Hi All

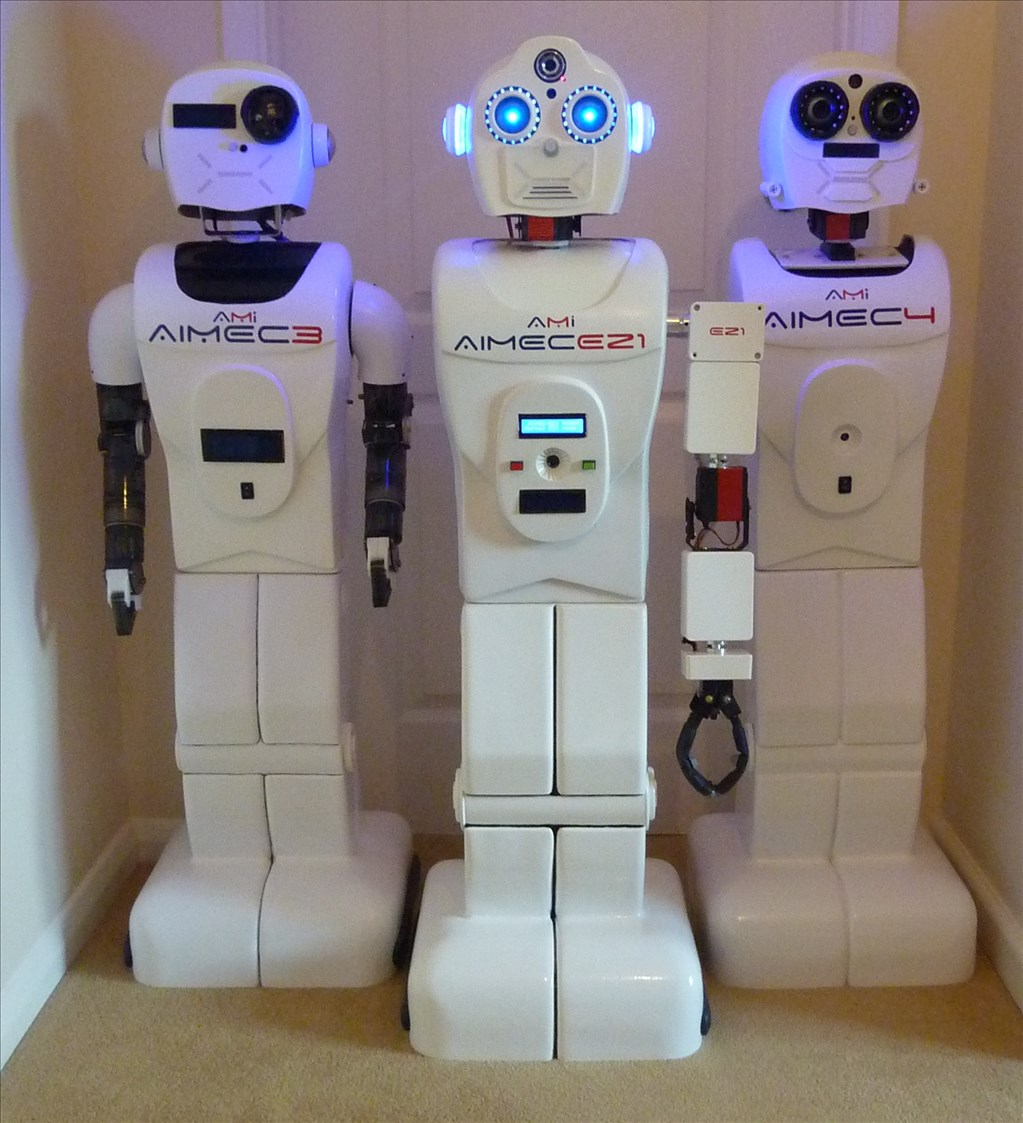

Introducing the AIMEC:EZ1

We are in discussions with DJ to produce a special version of our AIMEC (Artificially Intelligent Mechanical Electronic Companion) robot for the EZ-B, this will be a very advanced robot that will be made available in kit form, which will probably be by the end of this year.

Some history, the first AMI (Applied Machine Intelligence) robot was the AIMEC:3 which is a "hyper-tech" toy and we were very close to licensing this design to a large US toy manufacturer, but the deal fell through. Our most advanced robot is the AIMEC:4 which is still in development, this robot has advanced voice recognition (Dragon 11), face recognition and eye tracking and object recognition the robot has an advanced Ai core and is capable of self learning. When we came across the fantastic EZ-B system that the genius DJ Sures produced we immediately thought that it would be really cool to make a EZ-B version and this is what we are currently developing the AIMEC:EZ1. This robot is the development platform for a ground breaking robotics kit that we plan to sell to the general public, for the first time a highly advanced robot will be available (in various versions) at a price that hobbyists would be able to afford.

