Shlomo

Canada

Asked

— Edited

is there any way to connect with someone experienced with building and remotely controlling a large robot for collaboration on a commercial project?

Related Hardware (view all EZB hardware)

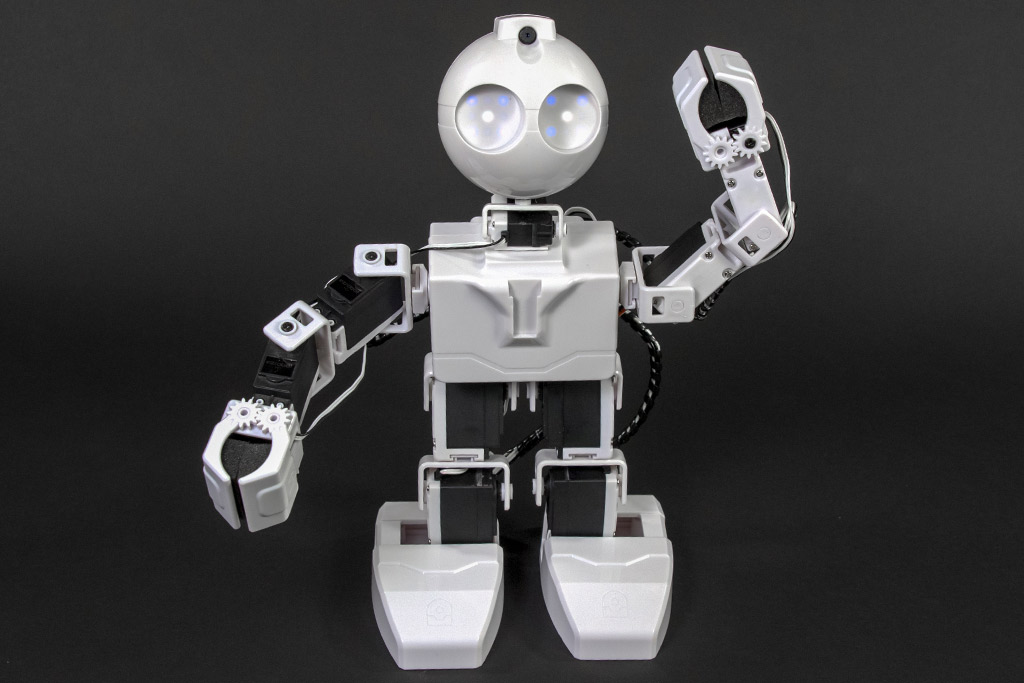

JD Humanoid

by EZ-Robot

JD humanoid robot kit - WiFi-enabled, 16 DOF with metal-gear servos; easy, fun, educational, available from the EZ-Robot online store.

Wi-Fi / USB

Servos

24

Camera

Audio

UART

3

I2C

ADC

8

Digital

24

PS. I should've included my email to be contacted directly - it is [email protected]

First, welcome to the forum. there are a number of people making human sized robots who could give advice. If you can give some more info about your project goals you will probably get more input.

thx very much for your timely response. I just happened to get back to my computer so I can respond with the same timeliness (this time, at least). I don't want to publish on a public forum too much detail because of non-disclosure concerns and that is why I added my personal email address for followup conversations that could be more private. However, I can say this: the main requirements are 1) stable mobility (eg. wheelchair base), 2) instantaneous response to commands from a remote operator (eg. move forward, rear, right, left, etc.), 3) realtime audiovisual communication between remote operator and robot's environment, 4) 12 hour operation in between charges, and 5) some arm movement - to be discussed I do not have the detail orientation to build this myself. I am looking for someone to build it according to my vision (allowing for modifications based on input from the builder). I can contribute towards the expenses. The split in profits would be commensurate with the relative proportions of input from the participants and their ongoing contribution to revenue production.

OK, nothing there is outside the capabilities of the tools available here. Several ways to use ARC software remotely, some better than others. There are some license limits on commercial use that you would want to discuss with DJ Sures. If this is a small number of devices, probably not an issue. If you are prototyping something that you plan to market / mass produce, probably more of a concern.

