I just decided to redo one of my TIP122 Transistor Switching Circuits (mainly because I needed a break from working - there is nothing wrong with the 2 that are already in my Hearoid). So now's as good a time as any to do a small tutorial

This has become an evolving tutorial with additional information and options available being added. The change log at the end of this post explains changes made. Any additional information will be added as and when discovered.

Parts needed: 1 x TIP120 or TIP122 Darlington Transistor or IRL3103PBF Mosfet (see notes at the end) 1 x 1k ohm Resistor 1 x Small Piece of Strip Board (7x5 holes) 1 x Pin Header (1x2) 1 x servo Extension Solder Soldering Iron Cutters

Extra parts needed (if inductive load): 1 x 1n400x Diode as required

Search for part numbers in google or ebay or use your preferred supplier.

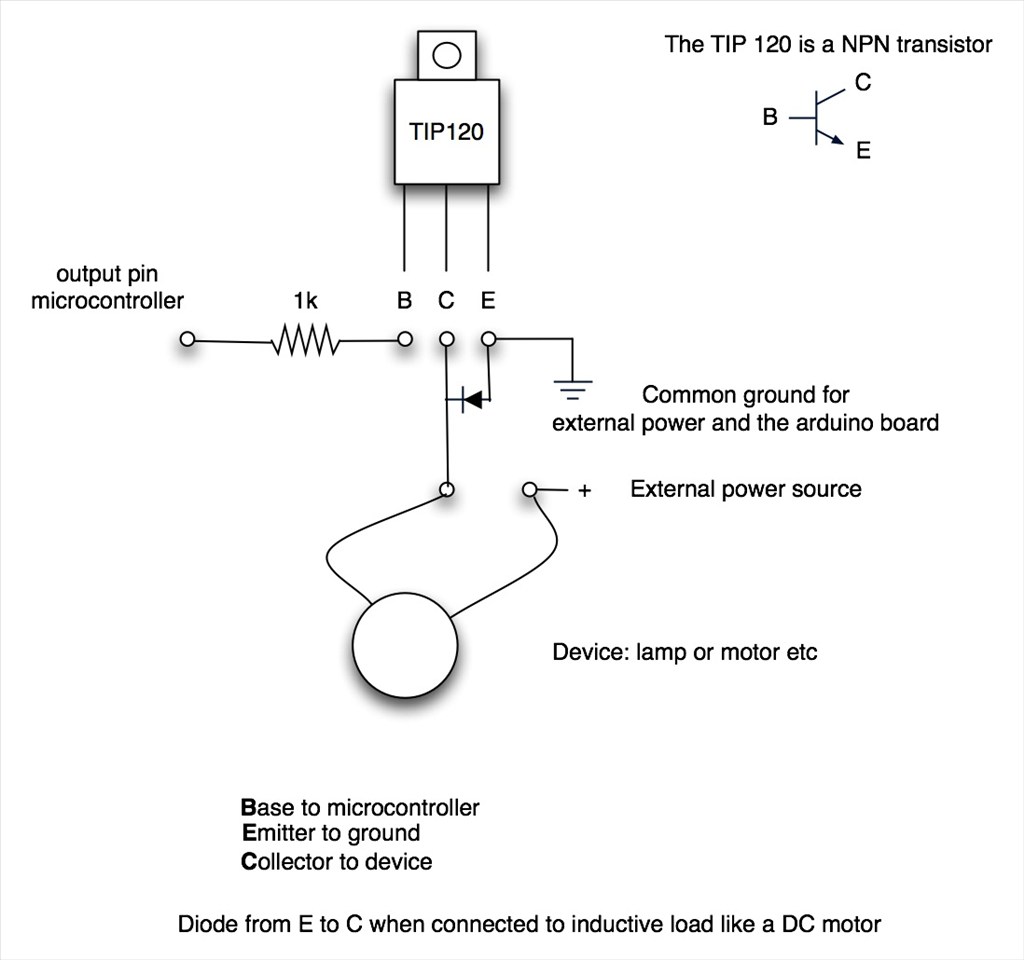

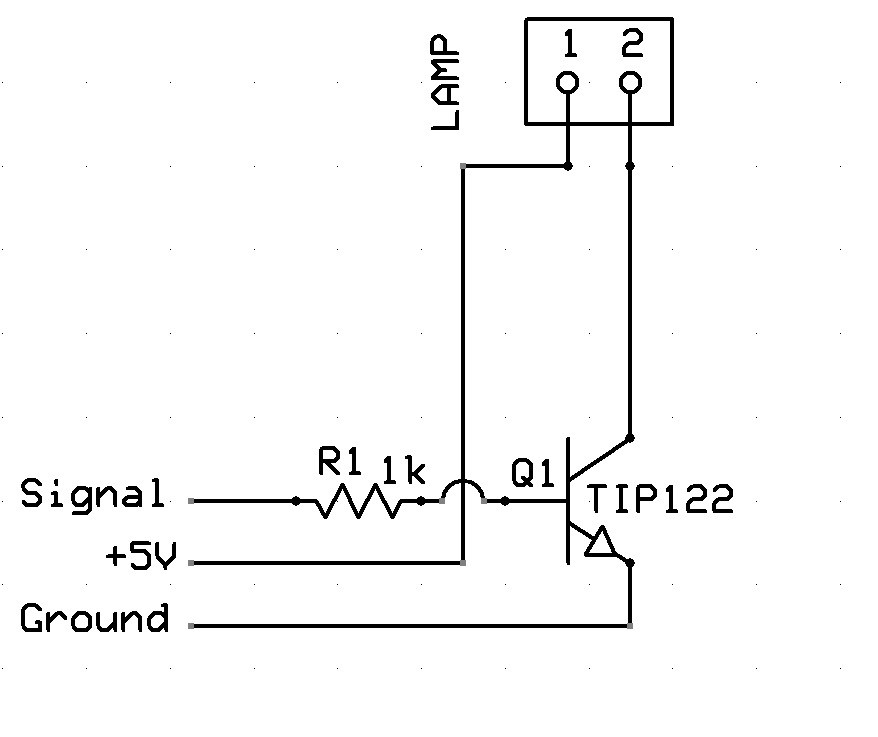

The Schematic:

