Giskard

I understand that not calibrating servos properly could cause serious damage and so an electronics engineer and RC specialist was called in to set mine up from the start.

Day one was amazing! Day two however..

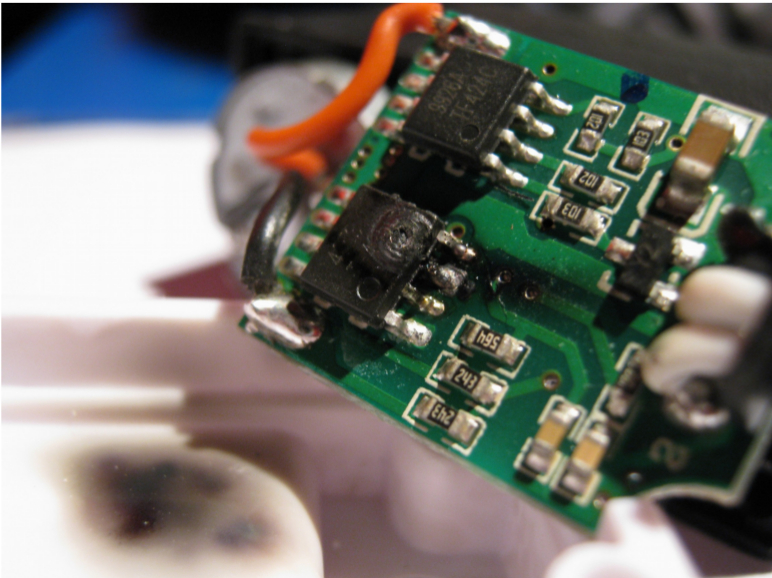

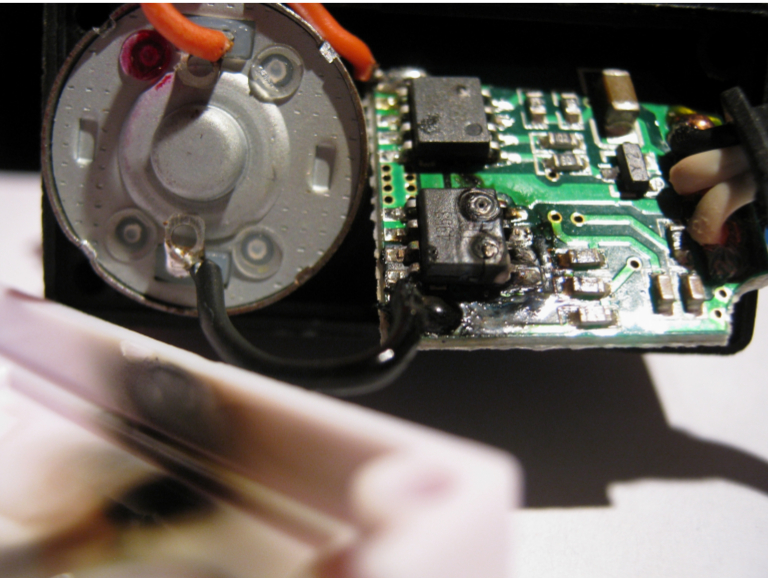

Just one of the chips blew in this servo. Both chips show damage here in this servo. One chip has blown in two places, the other is showing a tell-tale bubble.Two seperate servos smokin' within 24 hrs. And before anyone has a fit and tells me that I no longer have a right to claim warranty now that my technician has simply removed a cover to take a look, read this: I DON'T CARE.

Perhaps ezrobot are not aware of what chinese manufacturers get up to, but an unbranded mosfet 9926a chip is typical of them. An original Fairchild 9926a mosfet chip retails for 85 cents --but apparently that's too much, or, the chinese don't have a licence to use a quality brand (probably both) and so their own copy has been used.

