RIP: Anki, Jibo, Baxter, Mayfield, etc...

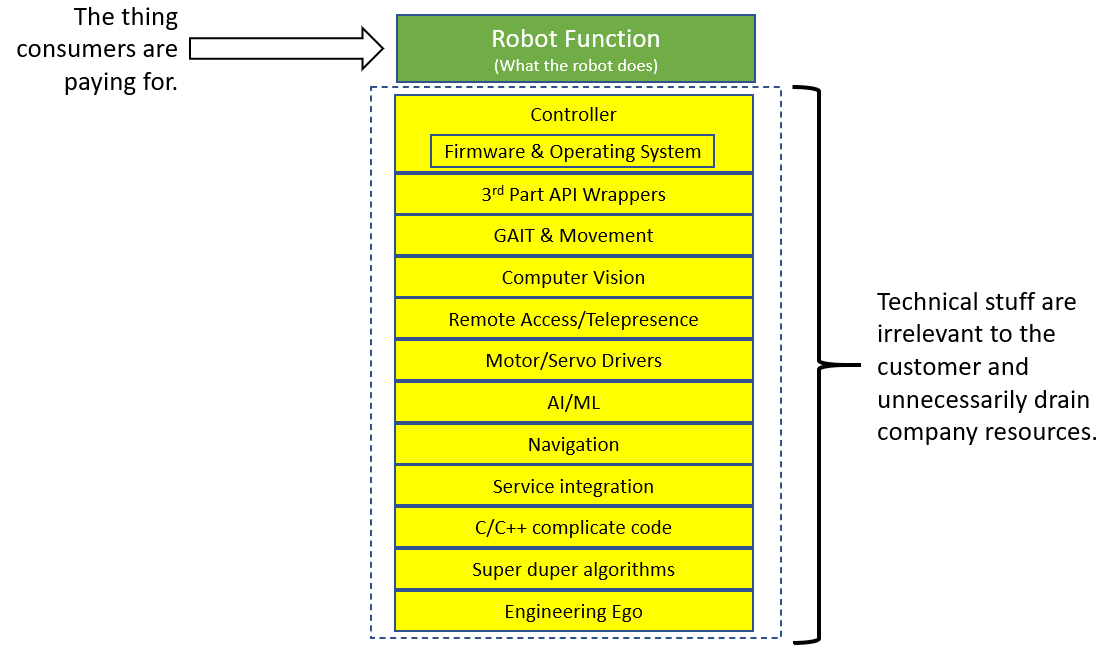

History foretells the fate of robot companies that attempt the burden of building and sustaining "the full-stack." Similar outcomes have affected companies from all industries where the founding partners were engineers. Today, we begin to ponder the question of where are the robots? Most importantly, why have so many robot companies failed, and what can we do to help robot companies succeed?