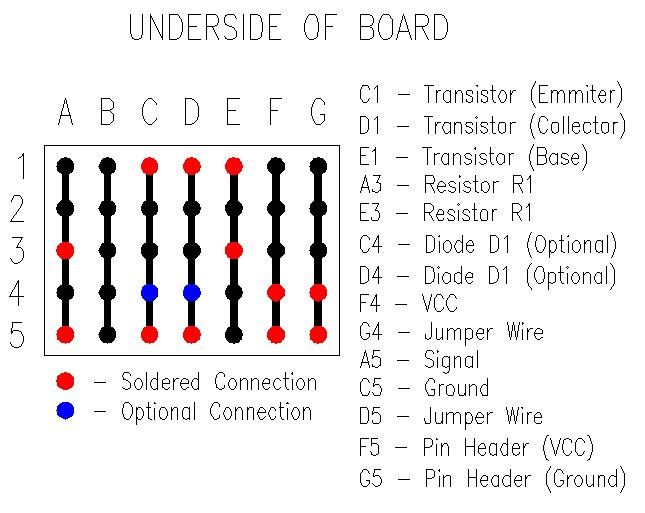

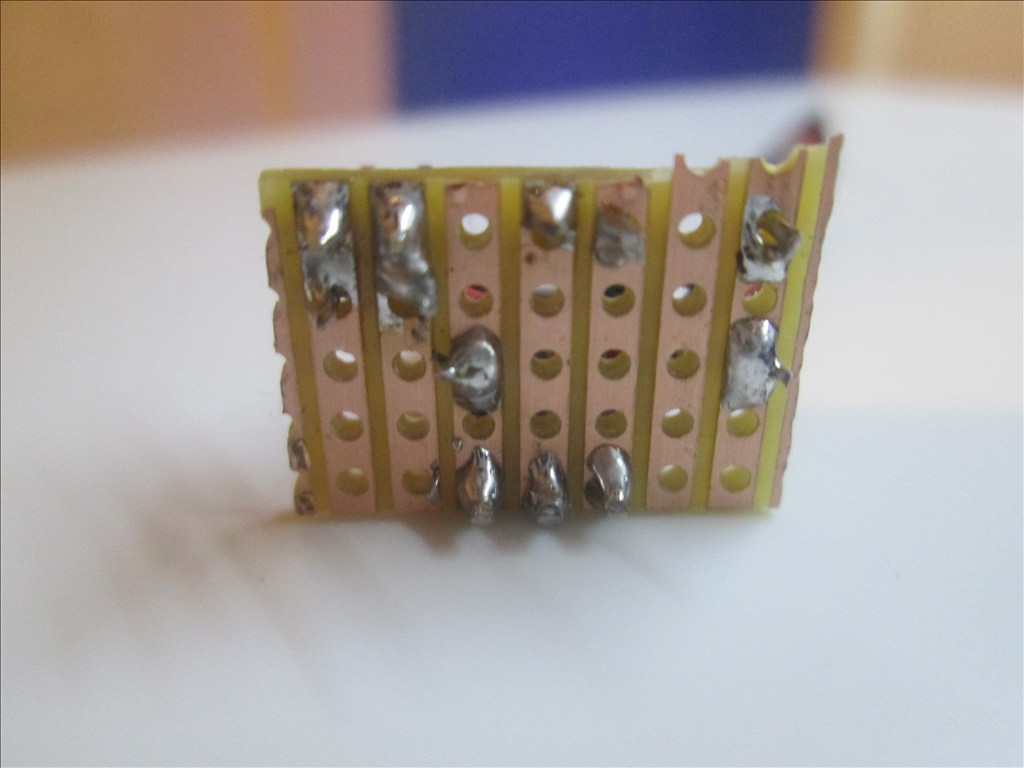

Underside of Board:

The optional connections are for Diode D1 covered at the end of this post.Method:

