Asked

— Edited

I am printing JD Humanoid but I noticed a lot of the parts don't have supports. Example servo connectors start about 3mm off the ground, the top of his feet don't print well upside up or upside down. Has anyone created a modified version of JD Humanoid (and other bots) with supports that are optimized for 3D printing.

That's not up to the design file. That's up to you as where to place the object in your slicer. Perhaps there's an online course you can start with to learn how to use your printer? We thought of doing a course before, but there's so many printers and so much software that's it's impossible to standardize.

When you load the part into your printer software, you can move it around and flip it to position the best printing angle.

Such as, you mentioned the bracket prints off the bed. That's incorrect - the object prints where ever you place it in the software slicer.

A little bit of time and you'll get it :). If you mention the printer and software, maybe a community member is familiar with it and can help. Otherwise the printer manufacturer can explain more in their tutorials.

Thanks @DJ If someone in the community could please teach me how to use my Prusa I3 clone and start a print line 3mm above the surface of the print bed without the use of supports, I would really appreciate it.

@Nink Complicated STLs are going to need certain orientation and or supports in order to print right... It would be great if all stls were shaped like a box then printing them would be a breeze... With (as mentioned) complicated stls like ez robot's lever servo part there is no real way to print it without supports... In your slicer you need to enable supports for an angle usually greater than 45 deg... PLA "bridges" better than abs but printing parts with angles greater than 45deg usually will require supports...That lever servo part will need supports no matter what type of filament used... So bottom line where you see that 3mm gap is where supports will be needed. You can't print in mid air... As @DJ mentioned orientation and supports (among many other settings) is done in your slicer software prior to printing...

Thanks I found it, generate support material greater than 45 degrees. :-)

Thank you @Richard_R I will try it out.

Hi Nink, I have fairly extensive knowledge of 3D printing. Don't be afraid of using slicer driven supports. You slicer may just need some tweaks.

What slicer are you using? Type of filament? Judging from your photo of the part you are over extruding. This means too much filament is being pushed through the nozzle. It is an easy adjustment in the slicer. You may also be printing too hot and too fast. Once you have the settings right the part will come out cleaner and supports will separate easily. Here is link that will surely help. www.simplify3d.com/support/print-quality-troubleshooting/

Thank you @Holy1 I did not even realize I was over extruding. Learning ... I just switched from PLA to 1.75mm ABS as it was clogging all the time. I find my ABS prints are warping on large print jobs like the inmoove arms and also separating sometimes. Temp is 140 C on print head and 100 C on bed. Slic3r v 1.1.7 fill density 50% speed 60mm/s on perimeters and 40 mm/s on external perimeters.

thanks for the link will have a read and play

Warping is always an issue with ABS. Look into this, it is a game changer > spool3d.ca/pei-polyetherimide-sheet-200mm-x-200mm-x-2mm-8-inch-x-8-inch/ There are adhesion sheets available on a different page.

PEI will make a world of difference. 65c for PLA and 100C for ABS.

ABS for taller prints may need an enclosure. Doesn't need to be pretty just something to stop drafts. Even a cardboard box or something similar works wonders.

50% infill will cause warping too as it will cool at different speeds for the interior to the exterior. 15-20 % is all you need if you have a thicker exterior, say 3-4 perimeters.

I am hoping the 140c for the printhead is a typo. Should be 220-240 c for abs and 200ish c for PLA

Yes 240 :-) for ABS temp. I will try dropping to 220 ish after first layer and reduce fill density thanks for the guidance and info on PEI sheets. Today I use blue painters tape or a glue stick.

These are great comments. I'll have to bookmark this thread in the 3d printing section for others to find. Good work everyone!

I would suggest Petg. I've been printing with it for the past year. It's stronger than ABS and no fumes. You have to print a bit slower but there is no warping on large parts and you don't need a heated enclosure.

