This project has evolved some , the basic rundown is I'm modding two Omnibots , one a regular the other a larger 2000 model. I will have two ezb kits , rad base idea was thrown out because of so much noise but could go back on the table if the omnibot drivetrain is too weak to pull it.

By jstarne1

— Last update

Other robots from Synthiam community

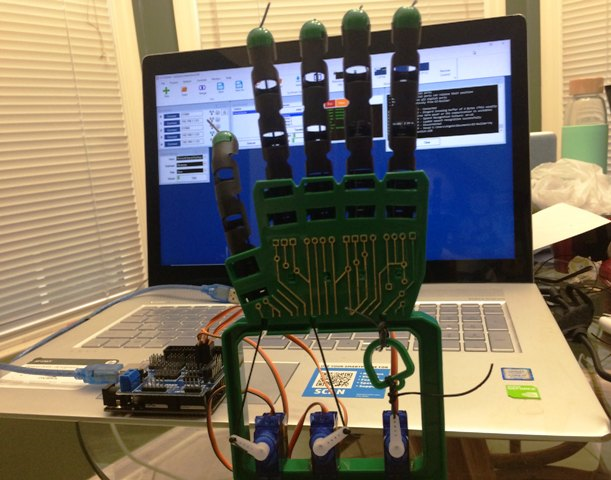

Ezang's Here Is A Picture Of The Hand I Am Practicing With

Photo of the hand I am practicing with

Nekoeccentric's Dr.Who's Nsd Dalek

Robot build with working drive system and ongoing fabrication; EZ-B audio stopped working before a weekend event.

Daman's Meet Ray. My Custom Friendlybot

Custom Ray box-bot with foam board body, tracked drive and ping sensor, explores servo torque limits and DC...

cE9s4PsOgeBQIORwjd5!~~60_1-634818020230156250.jpg)

BO)Lupuc4g~~60_35-634706297915000000.jpg)

LupbT6!~~60_35-634706298769375000.jpg)

C5j!~~60_35-634655044863125000.jpg)

C5j!~~60_35-634659603510781250.jpg)

C5j!~~60_35-634651704046230469.jpg)

needs to be 4000 series,like 4200 or 4400 may need the OSMO HACKER,to fix the SCI commands to work with EZB ,very small tool and i have one you can borrow,since i use it lot,models i mostly buy is 4220 discovery,but do have others that work in the 4000 series i have i guess i can sell you one and buy another one latter,i paid $40 plus shipping so maybe $35 plus shipping with vacuum parts already removed ,and ready for EZB

After getting up and moving around I descided I couldnt get anything done because parts are everywhere with little workspace , my little dog chewed just a little on the edge of the handle he locks up his toolbox where we use to share, so I had to pickup some tools but didn't have anywhere to put them , so I picked up all the black boxes you see plus the middle box.

In the center I added a charging station in the center for drills and lead acid batteries ect. The totes at the bottom hold various robot body parts. I have not put anything away yet but I believe this will really free up workspace. I work tomorrow but I will Start putting away tools and organizing the parts so I can get back to being productive!

Awesome.... I clean up every Friday so I have the weekend to play and mess it up again.

I found a set of colliers encyclopedia 1966 edition seen in upper left lol.

Ok parts update , I have 2 lynxmotion pan brackets on.the way and another shark vacuum to have extra parts.

To do - Make top n bottom of torso ext , frame it and fiberglass Either cut holes or pattern drill for pc speakers Rotate base 180 degree so vacuum head is in front Cut.notches for.DVD player in.chest

I'll keep it simple , I have been inpatient lately lol

So could I just use high torque servos as a drive system? Maybe some 200 oz in servos , two on.each side ? That would only be a backup plan. Looks like using a roomba board would be a great option as long as it can handle the amps that my.motors draw.

@josh on the roomba pcb it can handle little over 1.5 amps,i am working on a design to make it double

1.5 amps? Hmm. I guess I just need to wait and get this.guy together.