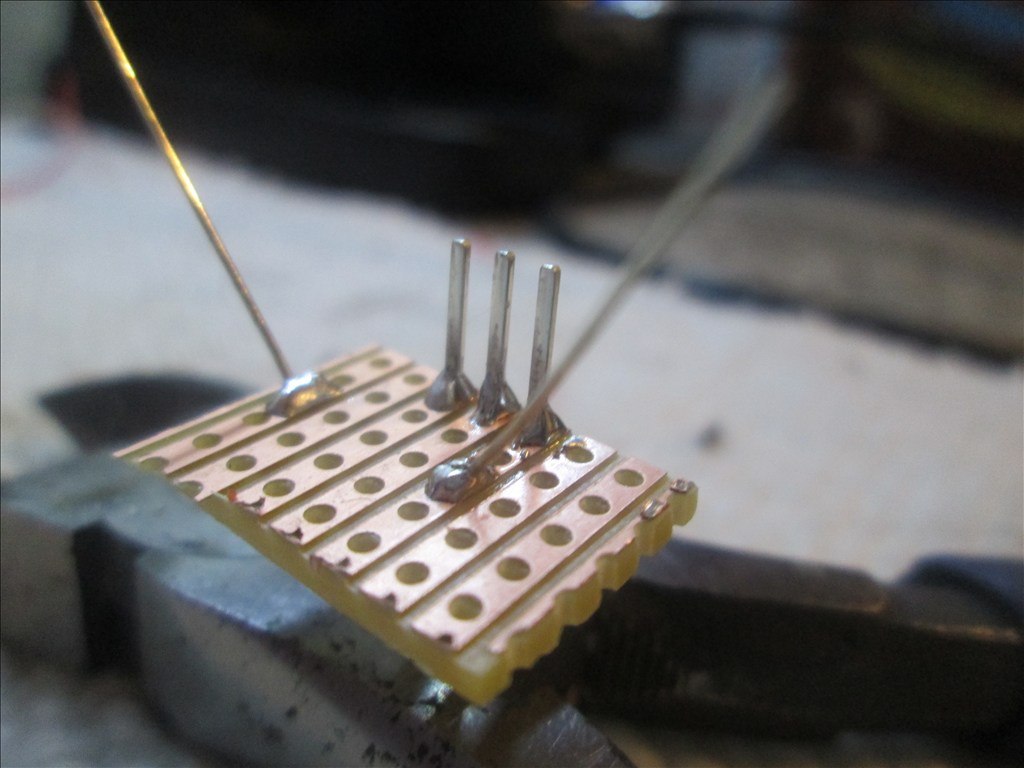

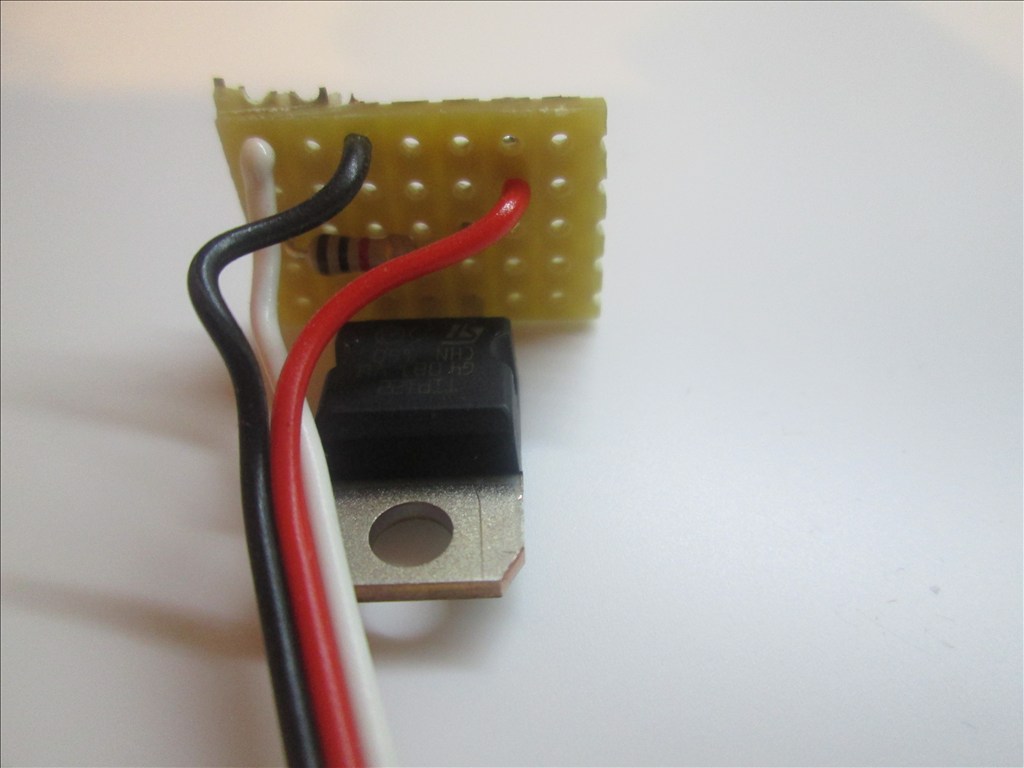

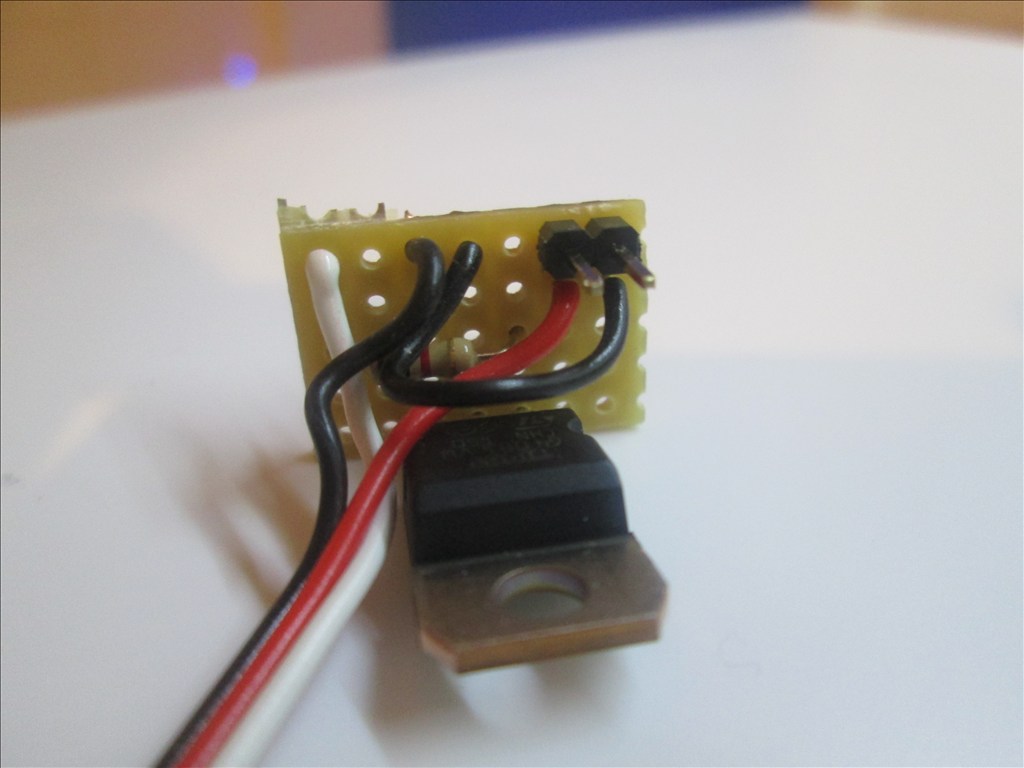

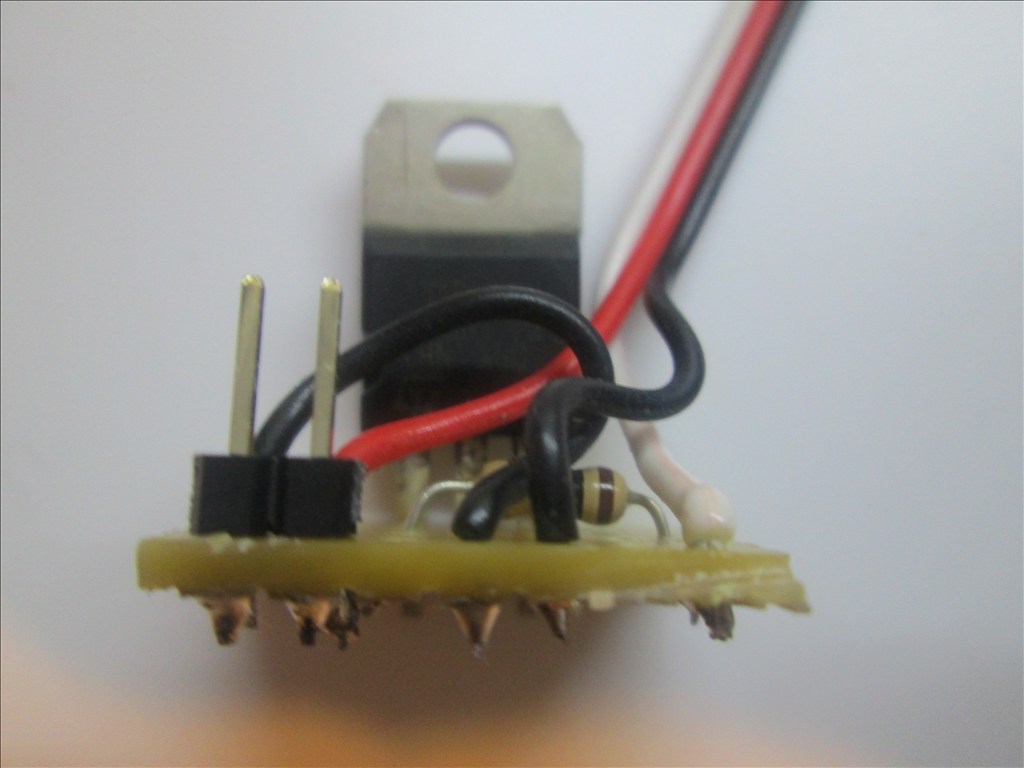

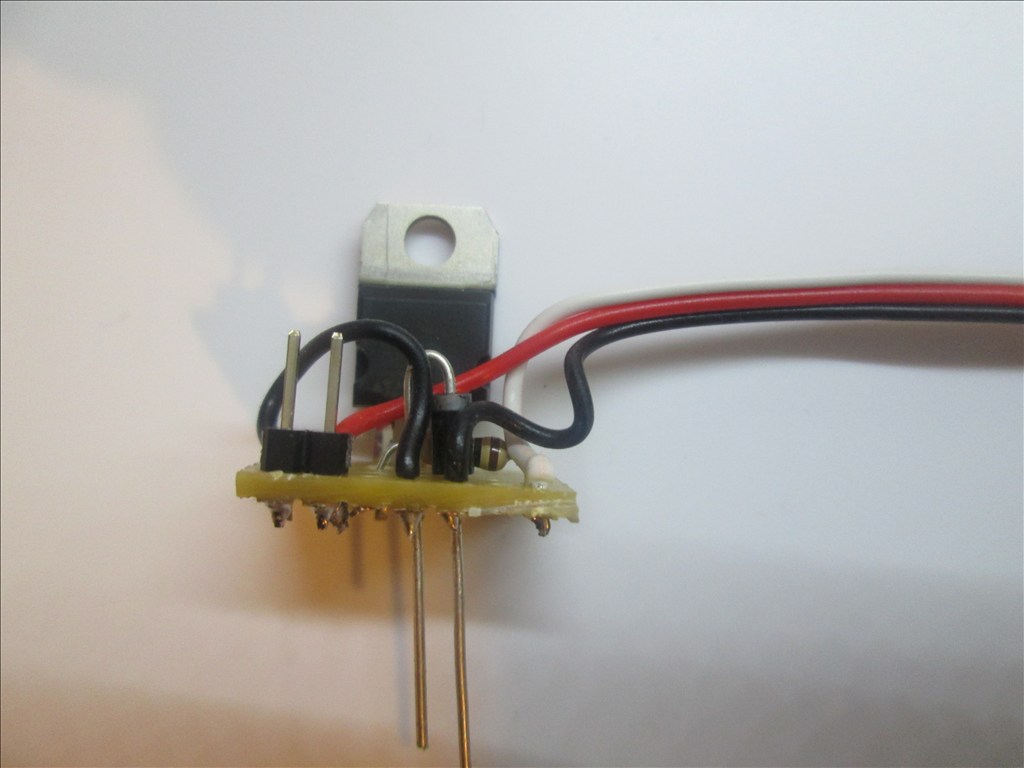

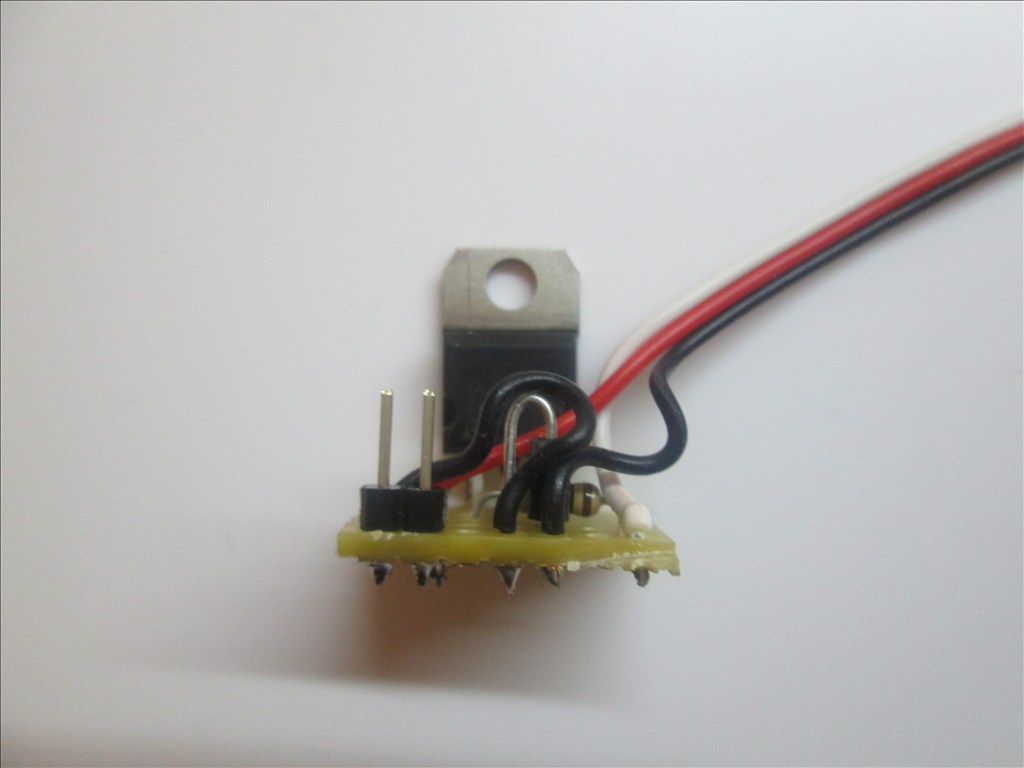

Solder the TIP transistor to the strip board so each pin is on a separate strip of copper

Solder the resistor from the Base of the transistor to a spare copper strip

Cut off the end of a servo Extension and strip back the wires

Solder the Black wire of the servo Extension to the strip connected to the Emitter of the transistor

Solder the White wire of the servo Extension to the strip connected to the end of the resistor (not the transistor end)

Solder the Red wire to a spare copper strip