I would also suggest getting Simplfy 3D which supports about every 3d printer on the market. Super fast slicer and I feel prints look better than with stock software for the printers. Simplfy has a superior support generation that creates easy removal and very little post clean up.

Nink. I have a similar printer to you. You will do well to print some calibration cubes and calibrate that printer. You can download them from Thingiverse. I also use Simplify3D. I could not get the supports to work wit any other software. I have trouble with ABS and most of my prints are with PLA. The supplier of your filament is important as well. I use Hatchbox. I have problems with other brands. They can be fickle.

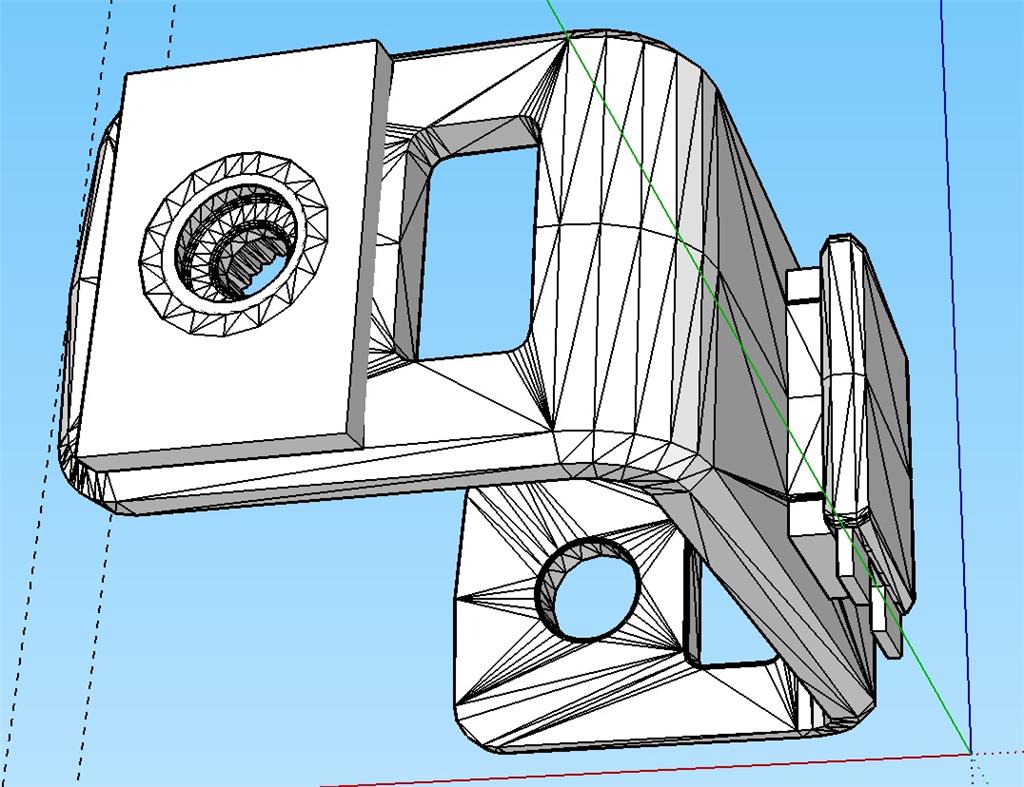

To answer your original question here is a part with supports generated by the slicer software. They are the darker orange feature. They are peeled away after the print is complete.

I'll add to Hatchbox (which i like but i use grey and they are out alot ) , so my new favorite has been Esun. You can find deals on Amazon often.

Wow thanks for the help everyone, Really appreciate the patience and the assistance.

@Perry_S trying the calibration cubes now, Unfortunately I am going to have to hold off on the Simplify3D software (already in the dog house with my recent purchases that just turned up on the last credit card bill and now I need some more parts :-)

@fxrtst I have never heard of PETG, I will take a look at it when I run low on ABS. Looks like it is more durable than ABS when reading the info on the web so maybe ideal for robotics.

@DJ you have a really great community here. I appreciate all the help getting started.

