jstarne1

I have 2 Makerbot Replicator 2 series 3d printers as many know. These are very popular printer that is good enough for a entry level engineer and great for the individual who wants to create. There are many off brand machines that basically duplicate the makerbot . When I took my machine apart recently the first thing I noticed is nothing says makerbot on it , not the stepper controllers , not the reprap controller , or any of the steppers which tells me they outsource all of this. What I want you to take away from this is though makerbot has a great product there are excellent replacements or even upgrades.

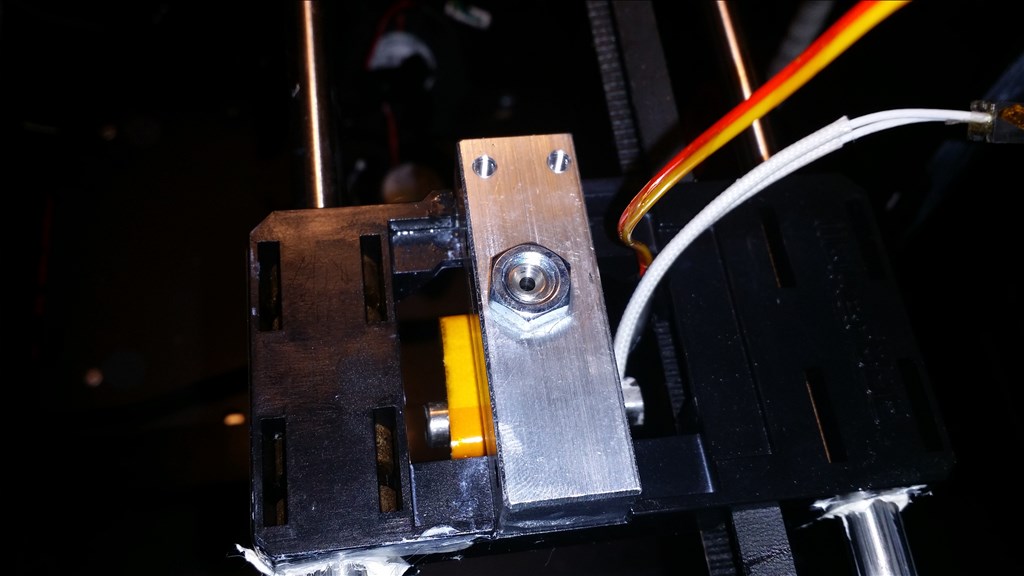

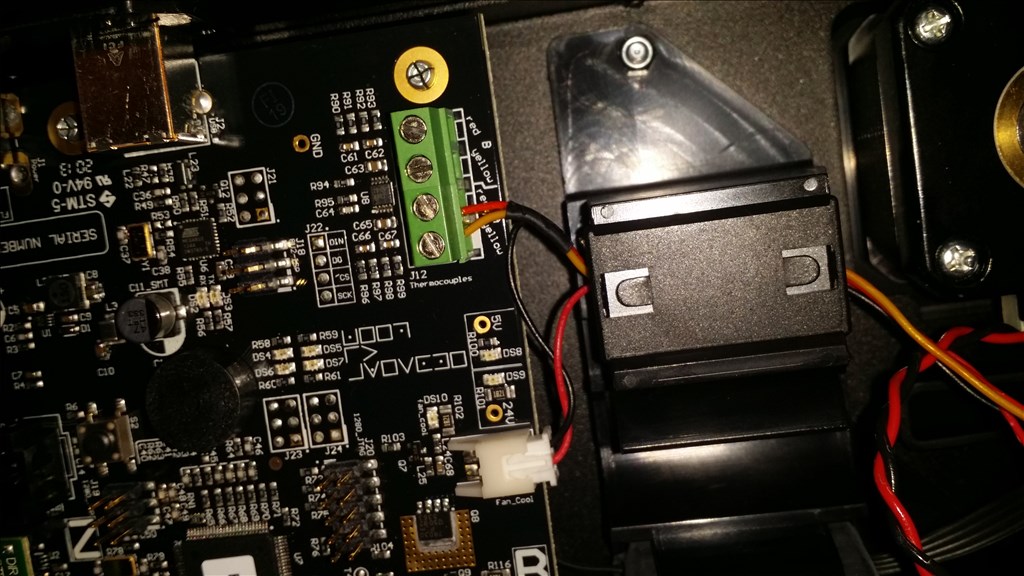

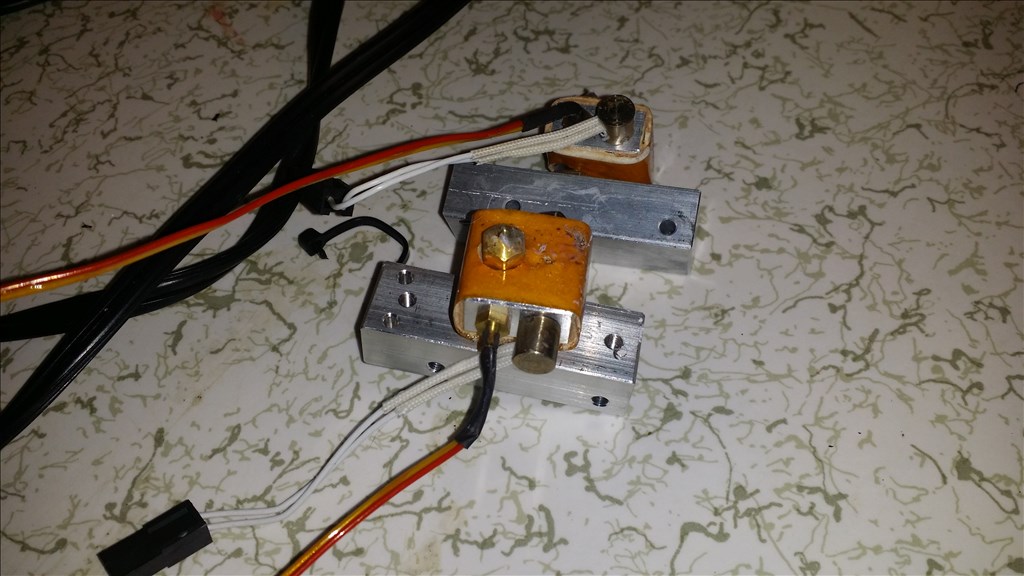

The original tips that came with maker bots were prone to clogging and heaters wear out quickly. Here I am swapping out the original assembly for a mk6 bar assembly.