Use a small off cut from the servo Extension and solder one end to the strip of the Collector of the transistor

Solder the other end of the off cut to a spare copper strip next to the Red wire.

Solder the Pin Header to the copper strips with the red and black wires soldered

Job done. Plug the servo Extension in to a Digital port on the EZB and connect the circuit that needs switching to the Pin Header, I do this with another servo Extension (as I have hundreds of them)

Or a JST connector works very well also

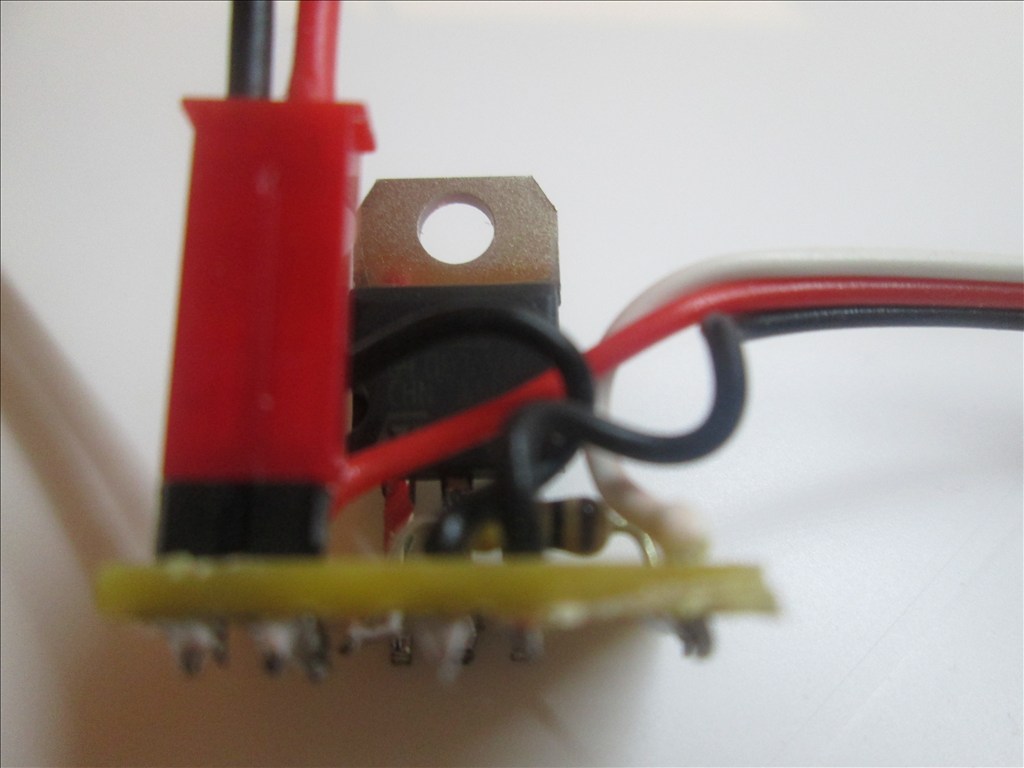

Adding the Diode If using the circuit for a motor or other inductive load a diode needs adding between the transistor Collector and Emitter. This is easily added in to the above circuit.