What brand printer do you have. You might benefit by Repetier Host. My printer came with it and it is free. If your machine is a true Prusa there are settings specifically for it. If not, there are ones that can get you close.

I still use Repetier for my print server.

Hey @Perry_S my printer is similar if not the same as yours, Geeetech Pusa i3 Pro B the acrylic one not metal, apart from Pi and LCD looks same as yours. Came in a cardboard box from China in about 100 pieces and I sat there for 24 hours assembling them all together. Was an interesting experience. What I like most about it was that no matter what goes wrong with it, you can fix it because you literally built it. I have Repetier as well. I see they are around $200 US on ebay now

When my credit cards cool down, I will probably buy another one so I can have spare parts in future and speed up printing times.

https://www.ebay.ca/itm/Print-5-materials-Geeetech-Acrylic-Reprap-Prusa-I3-Pro-B-3D-Printer-MK8-LCD2004/231472986888?hash=item35e4dd7b08:g:r6gAAOSwoudW7764

I played with various printing settings and things improved but I still had issues with strength of objects and printing on my printer. I have started to modify them so they are more in line with my bad printing skills, adding supports and reinforcements in areas that I am struggling with splitting or breaking.

If anyone else wants I will add a package when I am finished to Thingiverse

You are filling a predictable path. I did the same. Exploring the capabilities of your machine and changing the parts to accommodate. I did it for a long while. I modified many of the parts. Thing is, the end goal is to not have to do that. So you are kinda shooting yourself in the foot. Take the time to figure out your printer (the one I have) and work on the end goal. IT will be easy with a bit of patience.

A nice experiment might be to propose a part to print and a few of us can slice it for you and show you how we would do it.

Perry

Hi @Perry_S yes perhaps my "Printer Optimized" parts may not be required if I had mastered my printer. I have not had many problems with my inmoove prints, it is primarily JD that I am having challenges with. Auto creation of supports is not working well so ABS can't bridge with my software. I have annealed the pieces in acetone to reinforce and remove printing imperfections but still they crack when doing headstands etc. Example very small but important pieces like the neck on JD break when doing a somersault with the 3D printed parts but not the real parts.

Perhaps others who have 3D printed JD humanoid's can share experiences.

@Nink I also have an i3, its the MK2 by Josef Prusa...I bought the kit and it took me about 15h to assemble! I must agree that it is worth the time, it is just so rewarding in the end! :D

@fxrtst I also just started to print in ABS, had to realize that warping is much heavier than PLA, and I noticed the smell of it is quiet heavy! I will try PETG next! I switched to ABS because I noticed that PLA bends after some time, so I figured it is no use for robotics, but one thing that occurred to me was that ABS cracks really easy when I got the slots for my screws just a bit to tight...PLA was more forgiving on that part! stress

Nice you guys mentioned your favorite brands...I am always having a hard time deciding what to buy, availability is a factor too I guess.

@nink ABS is your problem. You can't print ABS very well with an open frame printer. You need to enclose your printer to keep the heat in. ABS also has to be printed at a relatively high temperature. I use 240C for basic run of the mill abs. If not you will get weak parts, layer separation and warping,,. I have an UP Box+ and an UP Mini 2.... Both print abs like a boss due to their all metal hot end and enclosed printing platform...

As Richard R says and I mentioned earlier an enclosure will make a huge difference. Printing slow will also help, say 30mm/s. If it is a smaller part, print 2 so that part 1 can cool for a moment while part 2 prints a layer.

I will add that for really strong parts adjust your infill to 80-100%

Here is an example of a simple enclosure I made up a while ago . It's just 1/2" dowels and a large plastic bag. Keeps the inside temp about 31C. I'll enclose the .stl for the dowels.

Dowel3wayv3.stl

Cool thanks for the tips. I really don’t want to switch to PLC as it always clogs on me and I hate finishing it. I.like abs as post process is so easy and any mistakes can be fixed with some acetone and a paint brush. I will try making an enclosure.