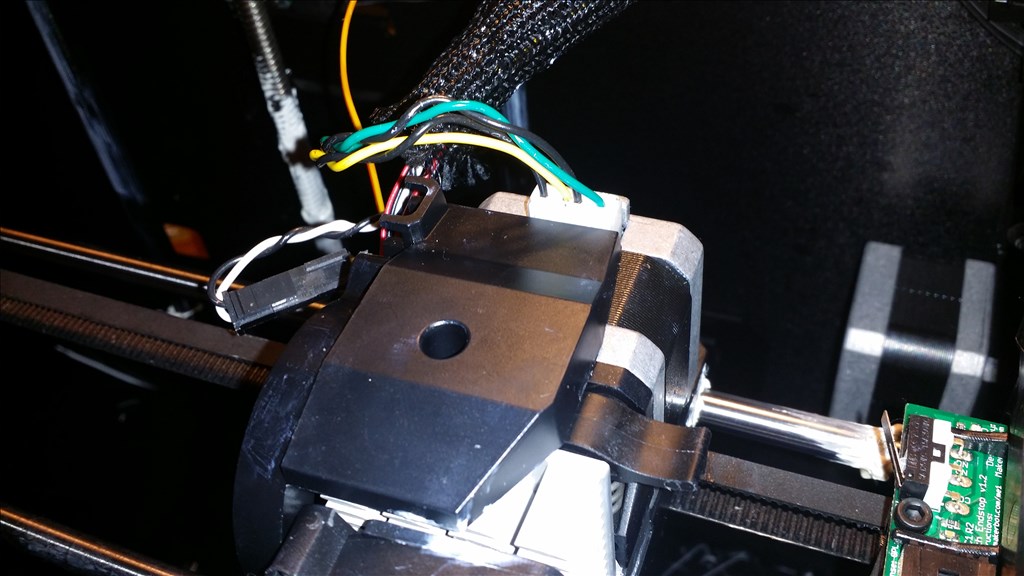

Removing extruder

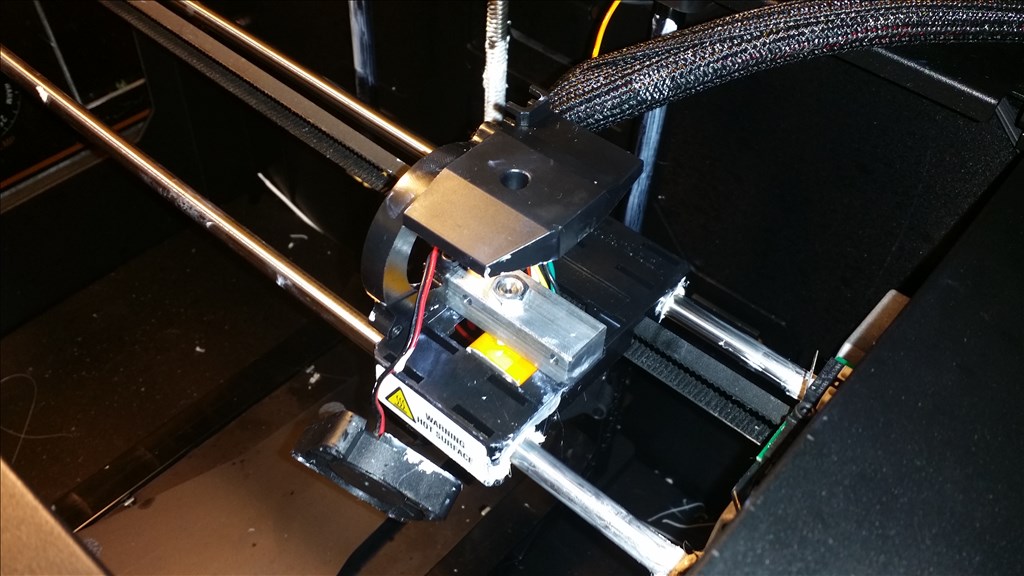

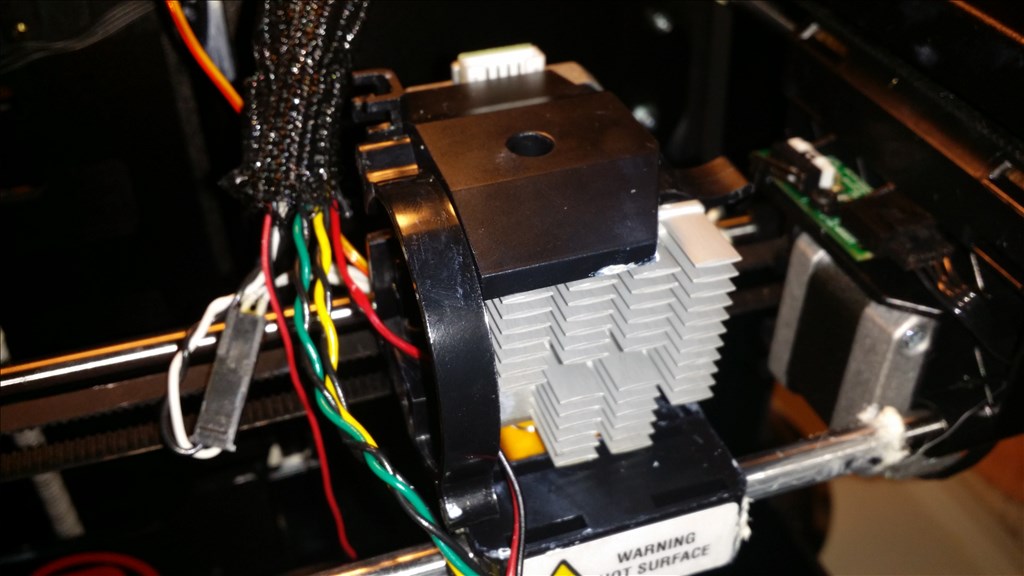

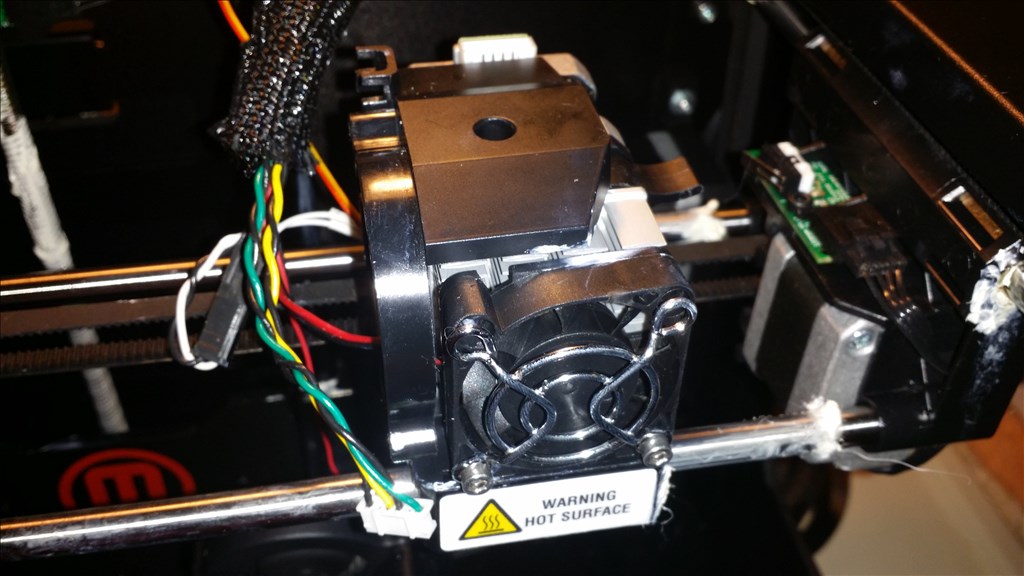

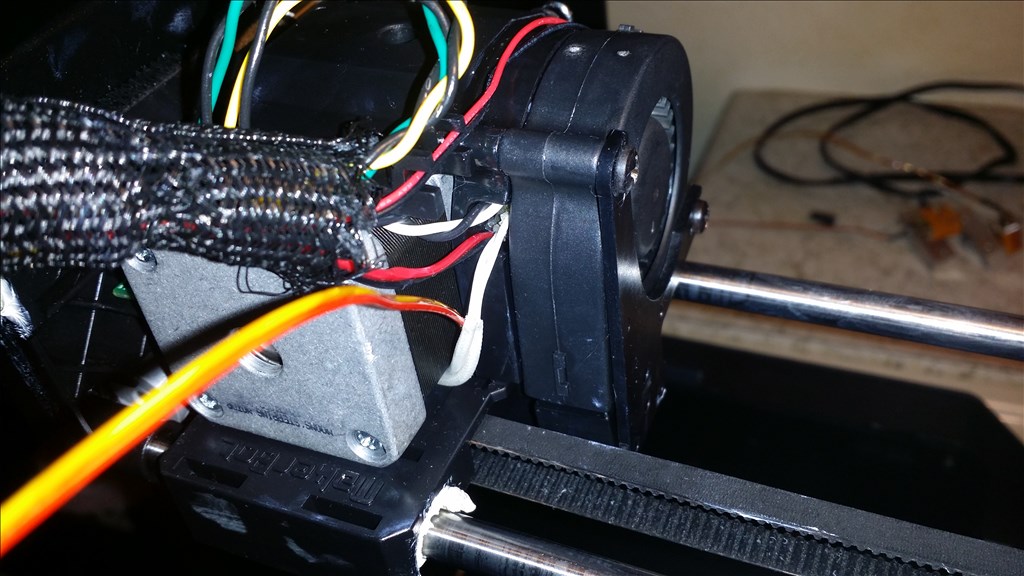

Installing the extruder

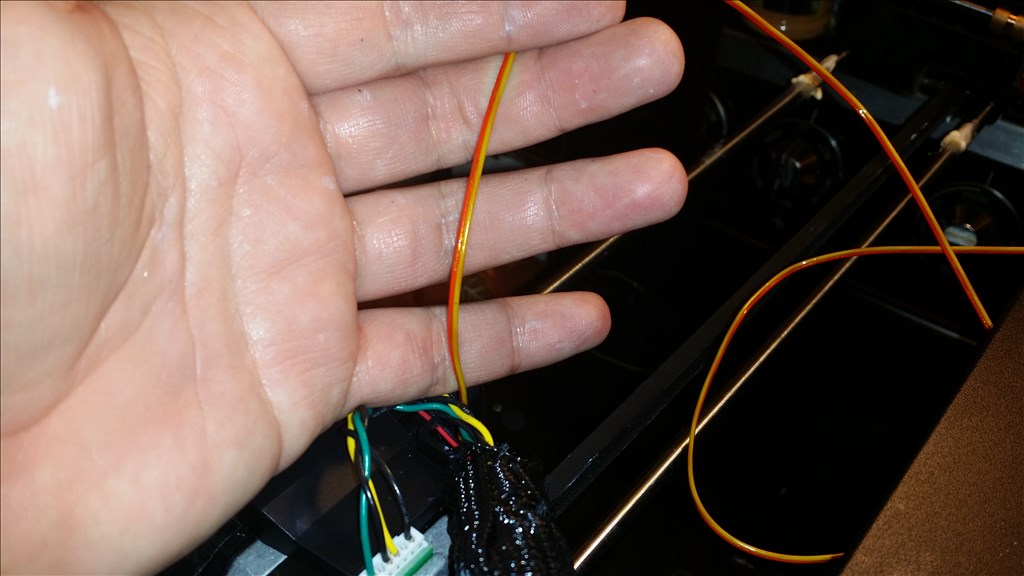

-plug in the heater

When everything is back together you can use 4 zip ties to affix them to the designated mounts , 2 on the back , one by the stepper on the carriage and one at the base of the cake bundle.

The makerbot extruder tip I'm told is .2mm but for some red the one they sent appears to be a tiny bit bigger. Maybe the original was a .1? I have read the smaller the tip the more likely a clog and also it is difficult to clean.

Cleaning - I picked up a set of extruder cleaners. They are like tiny drill bits the exact size of the extruder tip you use to clear it from the outside. In the future I'm going to clean the tip every few hours of printing because I really don't like the se clogs. I have had 7 all together , two in the he same day within a couple hours.