Bend the leg on the Diode so it will fit though 0.1" hole spacing

The band on the diode is to connect to the Collector and the other end to the Emitter. It will drop in to two spare holes.

Solder in place and cut off the excess legs.

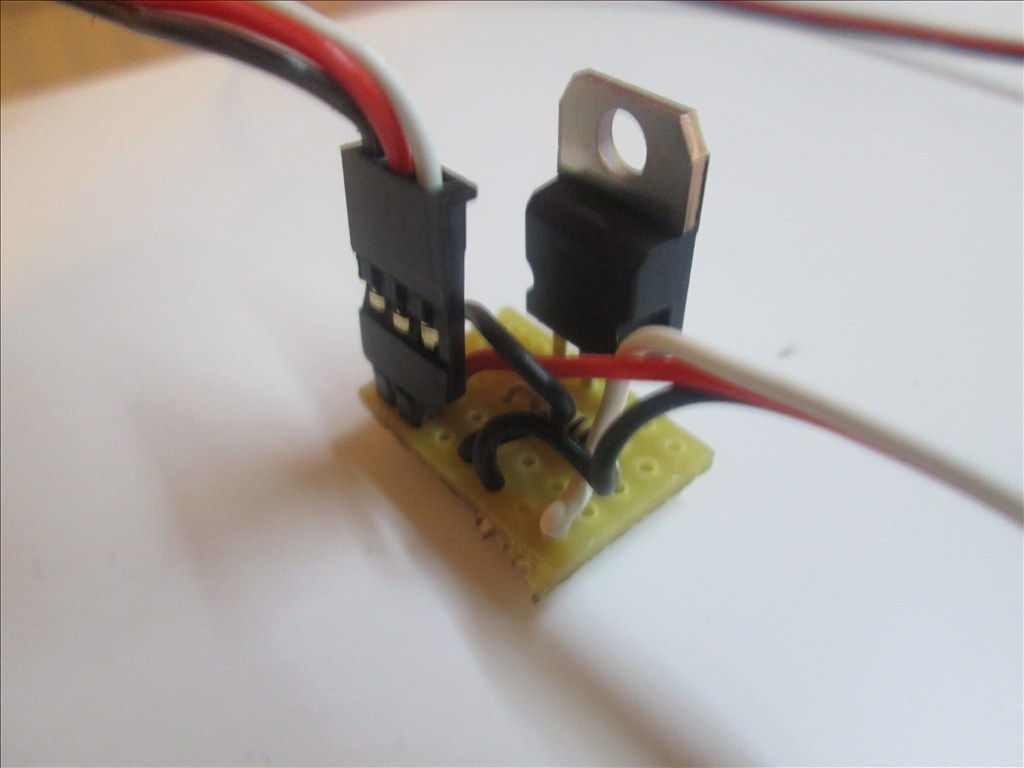

All done. You should have something like this.

Additional notes You may also use a Mosfet for this switching circuit. A IRL3103PBF mosfet can replace the TIP120/122 Darlington transistor. The circuit is the same however the pins on a Mosfet are named Gate, Drain and Source. The mosfet fits in the same place as the Darlington with the Gate to the left (replacing the Base of the Darlington).

Updates:

Edit 1 (2013.03.07): Underside of board diagram added.

Edit 2 (2013.03.07): For some circuits a diode is needed as shown in the first schematic. The board here does have space for a diode (C4 to D4 - would have to be with legs bent to accommodate 0.1" spacing) however I have not shown one - watch this space

Edit 3 (2013.03.07): Underside of board optional connections for D1 added.

Edit 4 (2013.03.07): Added diode information.

Edit 5 (2013.03.18): Added IRL3103 Mosfet information.

Very nice, Thanks Rich. I'll be making a few of these this weekend.

Updated it with the diode addition now too... 4 updates in one day ... I don't think I can do much more to it now but have added in the Diode if using motors etc.

... I don't think I can do much more to it now but have added in the Diode if using motors etc.

In case my photos aren't clear enough here are some rendered images of the step by step... Just like Lego

An alternative option using pin headers for the servo extension (although you would need male to male servo extensions)

this is the correct place to add a diode

IT DOES 2 types of protection not just one protection

it protects the rest of the circuit for spikes and surge and protect the darlington

here is the link to it

transistor switching circuits

Useless post, please ignore.

DIODE IS same you have in your circuit ,only need to place it across the coil.yours will work only it adds a extra protection for noises and spikes 1N4001 TO 1N4007 WILL WORK ,last digit after 1N400 is voltage RATING

Useless post, please ignore.

1N4001 foreword voltage is 50v and reverse is 35v 1N4004 foreword voltage is 1000v and reverse is 750vdc!

These and in between can handle up to 1 amp.

Rich, the picture you have there looks like a resistor not a diode. This is important because a diode picture will show you a band on one end and which direction it would go.

Edit: woops sorry, I see you haven't added it yet. Sometimes it's hard to see things on a little smart phone. I just built one of these circuits yesterday and it works great.

Dave, you misunderstand (perhaps I was not clear that I was showing the picture which needs updating).

I am unsure about the exact positioning of the diode and was asking for advice. I believe I was incorrect initially, rather than replacing the red jumper wire it needs to go from ground to live, so in parallel with the 2pin header on the next row, or a couple of rows up.

I'll make all this clearer later when I get home and have the correct software to make the changes.

@dave, what did you put on the underside to avoid shorts etc.? If anything?

Personally I used the one made in the photos on my Larson Scanner and used hot glue to insulate the underside of the board. Just interested in other options available really.

I actually just did mine on the FET itself. Put wire shrink on each connection, then a large piece on the entire thing. Then I just hot glue it where ever I want. But I like the idea of being able to add diodes and such like yours. Hmmmmm - perf board... I may have to give that a try.

That's how I originally did mine but I wanted something that was a little more re-usable (and had some spare stripboard and spare time on my hands)

So adding the diode across like this?.. If the diode is needed of course.

I'm sorry rich but I can't make it out where your red jumper is going to be in your picture. You need to have the diode installed so that the band is facing the center leg of the transistor. It then needs to be soldered somewhere between that leg and 1 of the leads of the motor or lamp. The other side of the diode needs to go to the right leg of the transistor. Then a jumper goes from that leg to the ground on both your power source and EZB. The left leg of the transistor goes through your resistor and to the digital signal pin of the EZB.

