The other day DJ suggested an easy way to make a touch sensor, see this thread https://synthiam.com/Community/Questions/7692.

So I started playing with that idea and made a couple of touch sensors by soldering a piece of foiling tape (I "borrowed" some from my wife's stain glass supplies) to the end of a wire. I attached the wire to an ADC Port and put the foiled end on the robot. Wrote a script and it works pretty good.

Here's a picture of the sensor.

A short video of them working.

Thanks for the idea DJ !

By bhouston

— Last update

Other robots from Synthiam community

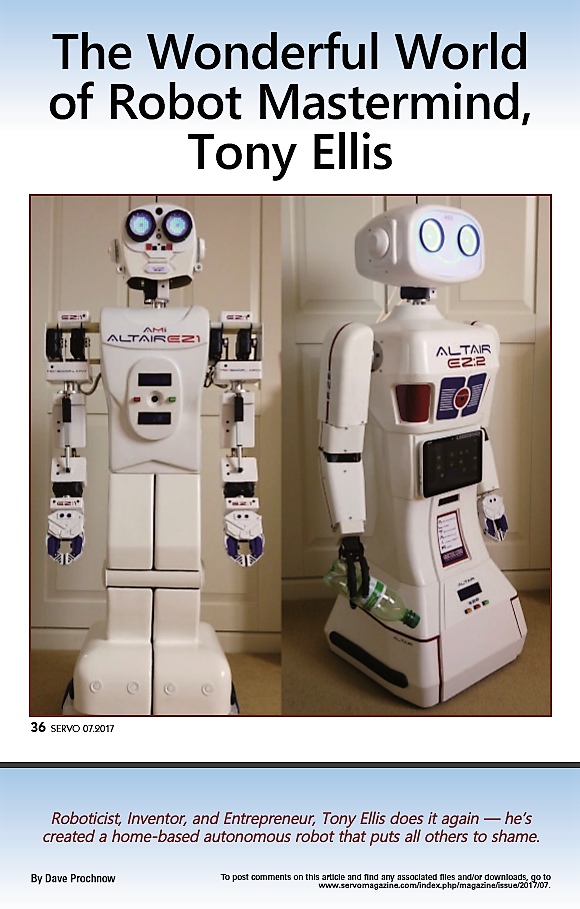

Toymaker's Altair Robots In Servo Magazine

ALTAIR robots featured on Servo magazine July cover; Dave Prochnow spotlights Tony's robotics work, 1979 programmable...

Mita's First Robot From Bits Around The House

Build a 4-ft robot from an EZ kit using household parts: voice-activated head, Wii control, DIY sensors and kid-friendly...

Lumpy's Lumpy's Hasbro R2-D2

Modify Hasbro R2 with EZ-B control, L298 motor driver and 12V LiPo for compact, upgradeable internals, planned dome...

@DJ, Thanks, but none of your suggestions have made a difference. If anything it is drier in my shop now. If humidity effects this type of sensor then I think I'll look at a different way to do the touch sensors. I'm thinking that if I make a sensor with a signal wire and a ground wire and when the sensor is touched, the ground wire and signal wire touch, this gives a more positive reaction - the ADC reading goes to 0. Do you see any problems doing that?

When I first saw this idea I was very surprised that it worked for you Bob. I can understand why you are now getting varying results. Since there are radio waves all around us the human body becomes an antenna (more often then not we become 60 Hertz antennas here in North America due to our electricity). Stick your finger onto an oscilloscope probe and you'll see it.

The response from your body to the copper foil will change based on humidity, cloud cover, metal in the area, and moisture of your skin. The better antenna you are the more signal you can send into the ADC port. The dry environment you are in probably isn't going to help in terms of being an antenna.

Seems like you were also trying to use a capacitive effect. If you'd like us this type of method you won't need a capacitor in line with the copper foil as this will only work if you are a good antenna. Since capacitors are transparent to AC voltage the signal will pass through the capacitor to the ADC and it'll work the same as the original way you were trying.

If you want to build a touch sensor that is a bit more reliable look into the sigma-delta concept. The concept does require you to have a capacitor attached to each copper pad, but it won't be in-line it will be attached from sensor to ground. Then you will need to charge that capacitor with 3.3V (maybe with a digital pin or use a single transistor to apply 3.3V to all the touch sensors). Once charged you can then start reading the ADC, then when the touch sensor is touched the capacitor will drain through the body (not enough voltage to hurt anything). You can detect the amount/length of touch based on how much time the capacitor takes to drain.

I'm sure I'm not explaining it very clearly but if you google Sigma-Delta touch sensing you'll get a better explanation

Have you considered these sensors?

The data sheet is here. There are some other configurations as well. https://www.interlinkelectronics.com/FSR408.php

They can be easily hooked up via a voltage divider. Here is a back and forth I had with Rentaprinta a while back concerning their use: https://synthiam.com/Community/Questions/8123