Tachyon

Just wanted to share. I found some nice gear motors at Princess Auto. I believe that they are car power seat motors which means:

- 12v operation

- reversible gearbox

- good power/torque

I just tried to current test them but my multimeter's 10A circuit has apparently taken a dump. I'll update when I get my other meter out of the truck. So I just tested them and the bad news is that they draw almost 2 amps no load. The startup bump is about 2.5A and steady at about 1.8A so a standard L298 controller setup is likely out of the question. As soon as I get a piece of square tube that fits the square keyed drive hole, I'll test current drain under load and as close to stall as I can get it by hand.

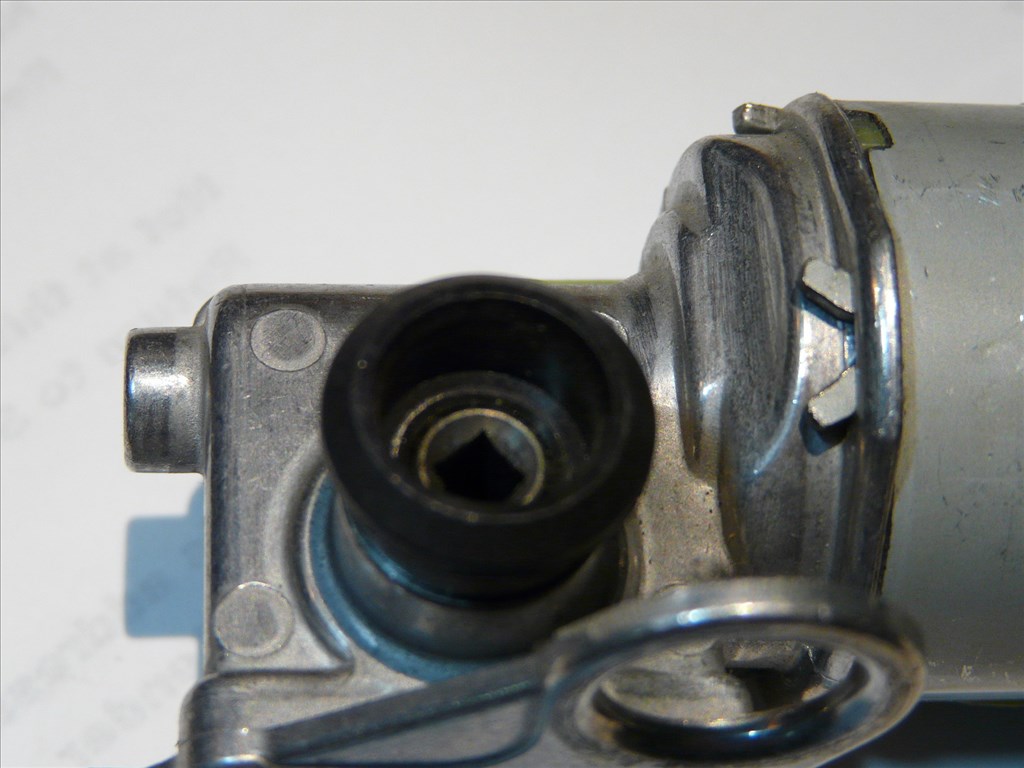

Anyway, these look like a great power source for something robotic. I can see them working really well in a tracked or skid steer vehicle. The output is square (see photo) and I'm going to see which size square tube will fit in there. They also have some nice mounting points built into the gearbox. My only concern is running them continuously for long periods. They may be fine, maybe not. I dunno. Anyway you can find them at: https://www.princessauto.com/pal/Miscellaneous-Surplus/12V-Reversible-Gear-Motor/8365298.p

Oh yeah, I got them on sale for $6.99 and I've seen them on sale before. They also carry a power window motor that goes on sale regularly so watch their ads.

Thanks for the note. let us know if you find anything while using them.

Sweet, I'm definitely interested too! I wonder how hard it's gonna be to interface wheels to that square output coupler. Hmmm, wonder if a No.3 Robertson would fit?

@skater_j10 I've been thinking about that too. My first thought is a piece of square tube or square bar. I'm going to hit the hobby store and see if I can get a piece that fits. After that I'll see what I can cobble together. I'm thinking possibly a carriage bolt that fits through the square tube. Then solder or epoxy it to the square tube. You would then have a drive axle that isn't hard fixed to the motor, but that can't go anywhere either.

OK, so I made a trip to the hobby store and I found some brass square tube that fits perfectly in the drive hole of the motor. This is that really common brass square tube that you see in the metals multi-pack display at every hobby store. It's made by K&S Precision Metals (who are easy to find online too) and it's 5/32 x .014 (3.97mm x .355mm) square Brass tube Stock #152. So any 5/32 square rod will work. I am not sure how I'm going to connect it to an output yet so I went with the tube in case I decide to epoxy or solder a piece of threaded rod in the end.

I also used the square tube to load up the motor and run an AMP test on it. Under load it runs between 2.25 and 2.75 AMP's. I wasn't able to stall it by hand but gripping it tight enough to slow it down I saw peaks a little over 3 AMP's.

Given that power seat gear motors are sitting around in junk yards all over the planet, they might be a great resource for putting powerful drivetrains into robots on the cheap.

Put a sprocket on that bad boy use a bicycle type chain to drive your wheels. That way you have plenty of options for mounting instead of a wheel direct to the motor.

@jstarne1 How would you go about mounting a sprocket on this setup? Ideas?

On another topic, I'm thinking about testing this with my L298 motor driver anyway and see how it does. At worst the L298 will protect itself and go into thermal shutdown. I'm also going to see what RPM this turns at 12v and do a little math and see what I can get away with if I gear it up a bit to trade speed for power. That should unload the motor some too.

I found a similar source for motors here. They are windshield wiper motors. They are bigger than window motors. I do not know how they compare to the seat motors. These ones definitely are designed to run continuously though. Here

A word to the wise when using wiper motors. Automobiles typically have the chassis grounded. Since wiper motors are not reversed in a car, the body of the motor is grounded. If you reverse the current to the motor, the case becomes electrically hot. This becomes especially problematic if you have several motors bolted to a metal frame. The motors that I bought have a simple work around to eliminate that problem. They come with a ground wire connected right to the case, and inside the motor, one of the brushes is connected to the case. If you remove the ground wire, and drill a small hole in the end of the motor, you can attach the ground wire directly to the negative brush, isolating it from the outside case. If anyone is interested, I can post some pictures of how it is done. It is about a ten minute job.