As far as insulating the back of the board, I like to use standoffs. It keeps the board away from the service and looks professional. However I have cut small pieces of thin plastic and attached the board to it with double sided foam tape. Then I either use more foam tape to attach the assembly down or hot glue. Velcro works nice too.

And what does this diode do for the circuit? I am unsure of what it would be used for....thanks.

When a DC magnetic field collapses in a motor it will send the voltage spike back into the control circuit. When that happens you can burn out your transistor. The diode blocks that from happening by only letting the power through one way. That's why they call it a blocking diode.

Suggested in this schematic

It is not as the usual schematic (or my schematic).

The red jumper links from the second column from the left to the 6th column from the left. These are two empty strips and it basically just allows for a 3 pin header on the bottom right corner to be fitted rather than soldering the servo cable direct to the board.

All components and wires have a slight greenish hue where they connect to the board. All copper strips on the underside run from top to bottom.

It seems it's just complicating matters, I see nothing wrong with the original way, it is the most common way that comes up on google too. And the schematic robotmaker added includes a resistor that I've not used either...

If unsure stick to page 1 post 1 it's the known method...

it's the known method...

cathode is always v+ ,cathode isalways the line mark on the diode other side is anode

only RB is needed and same value 1k resistor ,schematic is not mine its off the internet BUT would be same as mine only R is not really needed its used for the base is always off and relay is de-energized BUT is good to have so its not floating,sorry my info is very technical for most,that how engineers are

YES RICH you are correct its only for inductive loads,relays,motors and transfomer

Way it works is when the relay is turn on and then off it produces a very large voltage spick (flyback kickback) or inductive kickback and the diode blocks it

DAVE that is what said too.when on a transistor the diode from collector to base it protects the transistor ,BUT spike is still there and it can cause resets or other noises in to your system

there is a few names for the diode in the cicuit on is flywheel diode ,one called kickback diode ,but its really a blocking diode

MAIN reason i add extra protection ,my company i work for make testers that sells to techs and others and needs not to fail

people who build robots mostly dont care if the part fail or ,cpu resets or sensors unstable BUT i make mine so they never fail or has any problems and then you have to trace it down

I build 7 of the switches and model them after method 1 that are in my robot. Either 1 are controlling motors or lights. They all work great. However there's nothing wrong with over protection. If you have the room and money.

diodes are $.10 TO $.20 each and on this circuit it uses the same diode ,just it a better place so money and room doesnt matter

ONE not great about using transisors is that waste alot of power (wattage) compare to using low ohms mosfets and can easy use a small package compare to transistor T-220 CASE I dont know if you know how mosfets are ,but they use darling transistor in thier design and making it a lot better with less heat and cost is about the same too

I totally agree Dave. I have a few from method 1 in my robot and they run perfectly too.

The good thing is, if you decide you may need that protection it's easy to add in if you made it as method 1. There is space on the board where it can be dropped in - as confirmed by the addition of the diode in the extra info on post 1 (despite it being in not the best place). Option 2 (robotmaker's suggestion) can be added with ease too.

Where most people put it is across the coil ,so it uses less room on the board then in option 1

ON mosfet here is a link to about the same as TIP120 but at $1.96 each

irfz44 mosfet

it is a overkill for transistot since the transistor is rated at 3 amps and mosfet is rated at 25 amps ,but using a low amparage type the cost goes much lower

here is a great match for TIP120 at $.88 each

irfu11pbf mosfet and not metal heat tab on it like on TIP120 HAS and smaller size

looking at the data sheet on this mosfet it has the diode already on it ,so you save more room

IRFU110PBF DATA SHEET

i JUST re-look at the sdata sheet o the TIP120 where you have the diode from collector to emitter the transistor already has one

So putting a diode in parallel with another one doesnt do any good

Thats why reading a datasheet sheet is so important .

TIP120 DATASHEET

NOW on the other hand if you look at the circuit of the darlington you do need a diode across the coil or it with damage the first transistor

THE PATH of the spike voltage goes from collector to the first transistor to R1 to base

Thats the main reason why the diode is needed across the coil,

Useless post, please ignore.

Using a coil produces a spike .main term its called is flyback kickback thats where you get the high voltage spike ,its about 100 volts ,but depends on the inductance of the coil.

Here is a link to what is inductive kickback and protection for it ,do some reading it might help

inductive kickback

Useless post, please ignore.

NO ,you will still get 1000 volts in the first transistor to base ,look how current flows Also look at the link it tells the correct place to place the diode.

MOST people dont know this.

Re-edit to fix the grammar a little.

TRYING to fix my grammar with more time now so my info is more readable,but nobody is perfect.

Useless post, please ignore.

Thursday, 21 March 2013

Good Morning Rich !

GREAT Tutorial and P R E S E N T A T I O N !

Your Photo Flow and Detail are most professional documentation. This is the level required for High School Physics and Robotics.

I would enjoy a Tutorial on How You Made This Tutorial and Exactly What Presentation Software you use to do it ?

Thanks Rich,

DougPope@cox.net

I use a few different software packages.

The schematic was drawn using ExpressPCB however some of my schematics I draw using AutoCAD and CircuitLab

The renders of the stripboard were made using a combination of Fritzing and Adobe Creative Suite 6

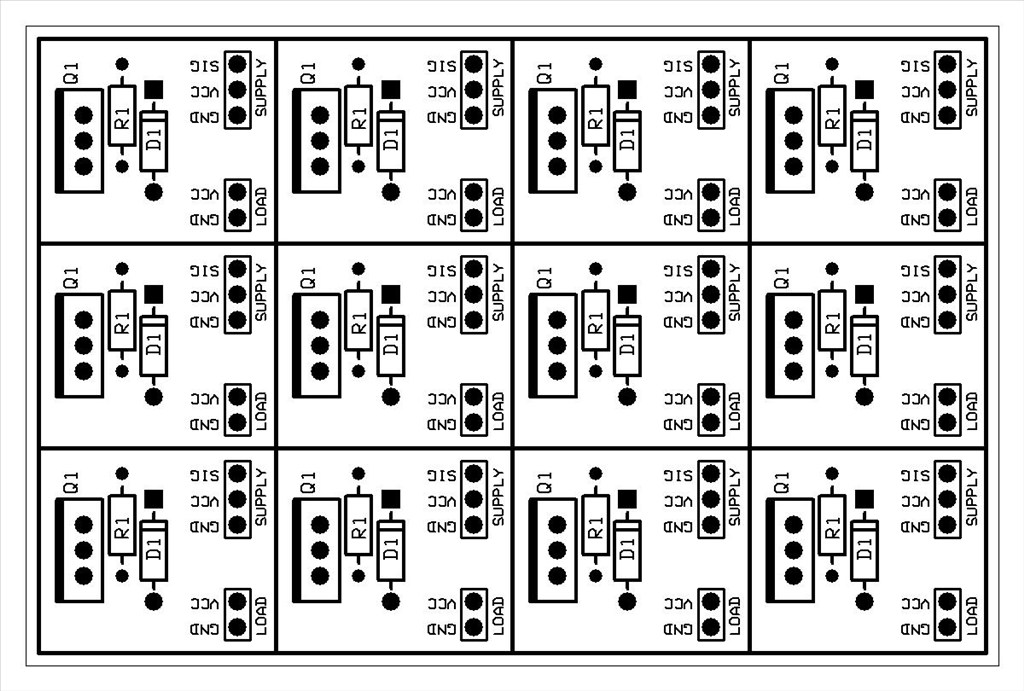

For anyone interested I just threw a PCB layout together for this in ExpressPCB. I've filled their miniboard size so it's $75 plus shipping for 2 boards which would house 12 of the circuits each. I have assumed their boards can be cut easily with a hacksaw.

