gray

I have been asked to assist the School production of Mary Poppins by supplying remote controls/automation for some of the scenery.

I am controlling 4 servos from one EZBv4 and a PWM output to a motor controller located in another part of the stage.

The first EZBv4 (main) is connected in AP mode. The second EZBv4 (secondary) attaches in Client mode once "found" by the Connections tool.

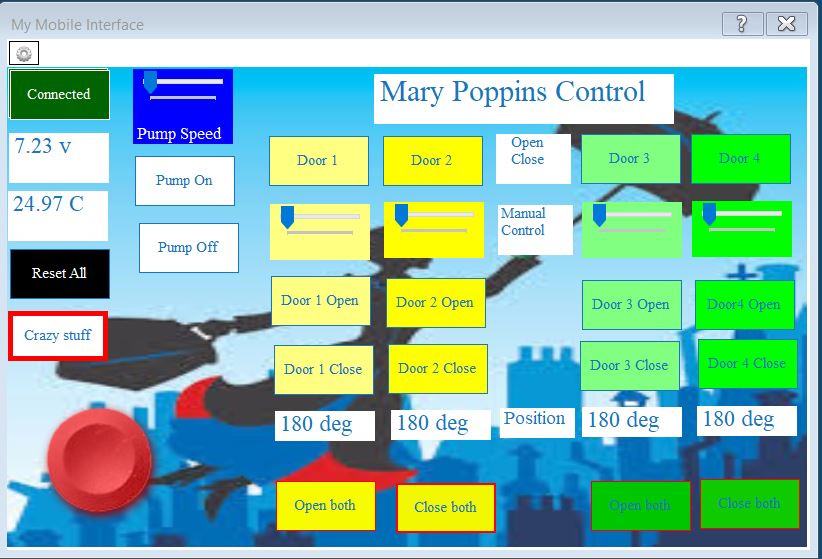

It all works perfectly on the laptop. As the system will be used by non-technical types I wrote an App to use as the operator interface.

It is totally awesome. And I have learnt heaps about using the EZBv4

I have been trolling through the online info but I have a low level of expertise in networking and I am having trouble answering (hopefully) some basic questions.

- Is this the best method to establish connections for this scenario?

- Can I automate the connection process

- Will it all work on an iPad? I would prefer this option for ease of use. All is good on my iPhone but I can't seem to connect the secondary EZBv4. Some of the online info suggests that may not be possible and I may need to come up with another way of running the pump.

I have attached a copy of the EZB file and an image of the interface I am hoping to use.

Thanks for any assistance.

Mobile isn’t the same as a computer because they’re far far far far less powerful. This limits mobile to connecting to only one ezb at a time. The solution is to use a pc OR only one ezb with longer wires OR two iPads

I’d go with using a laptop - also make sure the laptop isn’t set to "go to sleep" in power settings. You wouldn’t want it to hibernate sleep while the play is going on because that’ll disconnect.

Sounds like a super fun project! It’s exciting

@gray Very original and clever application! Please let us know how it is turns out

The project was a qualified success. When it worked it was brilliant but we learnt many, many ways that were not quite as successful. In the video (sorry for the quality) you can see the doors opening and closing and the PWM controlled pump spurting water into the air. Hard to make out and we ended up colouring the water and adding an LED to the basin to enhance the effect.

We 3D printed servo mounts and brackets fir the doors. It took a few iterations to get everything perfect but in the end it worked well.

We added software to put the servos into neutral when not being used after a slightly out of adjustment servo (we were restricting the action of the servos to match the mechanisms) drew so much current trying to drive to a restricted movement position that it melted the power cable from the battery and shorted the LiPOs. Very spectacular and we were lucky not to burn down the set!

We burnt out one servo and sheared the drive shaft in another before we got the linkages dialled in.

We ended up with the pump control on the "primary" EZB as this was considered the most important feature (a critical plot element) and it actually worked really well. The doors worked for 4 out of the 6 performances.

If we were doing it all again I would simplify the mechanisms to push the doors open but return on a spring. Much safer and easier to setup. Those servos can draw some serious current and can exert a lot of torque.

Overall a great learning experience for the students and the (stressed) teacher.

It was a hoot.

Thanks for the info DJ - saved us going too far down the wrong pathway.

Video didn't post due to format. Try this ....

Very cool gray! Thanks for sharing that! Did they at all ever get to use this button?

:D

This is amazing! Thank you for sharing - and i'm glad to see everything worked out!