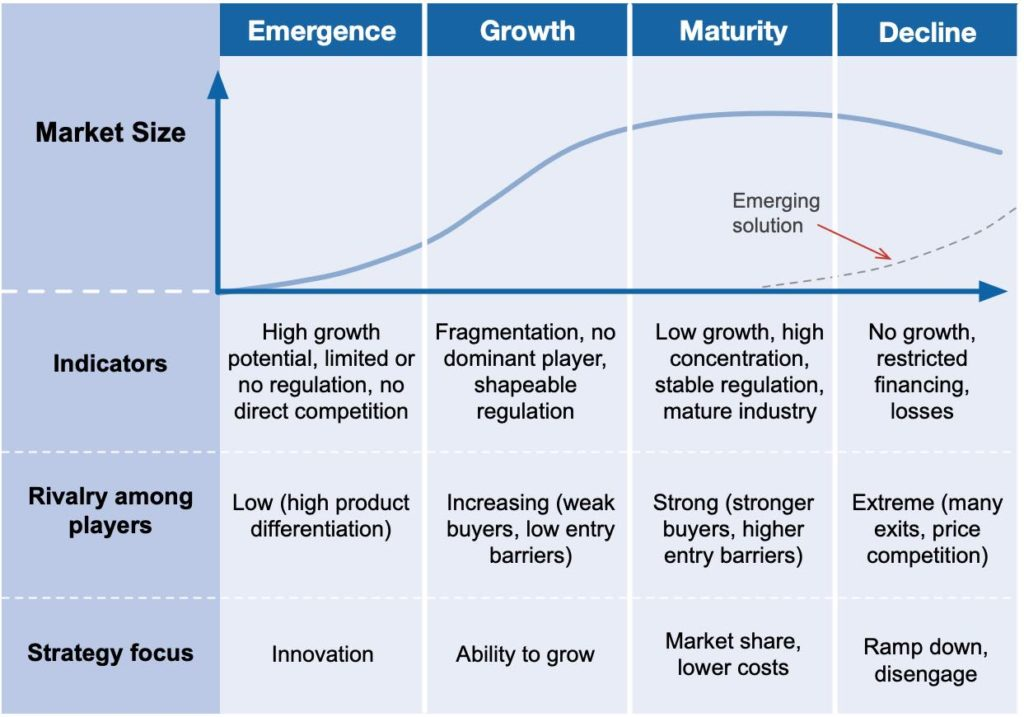

Perhaps the noise from social media, politics, and the current Covid-19 situation has caused startups and the investment community to forget a vital part of the industry life cycle stages. Organizations might have also overlooked this because it has also been several years since a new industry has emerged. Even the last few personal-computer sub-industries of mobile devices/apps, VR/AR, etc., have inherited sectors from existing mature and proven industries.

Robotics is a unique industry, albeit not too different from the personal-computer evolution, where multiple disciplines united to form a consumer product. The Personal Computer took many decades to influence and support sub-industries of software, hardware peripherals, and a wide range of use cases. Today, a computing device is user-friendly and esthetically pleasing, and the complex engineering disciplines are well hidden (CPU, operating system, drivers, power management, etc.). Readers may recall early personal-computer diagrams that included input, output, processing, and storage devices. Even earlier than the 1980's personal-computer, a computer consisted of even more complicated engineering disciplines that seemed impossible to scale to what we have today. Today, a computing device is common-place, and the components that make up computing devices are not taught in school as they once were.

The Revolution of Robot Platforms

Today, a child can operate a computing device before knowing how to speak. This results from a mature industry in which every contributor plays their strength by focusing on what they do best when contributing to product development. For example, some profitable companies make integrated circuits with a single function of performing mathematical floating-point calculations incredibly fast; because that is their strength. Another company will manufacturer a button or connector because that is their strength. Again, another produces batteries because it is their strength. The distribution of these disciplines in computing is how organizations can build platforms like Unity, Android, and Wix. Creative entrepreneurs use these platforms to make products that seamlessly integrate with our lives as tools and entertainment. What will it take for the robotics industry to distribute disciplines across specialists and enable creative entrepreneurs to make robot products rather than engineers? Imagine the impact that robot products made by creative entrepreneurs would have on our lives!

So, Where Is My Robot?

This is the first blog entry in a series titled "Where Is My Robot?". We will cover the robot industry failures, strengths, and areas of improvement needed to fulfill consumer and financial potential. We will reflect on the fallen venture-backed giants that attempted to skip the industry life-cycle steps, such as Baxter, Anki, Jibo, Mayfield, Romo, and many others.

This is the first blog entry in a series titled "Where Is My Robot?". We will cover the robot industry failures, strengths, and areas of improvement needed to fulfill consumer and financial potential. We will reflect on the fallen venture-backed giants that attempted to skip the industry life-cycle steps, such as Baxter, Anki, Jibo, Mayfield, Romo, and many others.

We will examine organizations that repeat Synthiam's message that "too many robot companies focus on the robot and not the business"; however, these same organizations build complex solutions targeted at engineers instead of creative entrepreneurs. In this article by TechCrunch, hardware manufacturers use Synthiam's message that "making robots should be easy" while contrarily designing products targeted at engineers.