The layout includes the position for the optional diode across the load, as taken from @robotmaker's links. This is an optional component and is only required for inductive loads.

If people are interested in using one it may pay to do a group buy to bring down costs.

Sorry, ExpressPCB removes the tracks on export.Source files attached for if you want to place any orders or even modify the board to suit your needs. tip.zip

I did the same when i made a sensor board ,where it would have many boards on one sheet

RICH is a good idea only thing i see missing is holes to mount it ,is the only thing i would add.

ONLY other part would be the shipping from UK to usa and would need to have a lot of boards made to reduce the cost.

HOM much would you charge for shipping

IF you read about the inductive kickback ,ITS very high voltage because it acts like flyback. I guess you dont how a flyback works.

On turning on restance loads you dont have that problem.

Useless post, please ignore.

Here is a board about your size i bought about 500 and sold all of them,and some to moviemaker in this forum

As you can see it has 4 holes to mount it easy without using hotmelt.

IF you what the holes can be easy added to yours,but up to you

Thats about $6.50 a board,can easy buy a radio shack board for less. BUT IF there is a lot of buyers price can drop down ,but i think to bring it to $2 or less you need to make about 500

RICH thanks for the comment about giving credit to robotmakers link IF i see one of yours i use i will do the same .

I ts good to give credit to others that had the idea first.

Also RICH i guess you dont have a good 0-SCOPE but with that you can see the high voltage spike (kickback) on inductive load with a diode and without a diode across the coil.

I have 2 types of scopes one analog 20mhz dual trace and one digital 100mhz dual trace.

WITH me i just dont design or make the circuit i test it ,for current use,rfi noises,spikes and lot more.

One main reason it takes a while for me to post my design,i make shore it last for ever and no problems causing resets and trying to find out why i get them.

Also RICH would be very helpful to others to place links to the parts you are using and costs. ome item i dont see on yours,

Mine when my design is done i have links to the costs and where to get them.

Useless post, please ignore.

PEOPLE said on my posts i did they wanted the costs for it.

RICH it gives the person about how much the project will cost,and at the same tome makes it easy for the person to buy them.

In my projects it will be alot better ,instead of just USA prices ,i am adding outside country prices too.

Second nowi am called the robot santa ,i can give the parts to others for free if i have them.

I have a very large warehouse of all types of componets and even if you need them i would still give them to you.

Useless post, please ignore.

OK but one or 2 links dont clog up a page . I design my circuits from memory dont use the internet to get info.

ONLY time i post info from the internet is for proof and design info.

I see it about double the price of using a mosfet instead ,and seems most here want only to dsave money and want it as cheap as possible.

main reason i put the links up to find the lowest cost and anyone doesnt have to spend time looking for the best price .

Useless post, please ignore.

ME TOO.

I do noticed something ,almost every idea or design i come up with ,you dont like it and always have something bad to say about it BUT YET i made some many good comments on your design.

NOT once did you.

Useless post, please ignore.

YOU can say its wrong ,YOU HAVE YOUR OWN Opinion Just like you say something thats wrong i will comment on it and explaining why its wrong too.

Useless post, please ignore.

MINE ARE FACTS ,yours are opinion and can easy prove like i did on inductive kickback.

Everything i said like on mosfets or zeners can easy be check to see i am right.

sorry not my post to add that comment had to re-edit it and copy to mine

Here are a couple of sources for compatible boards if you don't want to build from scratch. Beware that you still need the required protection for inductive loads. Also check the specifications to see if it will work for your application.

Link1

Link2

Full disclosure: I have not used either.

Thanks for the links Troy, they look like they would do the job although cost more than the proto-board method but much easier And uses mosfets which should please someone...

And uses mosfets which should please someone...

TROY very nice links on the mosfet design,makes a lot easy to use them mostly best one is isolated design link 2

One very good item is that no soldering is needed ,it makes it easy for most builders PLus the need to buy a fair big sheet of prefboard.

ONLY drawback is comming from china.

SMALL edit ,i see the first link is really good 52 amps and no heatsink ,might get a few

RICH did you get the email i sent you

Yeah they do cost more. Also it's from China and will take a bit long to get. Convenience has it's price.

Useless post, please ignore.

There might be others out there at a lower cost,second the price is higher also because of the large current driving load 52 amps.

I think another company sells types like that too,will find the links.

LIKE i said i am doing the same also. so there will be no more problems ever on this forum.

Here is some very good info off the web that compares darlington transistors with mosfets

darlington transistor vs mosfets

i TRIED VERY HARD TO APOLOGIZE to RICH and this is what he said in a email to me

F*U** your apology, I really couldn't care less, it didn't hurt or upset me my concern was for future members who don't know how full of s**T you are.

I edit the bad words

Useless post, please ignore.

IT does no good to email you,oi tried to be a nice man and sent you a very long apology to you RICH and see what you sent back to me.

IT takes a good MAN to apologize and a better MAN TO ACCEPT the apology ,but with your comment you sent me your not both of theses

IF you send me a nice email .like i sent you i would remove this.

I was given a idea ,do not reply to you RICH and for you not to reply to me. AND there will be no more problems ,end of story

I WILL NOT REPLY BACK

Well guys setting all the drama aside, look on the bright side. You are both obviously intelligent and talented in your own rights respectively. Rich to answer your previously posted question about diode placement (and this is not me choosing sides by any means merely attempting to offer non biased rational clarification) robotmaker's placement of diode is not the only "correct" placement it merely offers added protection to the circuit. Rich your original placement simply didn't protect the first transistor in the darlington and the TIP has built in protection with diode to second transistor which is the same as the one you were adding. That's all not a big deal. Also in the spirit of full disclosure Rich was also right about the diode unnecessary unless inductive load. Furthermore, depending on the motor Rich's original design probably does work just fine for most applications. However, Robotmaker's design is the more reliable one. As far as mosfet vs. darlington you two are not the first to disagree on this and you probably won't be the last. The advantages of the mosfet are undeniable and Rich's original post gave that as option. That being said I am guessing that the either method is just fine for most applications used by the members of this forum. I can answer most any question concerning problems created by inductive loads as i work as an engineer for an electric utility provider and have to keep an eye on that along with many other conditions on the system. I'm sure you both knnow all of this, I am posting so if any other readers look at this may it helps pulls some fact away from the dispute. I mean no disrespect to either of you and truly hope that this offends no one.

