steve.neal

Australia

Asked

— Edited

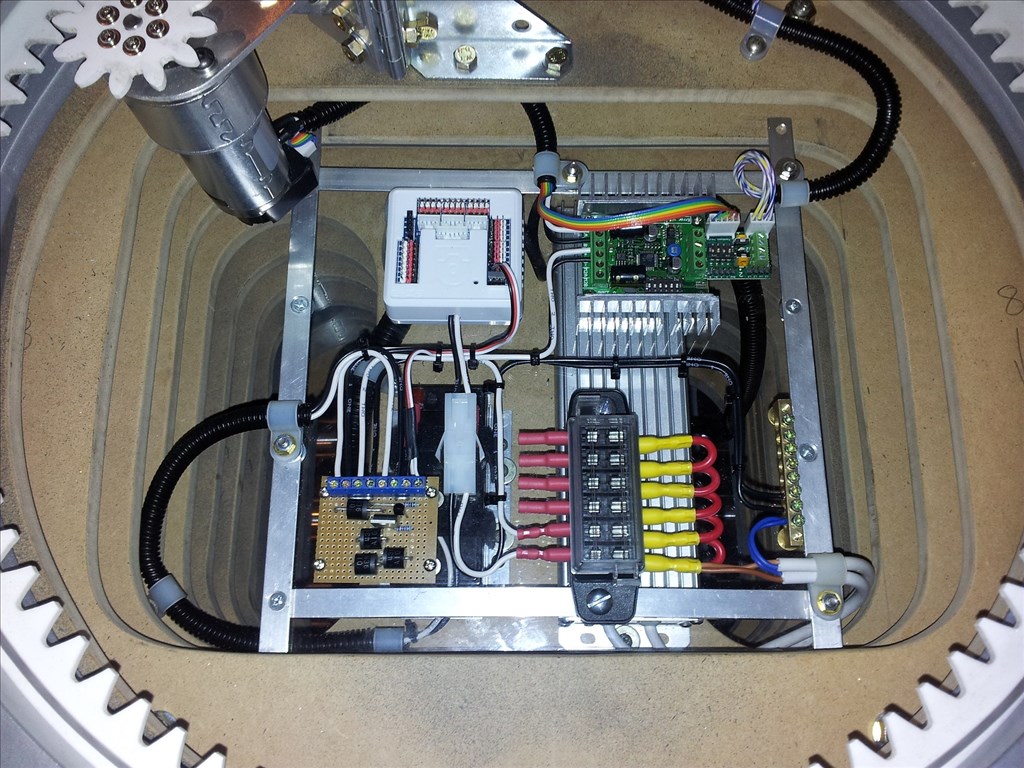

I cant seem to get my sabertooth/kangaroo to do an autotune. The moment I apply power to the sabertooth the motor starts running at about half speed and wont stop till I disconnect power. I am using a REX motor with encoder, limit switches, a 12 volt power supply and a battery to dump the regen power into. I have the sabertooth dip switches set to 1 on, 2 off, 3 on, 4 off, 5 on, 6 on. I have the kangaroo dip switches set all four on I just cant seem to work out what I'm doing wrong. Here is a pic of my set up.

;)

Hi Dave,

I have him doing some basic moves like turn left, turn right and centre using the script manager and voice control. Once I had the position numbers from the tune I had to tweak them a bit to get him to stop where I wanted but all in all, pretty easy. I also tweaked the homing speed as it took nearly a minute to go from centre to the limit switch when first initialised. I had to find a happy medium with that though as if moving too fast there was a big jolt when it found the limit.

I'm having a ball getting things moving. very exciting Thanks to you Dave

Thanks to you Dave

Anyhow, must head off to work now tired

Steve

Hi Dave,

I was toying around with ways to stop the gears jumping and I noticed I had a roll of Velcro strap sitting next to me and thought that might help. I fed a length around the motor and the leg section as a temporary fix and it worked a treat. It still allows a small amount of motor movement via the spring but nowhere near enough to jump a tooth. Its also easily removed when needed. Works so well I may just leave it there.

Steve

Humm, how about that. Nice. Simple and elagent. We still want to let the motor and gears self adjust as the torso spins and the springed hinge let's that happen. I'm guessing that the little bit of slack in the velcro leash alows for that but keeps the gears from jumping when you have a quick start up.

You guys from Down Under are pretty smart.

I wonder if a short bungee cord or a rubber tie down cord would be to weak.