I don't even have time to work on my own robots right now, but based on your description, I am willing to bet someone will be interested in helping. If you don't hear from someone soon you can ping me. I actually have a wheelchair base and a Sabertooth controller for it currently sitting idle waiting for me to decide on a project, so if I can find some time I might be able to help you prototype, although my build skills are not what I would call commercial quality.

Where in Canada are you? There are a few builders who are very very good up there. @Richard R I believe is in the Waterloo area, and EZ-Robot/SynthIam are based in Calgary.

Alan

Vision is great but someone needs to fund the construction of your voice activated wheel chair. There are a lot of people on here who could knock off a prototype for you pretty quick but I would also assume at minimum they would look for you to fund parts and reimburse labour costs. The build it they will come idea is great but we have seen a lot of initiatives fail in the robotics space. IF YOU HAVE FUNDS, you may want to try some smart people like Josh (mechanical engineering / Design and PTP electrical engineering / coding) https://synthiam.com/User/Profile/jstarne1-585 https://synthiam.com/User/Profile/ptp-6106

To Alan the Techguru I say: I am in the Toronto area, about an hour away from Waterloo. I wouldn't mind travelling there but you can also get a lot done via Zoom. I would love to hear from Richard R. To Nink I say: I didn't realize one could overview each member - thx. Jstarne looks good but doesn't describe broadly enough the practical applications he addresses; doesn't provide videos of finished project?! Ptp has much less completed. Still, I would be pleased to chat with either of them.

To both Alan and Nink I say: I saw that ARC sw and hw addresses my needs in a quite full way except for the fact of size. I haven't seen this product implemented on a life size robot - I wonder if the servo's (HDD) can support the weight of a larger size. The bartender robot seemed to walk very slow which was surprising if it was on an electric wheelchair base, as I was given to understand. But conceptually, it is very close to what I envision - I just don't have the detail orientation the build will take. The license issue is interesting. Right now, my idea is to build a working prototype that looks good enough to get some customers to commit to a purchase. At that time, they will describe more exactly how they want it to look and act and we will then go back and forth between price and full features that will make eveybody happy. I wouldn't be happy unless the result promised a sales volume in the 1,000's and that would include working something out with licensing, as necessary. I hadn't contemplated the remote operator using voice to activate movement, although I can see it is feasible. By "move right, move left, etc." I meant moving a joystick or sliding a finger on the screen as I have seen DJ Sures do. I think I can fund parts, perhaps labour too, but them the other party would not have any call on future profits. I was hoping to find someone who would become as enthusiastic as I about the vision (to be revealed) that they would become a sweat equity partner. Thank you both for your comments. I hope they lead to finding the match I am looking for, or even "a" match.

The EZ-B is a controller (The brain). You can directly attach and power servo's, hbridge to motors etc from the EZ-B but you can also provide power direct to the actuator. So it doesn't matter what you attach to that controller in terms of load as you are essentially just providing a signal to the actuator and an external power source.

To give you an idea of troubled robotic projects take a look at the Altair project https://synthiam.com/Robot/Introducing-The-Altair-Ez-2-Robot-563 lots of time, money and effort invested was an amazing robot but it is really hard to move these types of projects forward. I know a guy in Toronto who has spent millions building and marketing a robot (crosswing) it is a great superfast smooth omnidirectional robot but can't get passed prototype.

why can't it get past prototype? If that means nobody wants to buy it, I can understand why. The presentation does not concentrate on its benefits, what it can do for you. How well do you know this guy? Maybe I could work with him by marrying my vision with his. I once presented on Dragon's Den for an invention I called Shelevator for "shelf-elevator". It was a drawer designed for too high to reach shelves - this drawer not only went in and out but also up and down, so you could easily bring the contents down, take out what you need, and return the whole drawer to its original place. It worked well and was inexpensive but nobody liked the way it looked - I had neglected to test the market - that is why I am focusing now on getting a working prototype to test the market first.