My techs are going to try and replace the chips with quality branded Fairchilds and see how that goes. And if that fails, new servos then. But they won't be coming from china. mad

The mosfet's are little switches that turn the power on and off to the motor to rotate in both directions. The servo alternates directions rapidly to hold position. If the weight of the servo is heavy, or the servo is moved rapidly for long periods, the mosfet's will get hot. This is because they are the component responsible for the motor.

The mosfet specifications on ezrobot HD servos were selected to provide failure of the load and heat is exerted. This is because the only other item which can cause failure would be burning wires or burning the motor, either which is an extreme hazard.

The failure of the mosfet's in this scenario is by design.

I caution you to replace the mosfet's with higher amperage rated ones / as this can potentially cause fire or ezb damage under the similar use case that caused this.

Servos are a wear item - which are expected to be replaced.

I value your feedback, however it's important to recognize that hundreds of thousands of ezrobot servos have been shipped to customers around the world. As you see from the very low number of posts with damaged servos, it's a rare occurrence. The occurrence of damaged servos can always be related to over exerting or stuck servos. A stuck servo usually occurs when a wire is caught preventing it from moving, or someone attempts programming a servo to move/hold too much weight.

If ezrobot recognized our servos as being an issue due to many warranty claims and complaints, they would have been updated a long time ago . It would be impossible for ezrobot to have tens of thousands of robots around the world with extreme quality issues.

. It would be impossible for ezrobot to have tens of thousands of robots around the world with extreme quality issues.

Not true in my case at all.

Perhaps you can tell me what I was doing when the servos smoked, because at no point have I actually said. I'm joking of course, because you wouldn't know.

I was in the hands of one of Australia's most experienced roboteers to be tested for a possible dead servo which hadn't been identified yet. When a 45 degree command was issued to my gripper, it smoked and died. Smelling the rest of the servos led us then to the faulty first we had been looking for.

Given the thirty or so people that frequent this forum, I had always wondered where the other 'tens of thousands' of happy robot people were? Not here, that's for sure. I would suggest that their robots are stored in cupboards somewhere, not working due to dead servos that haven't been reported. Or they have read the usual reply which goes... 'it must just be you, because our servos are fine'. I mean, what can one do with an answer like that.

O.M.G sick

45 Degrees is within the servo range defined in the Init script. This of course would require the grippers to have been calibrated to ensure they do not exert force without being able to move. And, not attempting to squeeze an object past their ability to move. I recommend adding foam to the grippers for holding objects. Here is a quick introduction i made to add foam to grippers: https://www.youtube.com/watch?v=OlNDyt9cXUY

Not everyone uses forums, specifically because most units are purchased through re-sellers and the largest percent is education schools & students. The activity of new member signups can be viewed in the achievement section on the main community page. However, the number of users of ez-robot products is mentioned for comparison to demonstrate that servo failure it is not a problem (less than 1% of total ez-robot warranty and a fraction of that is servos). It's best to begin by understanding how a servo works, and we have a great tutorial here: https://synthiam.com/Tutorials/Lesson/48?courseId=6

Knowing that a servo is a wear item, it's understandable how they need replacing and wear out over time as well.

A servo is powered by a motor. As you can imagine, if you hold a motor from spinning, it will get hot and burn out. If the motor does not burn out, then something upstream will burn out. In the ez-robot case, we have vast experience with servos and recognize the danger of not having a point of failure before burning wire or potentially starting a fire. When a servo is holding too much weight or prevented from moving, it will buzz extremely loud and get hot quickly. The point of failure are the mosfets in the servo. The safety point upstream of that is the fuse.

I do mention overexert as a danger to servos - which also applies with rapid back and forth movements for a lengthy duration. You can tell when a servo is being overexerted by heat.

As you have experienced, robots are at the mercy of motors for a while... at least until torque monitoring servos are more affordable.

EZ-Robot has been working on a torque monitoring servo that also contains stall detection and heat detection. It's a digital servo as well. We have quite a few prototype, but still have a few more hurdles to accomplish before it is available to the public.

Be careful with the mosfet that you swap in. Keep me updated in your progress as i'm always curious on experiences.