mantici

USA

Asked

— Edited

OK i've searched this forum for this answer to no avail, here's the story.

i've soldered up my hc-sr04 exactly as it is described in the tutorial, hook it up (in this case trigger/voltage is on D6 and echo is on D7, add a ping control (not the radar, tried that too) and it always returns a value of 255.

Currently running the EZ-B off of 6 AA Alkaline batteries (Tried new ones, still no luck).

Did i get a defective hc-sr04 with my "Complete Robot Kit"?

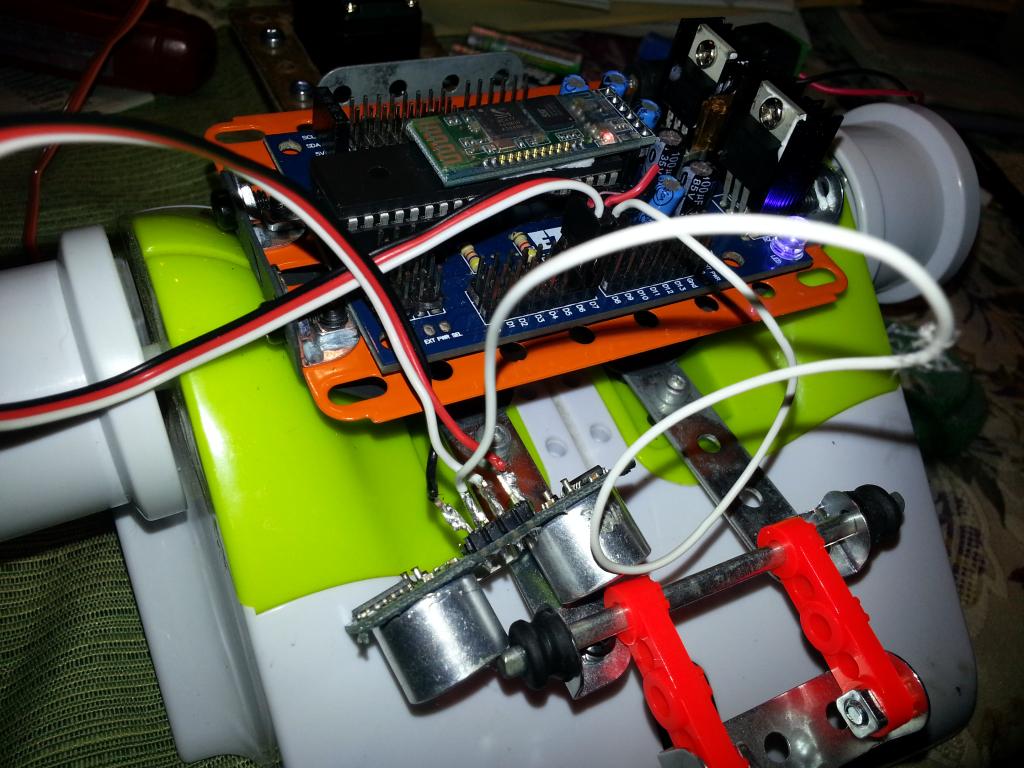

Any ideas? I've attached a pic of my connections. Please help. confused

BTW, the pins didn't want to hold the solder, my 14 year old son and i worked on this and i had to do the soldering, he just couldn't get it to stick. there are no cross solder connections, i've checked and re-checked.

It maybe that there is a dry solder joint which has a whiter crystaline apperance and although stuck to the wires doesn't conduct any electicity. Yours look ok in the pic excpt perhaps the red wire

If you used a lot of heat trying to solder the connections you could have damaged the sensor board. You should solder components as quickly as possible and let things cool down if it didn't take the 1st time

Whats the EZ-B mounted on is it metal and shorting any connections

that was my first concern, too much heat. . . i suspect that i did damage the sensor (ordered 2 more on ebay already).

No chance of shorting, there's rubber gaskets under the ez-b, even so, i tested this with the ezb off the mount.

stress

I had my hc-sr04 working fine until my camera panned into it and shorted it out. It now constantly reads 20 CMs.

I've now glued electrical tape over the pins of my replacements and the bottoms of other boards.

Best,

Bill

i dug up a 4 pin connector from my misc. server/computer hardware parts, fits perfectly, so when my new sensor(s) come in, it'll be plug and play, no soldering, no chance of solder heat damaging the sensor.

Good idea that connector! Noted.

Always tin the wires with solder , once they are covered and wire is still hot THEN touch iron to pin for a couple seconds. It is definatly possible to damage somthing if it gets too hot. Honestly i bought wire jumpers and connectors to prevent that kind of damage.

PS PS I used a 12" wire and it failed to read. Then shortened it to 3" and it worked. I haven't yet determined the maximum length though.

Bill