In this "Where Is My Robot?" series, other subjects we will discuss are operating system choices that support rapid prototyping for creative entrepreneurs. Most importantly, how using Linux for r&d increases the barrier of entry, adds unneeded operational complexities, and limits productive creativity.

Provide feedback in the comments of topics in this area you would like to see covered. See you in the next blog entry - stay tuned!

Both my examples (cobots and social robots) were successful in creating market demand for robots of these types.

I'm not sure how I could be wrong in thinking that market demand = market validation.

Market validation then in turn equals progress. Progress isn't success but it leads to it. It's the Edison light bulb concept!

I think we have to thank these companies for creating market demand and leading to the success that will eventually come.

P.S. I haven't mentioned it yet but I wholeheartedly agree that full-stack development is a bad idea

DJ, have you ever been in a manufacturing plant? Those are not hobby robots.

Walmart or any other store fronts do not need robots.

Distributors such as Amazon, and Manufacturing, especially Car plants are full of Robotics.

All over the car plants are robots, welding, moving product, assembling etc.....

These are not hobby robots

This is Carrie, EzAng's wife. I am a Mechanical Engineer with a Masters in Science in Management of Technology from Carlson College and Minnesota University of Mechanical Engineering. I started in Manufacturing in the late 70s before I went back to college. At that time I worked in injection molding of VHS and other products, Robots were introduced so when the parts were ejected, they would not fall on the belt, causing scratching on the parts. We had them on most of our molding machines. I also worked in Manufacturing where we bought and also built machines that completed processes that formerly were done by our employees. We had very good programmers for these. Later I was in car plants which have millions of dollars worth of Robots, that weld, die cut cold rolled steel, assemble, and move materials. So robots are everywhere in Manufacturing. Funac is big there.

Every paint shop in industry has robots sealing, priming, painting, and top coating.

I have been in many other manufacturing of other industries and will say the same. Even at Little Debbies! These are definitely not hobby robots and very expensive.

@EZANG Yes - the world knows about automation for manufacturing - I feel you're being cheeky by assuming I wouldn't know about manufacturing automation, so I'll let that slide. But automation for manufacturing are robots 1.0 and we're discussing the move to robots 2.0 for consumers and enterprises. The discussion of automation for manufacturing isn't part of this discussion - apologies if I wasn't clear on that. But manufacturing automation has been around since the 1800s starting with weaving machines and became most prevalent in auto manufacturing. This discussion is about robots that interface with consumers. I will not be discussing the industry of manufacturing automation because it is a mature existing industry that doesn't need help. Perhaps that will be a section of my blog series to differentiate the two so there's no confusion in the future about manufacturing automation and consumer and enterprise robotics. I thought that was clear given the blog post and companies mentioned.

@Jeremie I do not believe there is a market demand for these robots. But that's a good point you raise, which is that there actually is no market demand. If there was market demand, then that means there would-be consumers. And if there are consumers, there would be revenue. And if there is revenue without the cost of maintaining a full-stack, there would be profit.

A sustainable business model involves consumer demand, revenue, and resulting profit. None of those things have been demonstrated in robotics.

@All It's great this conversation is happening because it's clear the robot industry has a much larger issue to tackle - which is regarding what the industry is offering and what products will scale. There's a discussion about toys, cobots, and social robots in the comments. The robot industry revenue is proof that neither of those categories has products that consumers want - especially at their price point.

DJ,

I will leave the conversation for now with:

I simply asked:

Are we talking about hobby robots, cheap or expensive or household robots like iRobot, social robots, programed Alexa, Cortana etc... or commercial robots in whatever field like manufacturing, space, medical worlds etc...?

You answer to me was:

@EZANG, there are no robots outside of hobby robots. Don't let The Robot Report or any marketing fool you otherwise. If there were robots outside of hobby robots, you'd see them at Walmart. Walmart will put anything on a shelf that sells - that's your validation.

