Do you print EZ-Robot Parts on a Resin Printer. If so what make model?

Between broken pieces, missing pieces and various hacked pieces, my EZ-Robots are starting to look more like frankensteins these days with multiple 3D printed parts. I am using a prusa I3 printer with PETG and for most parts it is pretty good. The odd shaped components that are of course the ones that break all the time (Shoulders, Feet, Grippers) don't print as well as they all need supports and supports means lots of work cleaning them up.

I was thinking of moving to a resin printer but wanted to get some insight from anyone printing EZ-Robot parts on a resin printer (Just the small components not things like a large Roli body). Do the components print ok without supports, do the servo horns threads get stripped easily, how is the colour matching with EZ-Robot.

Related Hardware (view all EZB hardware)

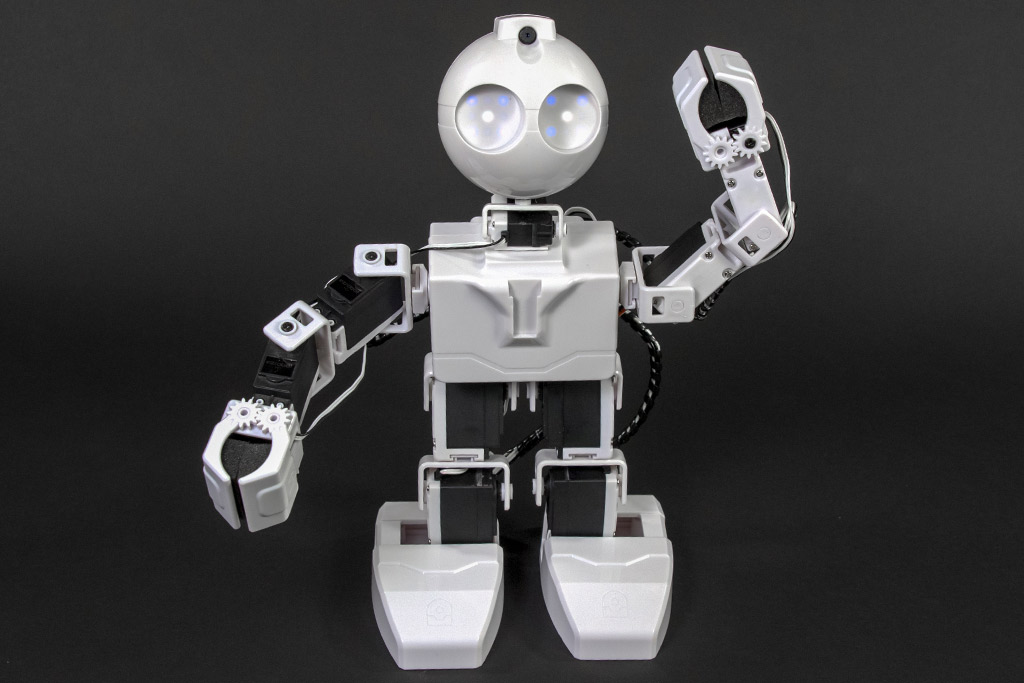

Hello @Nink. I have printed a full JD in resin. I own 2 x Elegoo Mars 2 resin printers. I use Anycubic clear resin and Elegoo ABS-like clear resin.

While it does look pretty cool to have an EZ-Robot in translucent material, there are some downsides:

Resin prints are very difficult to get dimensionally accurate, it always seems that one side of the print warps a bit no matter the orientation (I had the greatest success with printing at 45). Elephant's foot happens when you print directly on the build plate, and is a hard issue to overcome. Printing with supports helps but the part sometimes looks terrible due to the spots the support leaves behind. I have done everything I could (warm water, heat gun, slow removal) to mitigate the spots that supports create but you can only go so far

Resin is brittle. If you have a small feature you twist a bit too hard or if you bend something a little too far SNAP the resin parts break very easily under stress. Threading screws into resin is also very unforgiving, the crazy glue comes out pretty quickly. Even the toughest ABS-like resin breaks quite easily

Resin is not good structurally. As you can see in the photo below the JD leg brackets are sagging due to the weight. It doesn't matter how long you cure the resin it's just not great at load bearing. There's a trade-off here the softer/flexible resins sag more quickly and the harder/stiffer resins snap more easily

Unfortunately, resin won't give you the strength you're looking for. I too had hoped that I could recommend resin printers for printing replacement parts but this avenue was not a success. I had so many parts snap and others warped. I had to settle with many sub-par parts in order to finish the JD below

My recommendation would be to contact EZ-Robot customer service and we should be able to accommodate sending you a bunch of ABS injection molded plastic pieces (for a small fee of course).

Thanks for the detailed insight Jeremie. It sounds like purchasing a resin printer to print may not have any advantage although I do love the translucent JD.

The PETG works well apart from cleaning up all the supports and as you said when you can’t clean it off properly it looks rough. The colour match is also a little off.

I surf around Kijiji eBay Facebook market place looking for second hand parts but they rarely appear.

perhaps I need to bite the bullet and put an order in for all the broken parts.

The part that breaks the most is the shoulder. This occurs in both the injection molded and 3D printed models. I guess I need to design a new one with thicker reinforced sides.

here is a 3D printed one and injection molded one. They all break the same way.

hi ninck and jermie

you can order these shoulder parts .

ez robot parts

hi jeremie thats a cool jd you have made .

I forgot to add that the injection mold for the solder bracket has been updated. It was beefed up to be stronger. We haven’t seen shoulder bracket issues since the changes were made. I’ll try to post a picture later.

Here was my quick and dirty hack today. Old at the top new at bottom. Hopefully the extra support solves the problem. .

@DJ Spam post above.