Hi Dave,

I emailed DE regarding the "Beta" version of the DIScribe software and told them I needed it for speed ramping while using a kangaroo. They sent me the new version and an update file for the kangaroo. I have spent a few hours playing with it this afternoon and after some head scratching and two cups of coffee, I have the waist motor ramping. Nice soft starts and soft stops. The ramping effect does not seem to work on the first "homing" movement when first initiated so I needed to keep that speed down to limit the sudden jolt when it finds the limit switch. It wasn't that hard to do either... although, I made it look hard

Nice soft starts and soft stops. The ramping effect does not seem to work on the first "homing" movement when first initiated so I needed to keep that speed down to limit the sudden jolt when it finds the limit switch. It wasn't that hard to do either... although, I made it look hard

All in all, very happy. Far "Beta" than jerky starts and stops I had before.

than jerky starts and stops I had before.

Steve

I need some more advise regarding Sabertooth 2x12/Kangaroo motor controllers. I have the one in the lower half of my B9 as seen in the previous pictures working perfectly, ramping and all. This controller will only be controlling the waist rotation motor that its currently connected to. I have a second Sabertooth 2x12/Kangaroo in the upper half to be used for the bubble lifter linear actuator and the radar rotation motor in the head section. I have mounted a 100mm (4") linear slide potentiometer and external limit switches to the actuator for feedback to the kangaroo. I have done an auto tune and have it working awesome. It has just occurred to me that the motor for the radar section I intended to connect to the second channel of the sabertooth has an encoder for feedback.

I think this is where I will come unstuck. Is it possible to connect two motors to the one sabertooth with different types of feedback (Ch 1 potentiometer & Ch 2 encoder)?

My thinking is that I cant and I'm going to need another sabertooth/kangaroo combo for the radar motor. Can someone please confirm this for me before I buy another one.

Here's some picks of my linear actuator set-up.

Hi Steve,

I asked this same question to DE support and they told me "No". There is no way to mix a pot and encoder using the same Kangaroo X2. You need to choose this option with the dip switches on the Kangaroo and the choice is either one or the other. When I thought the process through it seemed to make sense to me. A pot measures the voltage difference as the wiper moves across a voltage bar. An encoder counts light flashes or electrical pulses as it turns. Two completely different functions. Hope this helps.

Soon I'll be setting up an autotune for the mechanism that will be moving my B9 arm in and out of the torso. I'm a little worried as it will be an oddball setup that the auto tune may have trouble with. I'll be using the same Rex motor your using in your waist with the encoder built in. If you can picture this; the motor will be mounted under a platform and have a double pulley mounted on it that will winch the arm in and out of the torso on a linear slide sitting on top of the platform. It will all be attached with a strong cord that will run from the arm above the platform to the motor double pulley below through multiple pulleys and spring tensioners (to keep the slack out of the cord). This is the same design RC Sailing Boat builders use to manage the sails on their big RC yachts. My worry is that the Kangaroo wont be able to autotune this setup very well. You have seen how crazy the autotune process is with the motor reversing motor direction, checking different speeds and generally acting nuts. It's will be interesting to see how this will work. I may have to manually adjust the settings in the Kangaroo if the autotune cant figure it out on it's own. I had to do this with the arm section and it was a pain.

BTW, very nice engineering and design on your feedback device for the linear actuator. How fast is this actuator? I was not able to find one fast enough to move my bubble with enough speed to suit my taste. If I had been able to find something my bubble lifting setup would have been so much simpler and easier to build.

Hi Dave,

Thanks for confirming that for me, another saber/roo it is

I have the linear actuator travelling about 80mm of its full 100mm of travel because that seemed to be the limit of the rubber neck boot from Will without stretching it too far. This also keeps the movement away from the actuators built in limit switches. I did have the external limits slightly closer to the ends of the travel at first but the during the auto tune as it found the first external limit, it would "jerk" a little, as it does during an auto tune, and it triggered the internal limit and just stop and the tune would fail. Took me a while to figure this out though. I thought I had the wrong settings on the roo dip switches at first, and then I thought I had the pot connected wrong, but what it needed was to reduce the travel a little as is was too close to the internal limits. Once I had this fixed and a successful auto tune, I checked the figures with the DEScribe software and wrote the script to the soft limit figures and ended up with the 80mm travel I was after. It does this travel in about one second from end to end. Its seems to be a good speed. I can tweak that with the pot on the Roo as well. I did try the ramping effect on the actuator but it was too jerky. I think that's because the linear pot is nowhere near as high resolution as the REX motor encoder. Another advantage of the linear actuator is I can stop it anywhere in its travel and it can hold the weight of the head with no extra support or whining from the motor. All in all I'm pretty happy with this set-up. I wasn't sure if it was going to work as I hadn't seen any other B9 bubble lifters done this way

Anyhow.... I must head of to work now

Thanks again Dave

Steve