So what was I suppose too think?

by the way, what is a robot 2.0 for consumers and enterprises and what is the job to do?

DJ, Are you talking about 'consumer/hobbyist' robots? The examples you gave had robots that provided no real lasting value. These companies are not failing because of value stack ownership, it's just bad products that nobody really wants outside of engineers and techno-geeks like us on this forum that build them simply for the joy of it. I am not really even sure what a companion robot is or what anybody would want it for. Early in the computer revolution computers were only of interest to engineers until the killer apps were found. That is what made computers ubiquitous. The killer apps have simply not shown themselves with robotics. Roomba was the first that it could be argued found one.

The comparison to computers is a bit of a misnomer because of the relatively huge expense of a robot that does what people may be interested in. Not only do you have the cost of the computer but the sensors, actuators, batteries, etc. Robots may never evolve due to this alone. Consumers want a C3PO to hang out with, at consumer prices.

I question your statement that there are no successful robot companies. There are many. Just not successful hobby robot companies. Successful robot companies from a variety of industries;

My response was far too generic in that I was referring to the flow of conversation regarding the companies being discussed. None were outside of hobby robots, and I assumed the mention of Walmart made sense. I highly doubt you'll ever see a manufacturing automation robot on the shelf at Walmart

I think robots 2.0 is most likely what we'll have to start calling the next phase of consumer/enterprise robotics. Because manufacturing automation is no longer considered robots in the sense that is being discussed. The automation manufacturing robots are pre-programmed with actions that continually loop to execute the same task. Robots 2.0 would be further focused on consumer and enterprise use by not being in a controlled manufacturing facility.

I'll stop referencing manufacturing automation in this discussion and it will be easier to progress and answer your question.

So the main answer to your question is - there are no products to provide examples of for robots 2.0. However, there is no shortage of examples in movies and sci-fi novels. The robots that were promised by the companies in the original blog post (scroll up to read), were combing a number of disciplines. These disciplines involve AI with human interaction and work alongside humans or in the home. For example, if you reference @Perry's objective with robotics is to have a robot actually perform tasks that humans can perform. Similar to the company Sanctuary, which has a goal to replicate robots in humanoid form.

I think the discussion about "what are robots 2.0" is actually limitless. It's important to dream big while we have the conversation flowing. I've had many posts in the past attempting to stir up ideas of what robots should do. It ended up becoming a discussion about bulldozers upside down. This blog series is not about "what should the robots do", but more about "how to support making those robots".

Synthiam's objective is to make robot programming easy and accessible to anyone with an idea. That is a very powerful statement because the goal is to support creativity by removing complications of programming. What other companies are doing is actually adding complications, and therefore the products are being limited. This is why we don't see the Robots 2.0 examples.

Let me realign the conversation to the original topic of this blog series and ask... what would your robot do?

I wrote that while you were writing your last post so disregard the 1.0 manufacturing comments. Of course you understand those.

The "killer app" in PCs required the hardware and software foundation - which was a combination of distributed disciplines that created a platform. In this case, it was Visicalc. And the well-known VisiCalc was not created by a programmer. By no way could the Visicalc author been able to create the application if it wasn't for the crude (for the time) platforms available at that time.

With that logic, a computer would still cost millions of dollars. You see, that's one of the troubles with deflation. One of Synthiam's board members wrote a fantastic book "The Price of Tommorow". If you're interested in the deflation problem of technology, and to better understand the reason I steered Synthiam toward software, it's a good read. Available on amazon here: https://www.amazon.ca/Price-Tomorrow-Deflation-Abundant-Future/dp/1999257405#:~:text=In%20this%20extraordinary%20contrarian%20book,alarming%2C%20but%20deeply%20hopeful%20situation.

Roomba is a good and bad example of a robot company - and perhaps we can dive deeper into that discussion about how much of a robot is a roomba?

Manufacturing robots were covered above. (got your last message about that)

So the two outcomes I'd like to see evolve over the series of this blog post are