The mosfet design he just added after he saw my post,as you can say he re-edit it

THERE will be no more DRAMA from me on any posts of RICH

AS about the mosfet the LINK proves what i said a long time ago before he added the info on this post.

I am only trying to help others to build a good robot design

GOOD to see someone thinks i am right.

SO LETS TRY TO BE FRIENDS AND BUILD ROBOTS PLEASE

well like i said i didn't read any of this as it was going on you had me curious with your question last night so i was just trying to see what all the fuss was about. hey man i'm trying to be friends with everybody on here. can't we all just get along as far as building robots for me the jury is still out. it's been about ten years since i did any work on anything less than 14.4kV so whenever i get my kit i'll get started and see where it goes i guess. I MAY EVENTUALLY NEED A LITTLE HELP FROM EVERYBODY TO MAKE MY STUFF WORK. i haven't done an electronics diagram like the one on this post since school.

as far as building robots for me the jury is still out. it's been about ten years since i did any work on anything less than 14.4kV so whenever i get my kit i'll get started and see where it goes i guess. I MAY EVENTUALLY NEED A LITTLE HELP FROM EVERYBODY TO MAKE MY STUFF WORK. i haven't done an electronics diagram like the one on this post since school.

same with me JDAWG,i try very hard to be nice to others mostly thats how i am,never see me get mad or anything.

LETS hope the drama has stop so no more problems ,drama is bad for the forum and its in any club you join also.

I love being friends with everyone.but doesnt alway work out.

Deleted. No longer relevant. Moderator please remove.

@JDawg, thanks for the info, I'm sure it will be of great help to myself and others.

It doesnt matter if someone uses my ideas,that why i post them so others can use them or not ,and i dont need any credit for it too.

I read a few posts and you did say i was wrong,but not all of them,NOT once did you say it was a good idea,except may be on a sensor idea.

I always said your design was very good.

YOU didnt use my idea ,since you pick another mosfet,but you did bring up after i put my tutorial up about them.

BIG part to understand your tutorial is about TIP120/TIP122 SWITCHING CIRCUIT TUTORIAL DOESNT SAY ANYTHING in the heading about mostfet tutorial

SO why would you add them that makes your topic off the subject.

Deleted. No longer relevant.

Would you look at the timing of this and Mr Herr Balls post...

I am not fighting with RICH

Deleted. No longer relevant. Moderator please remove.

THATS funny TROY,you are always funny

Deleted. No longer relevant. Moderator please remove.

@Rich,

A question and a suggestion.

Question: (which I assume the answer is yes), this is Unidirectional, right? I am looking for a way to control the motors in a robotic hand (and later an arm with more motors) and need to be able to reverse the power direction, but I think an H-bridge is overkill, and the one I own is serial rather than servo emulation, so before buying another I thought of this tutorial, but it seems it won't fit my need unless I am mis-reading.

Suggestion: You may want to go through this thread and do the same thing that Troy did an edit the no longer relevant posts so new users don't think you are insane arguing with vapor.

Alan

Think of this as a basic on off switch, nothing more, nothing less. It makes the circuit and therefore it illuminates the lamp, spins the motor forwards, sounds the buzzer or whatever. It can't be used to reverse the direction of a motor (that I am aware of).

However, you could use a servo board. I don't know much about it, I tried once but realised halfway through I could fit a servo in there so did it that way. But what i was trying was to strip down an old servo that's gears are shot, or just a cheap one and remove the motor from the board. Connect up the new motor. Connect up the pot (if you want feedback) or convert it to a modified servo. I have no clue on how to do it but google will know Just an idea to avoid using a HBridge.

Just an idea to avoid using a HBridge.

I plan to edit all topics etc. I've done a few, but I'm sure you are aware there are rather a lot where bad things happened. Eventually I will get there I think the first post is updated now... unless I'm thinking of a different one. But yes, you are right and it is on the list

I think the first post is updated now... unless I'm thinking of a different one. But yes, you are right and it is on the list

Thanks for the idea about cracking open a servo. Hadn't even though of that. Should work for the hand, which has small motors.

Alan

I'm told they (standard servos) can handle about an amp. I've done it with motors in Pinhead's....errr head. Since the motors were small and most likely not draw an amp I used micro servo boards.

Pinhead {Ignore the corny joke}

Standard servos Like futuba, power HD, tower pro can handle continuous 800ma ( .8 amps) High torque servos like power HD 1501mg , tower pro 995, hitec 645mg handle approx 3 amp continuous 5 amp max

If you want to make sure you have enough juice and the benefit of digital then use a high torque servo control board.

Oh I think I just had an " idea" using a servo control board from a high torque servo could be a easy to use alternative to an hbridge in general. Plus they are like 20 percent the size of a l298n board. Hmmm

I've often wondered if a servo board could drive a motor for driving a robot, or 2 of them to be more precise. A 2 wire h-bridge sure would help me out on Melvin's lack of Digital ports. Until you mentioned the high torques I had just dismissed the idea but knowing they can handle 3A it brings it back on to the drawing board.

@jstarne1 and @Rich ...are you thinking something like this.. PWM servo controler for 14.95$...it however does not list the current limits..

No, at least that's not what I was thinking.

What I was thinking is, using the board that drives a motor in a servo to drive a different motor, say the ones in the Omnibot drive system. 2 servo boards would drive both motors forwards and reverse with only 2 signal cables.

The board in the servo would govern how big a motor it could run, and it would need an external supply as with a HBridge but it would cut the signal wires needed down to 2 from 4 or 5.

Very clear! thanks so much Your idea is certainly worth pursing to reduce the number of signal wires!

Your idea is certainly worth pursing to reduce the number of signal wires!

GREAT servo to be hacked is futubu S3002 for the h-bridge,very low cost and the chip is easy to use cost is about $3.50 on ebay,and there is schematic on it also.

Ithink only one that there is a schematic for.

@Rich from what I read and my limited understnding of electronics in this post could this board be able to run a 7.2 DC motor like a servo, this would solve my vertical lift issues. P.S. great job on the drawing and the step by step assembly, SO what would you charge me to make me one and if I could run this board like a servo I would need 3.

Yes, just ensure you include the diode. There would be only 1 direction and no control other than on/off.

Think of it as if its a simple switch.

Edit: Just noticed the last part. If it wasn't for the shipping costs I'd send one over for free (it's about £1 worth of parts). If you really don't want to go through making it yourself I'll look at shipping costs, I'd guess it's about $5 or $10

This would be perfect Rich for my 1watt blue ray laser. Thanks again

@Rich: It is a very nice tutorial to make the switching circuit by using TIP122 transistor and the most important thing we don't need the relay but I am concerned about the position of diode whether it should be between base and collector to protect the microcontroller from the back current of load or it should be between the collector and emitter as you placed. Can you tell me the reason why you placed it between the emitter and collector?

electronic manufacturing services

That's the schematic that's floating around everywhere on the internet and the schematic I used to produce the perf board version, so that's the reason it's where it is.

An alternative position was mentioned in post 5. Personally I've never needed to use the diode as I have never used the circuit with an inductive load.