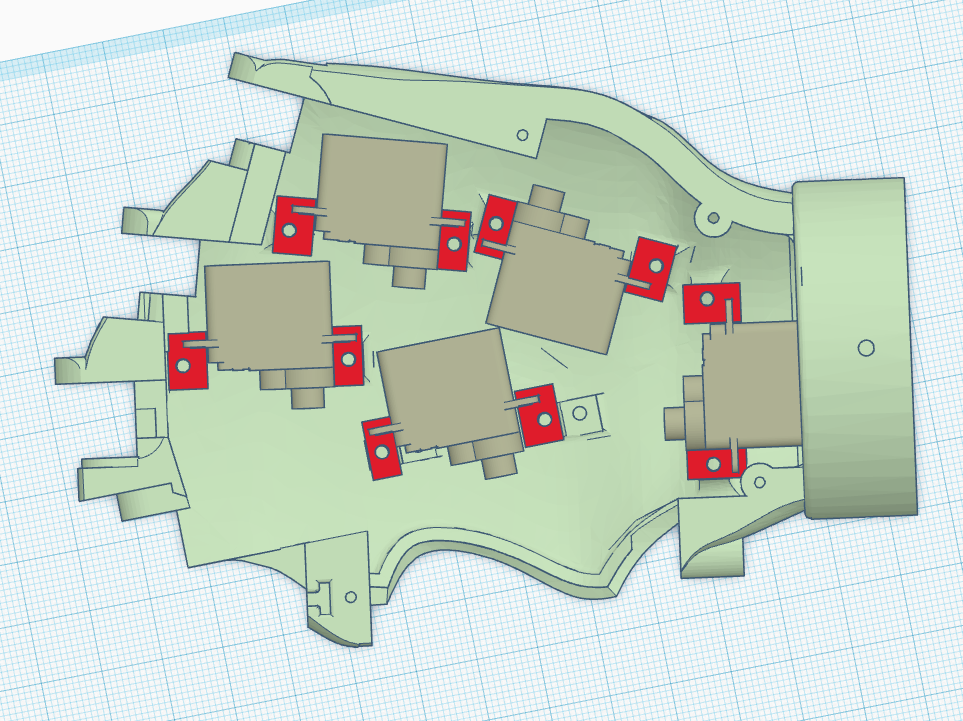

Well, I have completed my design updates for the Handi Hand to support the HS-40 servos as seen below my first try was not 100% correct but this one should have all the correct geometry and clearances needed.

I will get it on the printer today and see what happens!!!I have also designed a new bicep elbow replacement that will connect to the new shoulder.

I can't wait to try some of this stuff I just don't have enough printers and filament LOL...

@smiller29

That looks like a great design. Great job! Looking forward to the completed arm and how the placement of the Pots turn out for the shoulder, elbow, arm up/down and arm rotation.

Cheers