I have been building robots for over 30 years and some of my designs are recorded on Cybernetic Zoo

https://cyberneticzoo.com/?p=2280

https://cyberneticzoo.com/?p=3984

On our team we have the brilliant model maker (and engineer) Steve Cole (Articole Studios) https://www.articolestudios.co.uk/ who is also a member of this forum @ukrobotman, with Alex Cole on 3D design and (the incredibly talented) Mike Hodgson on software development. I am doing mechanical, electronics and sensor designs and firmware development for support PIC microcontrollers that enhance the EZ-B boards operation over the I2C bus.

We are all looking forward to working closely with DJ and his team in the new future!

Tony

-- Conceptioneering Ltd - Inventors of the Award Winning Cube World To see Product Innovation - visit our website at www.conceptioneering.co.uk To see Robotic Innovation - visit our website at www.appliedmachineintelligence.co.uk

Tony, are you using one of the Bosch actuators for the claw open/close?

Rex, no the claw has a smaller worm driven motor inside the claw enclosure.

Tony

@ Toymaker, I seem to have found bosch engines although I have seen 3 models similar to yours, a model incorporates a potentiometer 24v, 12v model not incorporates potentiometer. It's easy to incorporate the potentiometer? I guess yours are no potentiometer 12v and you had to incorporate it yourself, I would like to leave this question, I paerecen good candidates to become servos.

www.oemmotor.se/Produkter/Motorer/DC-motorer/Motorer_med_vaxel/Bosch_VMC_12_V_0_29_W/536572-500260.html

@Tony,

I love the smoothness and how quite the motors are. The speed seems good also but a little faster would be better. Not a deal killer though. Do you have the speed set all the way up? I'm looking for ward to getting my package from you as I'm going to be trying these in the arms of my B9. Still need the see if they will pick up the load of the entire arm (very heavy with rubber, slides, claws, motors and wrists).

Also Tony, do you have a print or drawing of the bracket you used to connect the two shoulder motors to the load of the arm?It looks very expertly built. Nice craftsmanship.

@R2D2, I'm under the impression that these bosch motors (engines) already have the feedback pots built into them.

@R2D2, Yes the Bosch actuators that I use have built in feedback potentiometers. Dave, when you get yours, the top 2 connections are for the motor and the bottom 3 are for the pot.

Dave, I can speed the arm up if I wanted to, just by the turn of a (multi-turn) preset on the buck convertor, but I dont want the servos to move too fast as this will cause the EZ:1 robot to lurch and be unstable when manipulating heavy objects in its claw. Its ok for big pick and place arms and car welding/paint spraying robots to be fast as they are bolted down to a concrete floor, but on a mobile robot that is to carry and manipulate "real" loads in its end effector, then lurching (and unbalance) can be a real problem, I want to see smooth and fluid movements in our heavy duty arm.

Light weight arms do not have this problem and can move quite fast, but they are not expected to do any real heavy duty work.

I have learnt to my cost that its not possible to make an arm of this capability (that I require) with RC servo's even high torque ones. The only servos that could get these arms capabilities are Dynamixel. You would probably need 2 x MX-106T for the shoulder and one for the elbow (vertical) at $500 each and a MX-64T for the elbow (horizontal) and wrist rotate at $300 each, so we are talking $2100 for just the servos! Also the EZ-B does not currently have the ability to control the RS-485 bi-directional comms link required, so it would be necessary (at this time) to design an interface micro that converted I2C commands from the EZ-B to RS-485 serial as (again currently) I2C is the only comms on the EZ-B that has read and write functions.

In contrast, the smart servo that I have developed for the EZ:1 and EZ:2 arms has just $20 of components in, so instead of costing thousands of dollars that a Dynamixel version would our arm will be in the hundreds. Of course you could make much cheaper arms with the Dynamixel AX-12 and AX-18 etc but they would not have any where near the power/torque required for our arm specification. The EZ:2 robot is being designed to do useful work around the home, so it has to have powerful working arms and manipulators.

The bracket connecting the 2 actuators is a standard "C" bracket on 6mm hubs

www.active-robots.com/motors-wheels/servo-hardware/aluminium-c-large-servo-brackets-2.html

Tony

The pre-production "Smart Servo" PCBs are in, they are fully self contained and measure 60 x 46mm. They can be controlled via regular servo PWM or the I2C bus

I will probably go for an even smaller board using SMT (surface mount) for full production units.

Here are the smart servos in the EZ:1 robots head pan/tilt setup which is very smooth and quiet in operation. The worm drives takes all the problems out of tilting the heavy head which used to buzz slightly under load when it was made from regular high torque servos, these are completely silent.

Tony

Fantastic Tony Hope you make huge progress in 2014 now you have a smooth motor drive unit ,well done

Pat

Hope you make huge progress in 2014 now you have a smooth motor drive unit ,well done

Pat

Thanks Pat, you finding the Bosch actuators (on ebay) for me helped a lot! Because I am now buying them in volume, I have got the unit price down to just over 4 which is incredible for such a powerful worm driven motor drive with integral feedback pot.

Tony